Guide conveying mechanism for lock tongue

A technology of conveying mechanism and guiding mechanism, applied in the field of machining, can solve the problems of difficulty in guaranteeing the dimensional accuracy of the lock tongue, low material utilization rate, low work efficiency, etc., and achieves the effects of compact structure, easy operation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

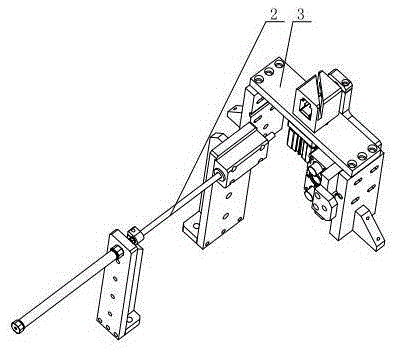

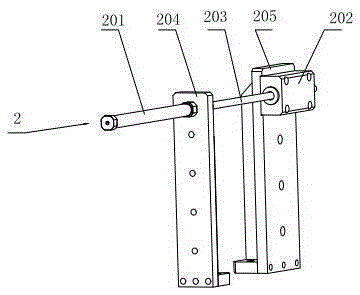

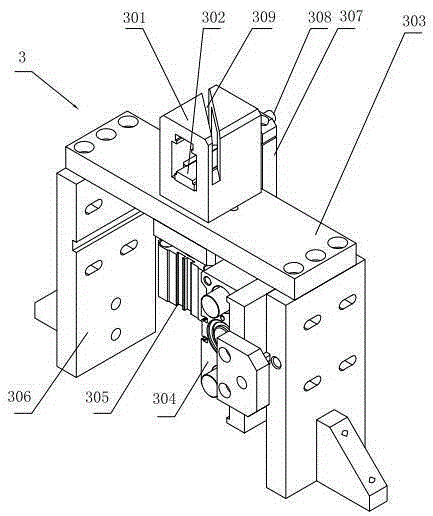

[0016] Such as figure 1 As shown, the guide conveying mechanism for the deadbolt of the present embodiment includes a deadbolt clamping mechanism 3, and one end of the deadbolt clamping mechanism 3 is equipped with a guiding mechanism 2, such as image 3 with Figure 4 As shown, the structure of the deadbolt clamping mechanism 3 is as follows: comprising supporting frames 306 arranged at intervals, a bottom plate 303 is fixed on the top of the supporting frame 306, a deadbolt clamping block 301 is fixed on the bottom plate 303, and the dead bolt clamping block 301 forms The cuboid structure is located in the middle of the bolt clamping block 301 and has a through hole passing through the bolt. The lifting cylinder 305, the output end of the lifting cylinder 305 is fixedly connected with the moving block 302; the moving block 302 can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com