Frame beam slope greening method and frame beam slope greening facility

A technology for sash beams and slopes, applied in the field of slope greening, can solve the problems of inability to restore vegetation on slopes, hidden dangers to pedestrians, uncoordinated natural landscapes, etc. Limit small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

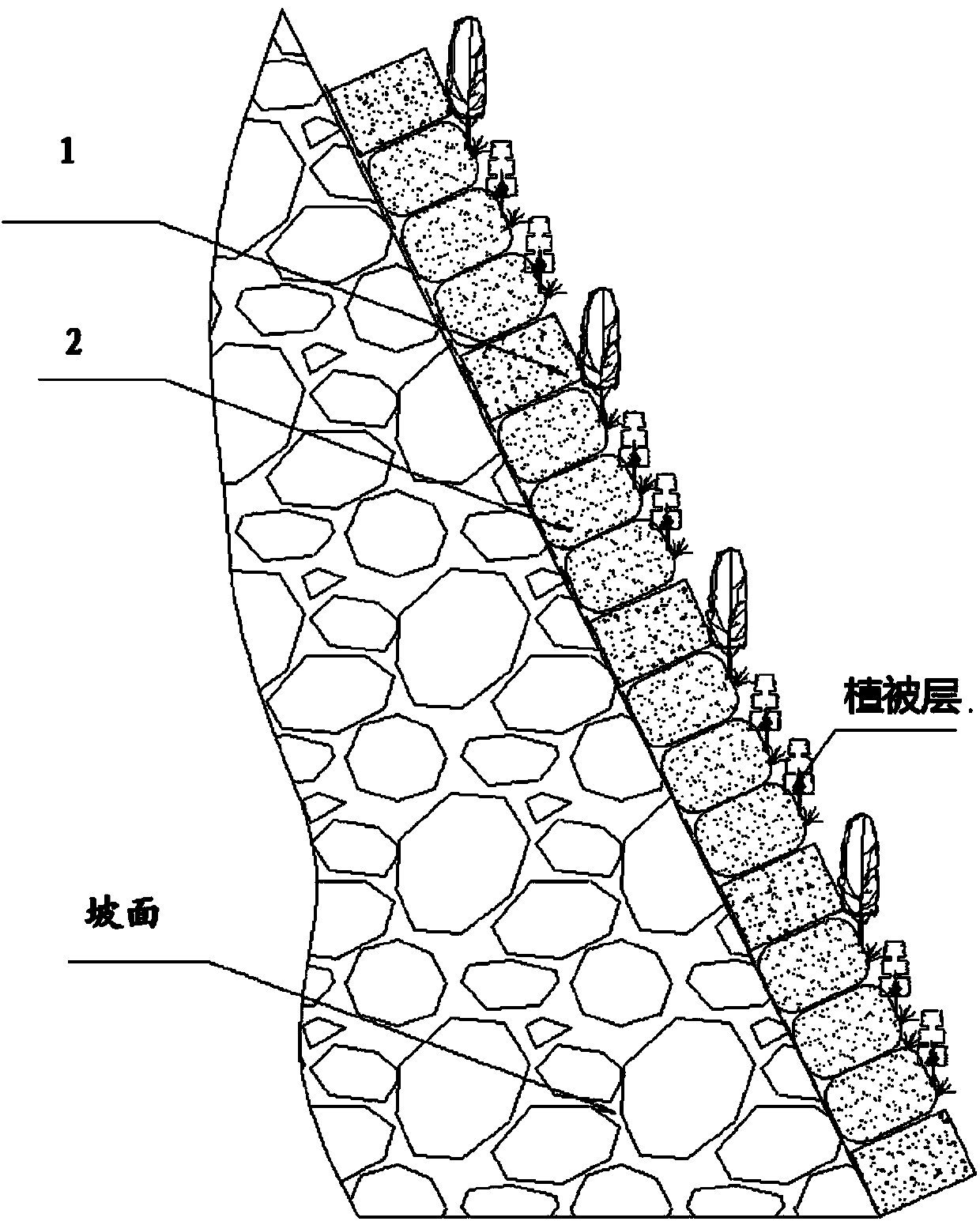

[0023] figure 1 According to a kind of sash beam slope greening method of the present invention, carry out the structural representation of slope fixation and greening; Method of the present invention comprises the following steps:

[0024] S1, pouring a sash beam 1 on the side slope, the sash beam is perpendicular to the slope;

[0025] S11, cleaning and leveling the side slope in the sash beam, manually or mechanically removing pumice and dangerous stones on the slope surface;

[0026] S12, processing the inner foundation foot of the sash beam; leveling the inner foundation foot of the sash beam, padding the uneven place with sand and stone, and pouring concrete for the local settlement section;

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com