Single bucket elevator with weighing function

A hoist and functional technology, applied in the field of single-bucket hoist, can solve the problems of inability to weigh the weight of materials in the bucket, increase labor intensity, and large operating errors, and achieve the effects of easy operation, reduced labor intensity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

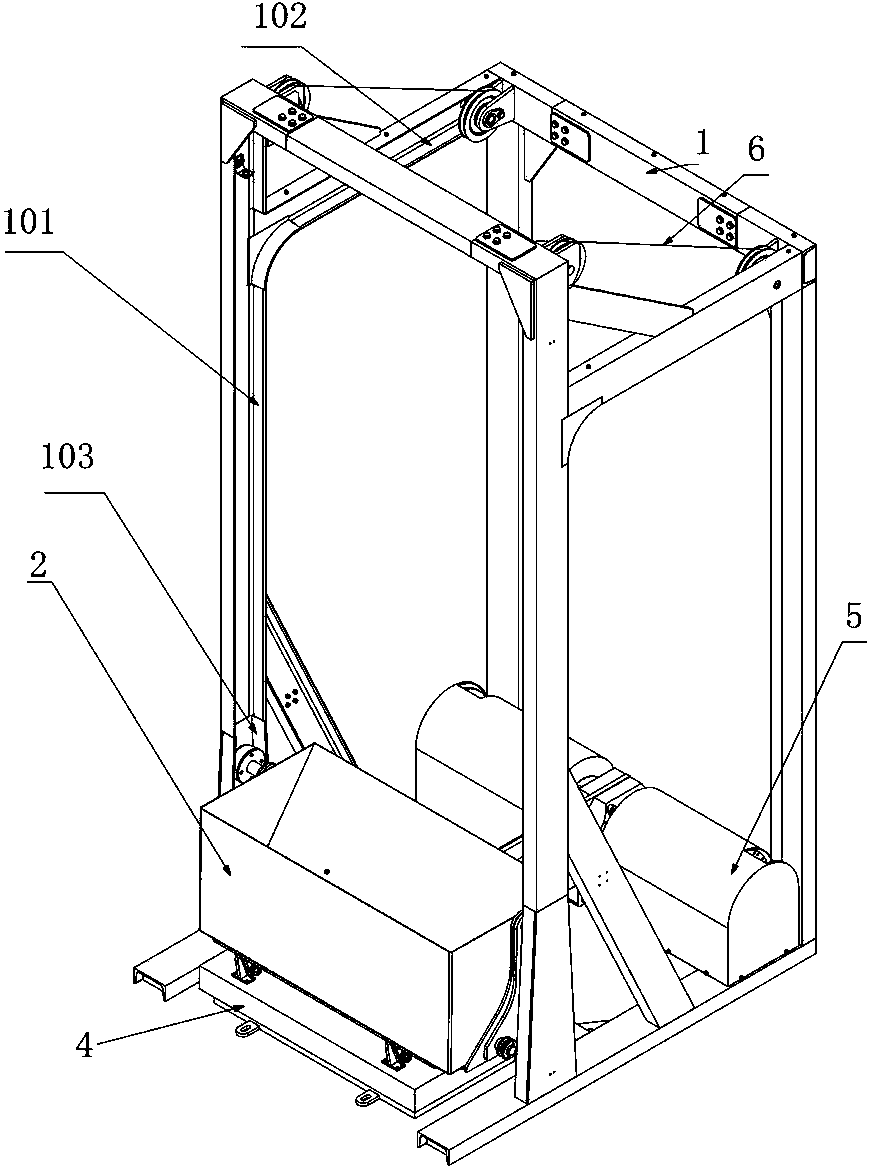

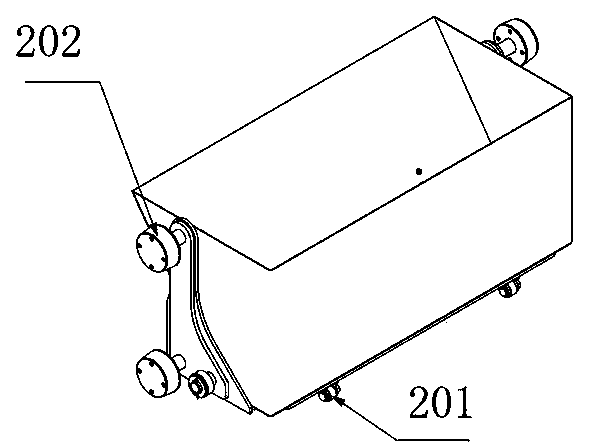

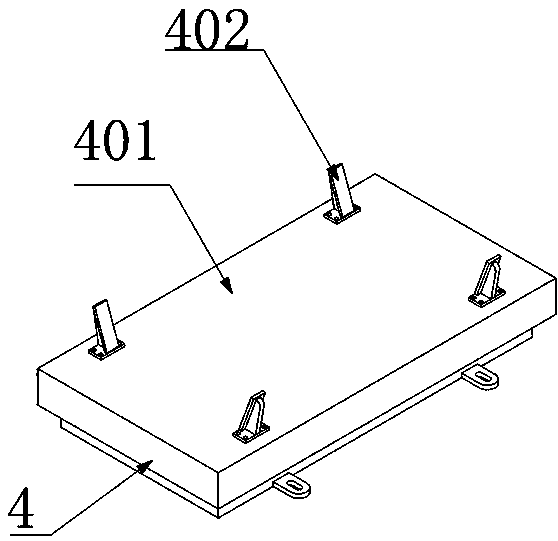

[0017] Such as figure 1 , figure 2 and image 3 As shown, the single-bucket hoist with weighing function of the present invention includes a frame 1, a hopper 2, a winch lifting assembly and an electronic weighing assembly 4, and the frame 1 is provided with a lifting track 101 and a dumping track 102, and the lifting track 101 It can be a track provided along the vertical direction, which is used to lift the hopper 2 to a certain height and drop to the initial position. The track can be a straight line or an arc, and a combination of one or more sections can also be used. The dumping track 102 can be a track opened along the horizontal direction, which is used to allow the hopper 2 to turn over and dump after being lifted to a corresponding height. The track can be a straight line or an arc, and a combination of one or more sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com