Leveling tool and leveling method for bridge deck pavement reinforcing mesh

A bridge deck paving and steel mesh technology, which is applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to ensure the design position of steel mesh, fragile concrete pads, etc., and achieves simple structure and low manufacturing cost. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

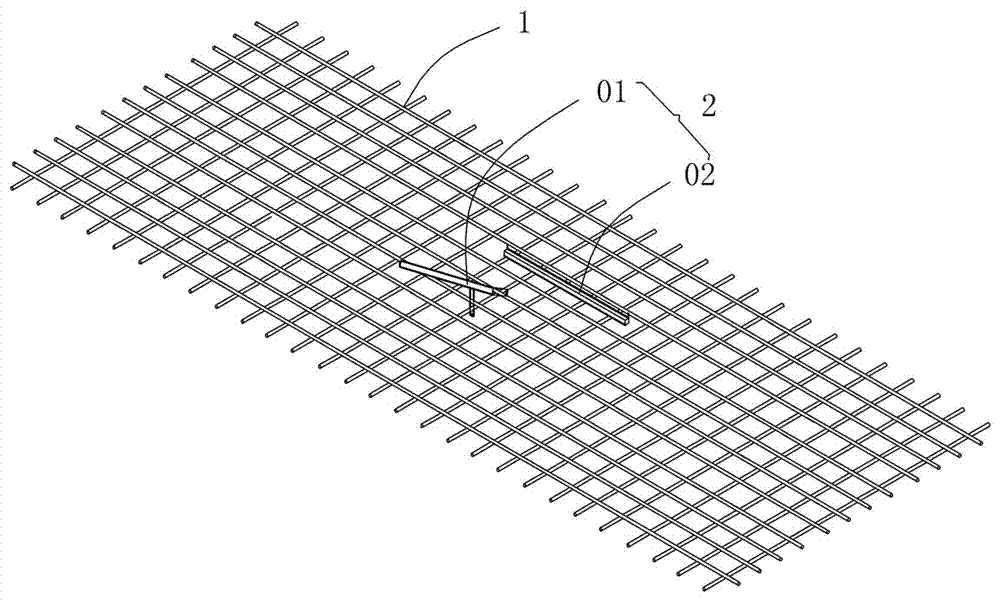

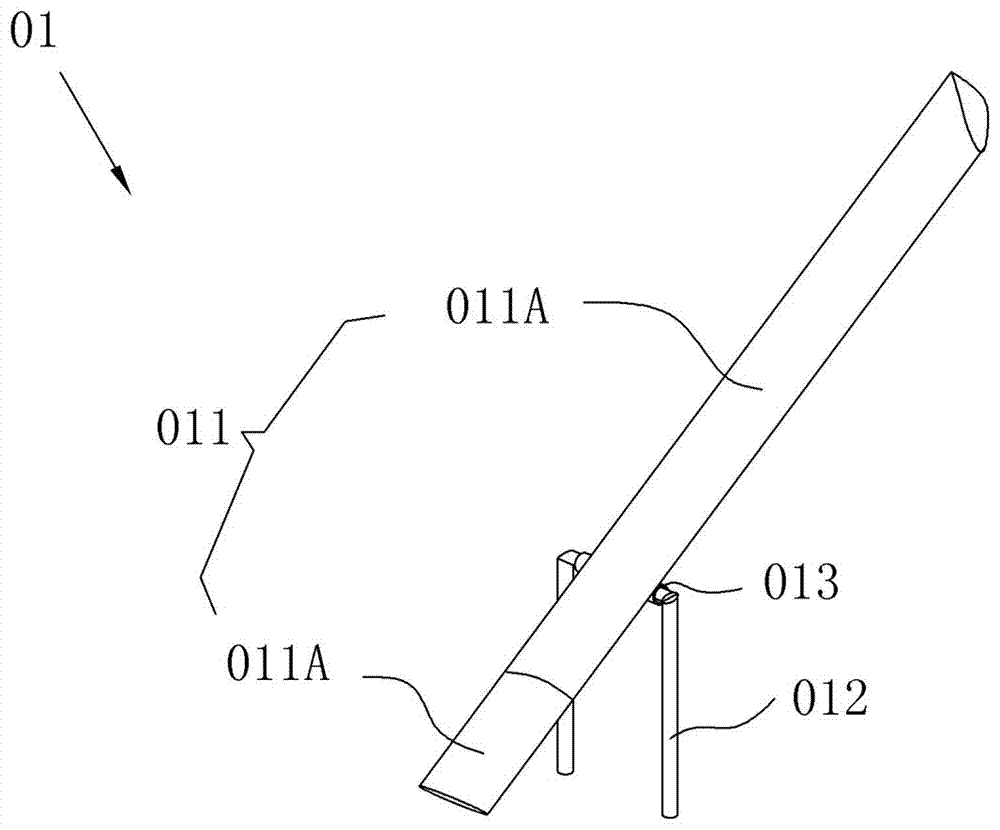

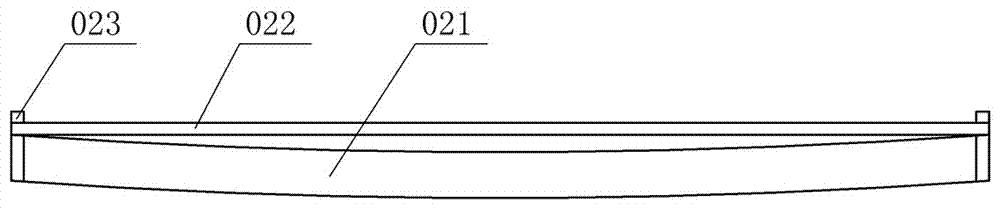

[0024] Example 1: see Figures 1 to 3 , a steel mesh leveling tool for bridge deck pavement, comprising: a rotatable crowbar for leveling the steel mesh sheet; a leveling tool, set on the steel mesh to be adjusted, for detecting whether the adjusted steel mesh is reach the design elevation; the leveling tool includes a leveling rod and a leveling rope, the leveling rope is arranged on the top surface of the leveling rod, and its two ends are respectively connected to the leveling rod through a fixing piece, and the leveling rope is in the Straight line state. The height of the leveling bar is the thickness of the bridge deck pavement protection layer. The leveling rod is hollow square steel.

[0025] The pivot rotatable crowbar includes a crowbar and a door-shaped bracket. One end of the crowbar is a gripping part, and the other end is a prying part. The head is fixedly connected with the pry bar through the connecting sleeve, and the cross bar of the door-shaped bracket is...

Embodiment 2

[0026] Example 2: see figure 1 with image 3 , a leveling method using the above-mentioned steel mesh leveling tool for bridge deck pavement, comprising the following steps: first, placing both ends of the leveling tool on a fixed design elevation point, and then using a fulcrum rotatable crowbar to move the The steel mesh in the area to be leveled is pried up, and the visual inspection leveling rope and the top surface of the leveling rod are in full contact and are on the same horizontal line, that is, the steel mesh here reaches the design elevation, and the supporting steel is welded to the steel mesh at the same time firm. According to the above method, all the steel mesh sheets in this area are adjusted to the design elevation. The lower ends of the supporting steel bars are set on the bridge deck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com