Adaptive grinding and polishing machine tool for complex curved surfaces based on electrolytically modified elastic conductive abrasive belt

An elastic, conductive, self-adaptive technology, applied in the field of complex curved surface self-adaptive grinding and polishing machine tools, can solve the problems of reducing grinding efficiency and surface quality, and achieve the goals of ensuring processing efficiency and surface quality, reducing tool wear, and high-efficiency grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

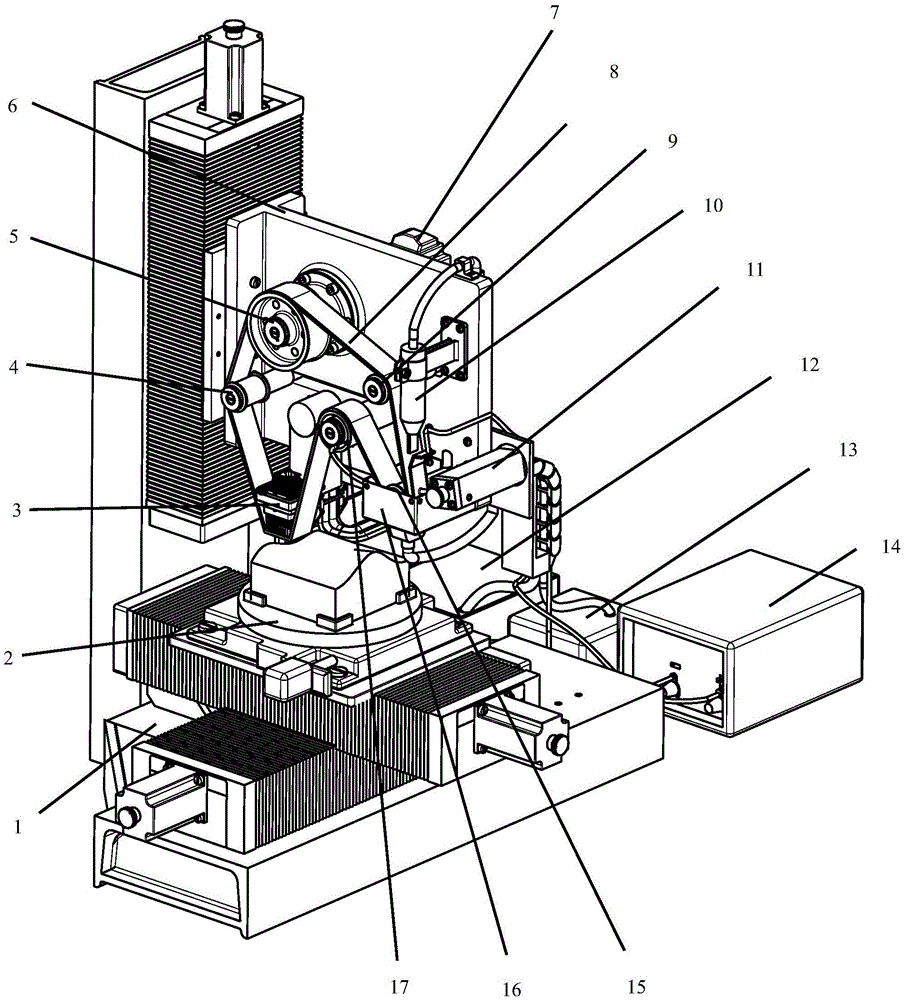

[0026] The rotary workbench 2 is fixed on the XY plane of the three-dimensional workbench 1. As the workbench drives the workpiece in the XY plane to perform two-dimensional movement, the conductive abrasive belt self-adaptive grinding and polishing tool system is installed on the Z direction of the three-dimensional workbench 1. Do feed motion in the Z direction, the positive connection 1401 of the electrolytic pulse power supply 14 is connected with the bearing bush 1702 of the positive connection tensioning wheel 17 of the conductive abrasive belt self-adaptive grinding and polishing tool system, and the negative connection 1402 is connected with the negative connection 1402 of the cathode distance adjustment device 11 The cathode metal sheet 1106 is connected, and the electrolyte pump station 13 is connected to the nozzle 10; the electrolyte pump station 13 sends the electrolyte to the nozzle 10, and the electrolyte communicates with the elastic conductive abrasive belt 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com