Thermo magnetic release for circuit breaker

A technology of thermal magnetic release and circuit breaker, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of affecting the stability and reliability of overload protection, difficult to install the thermal magnetic release in place, and low installation stability. , to achieve the effect of simple and reliable structure, improved reliability and stability, and improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

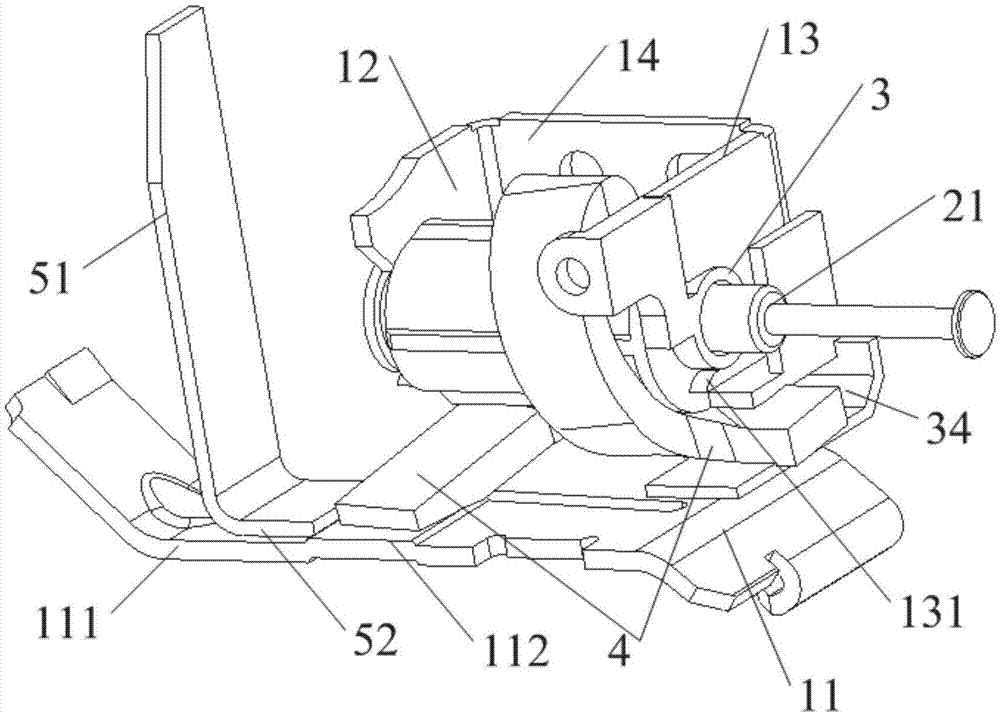

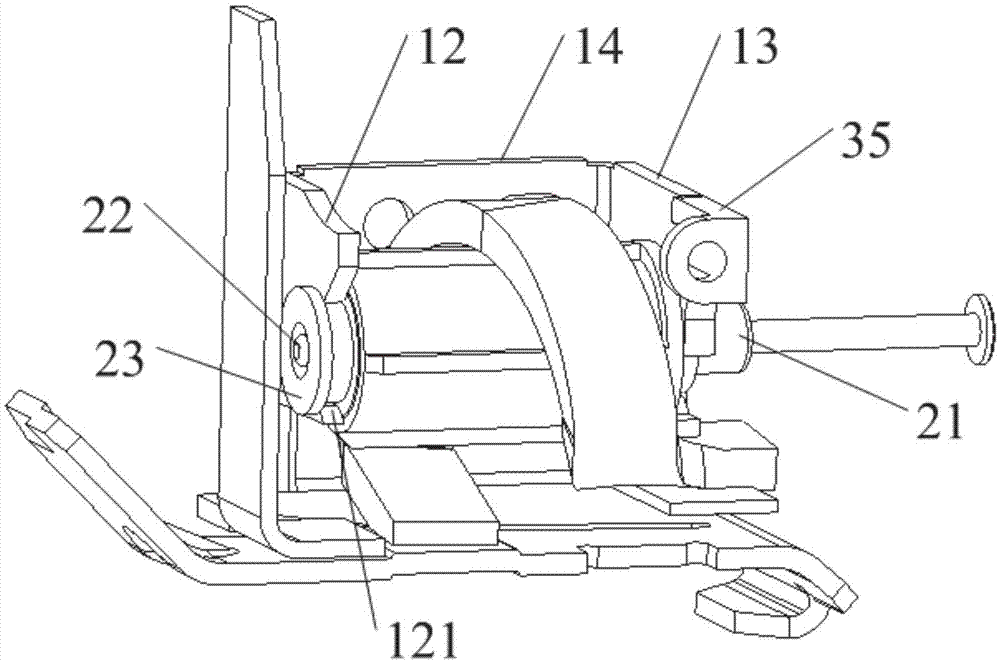

[0021] The following is attached Figures 1 to 5 The given examples further illustrate the specific implementation of the thermal-magnetic release of the circuit breaker of the present invention. The thermal magnetic release of the circuit breaker of the present invention is not limited to the description of the following embodiments.

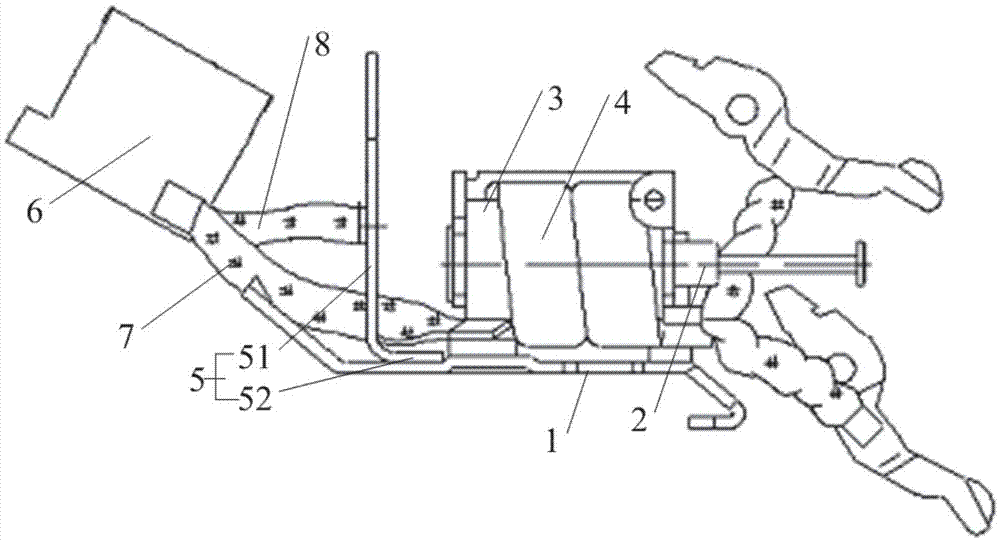

[0022] Such as figure 1 As shown, the thermal-magnetic release of the circuit breaker of the present invention includes a contact plate 6, a yoke bracket 1, and a bimetal 5 and a coil 4 connected to the yoke bracket 1, wherein the contact plate 6 is respectively connected to the bimetal 5 is electrically connected to the coil 4, so that part of the current flowing through the contact plate 6 flows to the bimetal 5, and the other part flows to the coil 4; and the bimetal 5 is indirectly electrically connected to the coil 4 through the yoke bracket 1, so that the The electric current of the bimetal strip 5 enters the coil 4 through the yoke sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com