Liquid raw material rapid quantitative injection system and its control method

A quantitative injection and liquid raw material technology, applied in the direction of analytical materials, instruments, etc., can solve the problems of easy moisture absorption and corrosion, high viscosity of liquid raw materials, slow feeding speed, etc., to achieve reduced manual operation, high degree of automation, and high injection speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

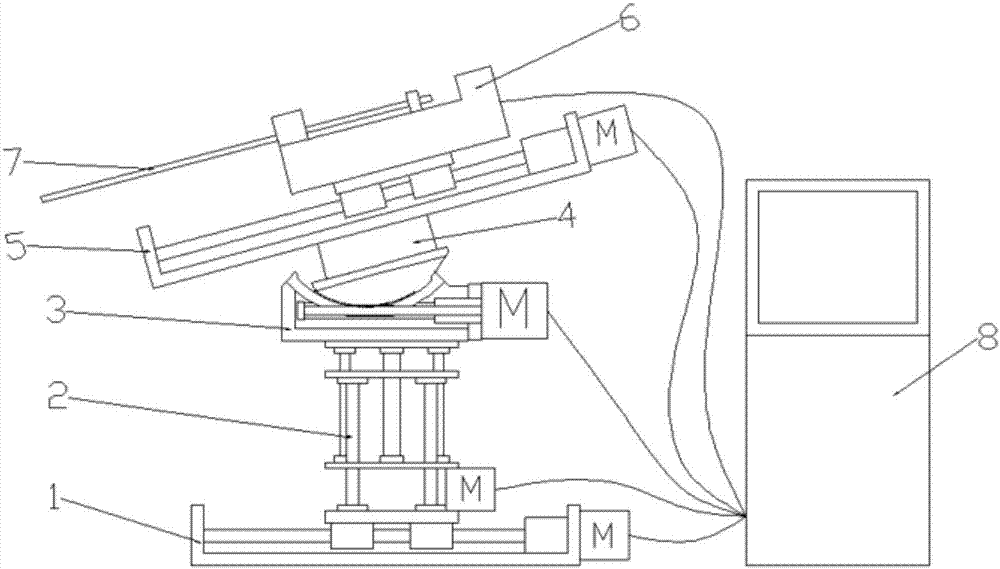

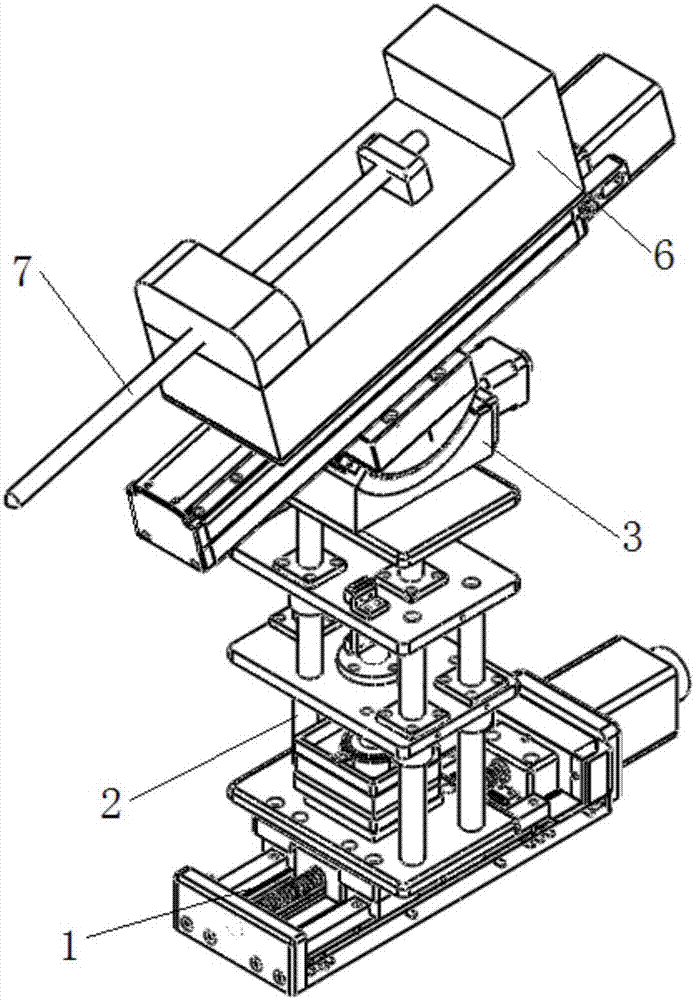

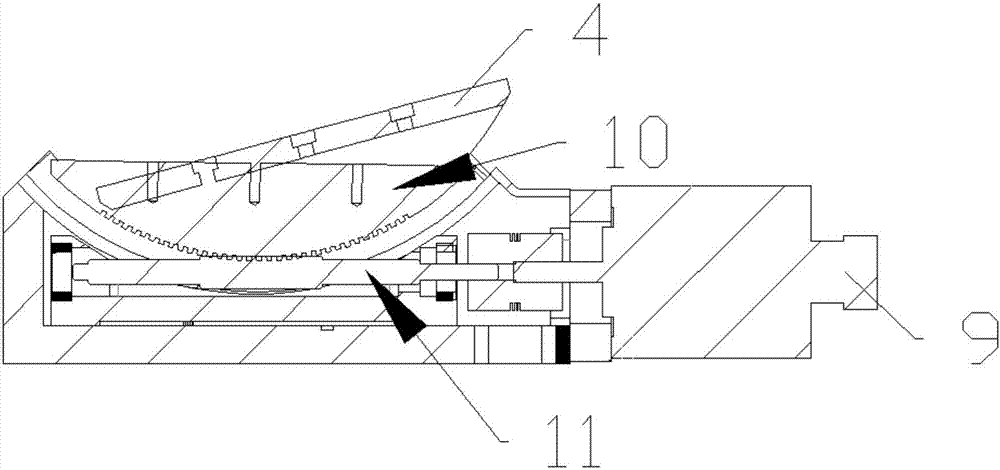

[0032] Such as figure 1 As shown, the rapid quantitative injection system for liquid raw materials includes a syringe pump 6 with a syringe 7 arranged obliquely downward. The syringe pump 6 is the RSP01-BD of Jiashan Ruichuang. Two pushing mechanisms cooperate with one syringe 7 to realize simultaneous injection of different raw materials; or, the syringe pump 6 and syringe 7 adopt the precise micro-sampling device for liquid raw materials disclosed in the application number 2014100387531, and at the same time, the syringe 7 is required to be non-corrosive material; the injection pump 6 is connected with the angular displacement mechanism 3 that drives the injection pump to rotate, the lifting mechanism 2 is fixed at the bottom of the angular displacement mechanism 3, and the translation mechanism 1 that drives the lifting mechanism 2 translation is fixed at the bottom of the lifting mechanism 2 , between the syringe pump 6 and the angular displacement mechanism 3, a sliding t...

Embodiment 2

[0040] The rapid quantitative injection system for liquid raw materials includes a syringe pump with a syringe set obliquely downward. The syringe pump is connected to an angular displacement mechanism that drives the syringe pump to rotate. The bottom of the angular displacement mechanism is fixed with a translation mechanism that drives the angular displacement mechanism to translate. A lifting mechanism is fixed at the bottom of the translation mechanism, and a sliding table mechanism is provided between the injection pump and the angular displacement mechanism to drive the injection pump to move linearly. Each mechanism is connected to the control system through a wired or wireless device.

[0041] Both the translation mechanism and the sliding platform mechanism are linear sliding platforms or centering crank slider mechanisms.

Embodiment 3

[0043] The rapid quantitative injection system for liquid raw materials includes a syringe pump with a syringe set obliquely downward. The bottom of the syringe pump is fixed on the slider of the sliding table mechanism through bolts. The bottom of the displacement mechanism is provided with a lifting mechanism, and each mechanism is connected to the control system through a wired or wireless device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com