Method for removing carbon deposition on inner wall of coal gas preheating pipe

A gas preheating tube and a technology for a preheating tube are applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. The effect of high efficiency, short process and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Using the method of the present invention to remove carbon deposits on the inner wall of the gas preheating pipe

[0053] To remove carbon deposits in the gas preheating pipeline, the specific operation steps are as follows:

[0054] A. With 45Nm 3 / h flow into the air, with 60Nm 3 The / h flow rate is fed with nitrogen, the temperature in the pipeline is controlled at 900°C, and the duration is 240min. After this step is completed, the pressure of the preheating tube is detected to be 13.4kpa;

[0055] B. With 60Nm 3 / h flow into the air, with 60Nm 3 The / h flow rate is fed with nitrogen, the temperature in the pipeline is controlled at 900°C, and the duration is 240min. After this step is completed, the pressure of the preheating tube is detected to be 4.3kpa;

[0056] C. With 75Nm 3 / h flow into the air, with 60Nm 3 Nitrogen gas was introduced at a flow rate of / h, and the temperature in the pipeline was controlled at 900°C for 180 minutes. After this ...

Embodiment 2-10

[0061] Example 2-10 Using the method of the present invention to remove carbon deposits on the inner wall of the gas preheating pipe

[0062] The operation steps of Example 2-10 are the same as those of Example 1, and the specific parameter settings are shown in Table 2-10.

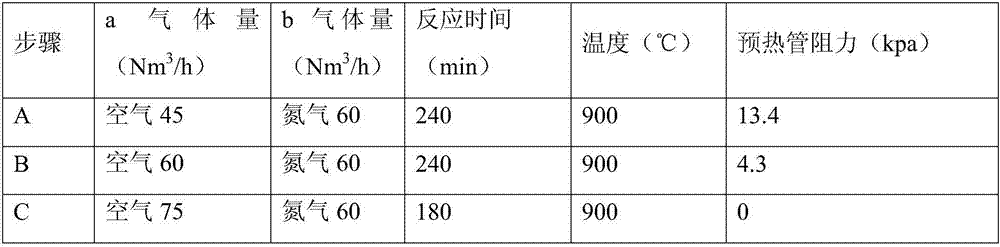

[0063] Table 2 The parameter setting of embodiment 2 carbon deposition removal

[0064]

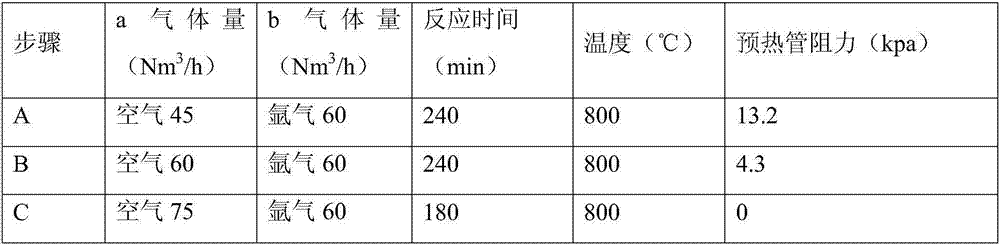

[0065] Table 3 The parameter setting of embodiment 3 carbon deposition removal

[0066]

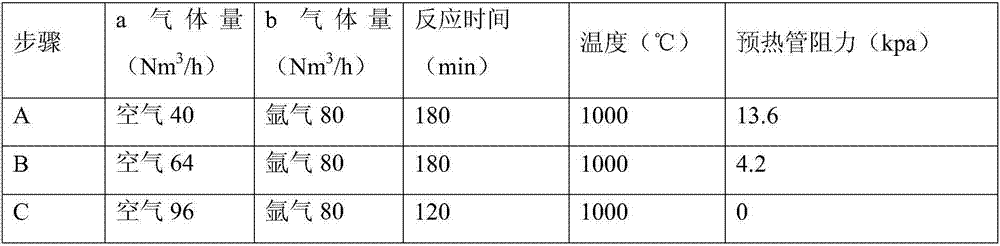

[0067] Table 4 The parameter setting of embodiment 4 carbon deposition removal

[0068]

[0069] Table 5 The parameter setting of embodiment 5 carbon deposition removal

[0070]

[0071] Table 6 The parameter setting of embodiment 6 carbon deposition removal

[0072]

[0073] Table 7 The parameter setting of embodiment 7 carbon deposition removal

[0074]

[0075] Table 8 The parameter setting of embodiment 8 carbon deposition removal

[0076]

[0077] Table 9 The parameter setting of embodiment 9 carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com