lever switch valve

A switching valve and lever-type technology, which is applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of switching valve switching force, long stroke, discomfort, etc., to improve resistance, save travel, and eliminate water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

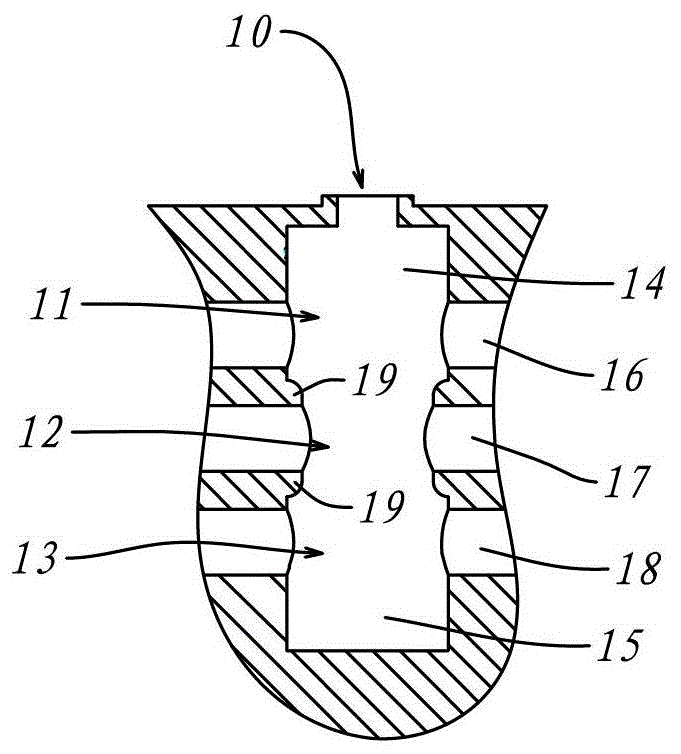

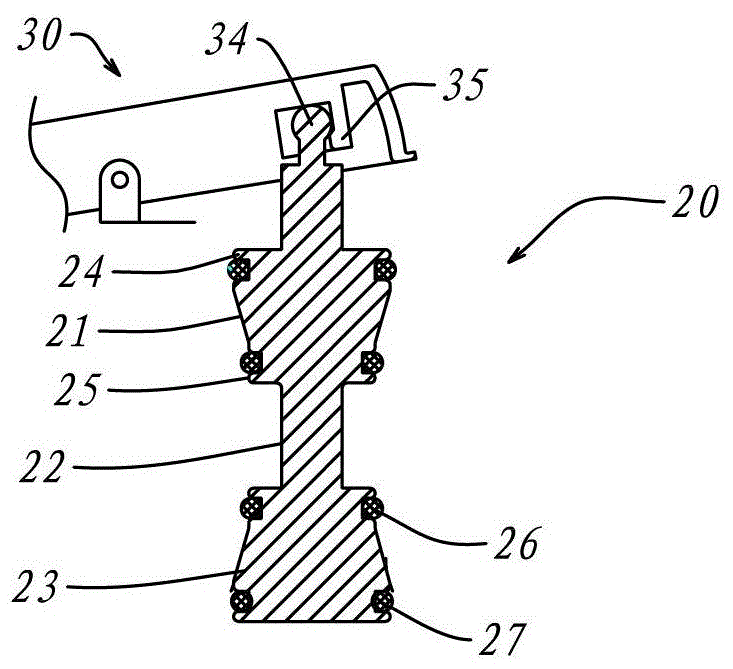

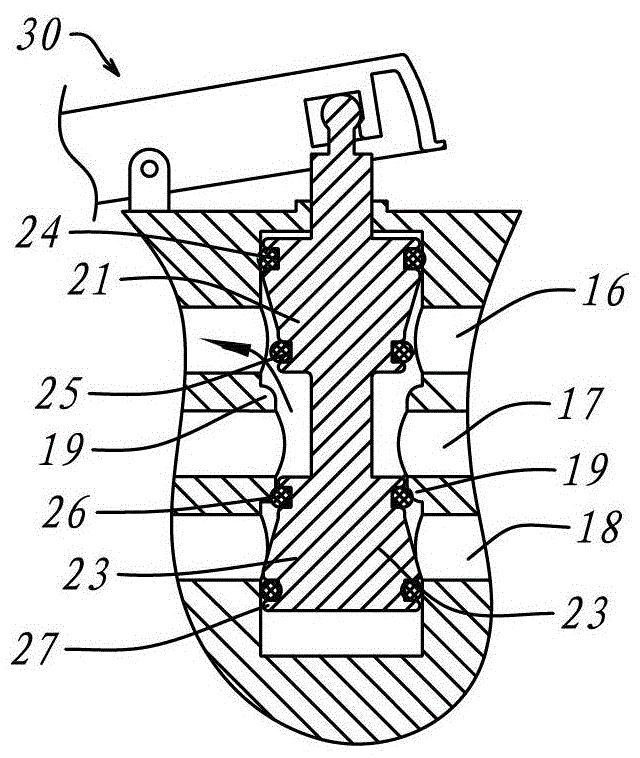

[0030] Such as Figure 1 to Figure 3 Shown, a series of schematic diagrams of Embodiment 1 of the present invention, wherein figure 1 is the configuration of the switching cavity 10, figure 2 It is the structure of movable bolt 20, image 3 is a schematic diagram of the device assembly.

[0031] Such as figure 1 , the switching chamber 10 is divided into three sections according to its axial direction, which are respectively the water outlet chambers 11, 13 at both ends and the water inlet chamber 12 in the middle section; the respective axial outer ends of the water outlet chambers 11, 13 each have a sliding section 14, 15 There is an inner convex ring 19 between both ends of the water inlet chamber 12 and the water outlet chambers 11 and 13; the water inlet chamber 12 is connected to a water inlet 17;

[0032] Such as figure 2 , the movable bolt 20 is dumbbell-shaped, and also includes three sections according to its axial direction, which are respectively pistons 21,...

Embodiment 2

[0041] Such as Figure 4 to Figure 6 Shown, the schematic diagram of embodiment two of the present invention; Wherein Figure 4 It is a sectional view of the switching cavity 10 and the housing 40 where it is located; Figure 5 is a schematic cross-sectional view of the movable bolt 20; Figure 6 It is an overall sectional view of the embodiment installed in a valve body 1 .

[0042] Such as Figure 4 As shown, the shape and structure of the switching cavity 10 in this embodiment are the same as those in Embodiment 1, so details are not repeated here. The switching chamber 10 is located in a cylindrical housing 40; the outer wall of the housing 40 has three water holes 41, 43 and 42 distributed axially, corresponding to the water inlet and two water outlets respectively, that is, having the same function.

[0043] Such as Figure 5 As shown, the sectional view of the movable plug 20 of the present embodiment, the pistons 21, 23 and the water passing section 22 of the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com