High-strength motor shaft

A motor shaft, high-strength technology, applied in the directions of shafts, shafts and bearings, mechanical equipment, etc., can solve the problems of inconvenient positioning and welding of rib plates, unreasonable structure of the motor shaft, and inconvenient installation and use, etc. The phenomenon, the structure is simple and reasonable, and the effect of ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

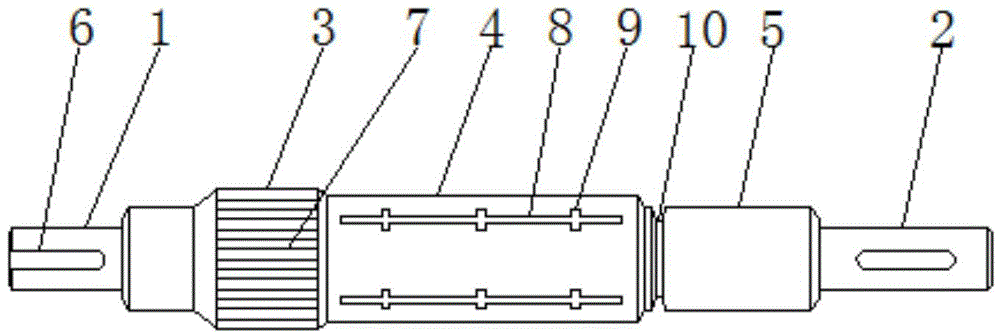

[0011] Such as figure 1 As shown, a high-strength motor shaft includes a front connecting rod 1 and a rear connecting rod 2, and a knurled rod 3, a first polished rod 4 and a second polished rod 5 are sequentially connected between the front connecting rod 1 and the rear connecting rod 2 , the outer circular surfaces of the front connecting rod 1 and the rear connecting rod 2 are provided with splines 6, the splines 6 on the front connecting rod 1 extend to the end face of the front connecting rod 1, and the outer circular surface of the knurled rod 3 is rolled There are straight knurls 7, and a plurality of axially arranged bar-shaped grooves 8 are equidistantly distributed on the outer surface of the first polished rod 4, and a plurality of cross-shaped reinforcing groove nodes 9 are distributed on the bar-shaped grooves 8.

[0012] An annular clamping groove 10 is provided between the first polished rod 4 and the second polished rod 5, and the motor shaft is made of high-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com