Rail transit half-height emergency exit lock and half-height emergency exit

A rail transit and safety door technology, applied in the field of rail transit screen door design, can solve the problems of complex structure of screen door locking and unlocking devices, unsmooth locking and unlocking process, and low control accuracy, so as to reduce processing costs and installation requirements, switch The effect of smooth locking process and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

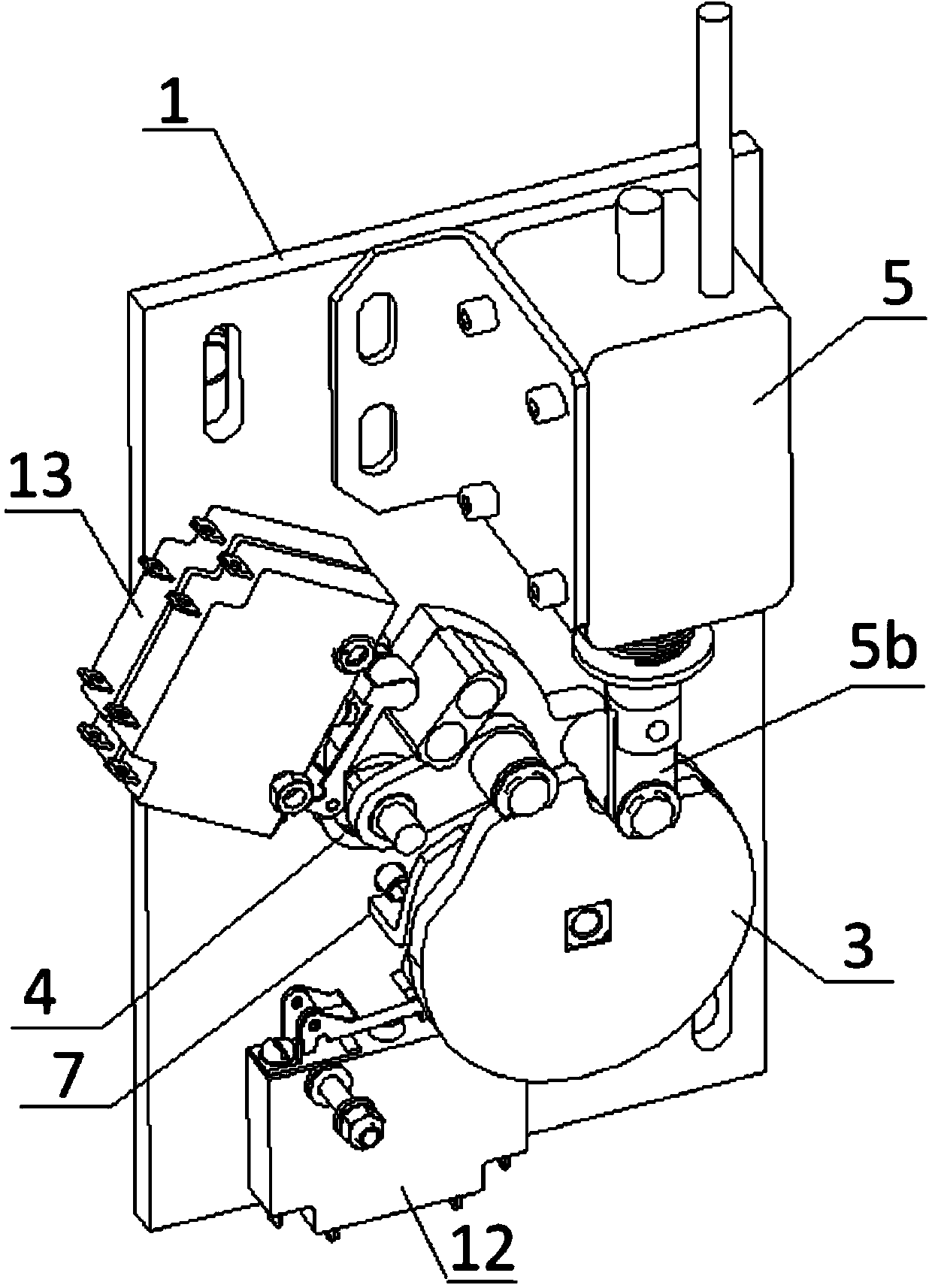

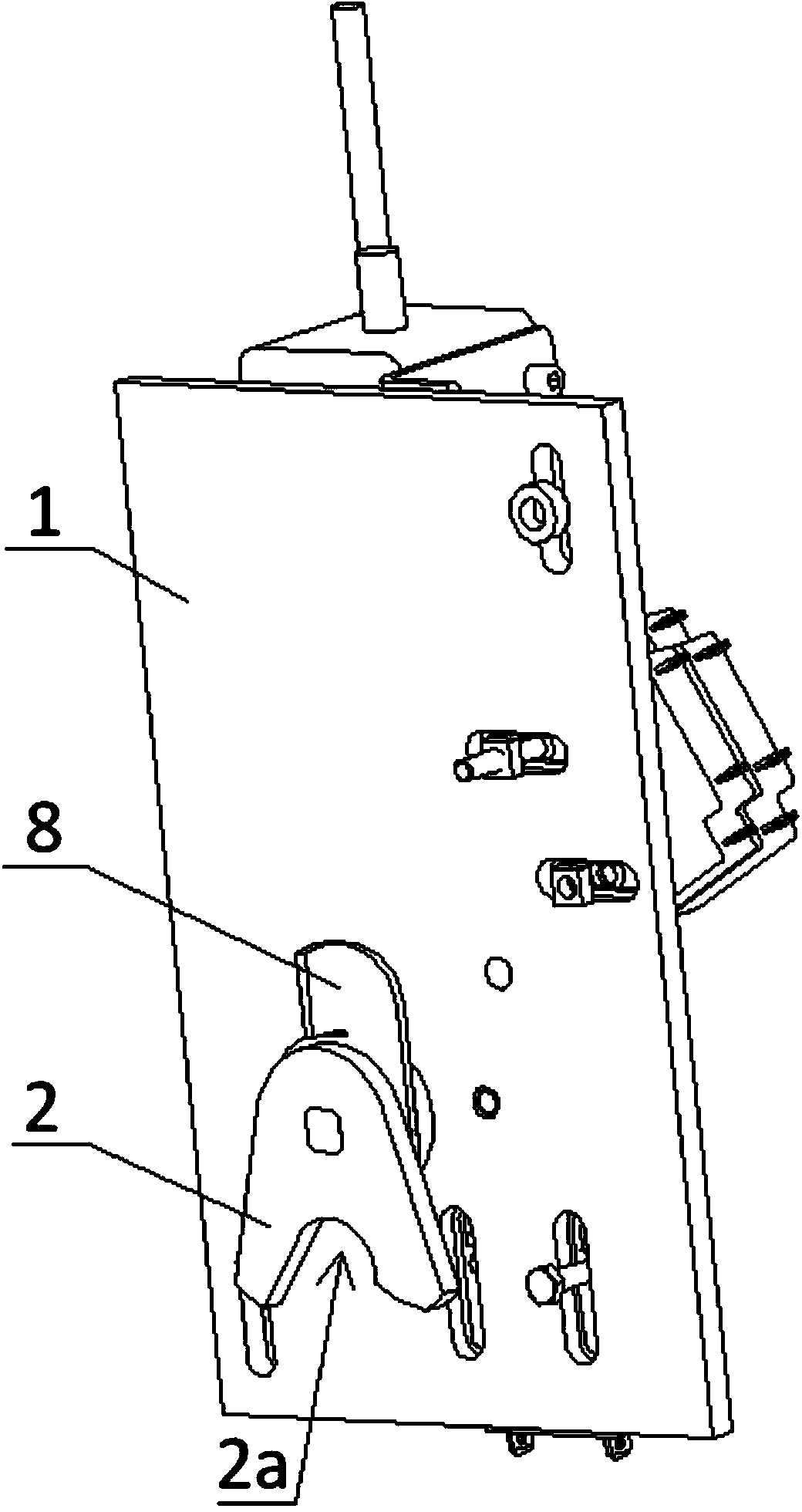

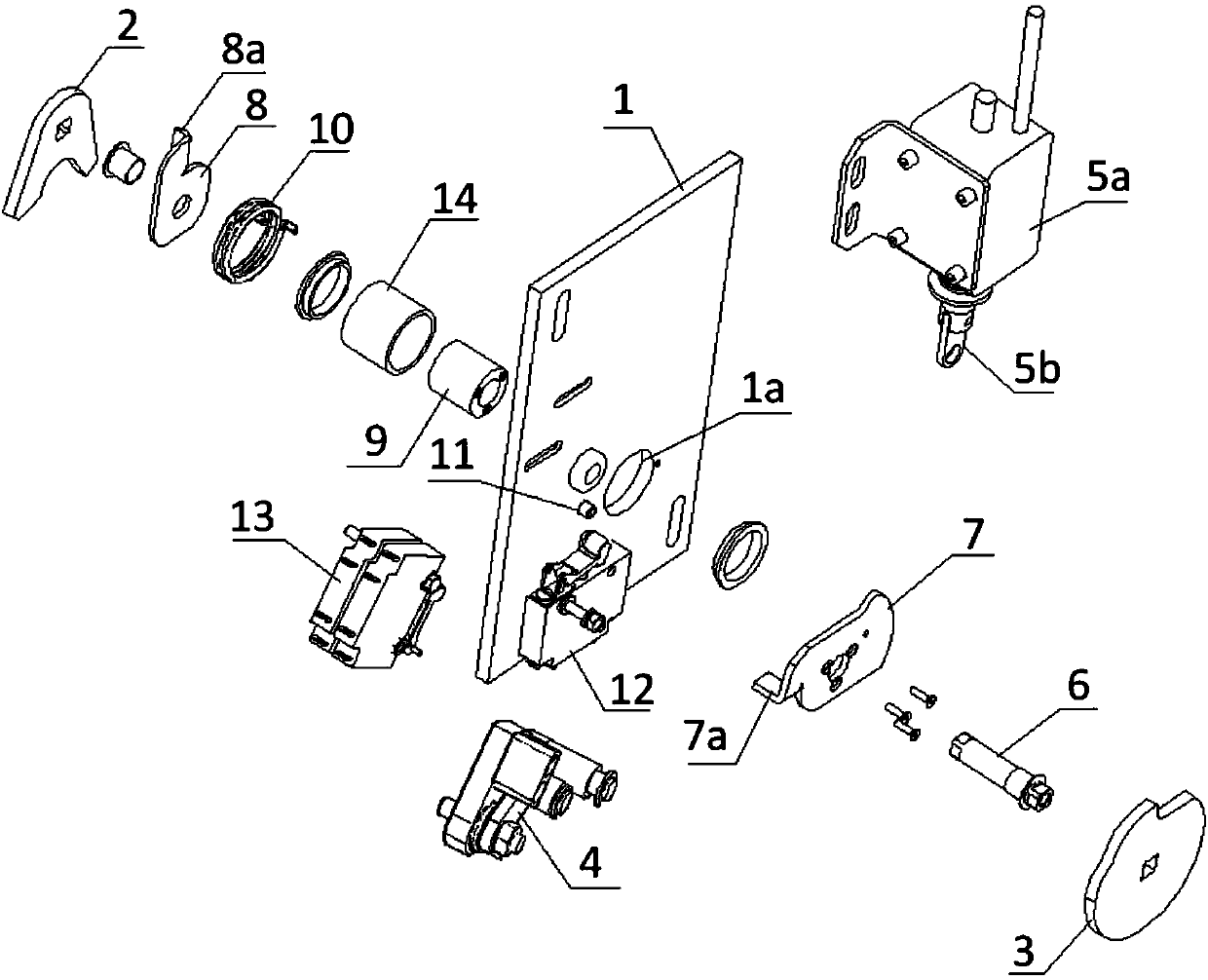

[0051] like figure 1 , figure 2 and image 3 As shown, a rail transit half-height safety door lock includes a drive mechanism 5 for driving, a lock arm 4 for locking and releasing, and a manual unlocking plate 8 for manually unlocking, which is used to lock the sliding door The outer locking disc 2, and the first travel switch 12 and the second travel switch 13 for monitoring locking and manual unlocking, the inner locking disc 3 for locking and positioning and the trigger piece 7 for manual unlocking.

[0052] The outer locking disc 2 and the inner locking disc 3 are locked together through the main rotating shaft 6 , while the manual unlocking plate 8 and the trigger piece 7 for manual unlocking are locked together through the ring shaft 9 . The two are also assembled in the mounting base 1 through a shaft sleeve.

[0053] Simultaneously, the manual unlocking mechanism then needs to be installed reset torsion spring 10, is used for the automatic reset of manual unlocking...

Embodiment 2

[0065] A half-height safety door for rail transit, comprising a sliding door lock pin and a door lock for locking the sliding door lock pin, the structure of the door lock is the same as that in Embodiment 1.

[0066] The running process of rail transit half-height safety door in the present embodiment is as follows:

[0067] In the door-closing process, at the beginning, the drive mechanism 5 does not work, and the second travel switch 13 is in the door-opening monitoring state, and the inner lock plate 3 is only subjected to the elastic force of the return spring elastic force of the electromagnetic push rod. And this sliding door is closed under the traction effect of the motor, when about to put in place, the door pin on the sliding door drives the outer lock disc 2 to rotate. When turning in place, the lock arm 4 swings under the action of elastic force and enters the locked position of the inner lock plate 3. At this time, the sliding door cannot be opened manually. Sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com