Method for removing carbon deposits in gas preheating pipes

A technology of gas preheating pipes and preheating pipes, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of large heat release, burnout of gas preheating pipes, etc., and achieve rapid removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention is further described:

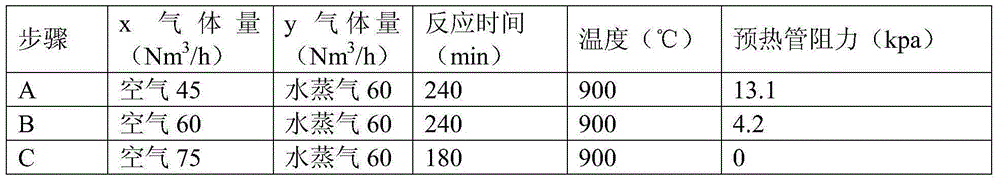

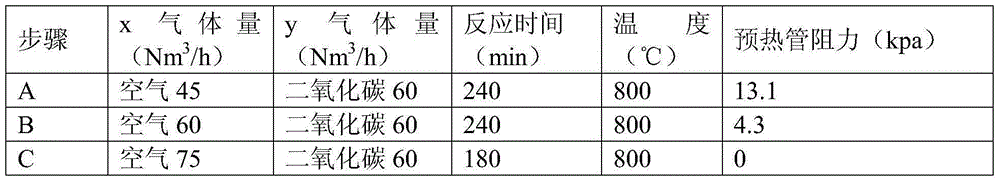

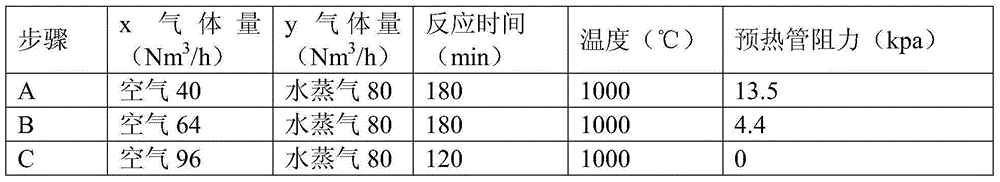

[0025] Gas preheating pipe carbon deposit removal method, feed x gas and y gas into the preheating pipe, control the reaction temperature at 500-1000°C, and continue until the gas preheating pipe ventilation resistance becomes smaller, first stop feeding x gas, and then Stop feeding y gas, and resume feeding gas, and the gas preheating pipe resumes normal operation; the x gas is a gas that reacts exothermicly with carbon, and the gas y is a gas that reacts endothermicly with carbon.

[0026] This method feeds gas x and gas y into the preheating tube, wherein gas x is a gas that reacts exothermicly with carbon, which can be a mixed gas, such as air, or a single gas, such as oxygen, ozone, etc. The y gas is a gas that undergoes an endothermic reaction with carbon, such as water vapor, carbon dioxide, and the like.

[0027] While feeding the gas, keep the temperature in the pipeline at 500-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com