Connecting rod lifting and overturning device based on differential screw transmission and rocker slider transmission

A technology of differential screw transmission and rocker slider, which is applied in the direction of lifting devices, etc., can solve the problems of high manufacturing cost, poor stability, and slow lifting speed, and achieve the effect of compact structure, good stability, and limited space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

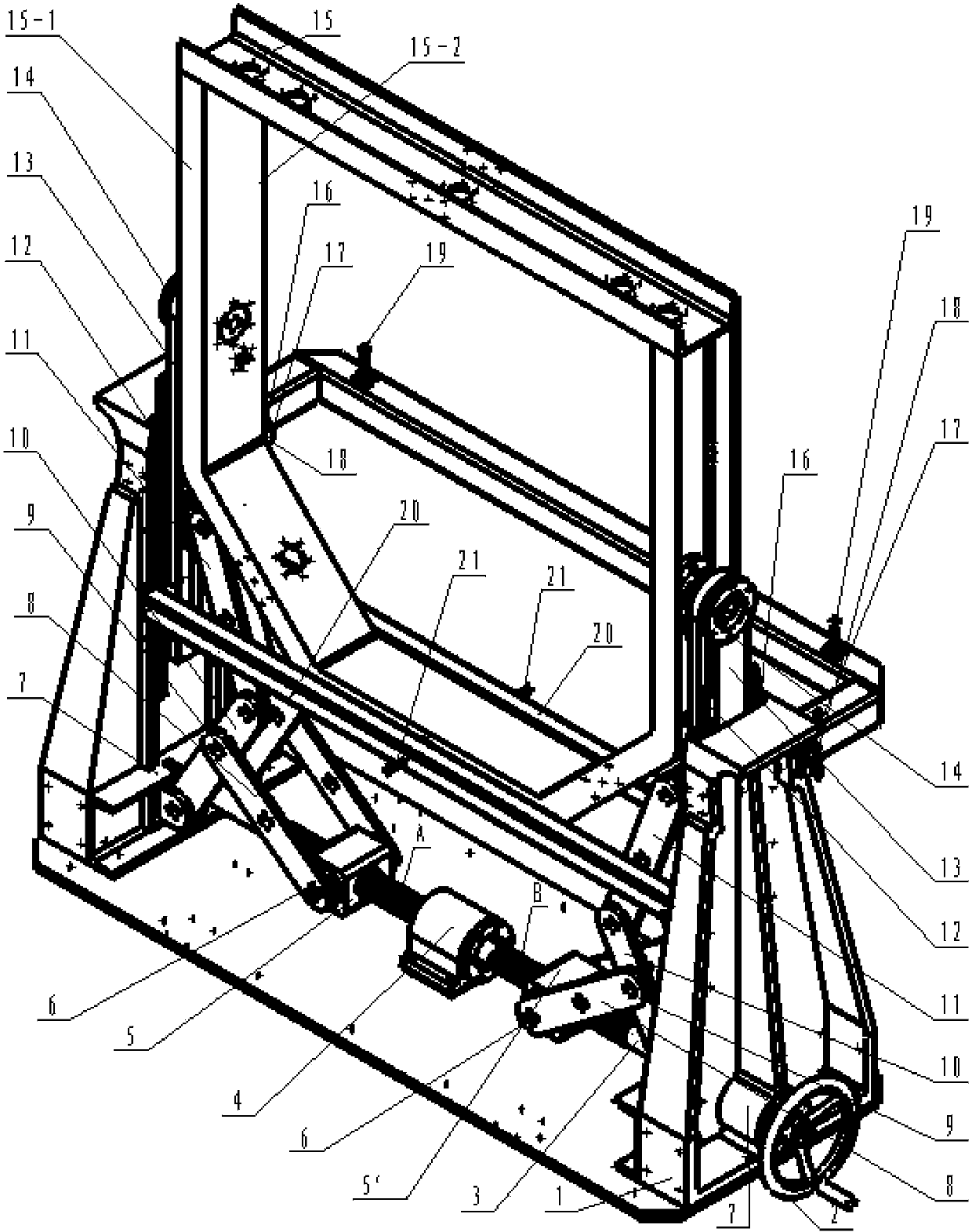

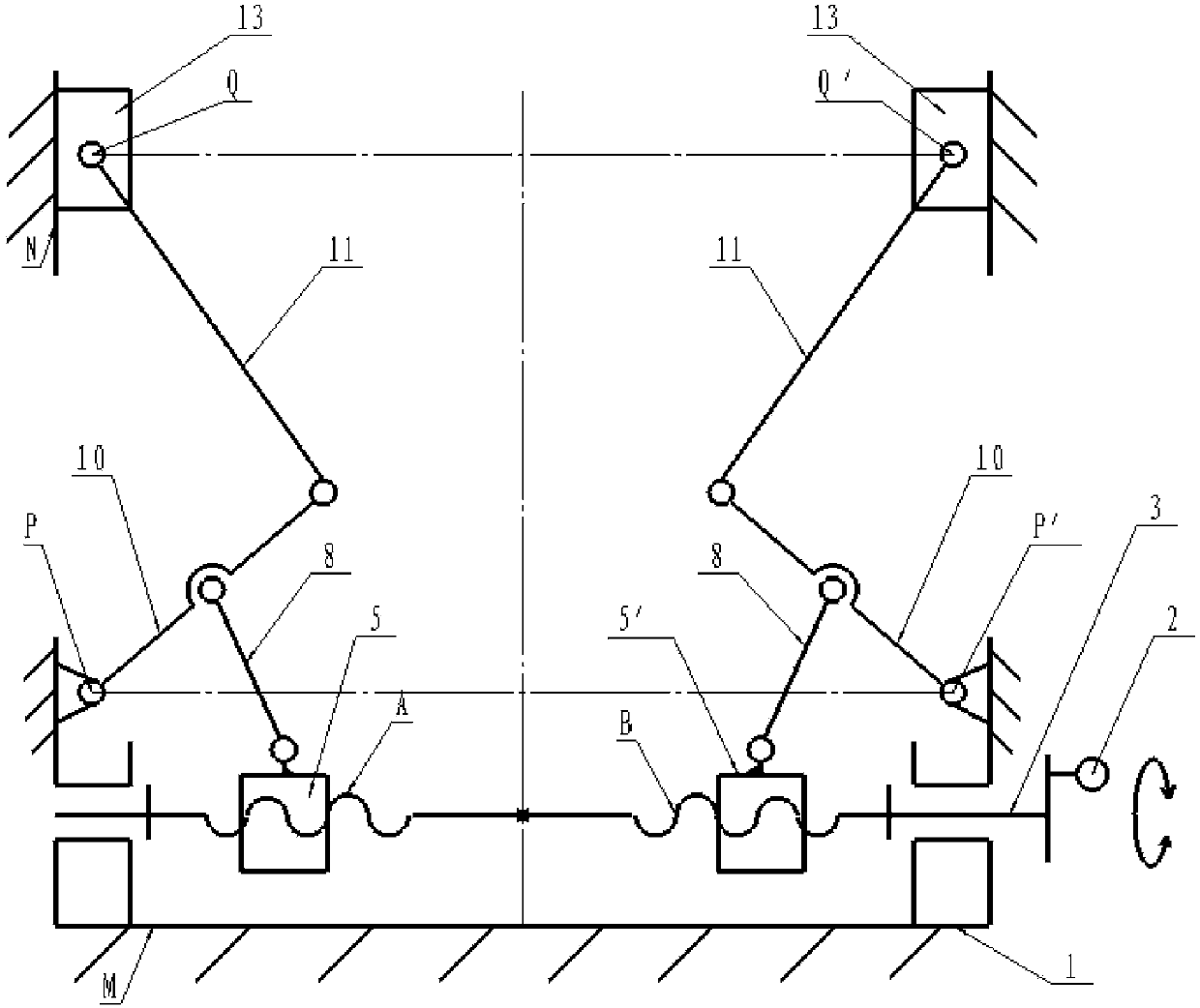

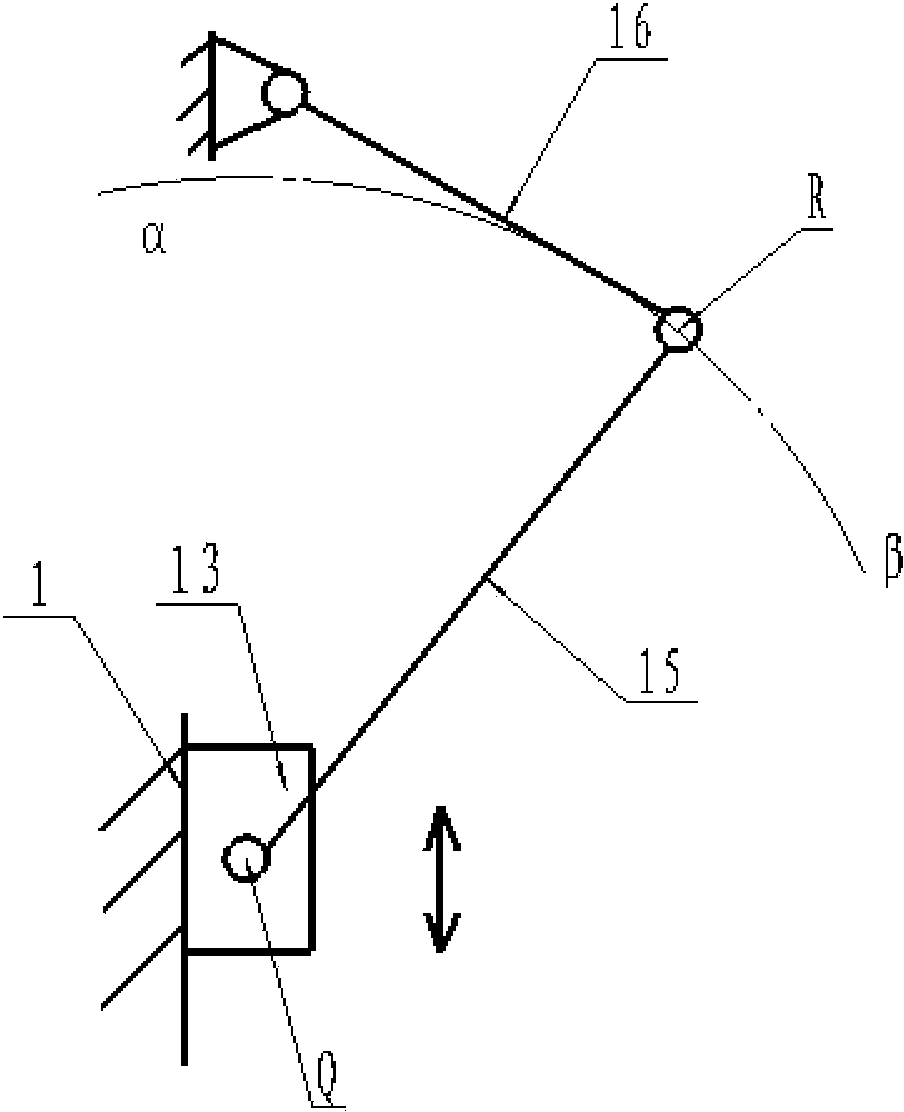

[0038] like Figure 1-Figure 5 It shows the connecting rod lifting and turning device of the present invention, which is characterized in that it includes a support frame 1, a feed hand wheel 2, a differential screw 3, a screw shaft seat 4, a left drive nut 5, a right drive nut 5', a method Blue pin shaft 6, bearing assembly 7, ejector rod 8, cylindrical positioning pin 9, rocker 10, connecting rod 11, lifting sliding guide rail 12, slider 13, shaft assembly 14, turning frame 15, turning connecting rod 16, fixing pin Shaft 17, pin clamping plate 18, limit block 19, pitch adjustment strut 20, adjustment screw rod 21, wherein:

[0039] The screw shaft seat 4 and the two left and right bearing assemblies 7 are all fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com