Front cover structure of rail vehicle head

A rail vehicle and front cover technology, which is applied to the railway car body, railway car body parts, transportation and packaging, etc., can solve the problem of the flexibility of the glass fiber reinforced plastic front cover, the inability to provide safety design data, and affect the accuracy of the anti-climbing device function of the rail vehicle. Problems such as the effect of hanging and energy-absorbing structures, to achieve the effect of retaining its own performance, simple and practical overall structure, and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

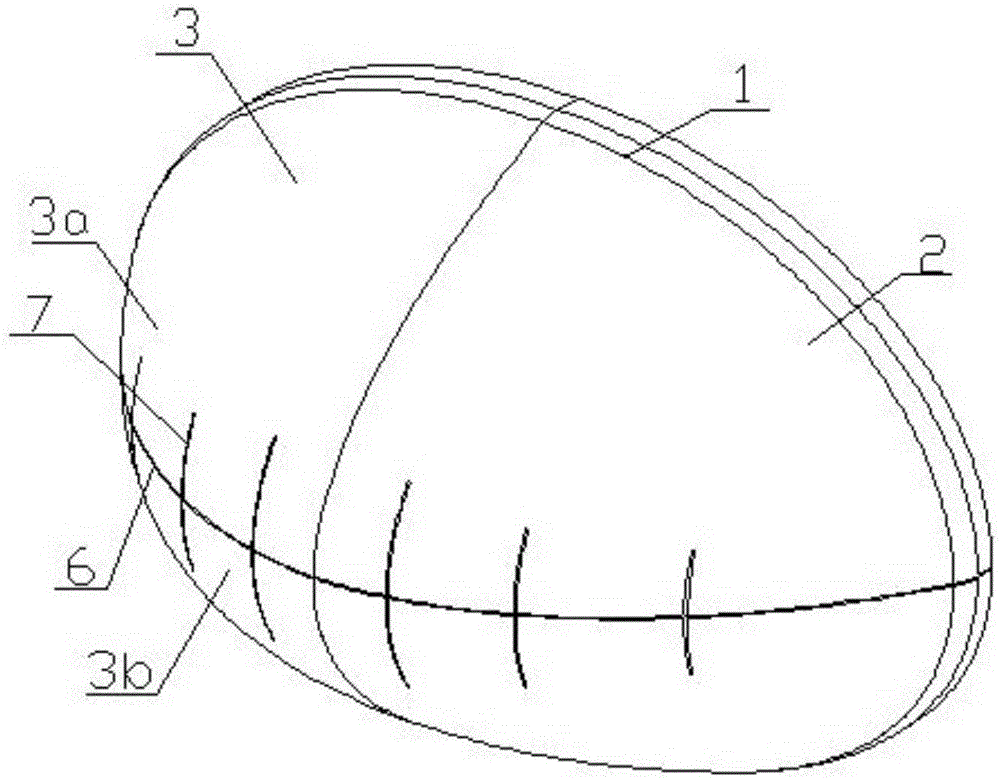

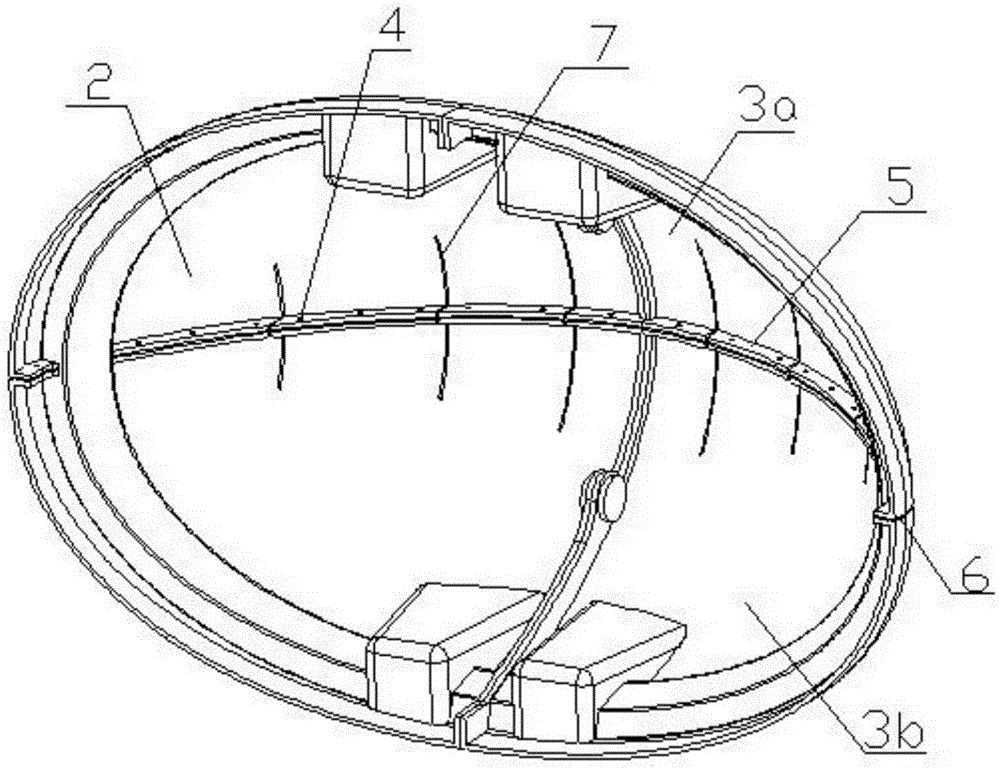

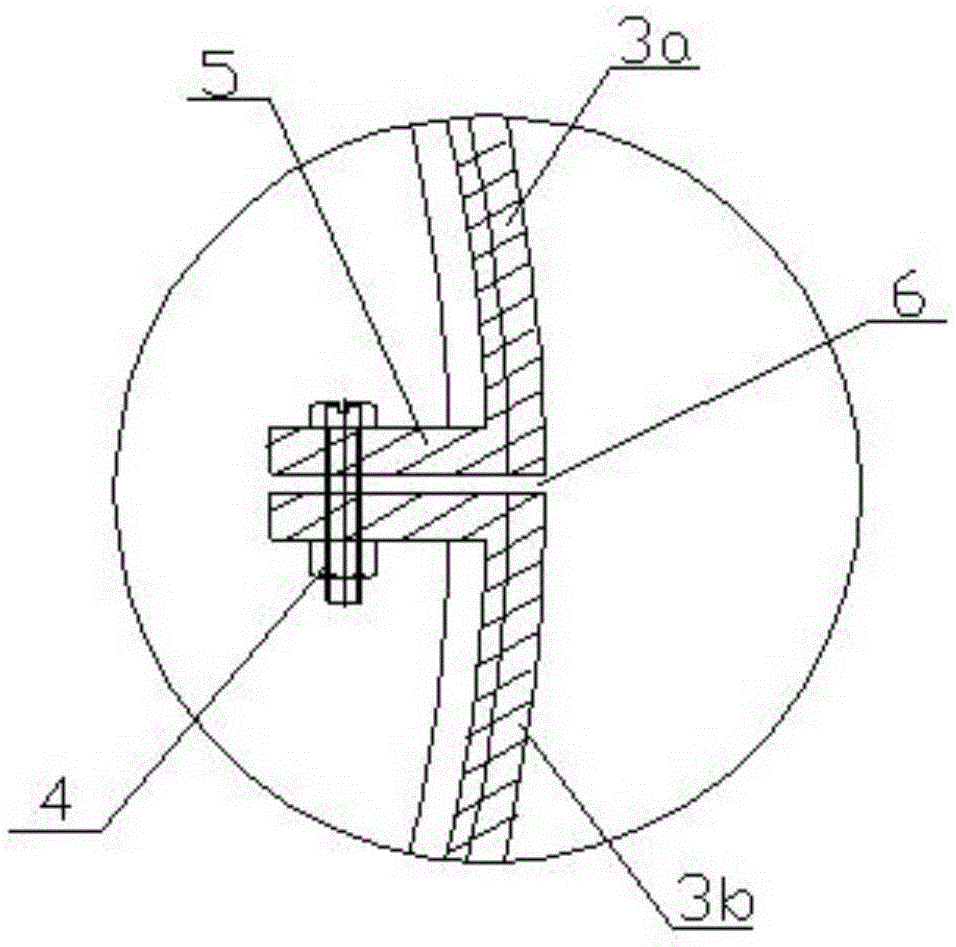

[0027] Such as figure 1 with figure 2 As shown, the present invention provides a front cover structure of a rail vehicle head, including a front cover 1 installed on the head of the car body. In order to meet the requirements of vehicle coupling, the front cover 1 is composed of two separate parts, left and right, respectively. It is the left front cover 2 and the right front cover 3, which are symmetrically arranged along the longitudinal center line of the car body. , to ensure that the running resistance is not increased when the vehicle is running. When the coupler is needed, the left front cover 2 and the right front cover 3 are driven by the opening and closing mechanism to open the coupler to expose the head of the vehicle to both sides of the car body. Both the left front cover 2 and the right front cover 3 are made of FRP, which can not only ensure the required strength and rigidity when the vehicle is running at high speed, but also reduce the weight to meet the re...

Embodiment 2

[0041] The difference from Embodiment 1 is that, not shown in the figure, the shape of the long slit 7 is a straight line, inclined to the side connected to the vehicle body, and the long slits 7 located on both sides of the gap 6 are arranged symmetrically to each other, and the symmetrically arranged Two long slits 7 form an included angle, and the extended lengths of each long slit 7 can be the same. In this embodiment, the extended lengths of multiple long slits 7 on the same side are preferably different, and gradually decrease from the front to the vehicle body.

Embodiment 3

[0043] The difference from Embodiment 1 is that, not shown in the figure, the left front cover 2 and the right front cover 3 are respectively divided into upper, middle and lower three pieces to form two slits 6, and each slit 6 is one on the horizontal plane. Arc, two slits 6 are parallel to each other, the height of the center line between the two slits 6 from the rail surface is consistent with the height of the coupler from the rail surface, and the distance between the two slits 6 is determined according to the size of the coupler.

[0044] Three long slits 7 are respectively arranged on both sides of the two slits 6, and the three long slits 7 located between the two slits 6 run through the two slits 6, and three long slits 7 are respectively arranged on the outside of the two slits 6, But the length of the long slit 7 arranged outside the slit 6 is shorter than the length of the long slit 7 arranged in the middle of the two slits 6 .

[0045] Except above-mentioned embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com