Accurate positioning method for stiffening plate of H-shaped steel component

A precise positioning, H-beam technology, applied in building components, elongated structural components for load-bearing, structural elements, etc., can solve problems such as time-consuming, positioning deviation, etc., to achieve convenient and simple adjustment, simple and convenient assembly, and suitable for Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

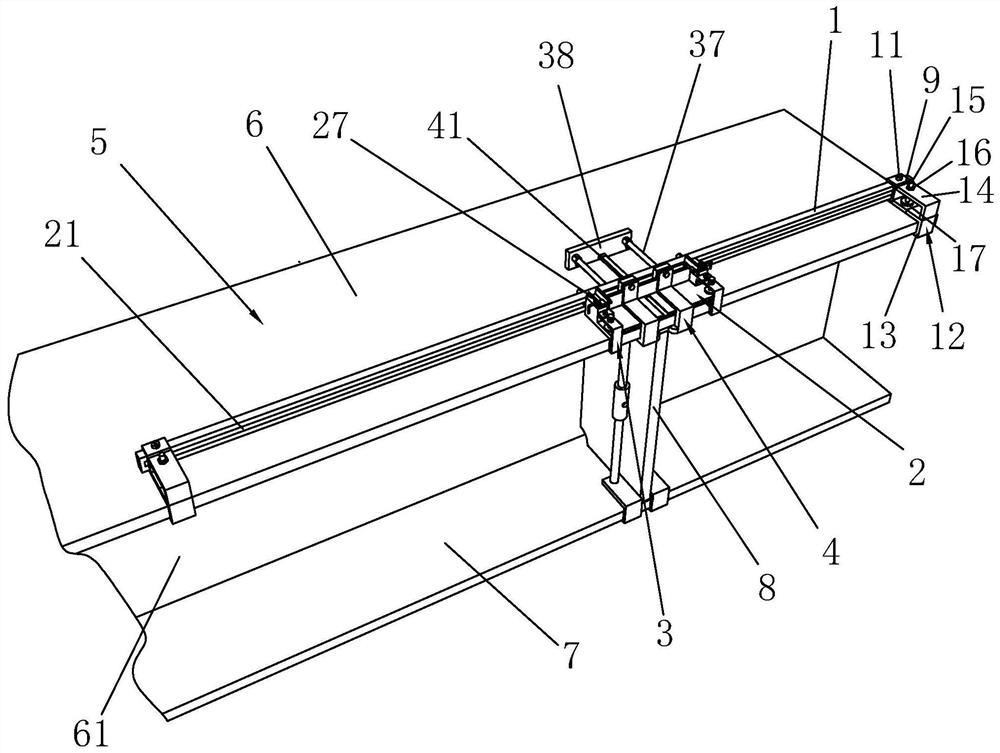

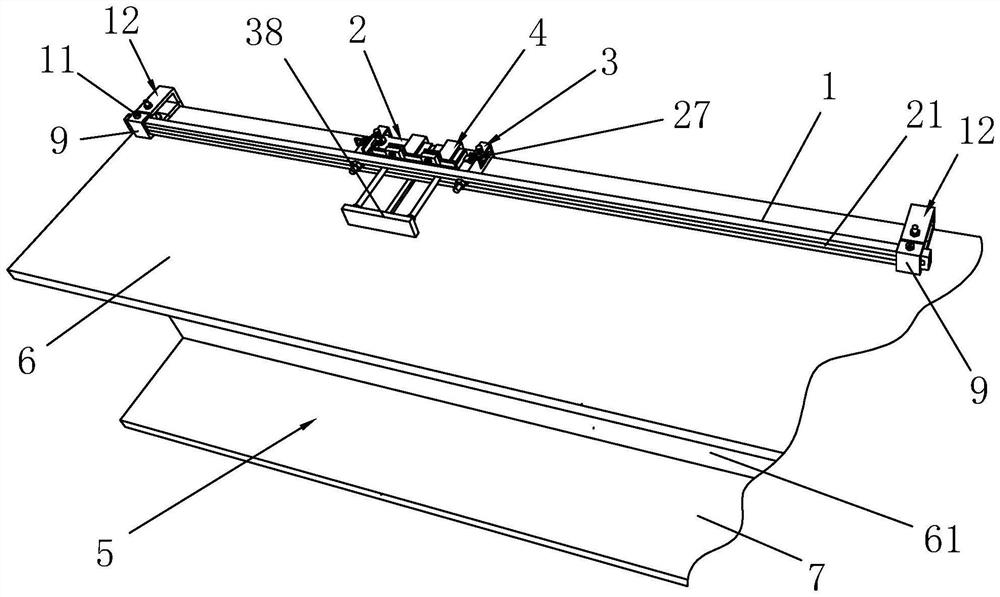

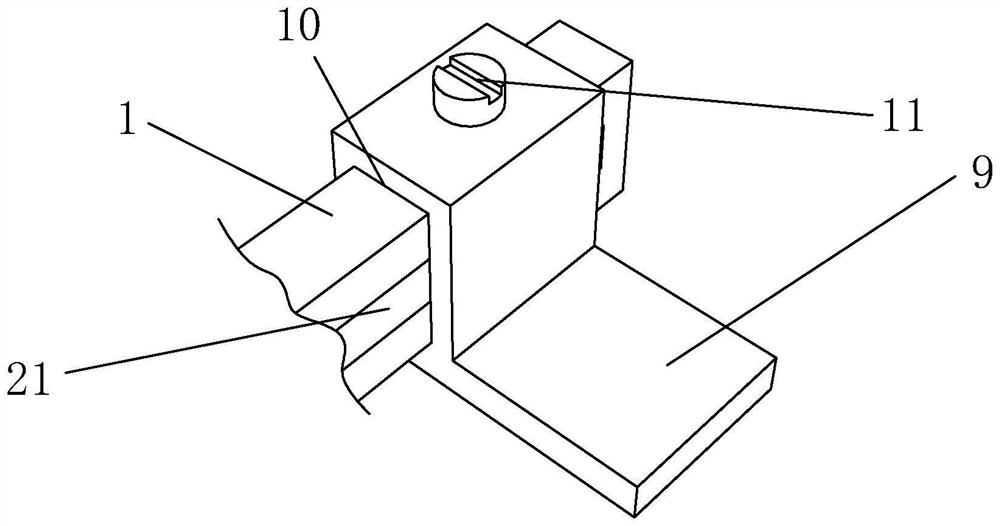

[0049] Such as Figure 1 to Figure 16 Shown, it is a kind of H-shaped steel component stiffening plate accurate positioning method of the present invention, comprises the steps:

[0050] (1) According to the dimensional requirements of the design drawings, use a marking pen to mark the position of the welding positioning line of the connecting plate 8 on the outer surface of the upper flange 6 of the H-shaped steel beam 5, and according to the actual length of the H-shaped steel beam 5 The H-shaped steel beam 5 is divided into sections according to the length of the guide rail 1, and then the welding installation of the connecting plate 8 is carried out segment by section; the position of the welding positioning line corresponding to the connecting plate 8 is marked by a marker pen, which is convenient for the subsequent displacement adjustment device 2 The precise positioning of the connecting plate 8 is realized, and because the actual length of the H-shaped steel beam 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com