Method for installing embedded type box base of container ship

A container ship and installation method technology, applied in the directions of ship parts, ship construction, transportation and packaging, can solve the problems of increasing shipbuilding cycle, unfavorable shipbuilding technology and industry development, cumbersome process, etc., to improve segmentation integrity, ensure Integrity, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

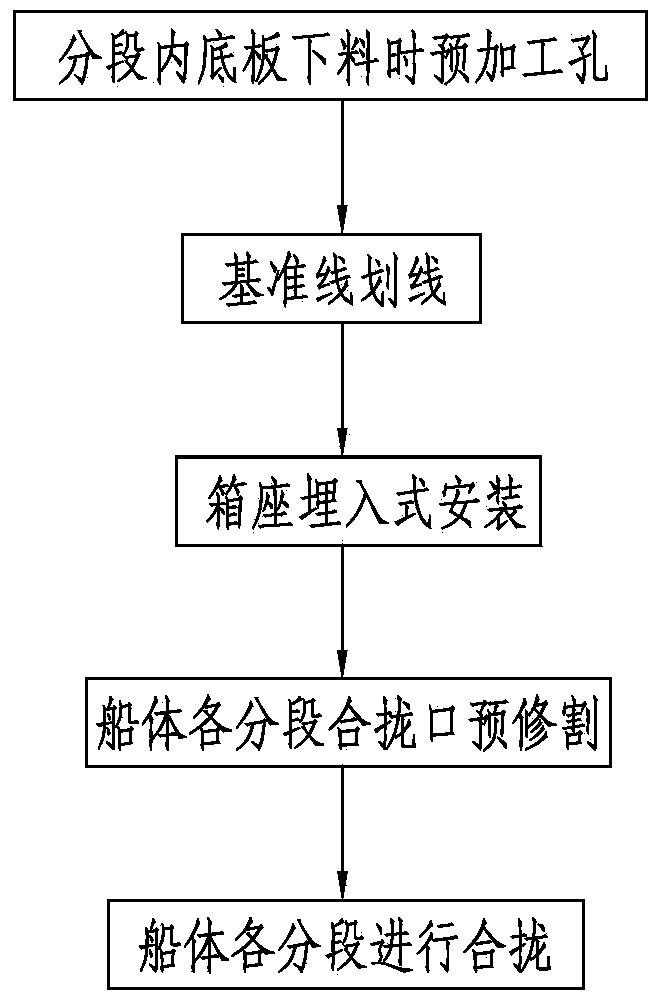

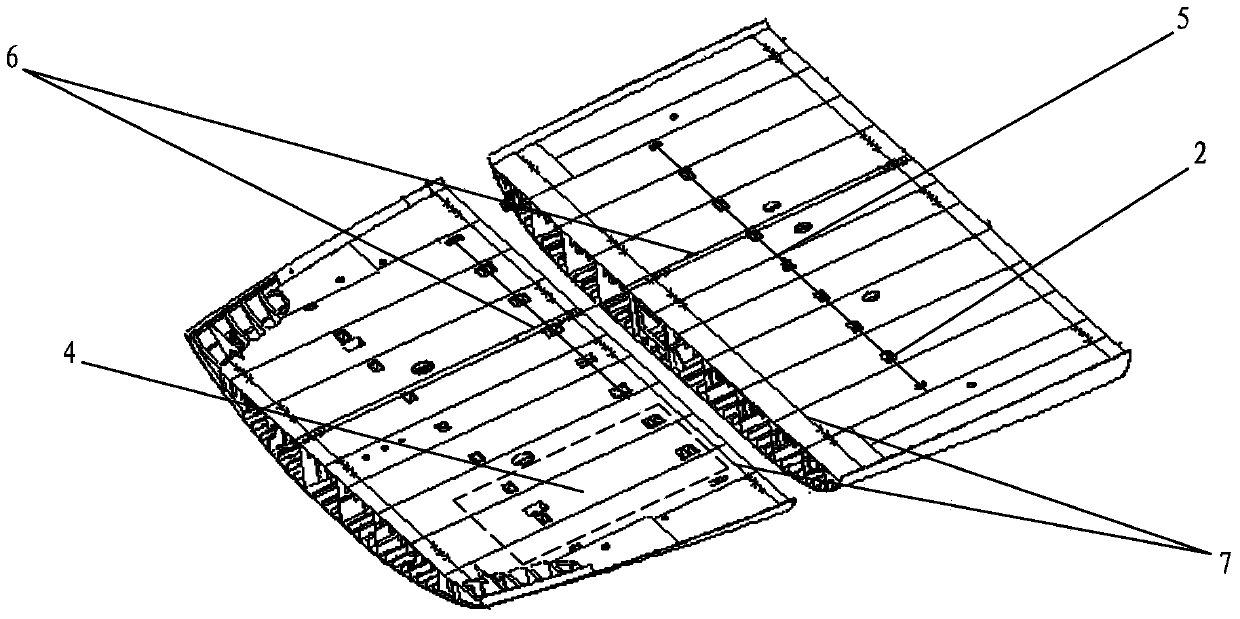

[0039] Such as Figure 1 to Figure 3 As shown, the present embodiment relates to a container ship embedded box seat installation method, which is characterized in that it includes the following steps:

[0040] The method for installing an embedded box seat of a container ship is characterized in that it comprises the following steps:

[0041] 1) Pre-machining holes when blanking the segmented inner bottom plate

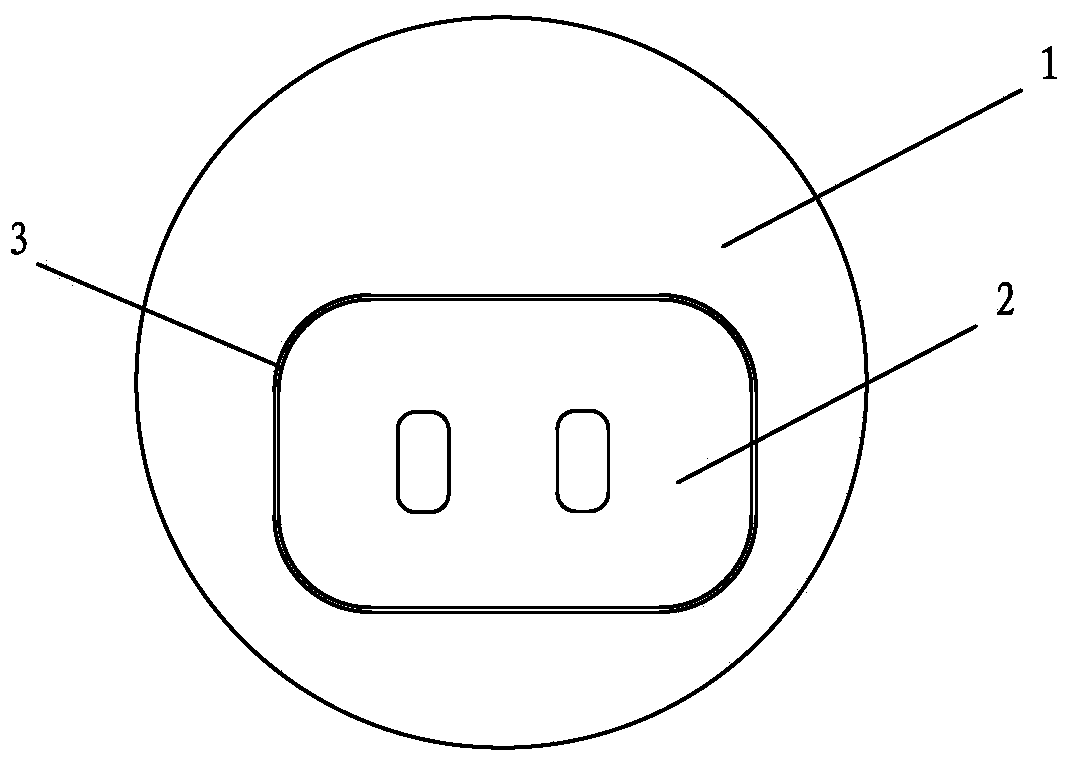

[0042] When blanking the inner bottom plate 1 of the container ship, according to the length and width of the container and the size of the box seat, the distribution position and size of the holes matching the box seat 2 are determined, and the inner bottom plate is prepared in advance through mechanical processing equipment. Open hole 3;

[0043] 2) Datum line marking

[0044] Draw reference lines respectively on the inner bottom plate 1 of each section of the hull, for positioning the box seat to install, and to position each section of the hull for carrying and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com