An environment-friendly sugarcane waste processing equipment

A technology of sugarcane waste and processing equipment, which is applied in the direction of lighting and heating equipment, heating devices, solid waste removal, etc., can solve problems such as decay, lack of drying components, and sugarcane waste that cannot be recycled, and achieves a scientific and reasonable structure , Safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

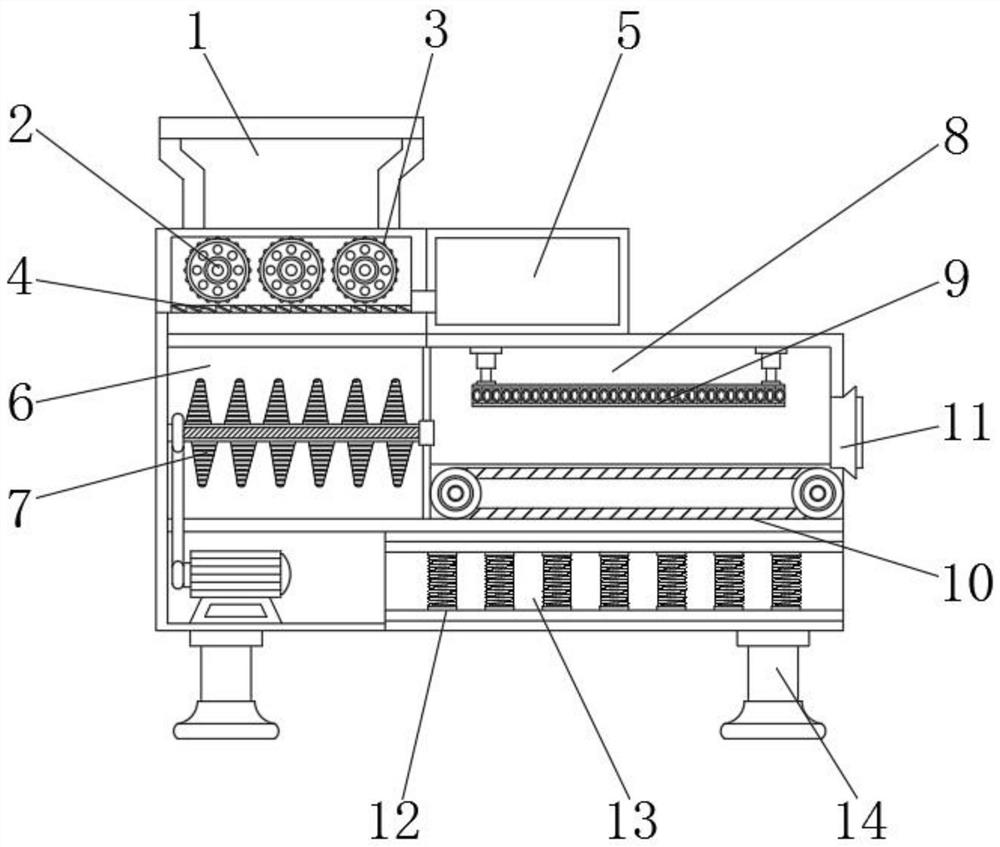

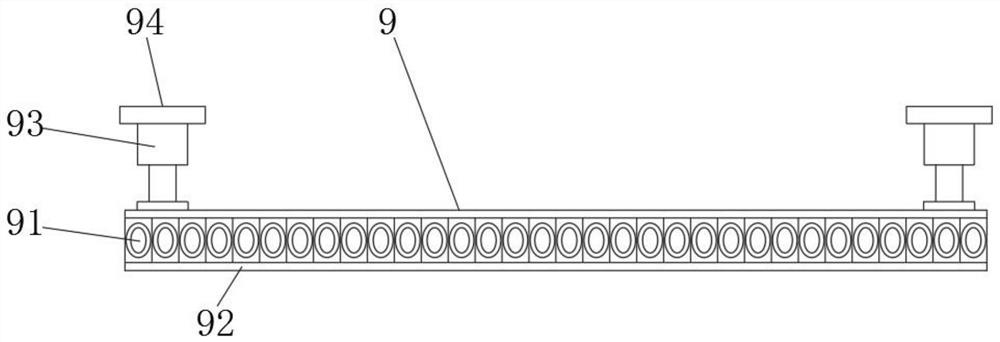

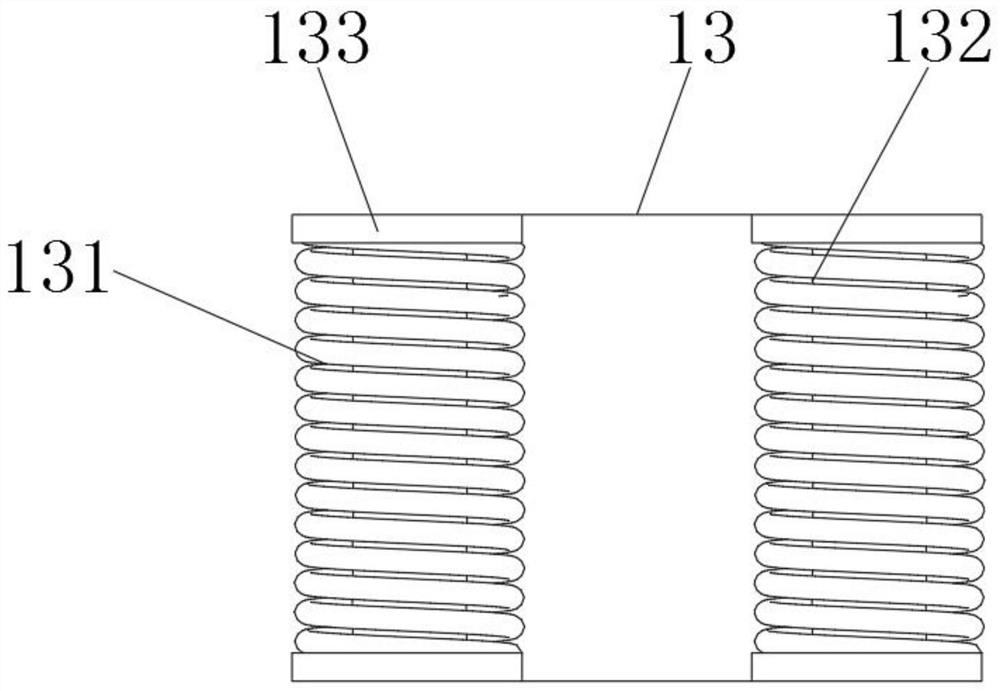

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, an environment-friendly sugarcane waste processing equipment, including a feed inlet 1, a rolling roller 2, a buffer lobe 3, a deflector 4, a sugarcane liquid collection box 5, a mixing material Chamber 6, turning auger 7, drying chamber 8, drying assembly 9, synchronous conveyor belt 10, discharge port 11, pressure plate 12, shock absorbing assembly 13 and support base 14, below the bottom of feed port 1 The rolling roller 2 is installed in rotation, and the outer surface of the rolling roller 2 is welded with a buffer lobe 3, and the bottom of the rolling roller 2 is fixedly installed with a deflector 4 by welding, and the end of the deflector 4 is sealed A cane liquid collection box 5 is connected, a mixing chamber 6 is provided under the bottom of the deflector 4, a turning auger 7 is installed rotating inside the mixing chamber 6, and a drying chamber 8 is provided on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com