Shielding grounding spring, connector employing same, and connector assembly

A technology of shielding grounding and connectors, which is applied in the field of shielding grounding springs, can solve problems such as poor contact between shielding grounding springs and socket housings, failure of shielding grounding, and difficult positioning of shielding grounding springs, etc., to achieve good circumferential shielding effect, Fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

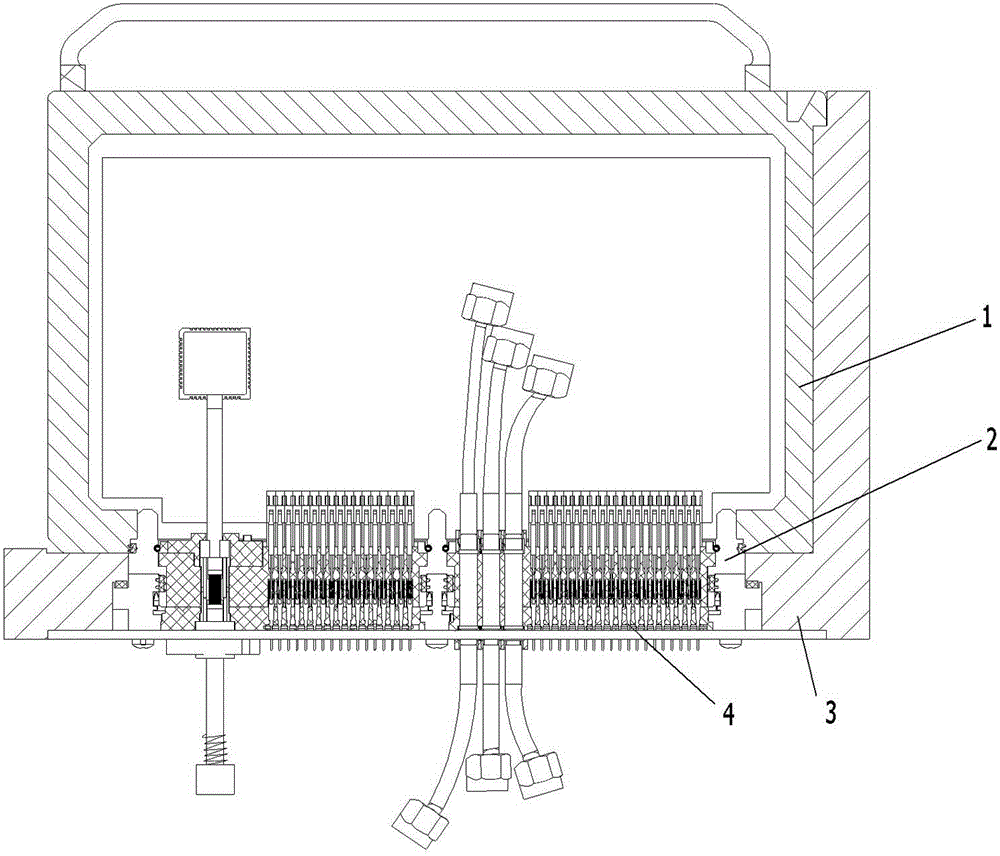

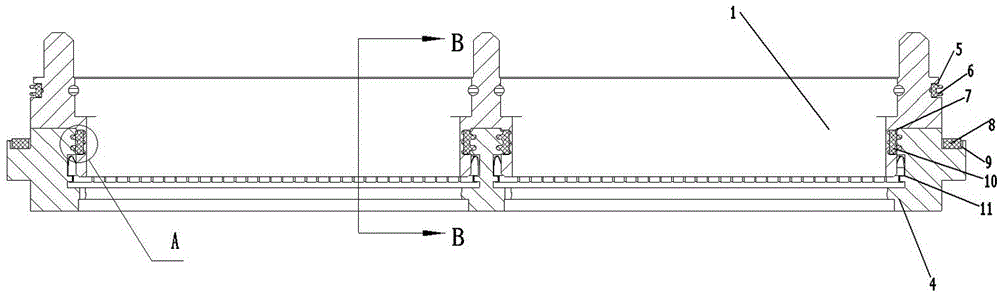

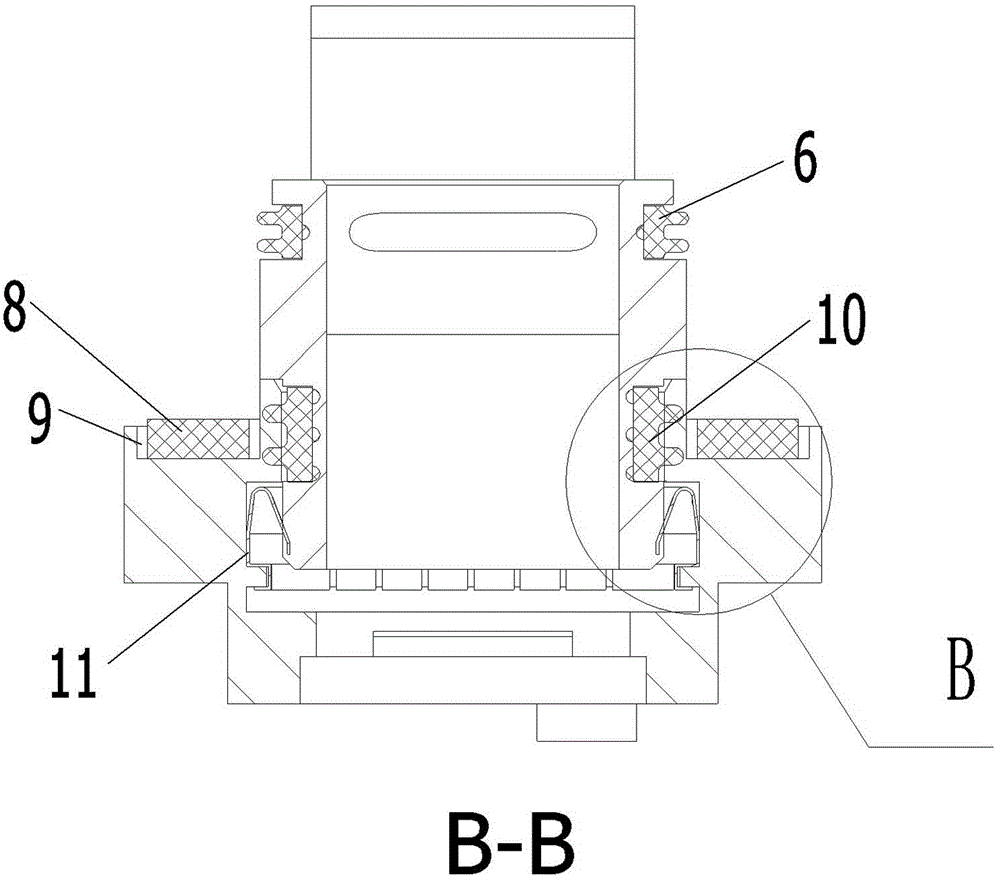

[0041] An example of a connector component is Figure 1~20Shown: This connector assembly is an LRM connector assembly, including a plug installation module 1, a plug 2, a socket 4 and a chassis panel 3, the plug includes a plug shell 13, and the socket includes a socket shell 12, and the plug and socket are connected in a rectangular shape Connectors, sockets and plugs are arc-adapted, so the socket can also be called a connector, and the plug is called a matching connector. A shielding grounding spring 11 is provided on the wall of the inner hole of the socket housing. The shielding grounding spring 11 includes an annular body 19. The annular body has an inner hole of the grounding spring for inserting the plug housing from front to back. The front end of the annular body is spaced along the circumferential direction. A plurality of reeds 17 cantilevered toward the center of the inner hole of the grounding spring are provided, and the reeds are located on the inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com