Patents

Literature

38results about How to "Convenience guide conveying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

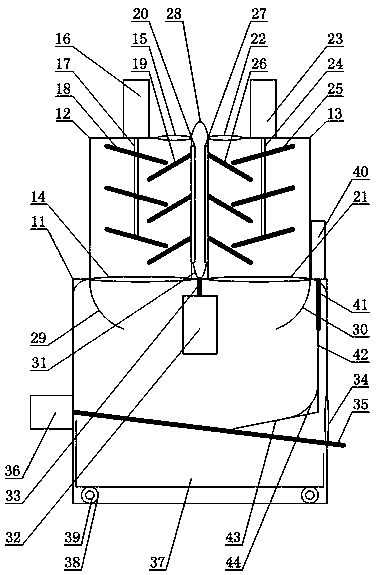

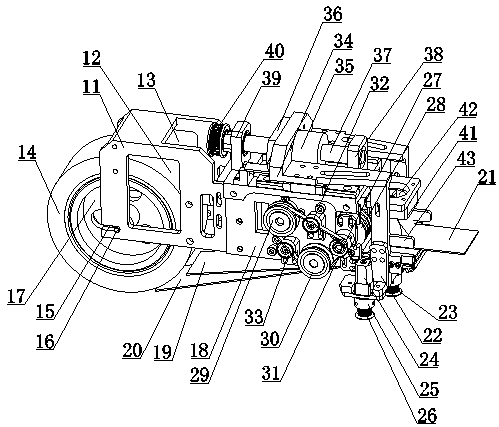

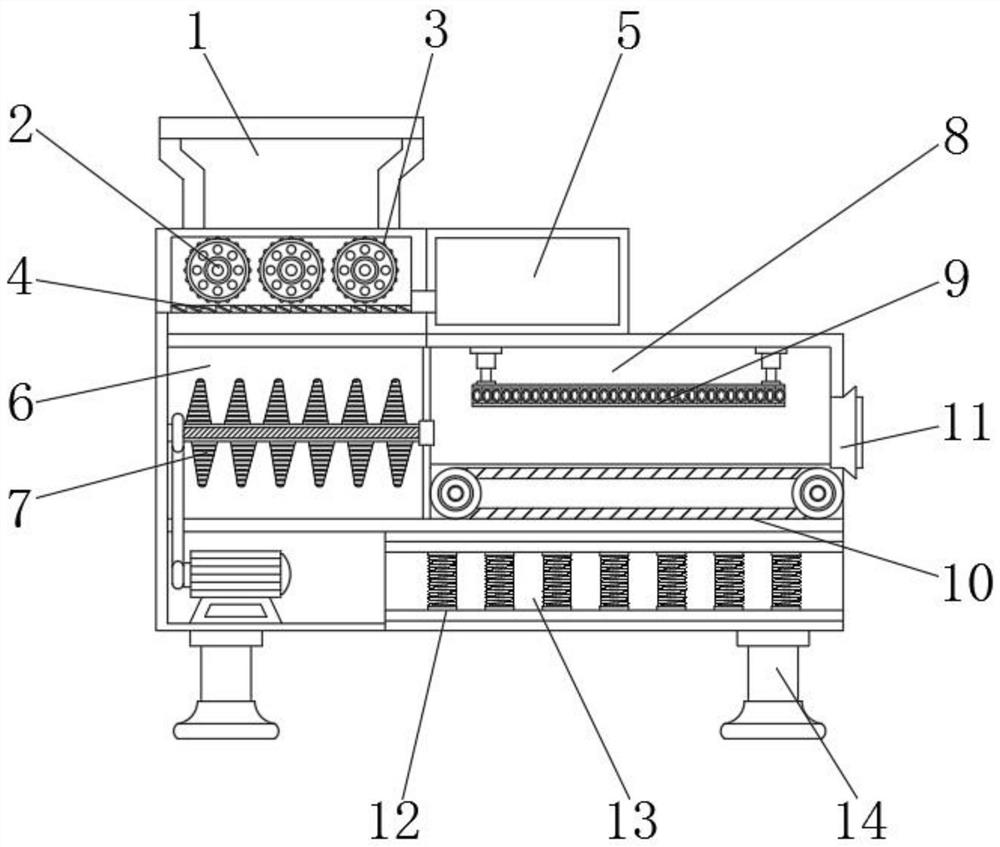

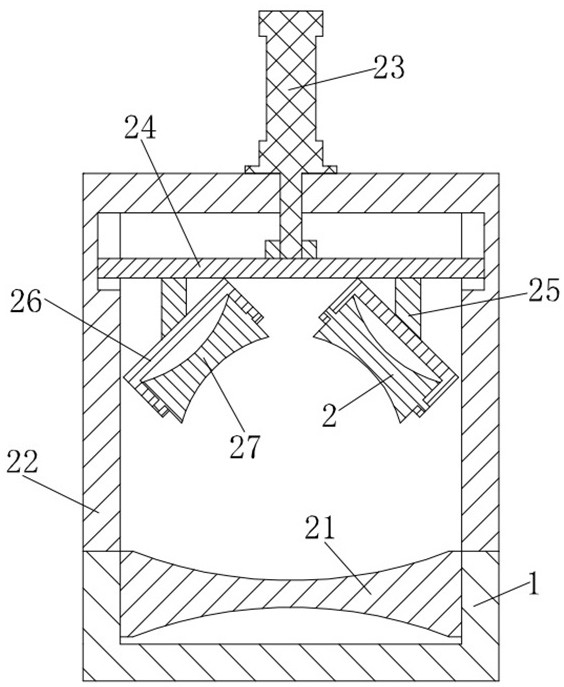

Masterbatch electric heating mixing device for plastic granulation

ActiveCN109352852AConvenience guide conveyingImprove heat treatment efficiencyEngineeringElectric heating

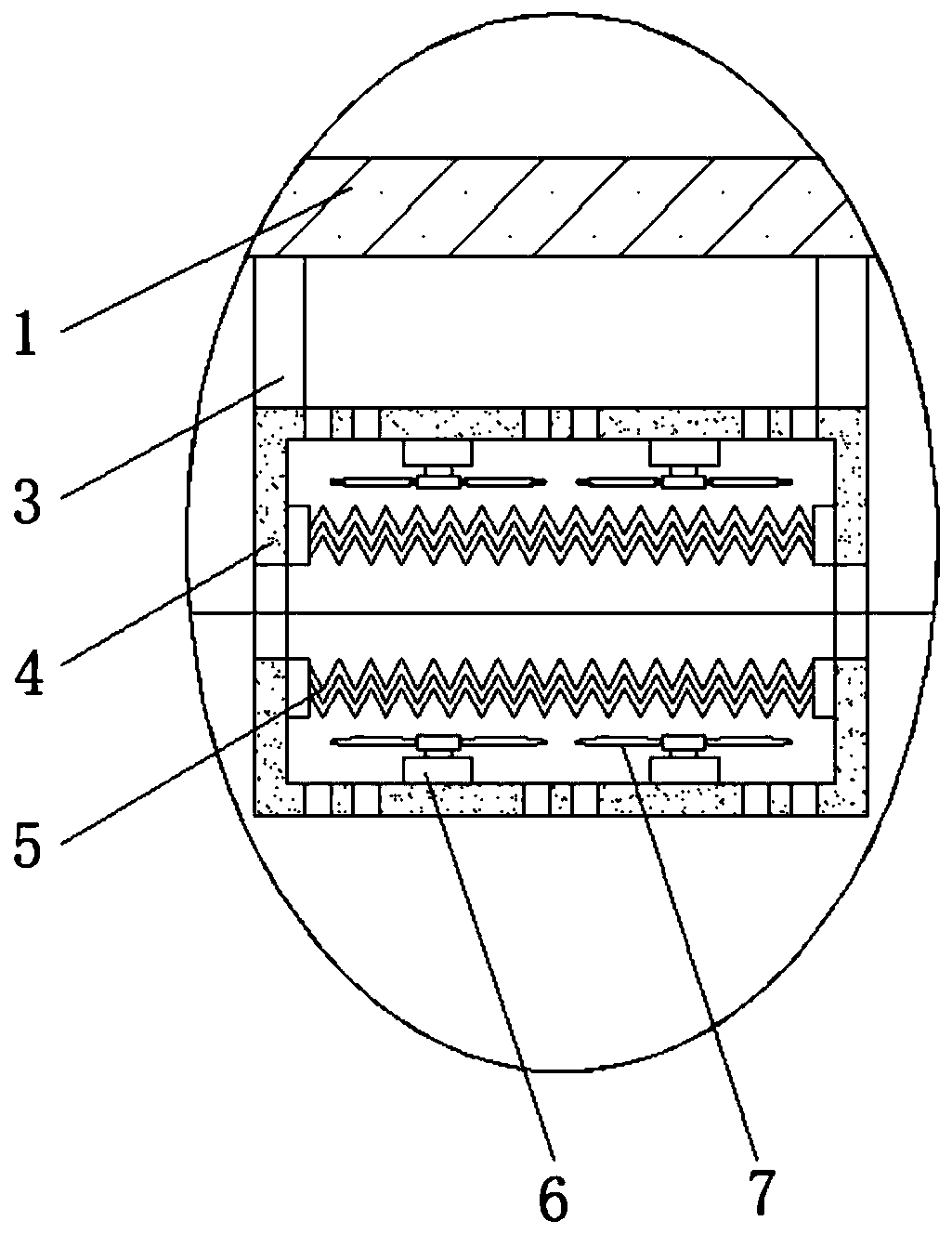

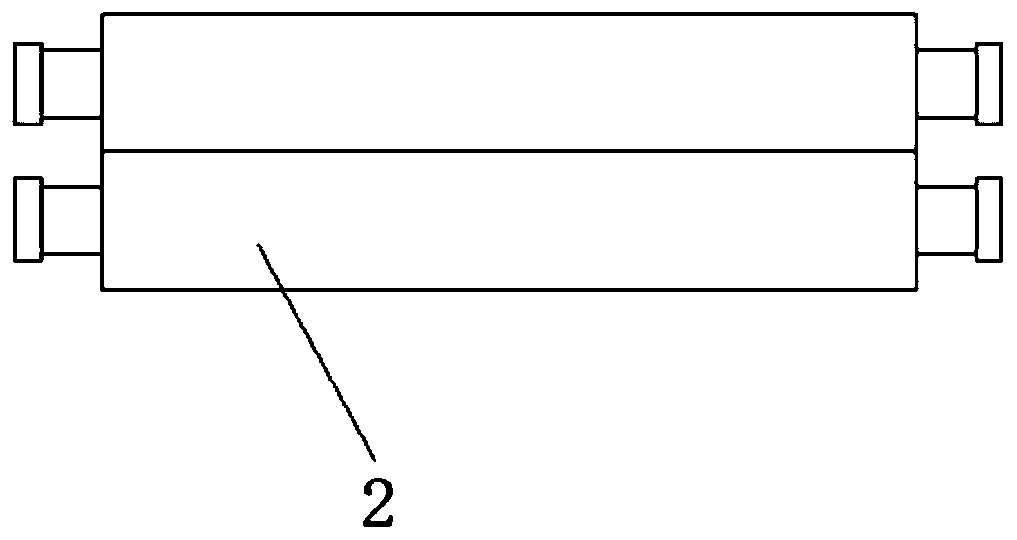

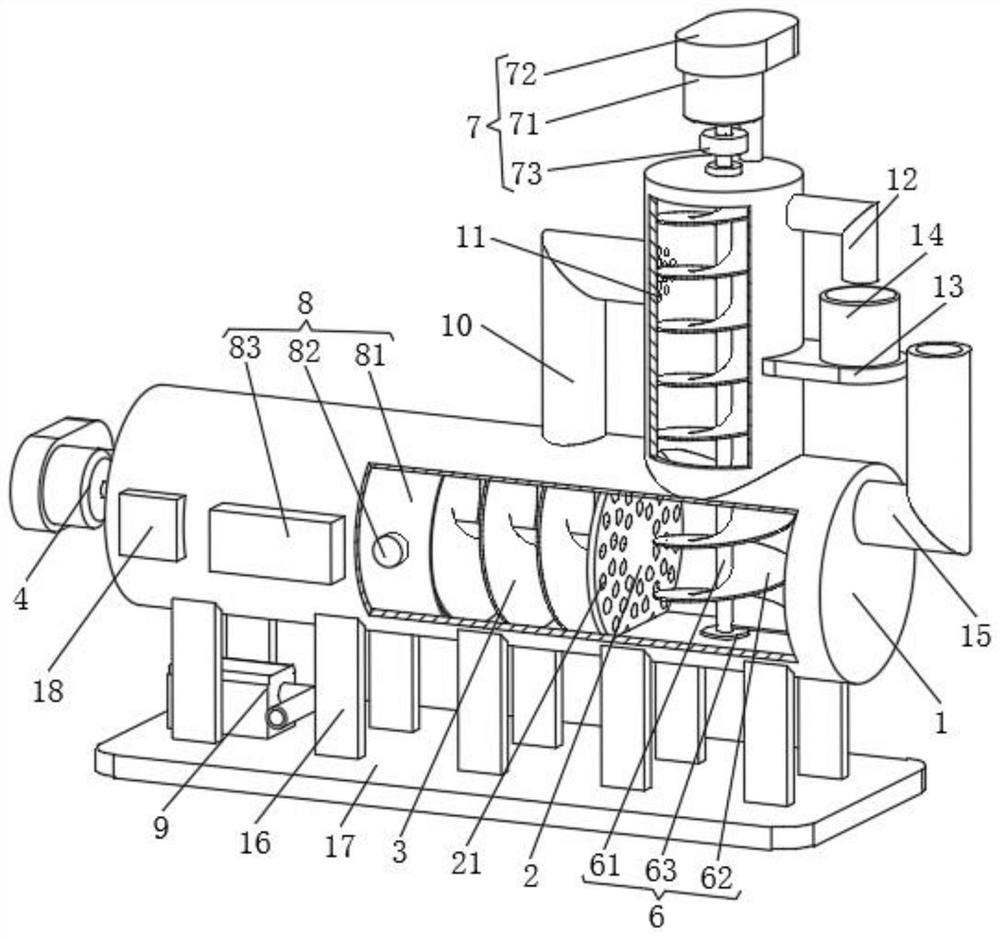

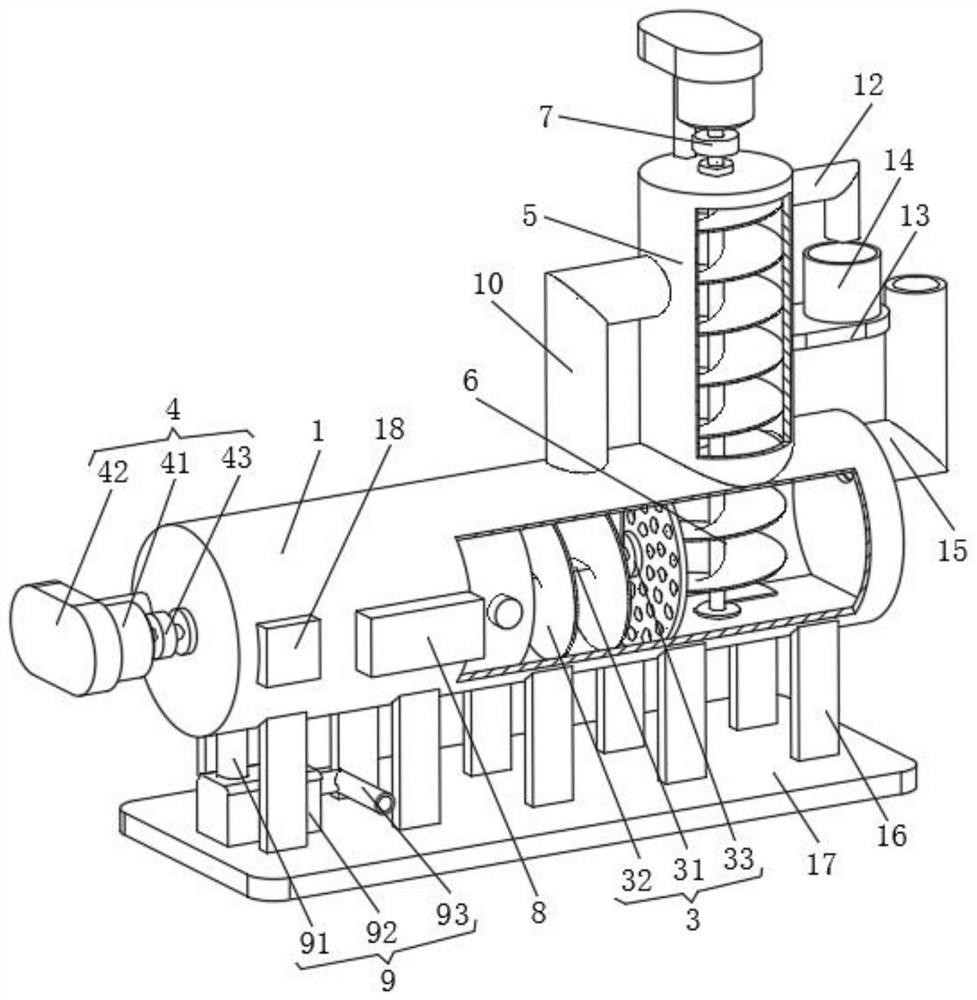

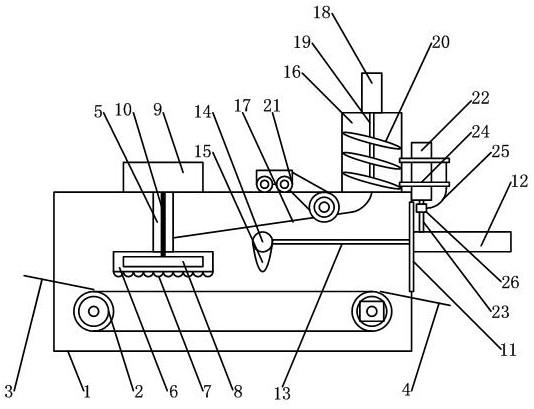

The invention discloses a masterbatch electric heating mixing device for plastic granulation. The masterbatch electric heating mixing device comprises a mixing bin, wherein a feeding mechanism is arranged on the top of the mixing bin and comprises a feeding bin; the feeding bin is arranged on the top of the mixing bin; a discharge chute is arranged between the feeding bin and the top of the mixingbin; a feeding port is formed in the top of the feeding bin, a rotating motor is arranged on the top of the feeding bin; a rotating shaft is arranged at the lower part of the rotating motor; mixing blades are arranged on the outer peripheral surface of the rotating shaft in a sleeving manner; an electric heating mesh plate is arranged on the inner side part of the feeding bin; a vibrating plate is arranged on the outer side part of the feeding bin; the electric heating mesh plate is connected to the vibrating plate; a vibrating and conveying filter screen is arranged at the inner bottom of the mixing bin; a discharging port is formed in one side of the mixing bin; a vibrating motor is arranged at the other side of the mixing bin; one side of the vibrating and conveying filter screen is connected to the vibrating motor; and the other side of the vibrating and conveying filter screen is connected to the discharging port. The masterbatch electric heating mixing device greatly improves the efficiency of heating the masterbatch while stirring.

Owner:南通瑞智新材料科技有限公司

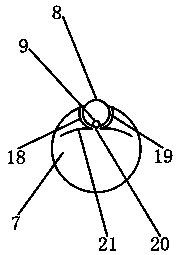

Plastic particle electrostatic-eliminating device

InactiveCN109862681AEasy to pourConvenience guide conveyingLoading/unloadingElectrostatic chargesEngineeringBlow out

The invention discloses a plastic particle electrostatic-eliminating device. The plastic particle electrostatic-eliminating device comprises a base; a body is arranged on the base; an electrostatic-eliminating mechanism is arranged on the body; a feeding cylinder is arranged on the top of the body; a feeding hole is arranged on the top of the feeding cylinder; a receiving vehicle is arranged on the base; the feeding cylinder is installed at the upper side of the electrostatic-eliminating mechanism; the receiving vehicle is installed at the lower side of the electrostatic-eliminating mechanism;the electrostatic-eliminating mechanism comprises a guide cylinder; an electrostatic-eliminating cylinder is arranged at the upper part of the guide cylinder; several ion wind rods, which are arranged at equal intervals, are arranged at the internal bottom of the electrostatic-eliminating cylinder; the upper end of the guide cylinder is communicated with the side wall of the bottom of the feedingcylinder; the lower end of the guide cylinder is installed over the receiving vehicle; a vibration feeding plate is installed at the internal bottom of the guide cylinder and the feeding cylinder; and the lower end of the vibration feeding plate is installed over the receiving vehicle. According to the plastic particle electrostatic-eliminating device in the invention, the ion wind rods are located and installed through the electrostatic-eliminating cylinder; the ion wind rods blow out electrostatic-eliminating wind through a wind output tank; and thus, the electrostatic-eliminating efficiency on plastic particles is greatly increased.

Owner:董江平

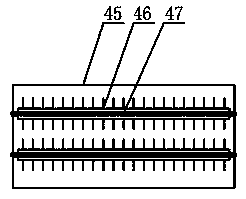

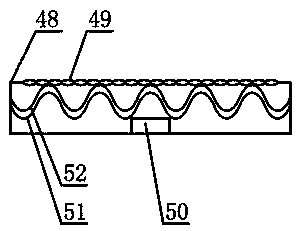

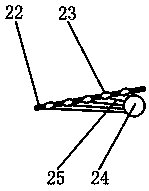

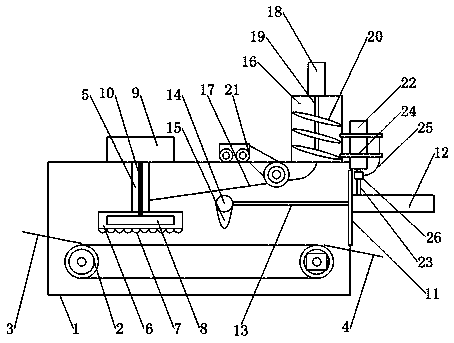

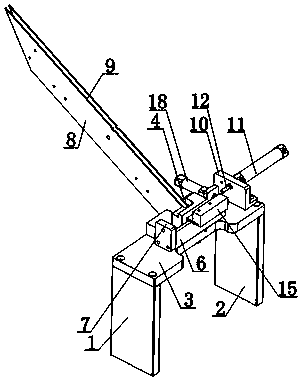

Water-discolored water-stop strip making device

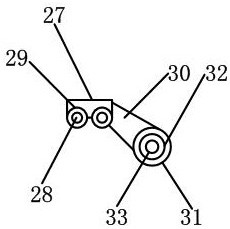

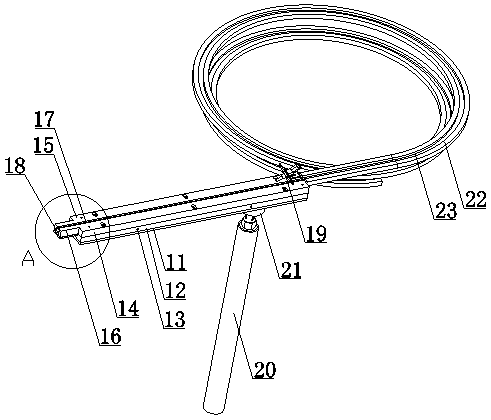

InactiveCN106862016AEasy dippingConvenience guide conveyingLiquid surface applicatorsCoatingsDrive motorElectric heating

The invention discloses a preparation device for water-changing water-stop strips, which comprises a bottom plate, a support is provided on the bottom plate, an unwinding wheel is provided on the support, a dipping tank is provided on the inner bottom of the support, and a dipping wheel is provided on the inner bottom of the dipping pool , the bracket is provided with a traction wheel, the bracket is equipped with a wiper tube, the bracket is equipped with an electric heating tube, an electric heating plate and a temperature controller, the electric heating plate is installed on the upper part of the electric heating tube, and the electric heating plate and the temperature controller are electrically connected; the bracket The second guide wheel is arranged on the top, the driving wheel is arranged on the bracket, the driving wheel is engaged with the second guide wheel, the driving motor is arranged on the bracket, the front part of the driving motor is provided with a driving shaft, and one end of the driving shaft is connected with the driving motor. The driving wheel is set on the other end of the driving shaft; the unwinding wheel, the traction wheel, the dipping wheel, the ink scraping tube, the electric heating tube and the second guide wheel are connected in sequence. The invention can heat-treat the water-stop strip through the electric heating tube, and can form a water-changing color layer on the surface of the water-stop strip; and can conveniently guide and recycle the water-stop strip.

Owner:SUZHOU ZHONGXINYUAN MICROELECTRONICS CO LTD

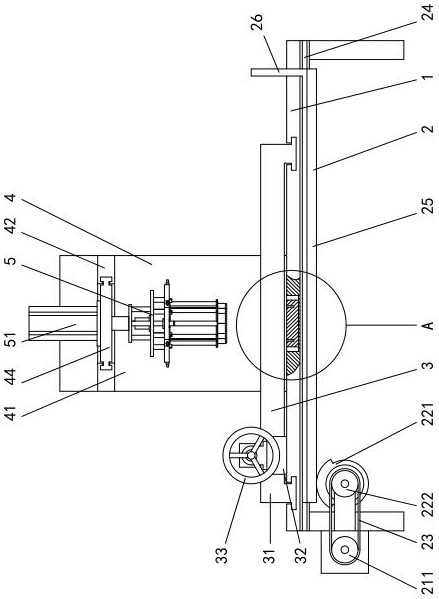

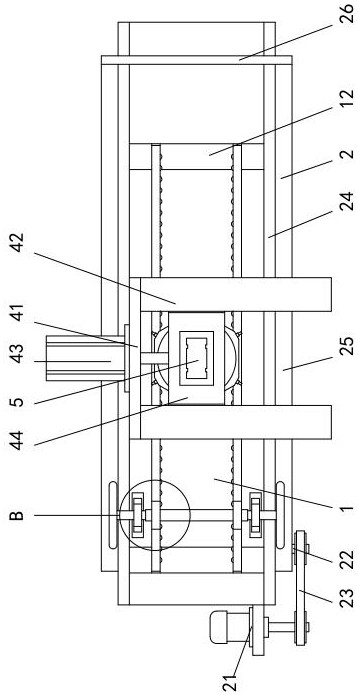

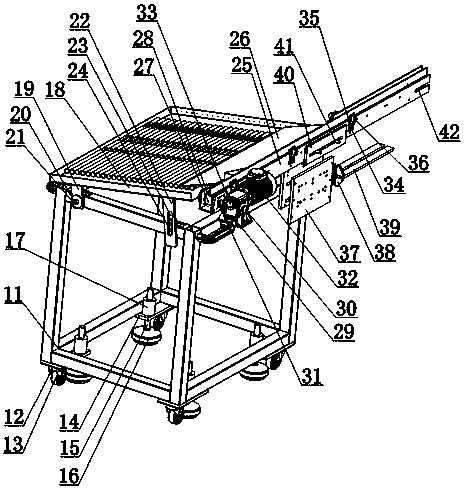

Concrete curtain coating guide conveying device for building construction

InactiveCN108657758AQuick stirring processConvenience guide conveyingMechanical conveyorsHydraulic cylinderEngineering

The invention discloses a concrete curtain coating guide conveying device for building construction. The concrete curtain coating guide conveying device comprises a rotary adjustment seat. A mixing drum is arranged on the rotary adjustment seat. The sidewall of the top of the mixing drum is provided with a side door. A conveying pump is arranged on the side portion of the mixing drum. A mixing motor is arranged on the top of the mixing drum. A mixing shaft is arranged on the lower portion of the mixing motor and mounted in the mixing drum. The mixing shaft is sleeved with mixing blades. The mixing blades are mounted in the mixing drum. Guide rails are arranged in front of the rotary adjustment seat. A moving rack is arranged on one side of the guide rails. The bottom of the moving rack isprovided with a moving seat. The bottom of the moving seat is provided with a plurality of moving wheels. A conveying vehicle is arranged on the guide rails. The concrete curtain coating guide conveying device for building construction can deliver concrete into the conveying vehicle. A hydraulic cylinder controls the conveying vehicle to move back and forth to conduct adjustment through a piston rod, and the conveying vehicle can move back and forth on the guide rails to be adjusted. Guiding and conveying of concrete are facilitated. The conveying vehicle runs from the high place to the lowerplace of the guide rails so that constructors can take materials from the conveying vehicle, and construction is facilitated.

Owner:江苏恒健建设集团有限公司

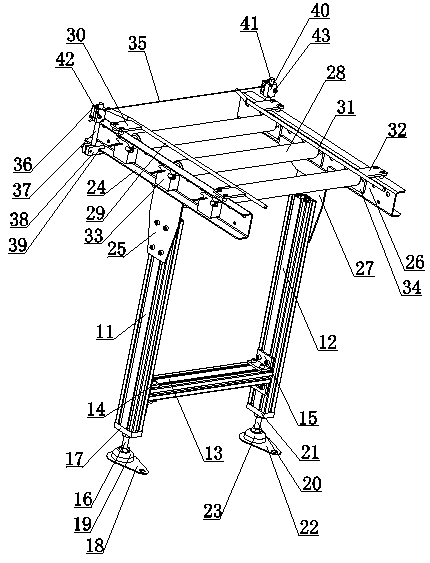

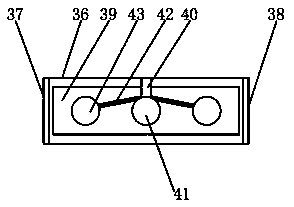

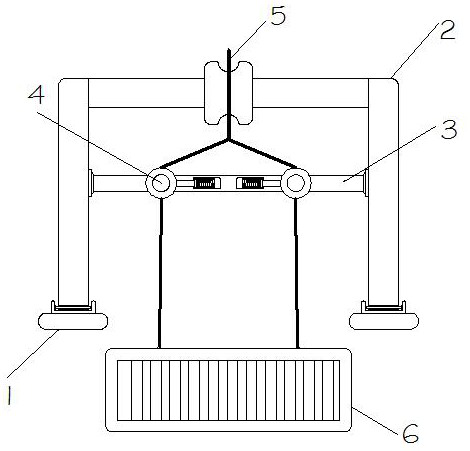

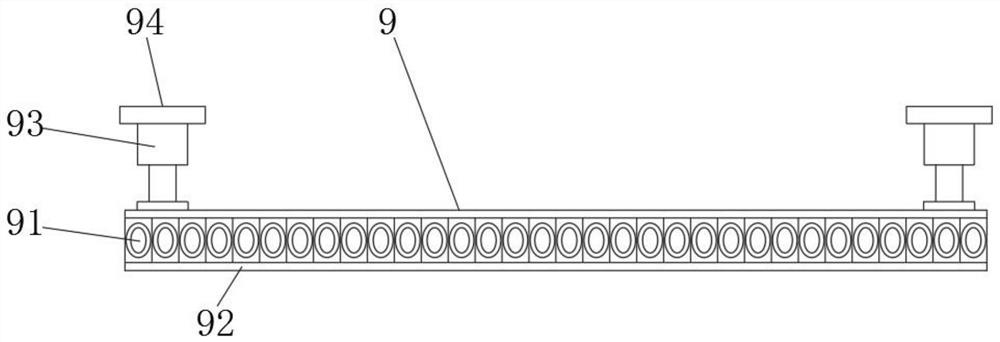

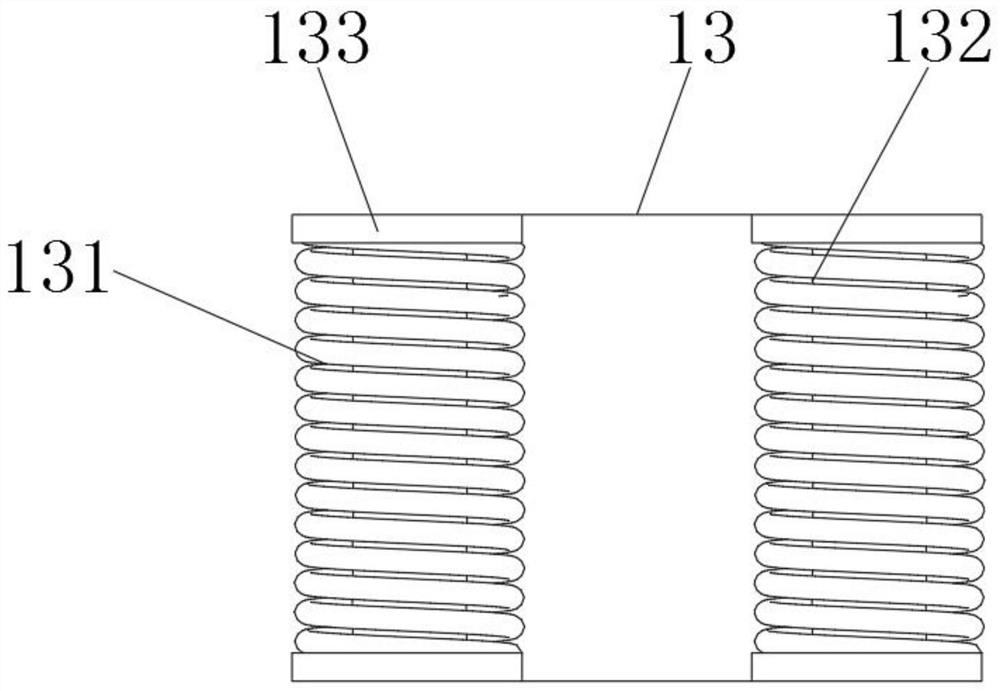

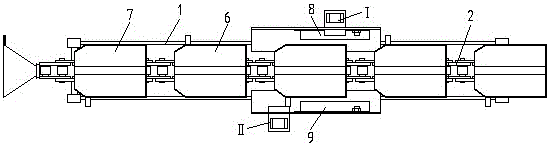

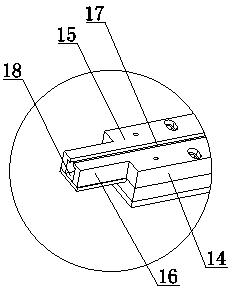

Aluminum honeycomb plate guide conveying device for push plate furnace

InactiveCN108820764ABlock deliveryConvenience guide conveyingConveyorsCharge manipulationAluminum honeycombEngineering

The invention discloses an aluminum honeycomb plate guide conveying device for a push plate furnace. The aluminum honeycomb plate guide conveying device for the push plate furnace comprises supportinglegs. The tops of the supporting legs are provided with side frames, and a plurality of conveying rollers are arranged between the side frames. The positions of inward faces of the side frames are provided with limiting strips, and the two ends of the limiting strips are fixed to the side frames through fixing pieces. The front parts of the side frames are provided with limiting wires, the outerside parts of the side frames are provided with locking bases, the locking bases are connected to the outer side parts of the side frames through locking shafts in a locked manner, and one ends of thelimiting wires are installed on the locking bases. According to the aluminum honeycomb plate guide conveying device for the push plate furnace, an aluminum honeycomb plate can be conveniently guidedand conveyed through the conveying rollers, the upper parts of the conveying rollers can be limited and controlled through the limiting wires, a too-thick aluminum honeycomb plate can be prevented from being conveyed to the conveying rollers, and therefore the aluminum honeycomb plate guide conveying device plays a screening role and is applied to the push plate furnace.

Owner:SUZHOU PISI SOFTWARE DESIGN CO LTD

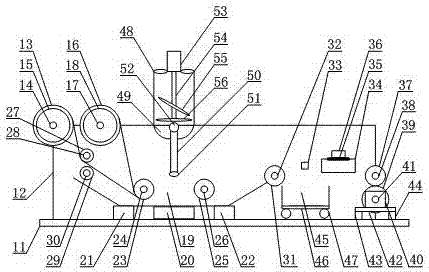

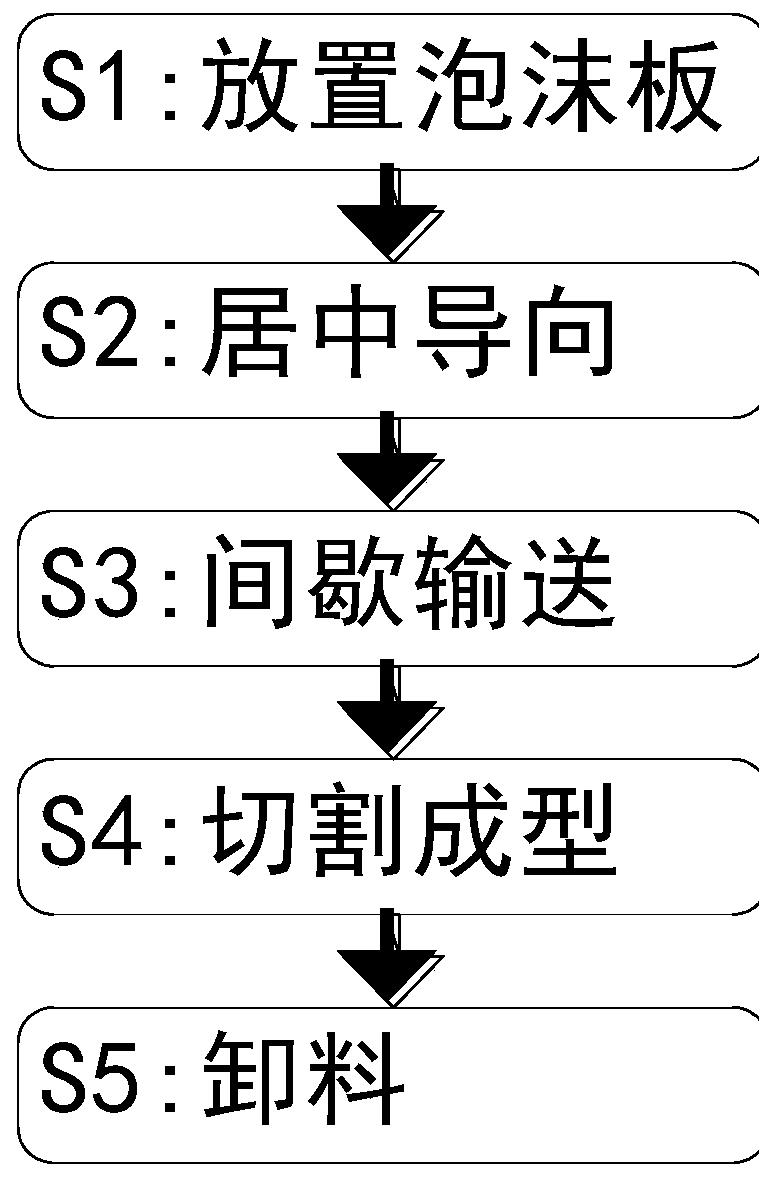

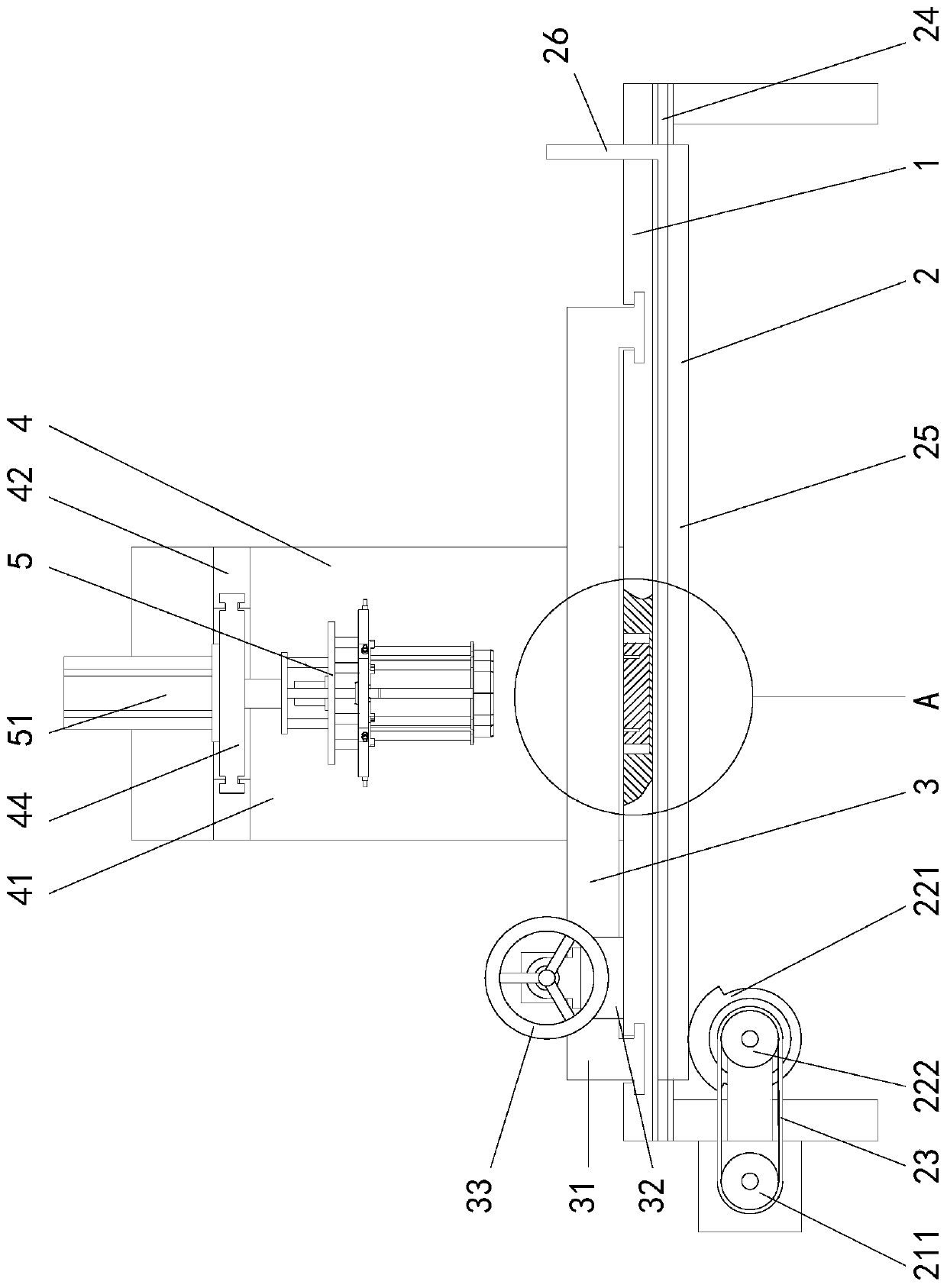

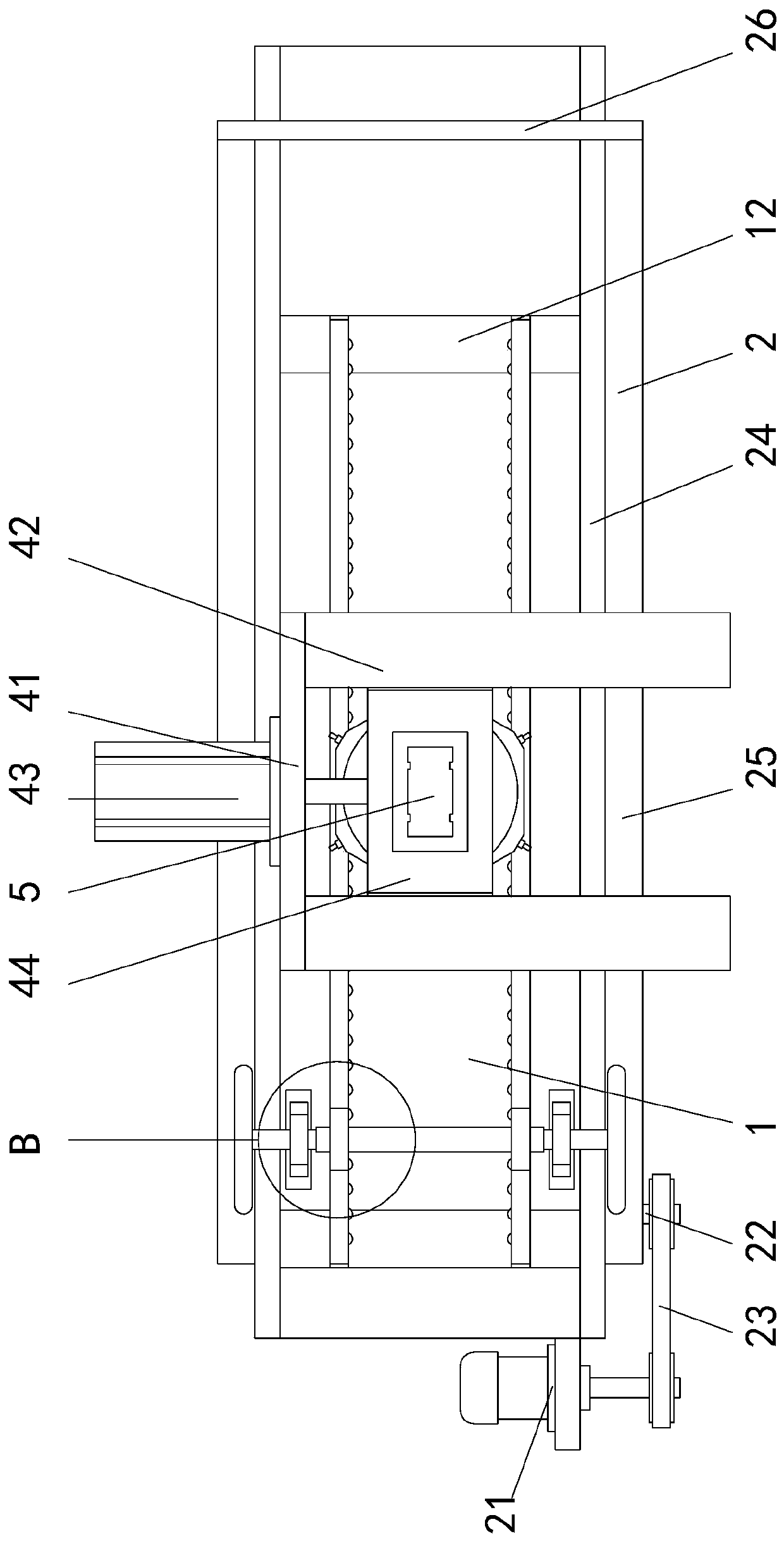

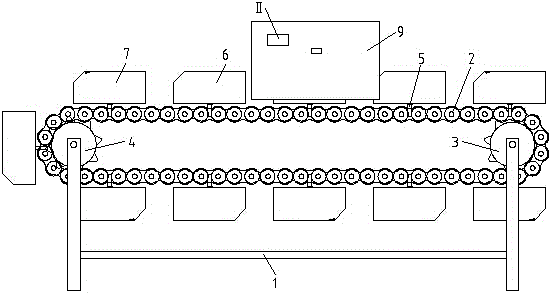

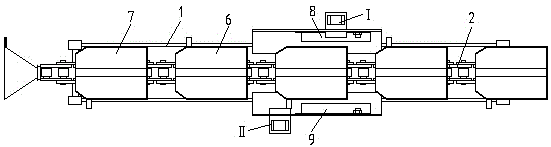

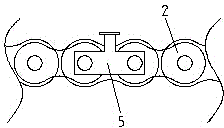

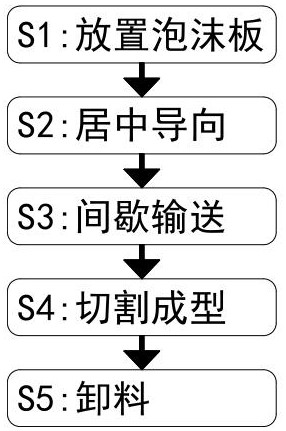

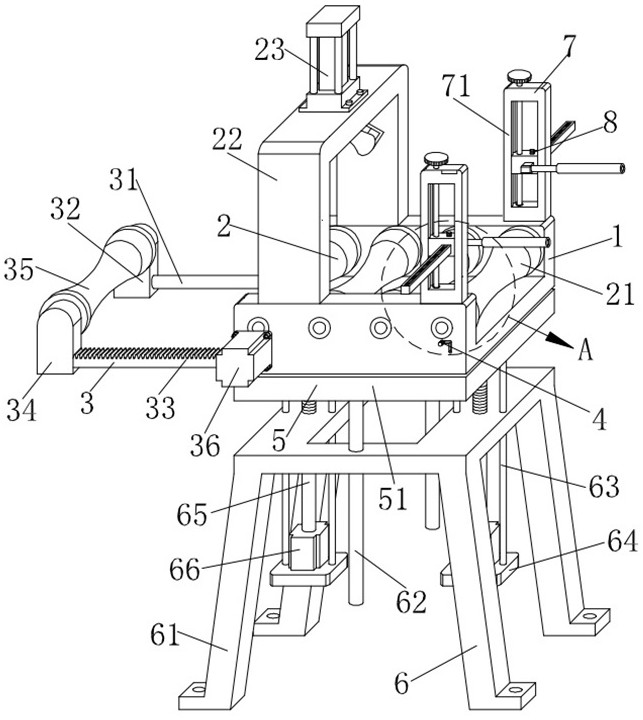

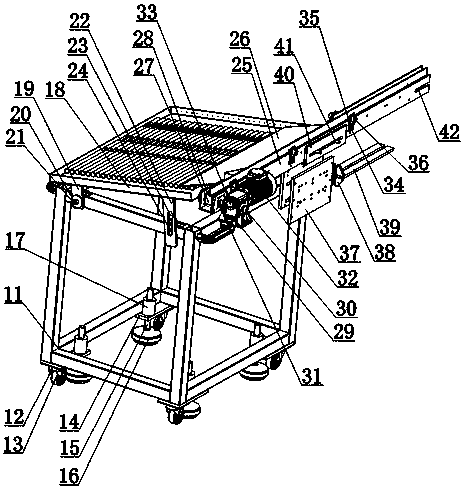

Foamed plastic packaging material manufacturing process

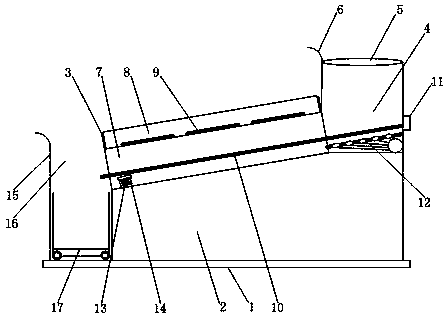

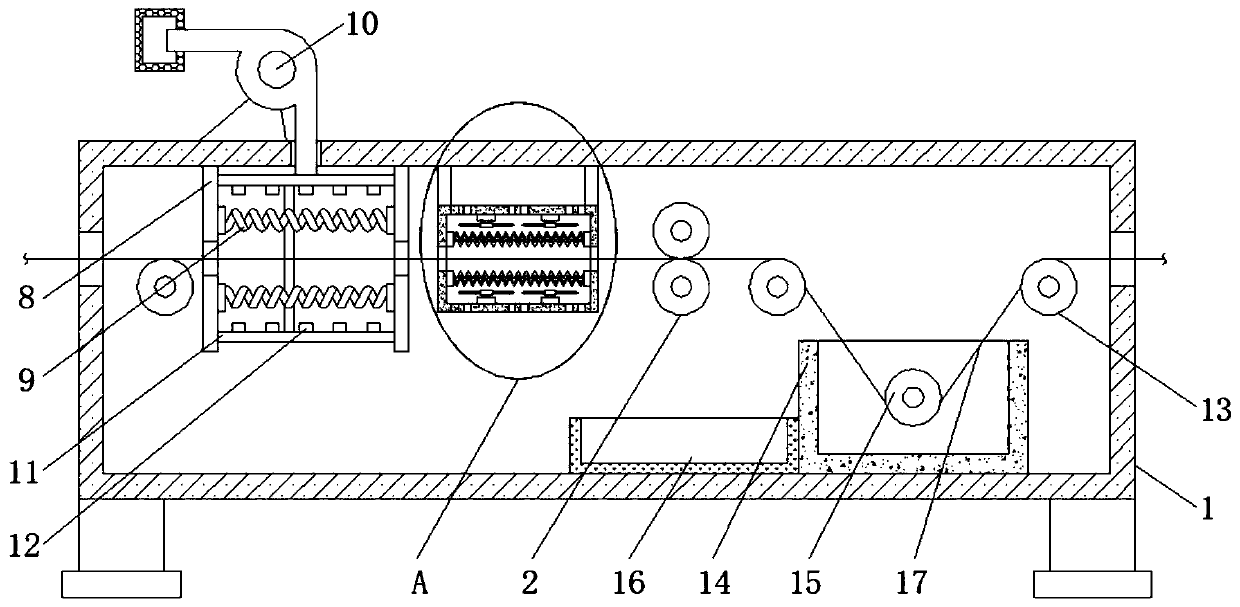

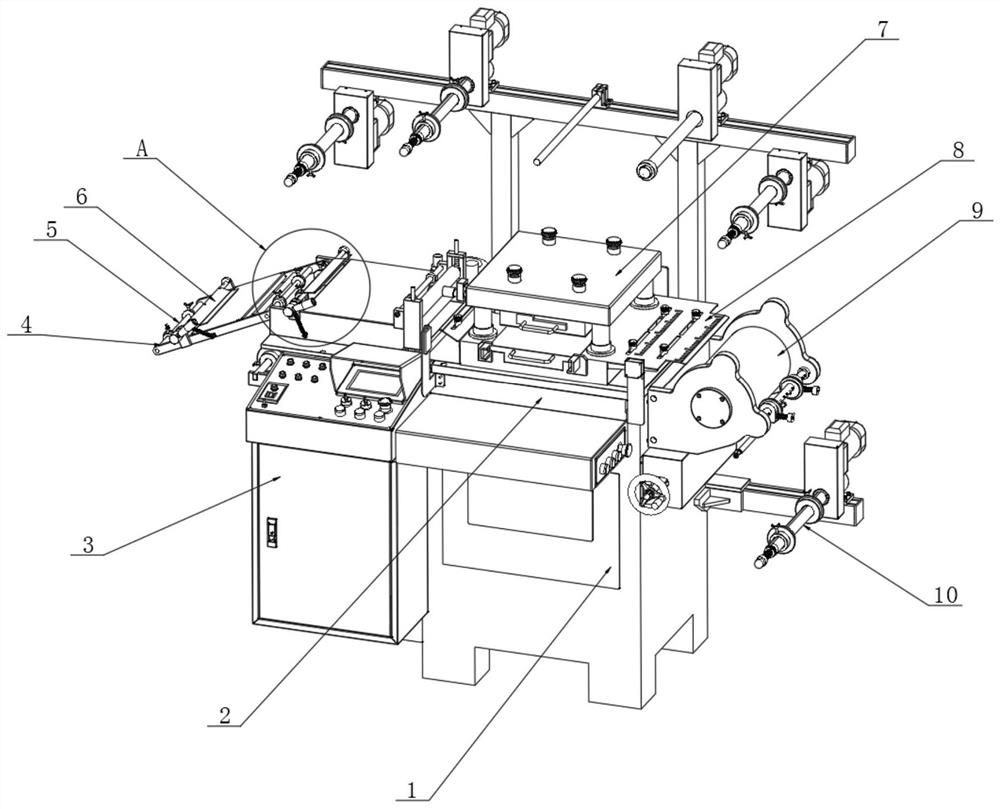

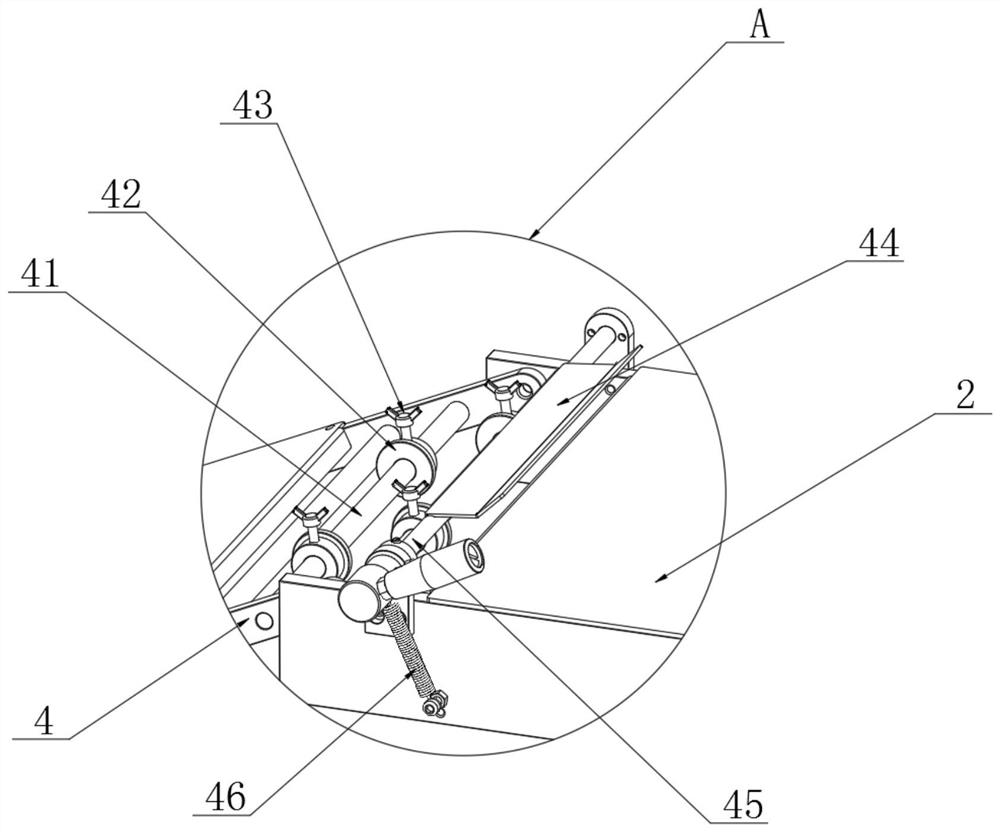

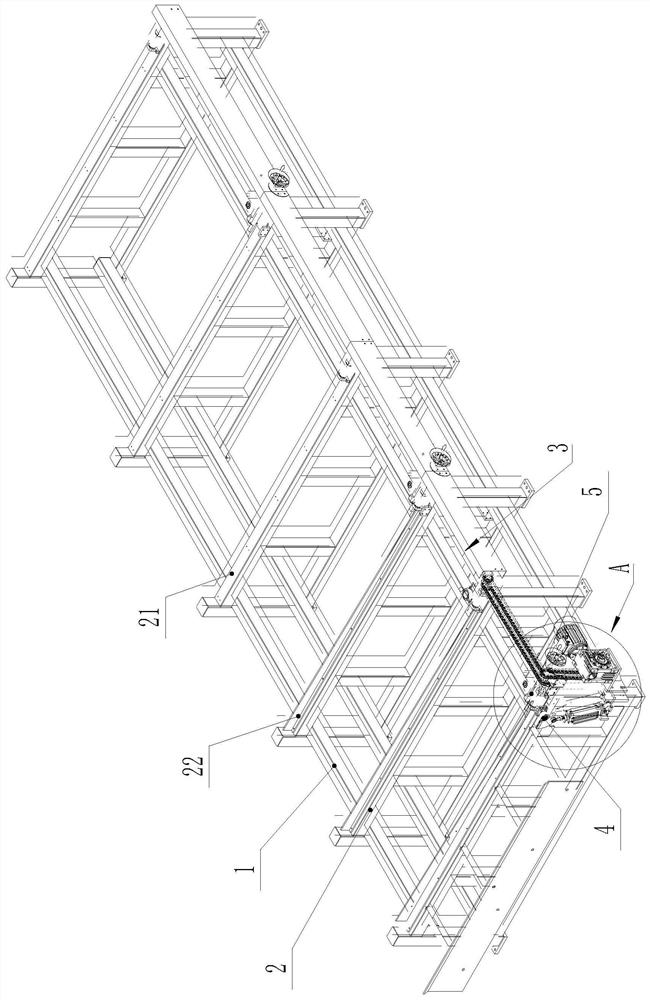

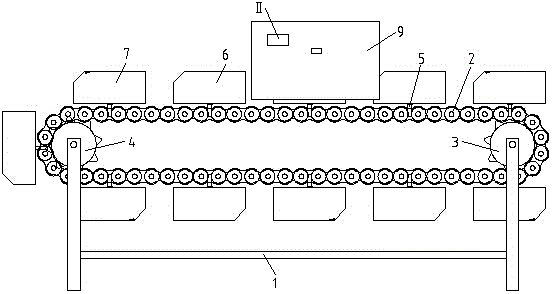

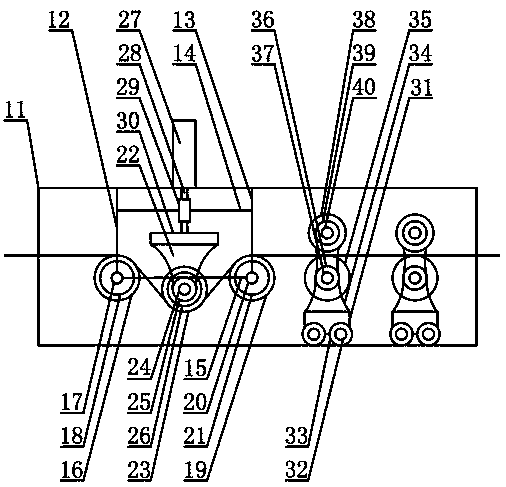

ActiveCN111438758ARealize continuous production and processingHigh degree of automationMetal working apparatusPlastic packagingMachining

The invention relates to a foamed plastic packaging material manufacturing process, in particular to a foamed plastic packaging material manufacturing device. The device comprises a worktable, an intermittent conveying mechanism used for conveying a foamed plastic plate, a centering guide mechanism used for centering guide of the foamed plastic plate, a forward extending moving mechanism and a cutting forming mechanism used for cutting forming. The device involved in the process is high in automation degree, risks during operation can be reduced, material waste can be avoided to a certain degree, automatic concentrated discharging can be finished, and the process and the device are also suitable for forming machining of hexagonal foam cushion plates of different sizes within a certain range.

Owner:福建省德化县日顺陶瓷有限公司

Polycrystalline silicon wafer solidification device

ActiveCN110314804AConvenience guide conveyingConvenient spray film processingPretreated surfacesCoatingsPolyvinyl chlorideSpray nozzle

The invention discloses a polycrystalline silicon wafer solidification device. The polycrystalline silicon wafer solidification device comprises a solidification rack, wherein a belt conveyor is arranged at the lower part of the solidification rack; a feeding platform is arranged at one side of the solidification rack; a discharging platform is arranged at the other side of the solidification rack; the feeding platform is connected to one side of the belt conveyor; the discharging platform is connected to the other side of the belt conveyor; a suspended ceiling pipe is arranged on the inner top of the solidification rack; a pasty polyvinyl chloride resin liquid spraying bin is arranged at the lower end of the suspended ceiling pipe; a plurality of pasty polyvinyl chloride resin liquid spraying nozzles are arranged on the bottom surface of the pasty polyvinyl chloride resin liquid spraying bin and are located above the belt conveyor; a spraying machine is arranged on the top of the solidification rack; a spraying inner pipe is arranged inside the suspended ceiling pipe; the upper end of the spraying inner pipe is connected to the spraying machine; and the lower end of the spraying inner pipe communicates with the pasty polyvinyl chloride resin liquid spraying bin. The polycrystalline silicon wafer solidification device greatly improves the efficiency of solidification treatmentand enables pasty polyvinyl chloride resin liquid to quickly form a film on the surface of a polycrystalline silicon wafer.

Owner:台州锐祥机械设备有限公司

Textile printing and dyeing equipment

InactiveCN110791898AQuality assuranceImprove drying effectLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTextile printerElectric machinery

The invention relates to the technical field of textile processing, in particular to textile printing and dyeing equipment, which comprises a box body; the upper end of the back of an inner cavity ofthe box body is rotatably connected with a heating roller, the left end of the top of the inner cavity of the box body is fixedly fitted with connecting rods, the bottoms of the connecting rods are fixedly fitted with a drying box, two ends of the top and bottom of the inner cavity of the drying box body are fixedly and respectively provided with stepping motors, the output ends of the stepping motors are fixedly provided with fans, and the upper end and lower end of the inner cavity of the drying box are fixedly provided with heating wire sets. Heating rollers, the drying box, the heating wire sets, the stepping motors, the fans, connecting plates, heating pipes, a blower, an air supply pipe and an air outlet are provided, so that the drying effect can be effectively improved, time and labor consumption and work efficiency reduction caused by reciprocating drying are avoided, uneven dyeing and drying are prevented, and the quality of a finished product is guaranteed.

Owner:江门市新会区德盈化工有限公司

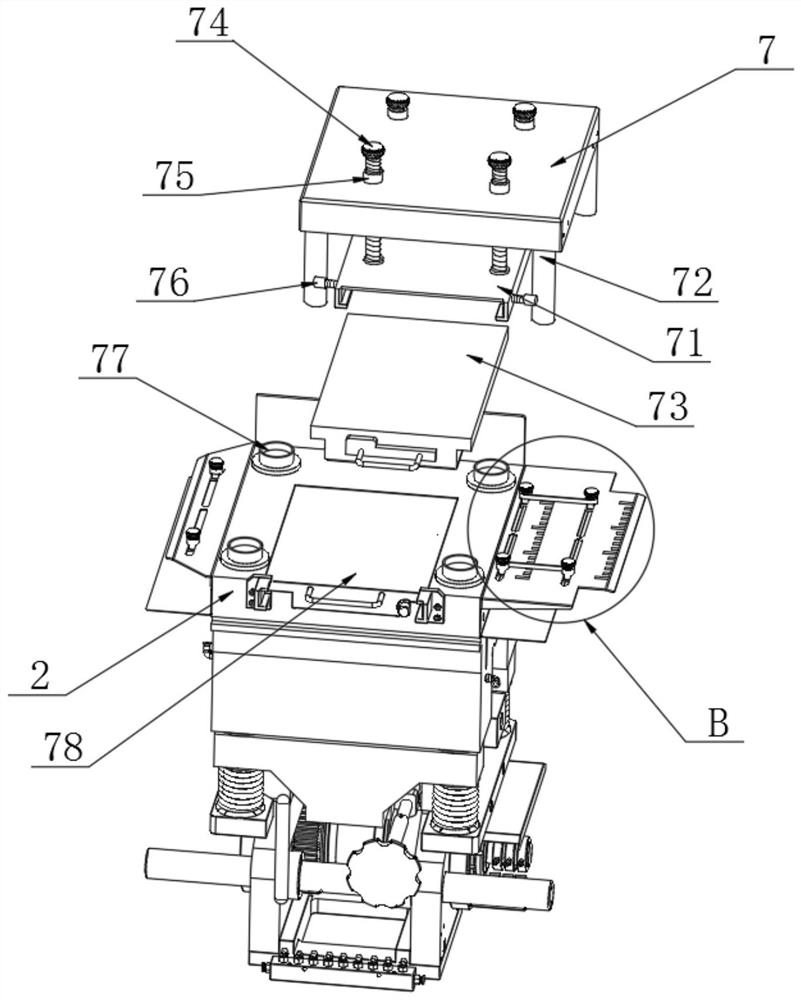

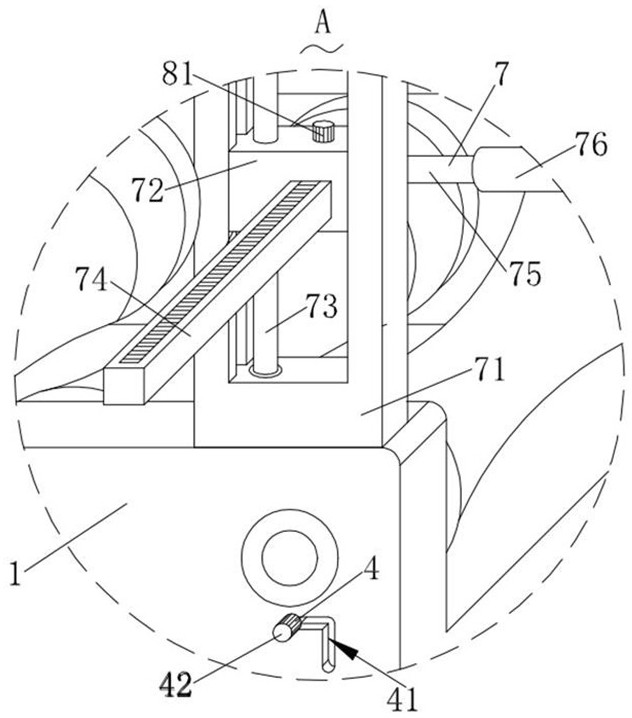

Novel die-cutting machine applied to thin film processing and with size easy to adjust

ActiveCN111805618ASpacing is easy to adjustFor quick maintenanceMetal working apparatusThin membraneEngineering

The invention relates to the technical field of thin film processing, and discloses a novel die-cutting machine applied to thin film processing and with the size easy to adjust. The machine comprisesa machine body. The upper end of the machine body is provided with a work table, and the other end of the work table is provided with a material-leading plate. The upper end of the middle part of thework table is provided with a pressing base. The position, corresponding to one end of the material-leading plate, of one side face of the machine body is provided with a material-leading roller. Oneend of the upper surface of a feeding plate is provided with a front feeding roller, and the upper surface of the feeding plate is provided with a front pressing plate which is located on one side ofthe front feeding roller. The lower surface of the pressing base is connected with an adjusting seat, and the lower end of the adjusting seat is connected with an upper knife holder. The position, corresponding to the upper knife holder, of the upper surface of the work table is provided with a lower knife holder. The novel die-cutting machine can conveniently adjust the spacing between the upperknife holder and the lower knife holder, so as to adapt to product processing of different thicknesses and die-cutting sizes, and knives are easy to install and remove; and meanwhile, a product is guided in the process of transporting to avoid the situation that deviation in the product transport process affects the efficiency of die-cutting or collection effect.

Owner:安吉圣杰钢塑制品有限公司

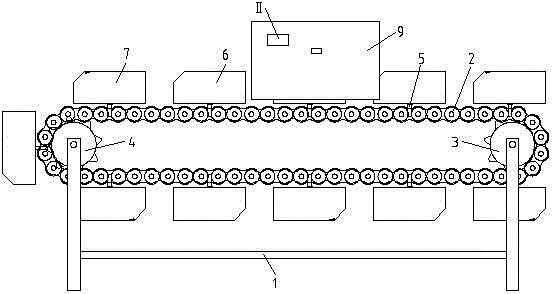

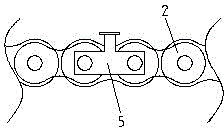

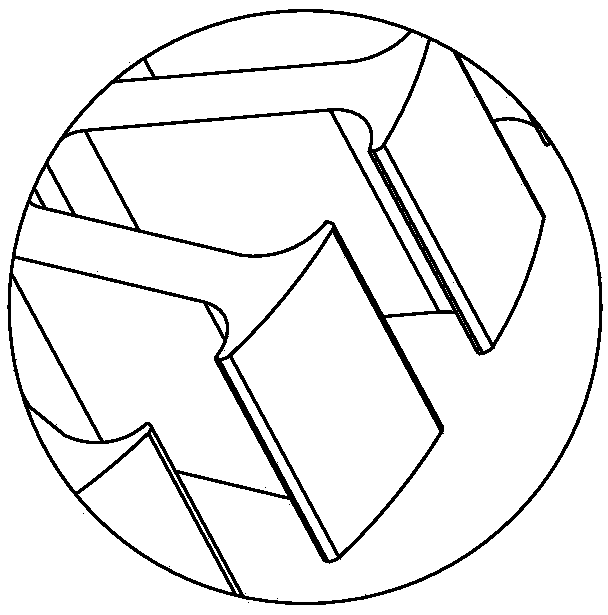

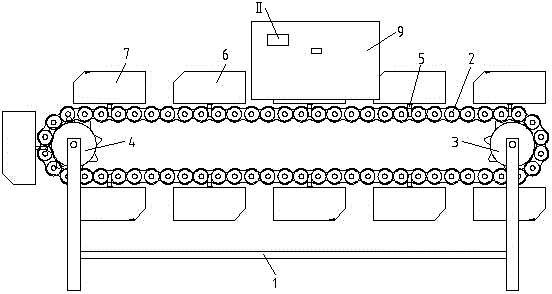

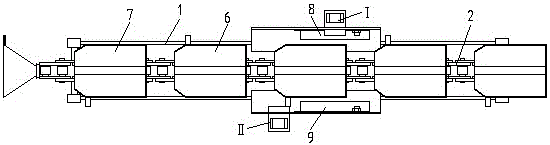

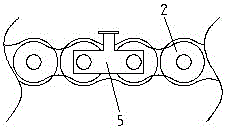

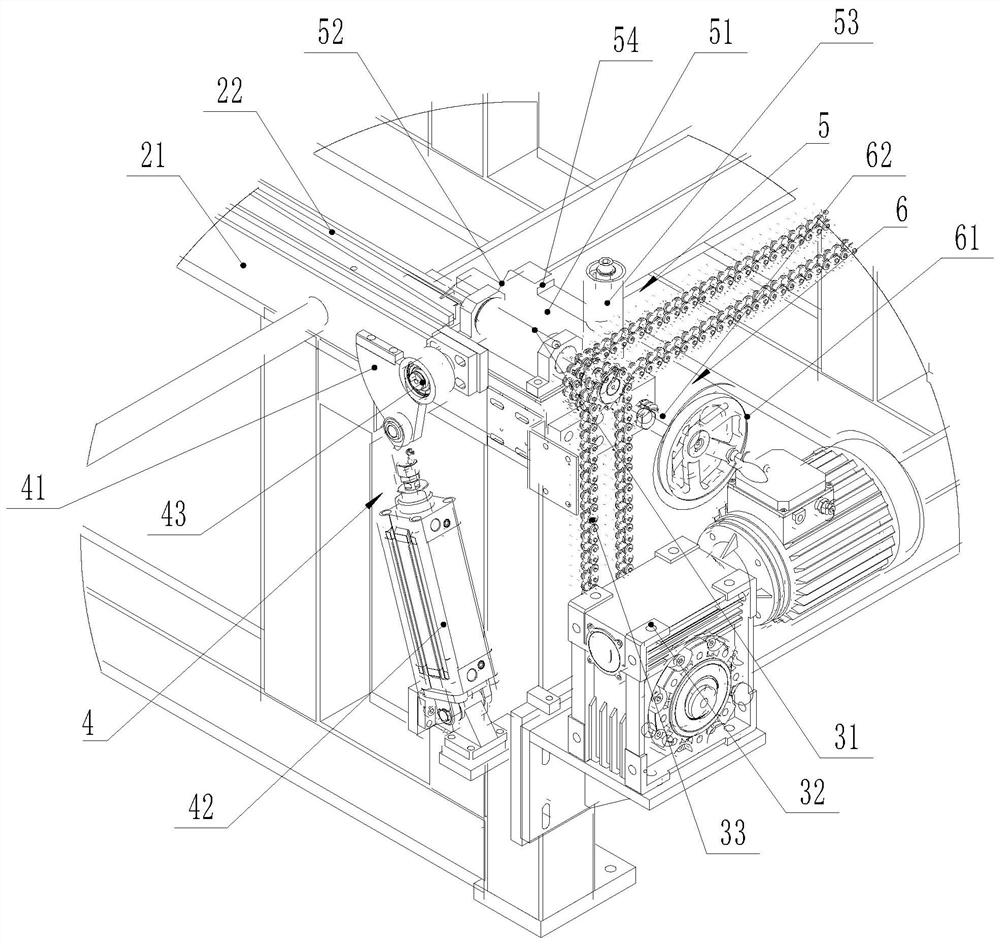

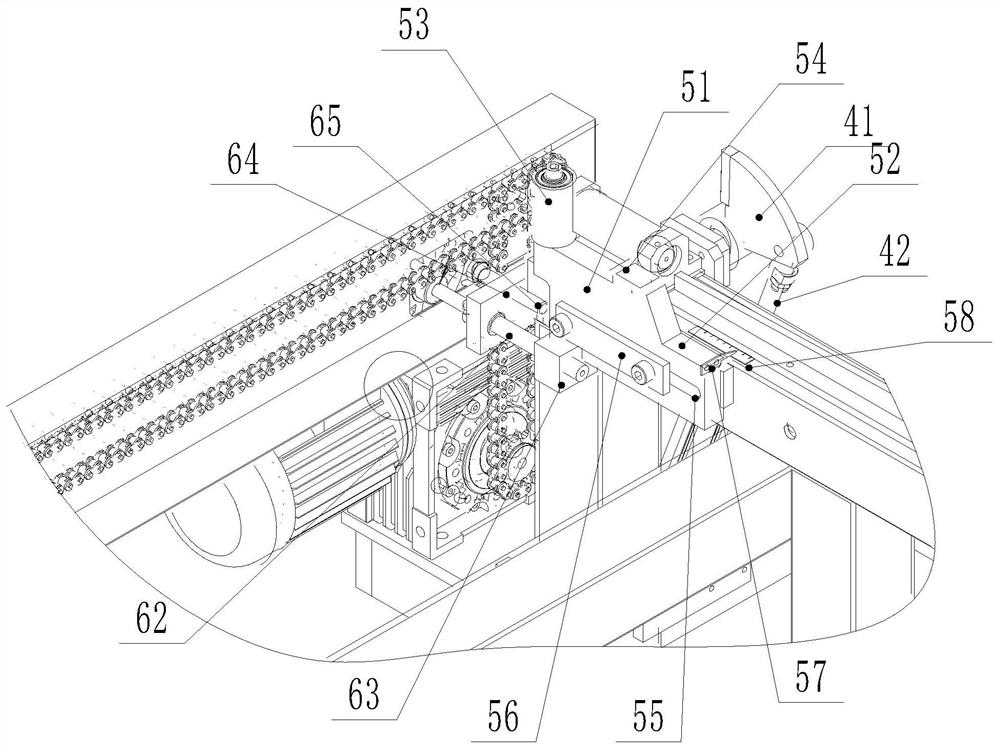

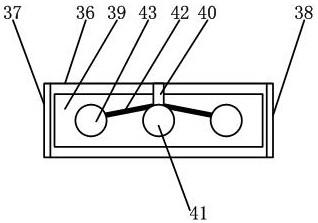

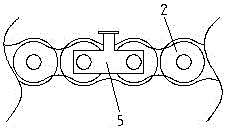

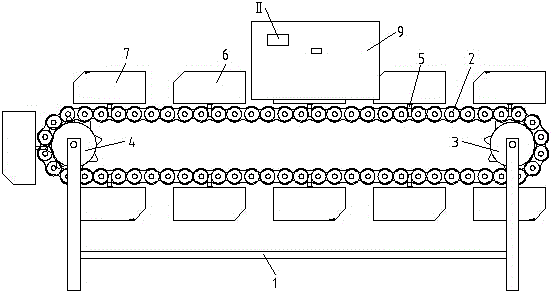

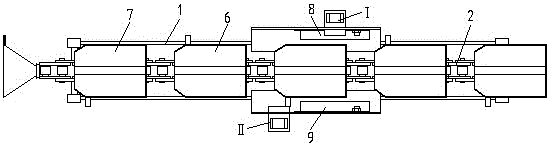

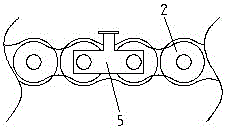

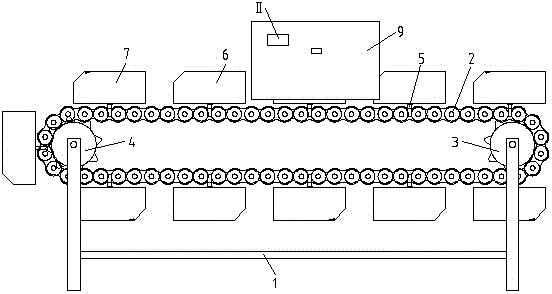

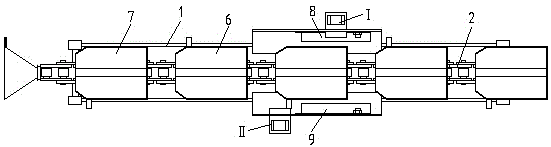

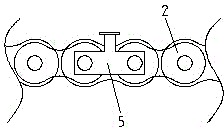

Special quantitative conveying device for chrysanthemum tea bag packaging machine

The invention relates to a special quantitative conveying device for a chrysanthemum tea bag packaging machine. The design of an existing quantitative conveying device for a tea bag packaging machine is not reasonable. The special quantitative conveying device comprises a chain and a driving gear, and is characterized by further comprising a left blanking control switch, a right blanking control switch, a left discharging nozzle, a right discharging nozzle, a plurality of conveying hopper fixing pieces, a plurality of left feeding conveying hoppers and a plurality of right feeding conveying hoppers; each left feeding conveying hopper comprises a left feeding conveying hopper body, a left blanking control ejection piece and a left feeding conveying hopper connection piece; each left blanking control ejection piece is fixed at the top of a left feeding left side plate; one left feeding conveying hopper is fixed on one section of chain by one conveying hopper fixing piece; the left feeding conveying hoppers and the right feeding conveying hoppers are alternatively arrayed; the left and right blanking control switches are located on the two sides of the chain respectively; the left blanking control ejection pieces are matched with the left blanking control ejection pieces; the left discharging nozzle and the right discharging nozzle are matched with the left feeding conveying hoppers and the right feeding conveying hoppers respectively. The special quantitative conveying device has a reasonable design.

Owner:TONGXIANG LVKANG CHRYSANTHEMUM IND

Cultivation soil rolling device for tree planting machine

InactiveCN107750481AEasy rolling and handlingConvenience guide conveyingSoil-working equipmentsAgricultural rollersAgricultural engineeringTree planting

The invention discloses a cultivation soil rolling device for a tree planting machine. The cultivation soil rolling device comprises a shell, two front sides of the shell are provided with slots respectively, the shell is internally provided with an open cavity, a rolling wheel is arranged on the front portion of the shell, two front sides of the shell are provided with clamping grooves respectively, a mounting shaft is axially arranged on the rolling wheel, and the ends of the mounting shaft are clamped in the clamping grooves. The rolling wheel sleeves the outer periphery of a hub which sleeves the outer periphery of the mounting shaft, and soil conveying plates are arranged on the lower portion of a frame which is arranged on the rear portion of the frame. By the rolling wheel, cultivation soil in land for tree planting can be rolled, and cultivation soil on planted trees can be rolled as well; by the soil conveying plates, guided conveying of clay on the rolling wheel can be realized conveniently; by an extension plate, guided conveying of the clay can be realized, and convenience and quickness in clay output are achieved.

Owner:SUZHOU ZHONGXINYUAN MICROELECTRONICS CO LTD

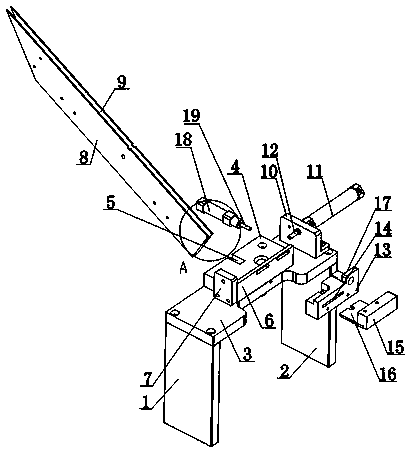

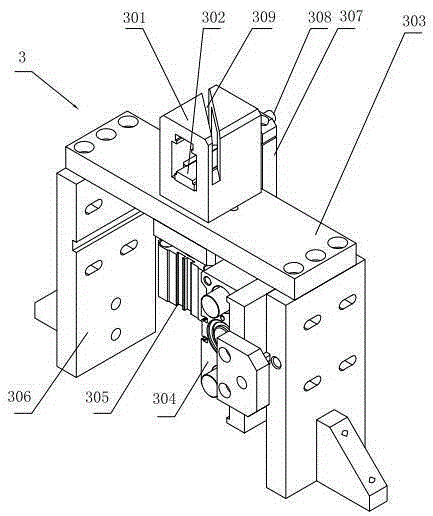

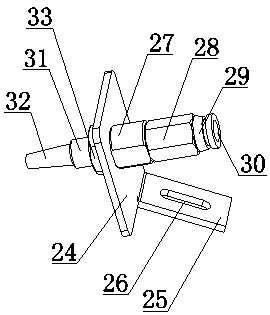

Material guide and recycling device for reinforced nylon

InactiveCN109132446AConvenience guide conveyingConvenient drop conveyingConveyor partsHydraulic cylinderMechanical engineering

The invention discloses a material guide and recycling device for reinforced nylon. The device comprises a first side plate and a second side plate, wherein the first side plate and the second side plate are vertically arranged, a top table is arranged between the top of the first side plate and the top of the second side plate, a clamping seat is arranged on the top table, a clamping groove is formed in the front portion of the clamping seat, a limiting plate is arranged at the rear portion of the clamping seat, a positioning plate is arranged on one side of the top table, a guide bin is arranged on the top table, the guide bin is arranged in an inclined mode, and the lower end of the guide bin is installed in the clamping groove; and a material conveying groove is formed in the guide bin, a fixing base is arranged on the other side of the top table, a first hydraulic cylinder is arranged at the back portion of the fixing seat, a first piston rod is arranged at the front portion of the first hydraulic cylinder, and the end portion of the first piston rod is arranged on the clamping seat. According to the device, the clamping seat can be used for conveniently and fixedly installingthe guide bin, and the guide bin can be used for conveniently guiding and conveying the reinforced nylon through the material conveying groove, so that the reinforced nylon can be conveniently descended and conveyed.

Owner:祁桂如

Special quantitative conveying device for chrysanthemum tea bag packaging machine

The invention relates to a special quantitative conveying device for a chrysanthemum tea bag packaging machine. The design of an existing quantitative conveying device for a tea bag packaging machine is not reasonable. The special quantitative conveying device comprises a chain and a driving gear, and is characterized by further comprising a left blanking control switch, a right blanking control switch, a left discharging nozzle, a right discharging nozzle, a plurality of conveying hopper fixing pieces, a plurality of left feeding conveying hoppers and a plurality of right feeding conveying hoppers; each left feeding conveying hopper comprises a left feeding conveying hopper body, a left blanking control ejection piece and a left feeding conveying hopper connection piece; each left blanking control ejection piece is fixed at the top of a left feeding left side plate; one left feeding conveying hopper is fixed on one section of chain by one conveying hopper fixing piece; the left feeding conveying hoppers and the right feeding conveying hoppers are alternatively arrayed; the left and right blanking control switches are located on the two sides of the chain respectively; the left blanking control ejection pieces are matched with the left blanking control ejection pieces; the left discharging nozzle and the right discharging nozzle are matched with the left feeding conveying hoppers and the right feeding conveying hoppers respectively. The special quantitative conveying device has a reasonable structure and a scientific layout.

Owner:TONGXIANG LVKANG CHRYSANTHEMUM IND

A kind of manufacturing process of foam plastic packaging material

ActiveCN111438758BRealize continuous production and processingHigh degree of automationMetal working apparatusPlastic packagingMolding machine

The present invention relates to a manufacturing process of foamed plastic packaging materials, and specifically relates to a manufacturing device of foamed plastic packaging materials, including a workbench, an intermittent conveying mechanism for conveying foamed plastic sheets, and a centering guide for centering and guiding foamed plastic sheets Mechanism, forward moving mechanism and cutting and forming mechanism for cutting and forming; the device involved in the process provided by the invention has a high degree of automation, can reduce the risk during operation, can avoid the waste of materials to a certain extent, and can complete automatic centralized unloading , It is also suitable for forming and processing hexagonal foam pads of different sizes within a certain range.

Owner:福建省德化县日顺陶瓷有限公司

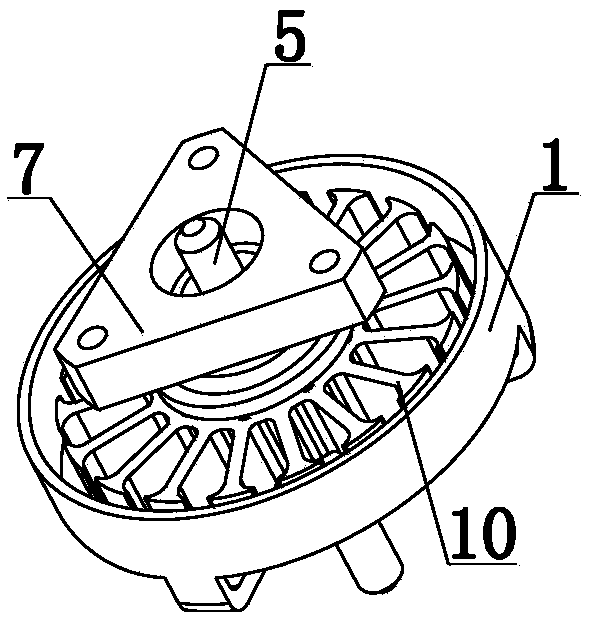

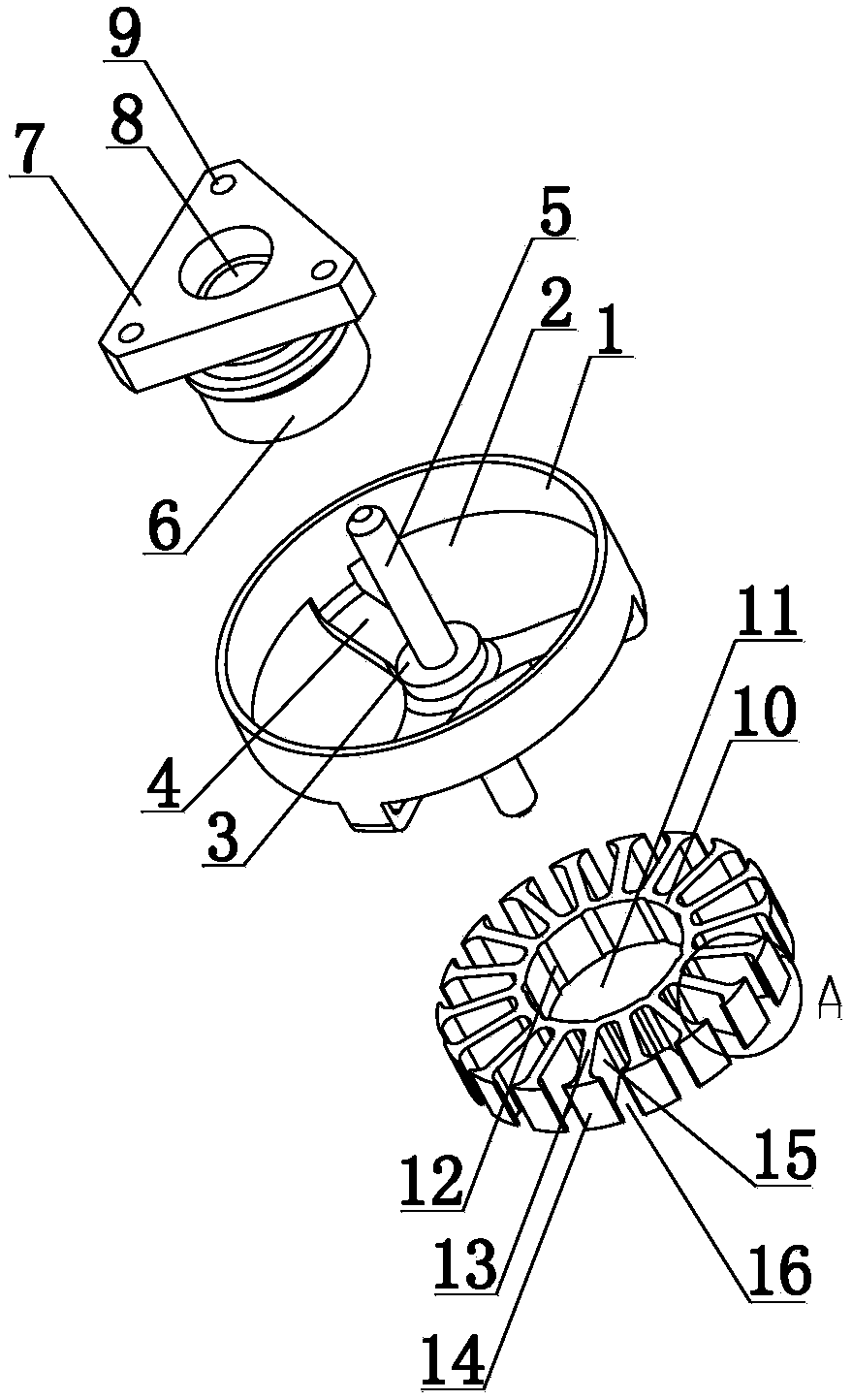

Air guide device for axial fan

InactiveCN108386390AConvenience guide conveyingEasy to controlPump componentsPumpsEngineeringMechanical engineering

The invention discloses an air guide device for an axial fan. The air guide device for the axial fan comprises a protecting shell, and the protecting shell is internally provided with a cavity. A guide pipe is arranged at the axial center position of the protecting shell, the guide pipe is parallel to the axial position of the protecting shell, and a plurality of connection strips are arranged between the outer circumferential face of the guide pipe and the inner circumferential face of the protecting shell. The guide pipe is internally provided with a rotating shaft in a sleeving manner, theouter circumferential face of the rotating shaft is sleeved with a casing pipe, the casing pipe is installed on the end portion of the guide pipe, and the outer circumferential face of the casing pipeis sleeved with an air guide base. A sleeving groove is formed in the axial center position of the air guide base, and the air guide base is arranged on the outer circumferential face of the casing pipe in a sleeving manner through the sleeving groove. The outer circumferential face of the air guide base is provided with a plurality of lugs. The outer end of each lug is provided with a protrudingpart, an air guide groove is formed between every two adjacent lugs, and an opening is formed between every two adjacent protruding parts. According to the air guide device for the axial fan, by means of rotation of the rotating shaft, blades can be controlled to achieve rotation, wind energy generated by the blades is guided and conveyed through the air guide grooves, and therefore guiding and conveying control over the wind energy can be conveniently carried out.

Owner:王鼎兴

Quantitative conveying device specially used for fetal chrysanthemum tea bag packaging machine

The invention relates to a special quantitative conveying device for a chrysanthemum bud tea bag packaging machine. The design of an existing quantitative conveying device for a tea bag packaging machine is not reasonable. The special quantitative conveying device comprises a chain and a driving gear, and is characterized by further comprising a left blanking control switch, a right blanking control switch, a left discharging nozzle, a right discharging nozzle, a plurality of conveying hopper fixing pieces, a plurality of left feeding conveying hoppers and a plurality of right feeding conveying hoppers; each left feeding conveying hopper comprises a left feeding conveying hopper body, a left blanking control ejection piece and a left feeding conveying hopper connection piece; each left blanking control ejection piece is fixed at the top of a left feeding left side plate; one left feeding conveying hopper is fixed on one section of chain by one conveying hopper fixing piece; the left feeding conveying hoppers and the right feeding conveying hoppers are alternatively arrayed; the left and right blanking control switches are located on the two sides of the chain respectively; the left blanking control ejection pieces are matched with the left blanking control ejection pieces; the left discharging nozzle and the right discharging nozzle are matched with the left feeding conveying hoppers and the right feeding conveying hoppers respectively. The special quantitative conveying device has a reasonable structure design and is convenient to use.

Owner:TONGXIANG LVKANG CHRYSANTHEMUM IND

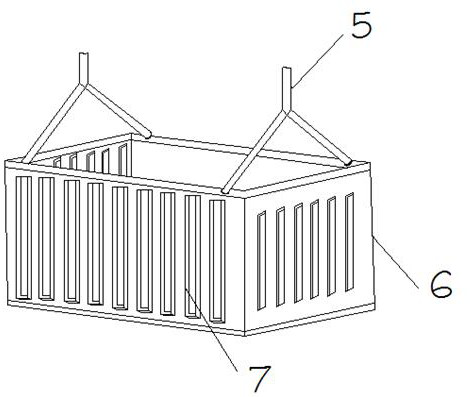

Folding and unfolding type bridge hanging basket construction device with wind shaking prevention structure

ActiveCN114875802AEasy constructionConvenience guide conveyingClimate change adaptationBridge erection/assemblyArchitectural engineeringHanging basket

The invention discloses a folding and unfolding type bridge hanging basket construction device with an anti-wind shaking structure, which comprises a bridge body and a bearing rod with a movable shaft mounted above the bridge body, and further comprises a hanging basket body connected to the lower parts of the two ends of a lifting rope through guide wheels, and a row of wind guide grooves are formed in the surface of the hanging basket body; the folding and unfolding type bridge hanging basket construction device with the wind shaking preventing structure is provided with a protection sleeve ring, an adjusting belt, a protection belt and a protection belt, and the protection sleeve ring and the adjusting belt are arranged in the hanging basket body; the position of a worker can be well protected and limited through clamping of the protective sleeve ring and the adjusting belt, and then the protective sleeve ring and the protective belts at the front end and the rear end of the adjusting belt are in sliding connection with limiting grooves formed in the front end and the rear end of the hanging basket body through two limiting blocks. And a worker can conveniently move in the hanging basket body.

Owner:SHANDONG LUQIAO GROUP

An environment-friendly sugarcane waste processing equipment

ActiveCN108906217BEasy to collectTimely collectionSolid waste disposalGrain treatmentsWaste processingProcess engineering

The invention discloses environmentally-friendly sugarcane waste residue processing equipment. The equipment comprises compression rollers, buffering convex corners, a material mixing chamber, an overturning screw conveyor, a drying chamber and a drying assembly, wherein the buffering convex corners are arranged on the outer sides of the compression rollers, the overturning screw conveyor is arranged in the material mixing chamber, and the drying assembly is arranged in the drying chamber. The equipment has the advantages of being scientific and reasonable in structure and safe and convenientto use, the compression rollers and the buffering convex corners are arranged, sugarcane liquid inside sugarcane waste residues can be subjected to compression rolling through the compression rollers,and the phenomenon that bonding is generated between the sugarcane waste residues and the compression rollers can be avoided through the buffering convex corners; the material mixing chamber and theoverturning screw conveyor are arranged, and the overturning screw conveyor in the material mixing chamber enables the sugarcane waste residues and additives to be more sufficiently stirred and mixed;and the drying chamber and the drying assembly are arranged, the drying chamber can dry the sugarcane waste residues through the drying assembly inside the drying chamber, and therefore the phenomenon that corrosion is caused to the later use due to the fact that water stains are included in the sugarcane waste residues can be avoided.

Owner:曹胜伟

A material guiding mechanism for producing rubber

The invention discloses a material guide mechanism for producing rubber, which comprises a shell, the lower end of the side of the shell is provided with a pillar, the lower surface of the pillar is provided with a bottom plate, the right end of the shell is provided with a feeding pipe, and The right side of the inner surface is provided with a partition, the side of the partition is provided with evenly distributed through holes, the left end of the partition is provided with a conveying device, the left end of the first rotating shaft of the conveying device is provided with a first driving device, and the upper end of the right side of the housing A barrel body is provided, and a lifting device is arranged inside the barrel body, a second driving device is arranged at the upper end of the second rotating shaft of the lifting device, and a discharge pipe is arranged at the upper end of the side of the barrel body. The material guiding mechanism for producing rubber can filter, guide and convey and heat the material, which can prevent pipeline blockage caused by material hardening, reduce material waste, and can filter and collect impurities in the material, which can effectively improve the efficiency of material delivery. Conveying speed, thereby improving work efficiency and saving time.

Owner:JINGDONG RUBBER

Conveying and screening device of water filter pipe for sewage treatment

ActiveCN108408336AFast deliverySimple samplingConveyorsConveyor partsWater filterMechanical engineering

The invention discloses a conveying and screening device of water filter pipe for sewage treatment. The device comprises a support, a lower pipe frame is arranged on the top surface of the support, and mounting arms are arranged on the two sides of the front portion of the lower pipe frame; the upper ends of the mounting arms are installed on the outer side walls of the front part of the lower pipe frame, and the two sides of the upper end of the mounting arms are correspondingly provided with adjusting arms; adjusting grooves are formed in the side parts of the adjusting arms, the adjusting grooves are inserted with lock rods, and the lock rods are locked on the top of the support; a conveying bin is arranged at the top of the support, the conveying bin is arranged at the outer side of the support, and a discharging plate is arranged at the top of the conveying bin; and the discharging plate is arranged on the top surface of the lower pipe frame, the two ends of the conveying bin arecorrespondingly provided with rotating wheels, and a conveying belt winds around the portion between the rotating wheels. According to the device, the water filter pipe can be conveniently and rapidlyconveyed through the conveying belt; an operator can also control a stepping motor to stop, so that the water filter pipe in a conveying process can be conveniently sampled.

Owner:山东铭浩环保科技有限公司

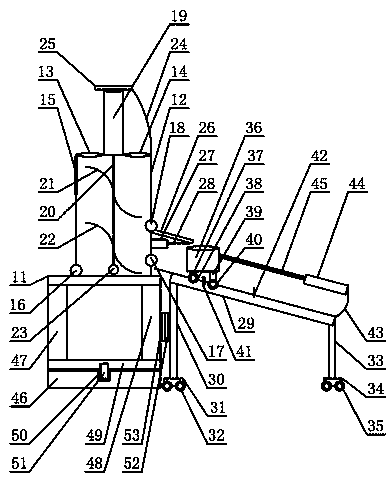

Material overturning and conveying device of short material sawing and drilling all-in-one machine

PendingCN112660765AIncrease contact areaAutomatic feedingMetal working apparatusConveyor partsMachineIndustrial engineering

The invention discloses a material overturning and conveying device of a short material sawing and drilling all-in-one machine. The machine comprises a rack, a plurality of support cross beams for placing bars are arranged on the rack, and inclined guide support surfaces for facilitating rolling of the bars are arranged at the upper ends of the support cross beams; the support cross beams are arranged on the lower side of the guide support faces to form transverse discharging sides, a longitudinal conveying device is arranged on a transverse discharging side of the rack, limiting blocking mechanisms are transversely installed on at least two support cross beams in a sliding mode, transverse adjusting mechanisms for adjusting the transverse positions of the limiting blocking mechanisms are arranged on the rack, each limiting and blocking mechanism is provided with an inner blocking structure used for blocking the bars on the support cross beams and an outer positioning structure used for positioning the bars to fall onto the longitudinal conveying device, and the support cross beams are further provided with a material overturning mechanism used for overturning and conveying the bars on the guide support faces to the longitudinal conveying device one by one. The material overturning and conveying device can be suitable for automatic feeding of bars with different diameters, and the automatic feeding requirement of the sawing and drilling all-in-one machine is met.

Owner:SUZHOU KINKALTECK MACHINERY TECH

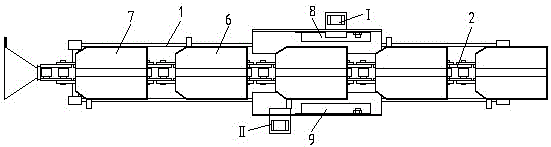

Solidification device

ActiveCN112427208AConvenience guide conveyingConvenient spray film processingPretreated surfacesCoatingsPolyvinyl chlorideSpray nozzle

The invention discloses a solidification device. The solidification device comprises a solidification rack, wherein a belt conveyor is arranged on the lower part of the solidification rack, a feedingtable is arranged on one side of the solidification rack, and a discharging table is arranged on the other side of the solidification rack; the feeding table is connected with one side of the belt conveyor, and the discharging table is connected with the other side of the belt conveyor; a suspended ceiling pipe is arranged at the inner top of the solidification rack, and a pasty polyvinyl chlorideresin liquid spraying bin is arranged at the lower end of the suspended ceiling pipe; a plurality of pasty polyvinyl chloride resin liquid spraying nozzles are arranged on the bottom surface of the pasty polyvinyl chloride resin liquid spraying bin and are arranged above the belt conveyor; a spraying machine is arranged at the top of the solidification rack; and a spraying inner pipe is arrangedin the suspended ceiling pipe, the upper end of the spraying inner pipe is connected with the spraying machine, and the lower end of the spraying inner pipe communicates with the pasty polyvinyl chloride resin liquid spraying bin. According to the solidification device, the solidification treatment efficiency is greatly improved, and thus pasty polyvinyl chloride resin liquid forms a film on the surface of a polycrystalline silicon chip quickly.

Owner:江苏长实基业电气科技有限公司

Quantitative conveying device specially used for chrysanthemum teabag packaging machine

The invention relates to a special quantitative conveying device for a chrysanthemum tea bag packaging machine. The design of an existing quantitative conveying device for a tea bag packaging machine is not reasonable. The special quantitative conveying device comprises a chain and a driving gear, and is characterized by further comprising a left blanking control switch, a right blanking control switch, a left discharging nozzle, a right discharging nozzle, a plurality of conveying hopper fixing pieces, a plurality of left feeding conveying hoppers and a plurality of right feeding conveying hoppers; each left feeding conveying hopper comprises a left feeding conveying hopper body, a left blanking control ejection piece and a left feeding conveying hopper connection piece; each left blanking control ejection piece is fixed at the top of a left feeding left side plate; one left feeding conveying hopper is fixed on one section of chain by one conveying hopper fixing piece; the left feeding conveying hoppers and the right feeding conveying hoppers are alternatively arrayed; the left and right blanking control switches are located on the two sides of the chain respectively; the left blanking control ejection pieces are matched with the left blanking control ejection pieces; the left discharging nozzle and the right discharging nozzle are matched with the left feeding conveying hoppers and the right feeding conveying hoppers respectively. The special quantitative conveying device has a reasonable structure and a scientific layout.

Owner:TONGXIANG LVKANG CHRYSANTHEMUM IND

Quantitative conveying device specially used for chrysanthemum teabag packaging machine

The invention relates to a special quantitative conveying device for a chrysanthemum tea bag packaging machine. The design of an existing quantitative conveying device for a tea bag packaging machine is not reasonable. The special quantitative conveying device comprises a chain and a driving gear, and is characterized by further comprising a left blanking control switch, a right blanking control switch, a left discharging nozzle, a right discharging nozzle, a plurality of conveying hopper fixing pieces, a plurality of left feeding conveying hoppers and a plurality of right feeding conveying hoppers; each left feeding conveying hopper comprises a left feeding conveying hopper body, a left blanking control ejection piece and a left feeding conveying hopper connection piece; each left blanking control ejection piece is fixed at the top of a left feeding left side plate; one left feeding conveying hopper is fixed on one section of chain by one conveying hopper fixing piece; the left feeding conveying hoppers and the right feeding conveying hoppers are alternatively arrayed; the left and right blanking control switches are located on the two sides of the chain respectively; the left blanking control ejection pieces are matched with the left blanking control ejection pieces; the left discharging nozzle and the right discharging nozzle are matched with the left feeding conveying hoppers and the right feeding conveying hoppers respectively. The special quantitative conveying device has a reasonable design.

Owner:TONGXIANG LVKANG CHRYSANTHEMUM IND

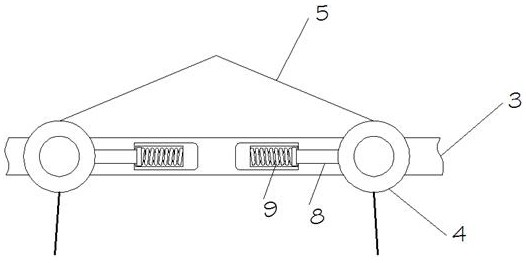

Adjustment device for coated paper conveying

The invention discloses an adjusting device for coated paper conveying and is a divisional application for the application with the Chinese application date being July 28, 2017, the application numberbeing 2017106280226, and the name being a tensioning adjusting device for coated paper conveying. The adjusting device comprises a machine frame; a ceiling frame is arranged at the inner top of the machine frame; a butt-joint frame is arranged between the upper portions of the ceiling frame; transmission rollers are arranged between the ceiling frame and the butt-joint frame; the transmission rollers are mounted between the ceiling frame and the butt-joint frame through mounting shafts; the lower portion of the machine frame is provided with a lifting frame; the lower portion of the lifting frame is provided with a tensioning roller; the axial position of the tensioning roller is provided with a third mounting shaft; the tensioning roller is arranged between the transmission rollers; theinner top of the machine frame is provided with a hydraulic cylinder; a piston rod is arranged on the lower portion of the hydraulic cylinder; a lifting base is arranged at the lower end of the pistonrod; and the lifting base is mounted on the upper portion of the lifting frame. Coated paper can be subjected to tensioning slight adjustment conveniently.

Owner:SUZHOU ZHONGXINYUAN MICROELECTRONICS CO LTD

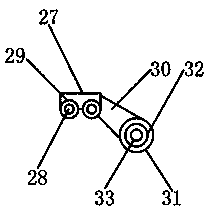

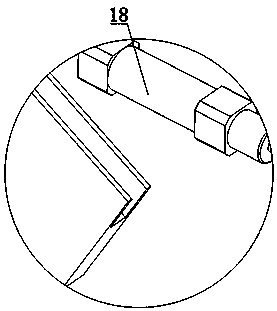

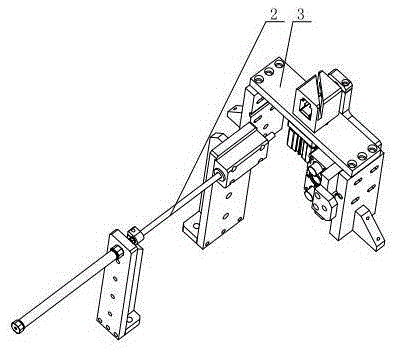

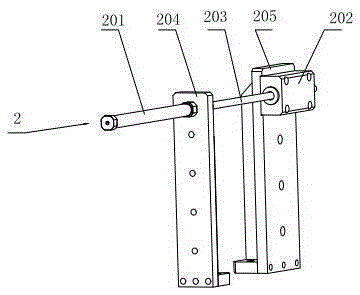

Guide conveying mechanism for lock tongue

A guiding and conveying mechanism for bolts comprises a bolt clamping mechanism. A guide mechanism is mounted at one end of the bolt clamping mechanism and structurally comprises support frames arranged at an interval, a bottom plate is fixed at the top of the support frame, a bolt clamping block which is of a rectangular structure is fixed on the bottom plate, a through hole penetrating the bolts is formed in the position of the middle of the bolt clamping block, a moving block is mounted on the lower portion of the through hole, and a helical cutter groove is formed in the upper end of the bolt clamping block; a lifting cylinder is mounted at the position located at the bottom of the bottom plate, and the output end of the lifting cylinder is fixedly connected with the moving block; a discharging cylinder is fixed on the inner side wall of the support frame with the output end connected with a fixing plate, a first guide rod is mounted on the fixing plate, and the head of the first guide rod is in butt joint with the bolts. Under the cooperative function of the guide mechanism and the bolt clamping mechanism, the bolts can be conveniently guided and conveyed; the guiding and conveying mechanism can be conveniently applied to assembly line processing so as to improve working efficiency.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Guiding and positioning device for engineering plastic pipe production

The invention relates to the technical field of plastic pipe production guiding and positioning, in particular to a guiding and positioning device for engineering plastic pipe production. A guiding structure is installed on a base, a bearing structure is arranged at one side of the base, a fixing structure is arranged in the base, and a rotating structure is installed at the bottom end of the base; and a lifting structure is installed at the bottom end of the rotating structure, a positioning structure is installed at the top end of the base, and a limiting structure is arranged on the positioning structure. Through the arrangement of the guiding structure, an engineering plastic pipe to enter a cooling box can be accurately guided and positioned, so that the situation that because the engineering plastic pipe collides and extrudes with a feeding port of the cooling box when entering the cooling box, the quality of the pipe is affected is prevented.

Owner:徐州祥瑞工程机械科技有限公司

Special quantitative conveying device for chrysanthemum bud tea bag packaging machine

The invention relates to a special quantitative conveying device for a chrysanthemum bud tea bag packaging machine. The design of an existing quantitative conveying device for a tea bag packaging machine is not reasonable. The special quantitative conveying device comprises a chain and a driving gear, and is characterized by further comprising a left blanking control switch, a right blanking control switch, a left discharging nozzle, a right discharging nozzle, a plurality of conveying hopper fixing pieces, a plurality of left feeding conveying hoppers and a plurality of right feeding conveying hoppers; each left feeding conveying hopper comprises a left feeding conveying hopper body, a left blanking control ejection piece and a left feeding conveying hopper connection piece; each left blanking control ejection piece is fixed at the top of a left feeding left side plate; one left feeding conveying hopper is fixed on one section of chain by one conveying hopper fixing piece; the left feeding conveying hoppers and the right feeding conveying hoppers are alternatively arrayed; the left and right blanking control switches are located on the two sides of the chain respectively; the left blanking control ejection pieces are matched with the left blanking control ejection pieces; the left discharging nozzle and the right discharging nozzle are matched with the left feeding conveying hoppers and the right feeding conveying hoppers respectively. The special quantitative conveying device has a reasonable structure design and is convenient to use.

Owner:TONGXIANG LVKANG CHRYSANTHEMUM IND

A screw conveying stainless steel shot static removal device

ActiveCN107618900BConvenience guide conveyingEasy to transportLoading/unloadingConveyor partsEngineeringScrew conveyor

The invention discloses a screw conveying type electrostatic eliminating device for stainless steel shots. The screw conveying type electrostatic eliminating device for stainless steel shots comprisesa bottom plate; a base is arranged on the bottom plate; guide bases are arranged on one side of the base; one end of each guide base is provided with a feed head, and an open slot is formed between the tops of the guide bases; a first conveying groove is formed in the axial positions of the guide bases, the other ends of the guide bases are connected with a conveying track, a second conveying groove is formed in the conveying track and communicates with the first conveying groove, and the conveying track is spiral; and the upper end of the conveying track is connected with the first conveying groove. The electrostatic eliminating processing can be conducted on stainless steel shots conveniently through electrostatic eliminating nets at the bottoms in the conveying grooves; and the lowerportion of the rear end of the bottom plate can be vertically adjusted up and down through a piston rod, so that the inclination degree of the bottom plate is adjusted conveniently, and the stainlesssteel shots are conveyed conveniently.

Owner:TANGSHAN DONGHUA IRON & STEEL ENTERPRISE GRP CO LTD

Filter pipe conveying and screening device for sewage treatment

The invention discloses a conveying and screening device of water filter pipe for sewage treatment. The device comprises a support, a lower pipe frame is arranged on the top surface of the support, and mounting arms are arranged on the two sides of the front portion of the lower pipe frame; the upper ends of the mounting arms are installed on the outer side walls of the front part of the lower pipe frame, and the two sides of the upper end of the mounting arms are correspondingly provided with adjusting arms; adjusting grooves are formed in the side parts of the adjusting arms, the adjusting grooves are inserted with lock rods, and the lock rods are locked on the top of the support; a conveying bin is arranged at the top of the support, the conveying bin is arranged at the outer side of the support, and a discharging plate is arranged at the top of the conveying bin; and the discharging plate is arranged on the top surface of the lower pipe frame, the two ends of the conveying bin arecorrespondingly provided with rotating wheels, and a conveying belt winds around the portion between the rotating wheels. According to the device, the water filter pipe can be conveniently and rapidlyconveyed through the conveying belt; an operator can also control a stepping motor to stop, so that the water filter pipe in a conveying process can be conveniently sampled.

Owner:山东铭浩环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com