Front suspension vertical double torsion car

A double torsion vehicle and vertical technology, applied in the direction of motor vehicles, bicycles, vehicle parts, etc., can solve the problems of lack of forward thrust, unstable connection structure, difficult control of universal wheels, etc., and achieve simple structure and structure Easy to build, diverse gameplay, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

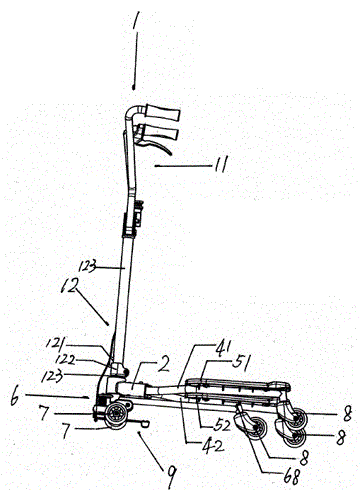

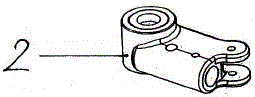

[0016] according to figure 1 , 2 , 3, 4, 6, the described front suspension vertical double torsion car includes handlebar 1, front seat 2, locking bolt 3, left beam 41, right beam 42, left pedal 51, right pedal 52, Pendulum 6, front wheel 7, universal wheel 8 and brake 9;

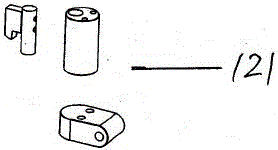

[0017] The handlebar 1 includes a V-shaped folding handle 11 and a folding handle riser 12. The V-shaped folding handle 11 includes a handle base 111, a lower connecting pipe 112, a U-shaped groove plastic liner 113, a left hand Handle 114, right hand handle 115, left locking piece 116, right locking piece 117, quick release 118, safety buckle 119, the handle base 111 described is a round hole in the middle, grooves on both sides, The aluminum extruded profile cutting workpiece with convex ribs on the inner sides of the two grooves near the bottom of the groove, the handle base 111 has a mutual opposite perforation on the lower parts of the two sides of the two grooves, the handle base 111 There is a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com