Porous rapid quantitative injecting box

A fast and high-speed material injection technology, applied in the field of porous rapid quantitative injection box, can solve the problems of waste of raw materials, shorten working time, inconvenient cleaning, etc., and achieve the effects of shortening working time, improving work efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

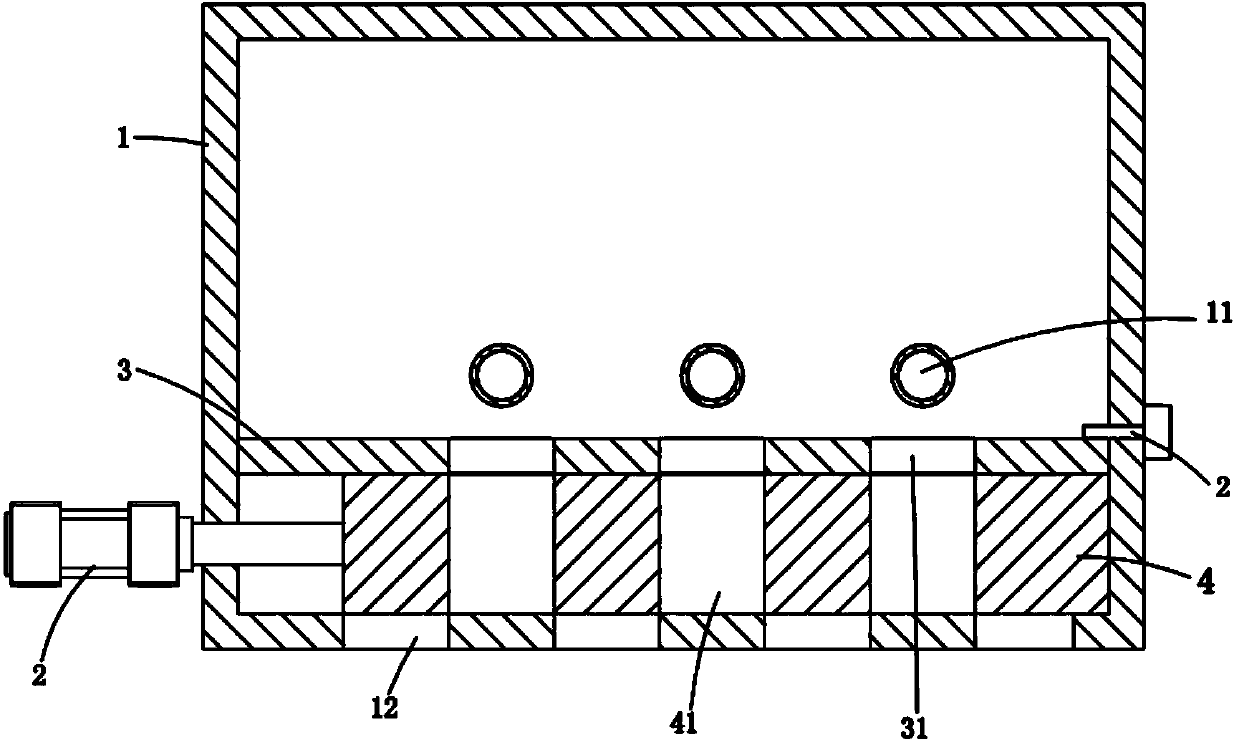

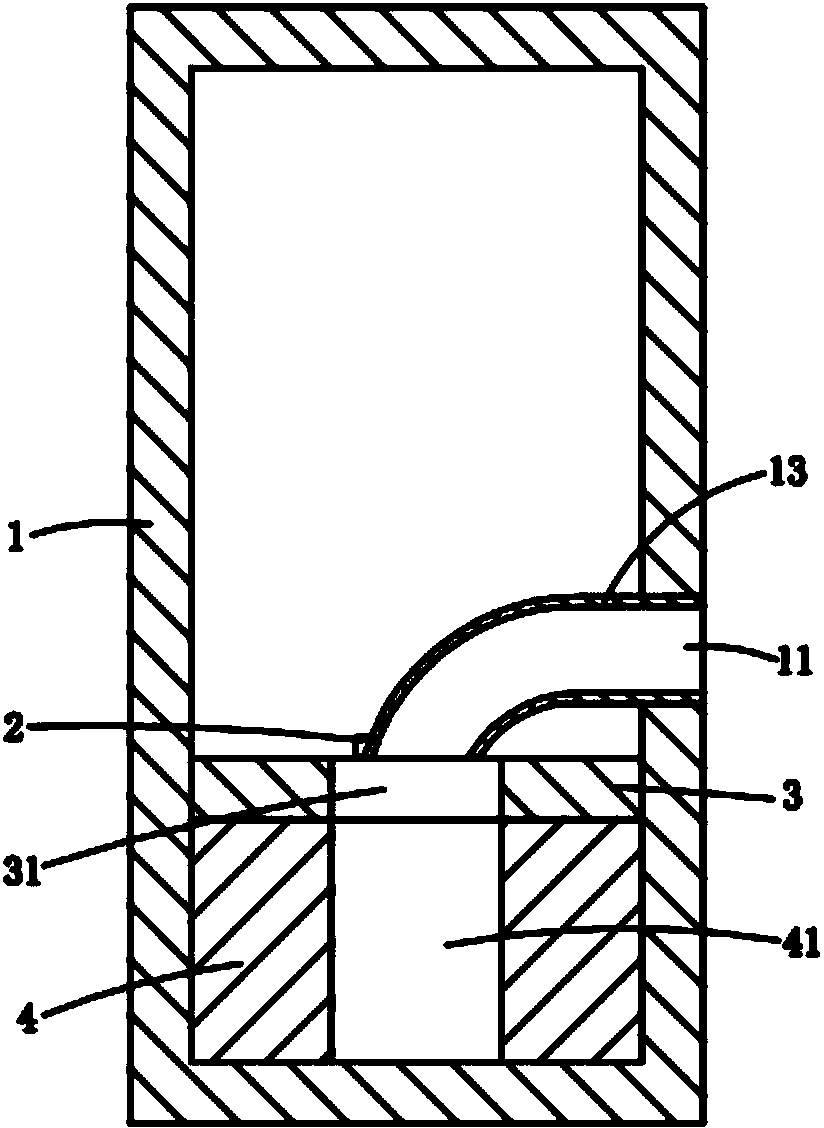

[0018] Such as figure 1 As shown, a fast quantitative injection box includes a box body 1 and a material level detection sensor 2. The material level detection sensor 2 is arranged on the outside of the box body 1 and connected to the main controller. A feed port 11, at least one feed port 12 is provided at the bottom of the casing 1; a positioning plate 3 is arranged in the casing 1, and the positioning plate 3 is placed between the feed opening 11 and the bottom of the casing 1, and the positioning plate 3 There are through holes 31 corresponding to the feed inlets 11 one by one, and the through holes 31 are arranged alternately with the injection ports 12 at the bottom of the box body 1; between the positioning plate 3 and the bottom of the box body 1 A slidable slide plate 4 is provided, and the upper and lower surfaces of the slide plate 4 closely abut against the positioning plate 3 and the bottom of the box body 1 respectively, and an air cylinder 5 is provided at one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com