Bearing quick-release lock

A force-bearing quick-release lock and lock seat technology, which is applied to aircraft power units, aircraft power unit components, and quick-moving fasteners, etc. problem, to achieve the effect of beautiful appearance, quick disassembly and high reliability

Active Publication Date: 2014-12-17

CHINA HELICOPTER RES & DEV INST

View PDF8 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Several kinds of quick-release nails used by several military and civilian helicopters currently in service have frequently encountered faults such as loosening, breaking, and ejection of the quick-release nails for the fairing, especially the quick-release of the fairing accessories for the engine fairing and tail reducer. If the nail hits the blade after it pops up, it will damage the blade, which will bring safety hazards and the consequences will be disastrous

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

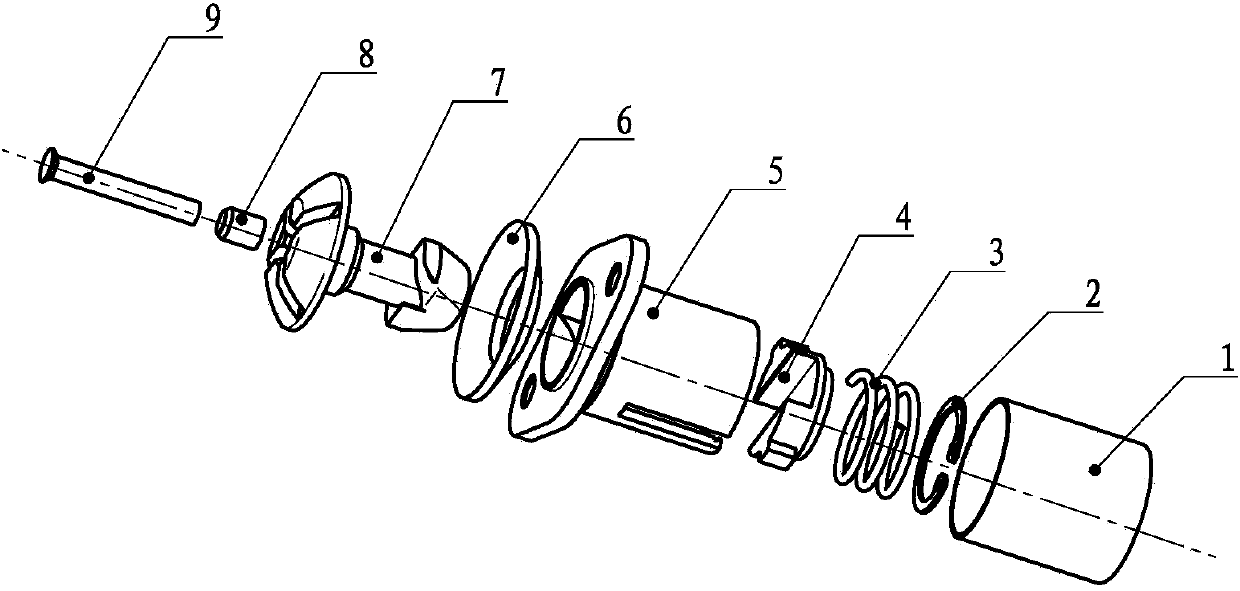

[0018] In an implementation case of the present invention, the snap spring 2 is a standard part, the lock seat 5, the lock nail 7, and the washer 6 are all made of stainless steel, the diameter of the lock nail 7 with the smallest diameter is Ф4.5mm, and the outer diameter of the lock seat 5 with the smallest diameter is Ф11mm, the bearing capacity (tension) of the quick release lock is 8500N, and the weight of the whole set of lock is 13g.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

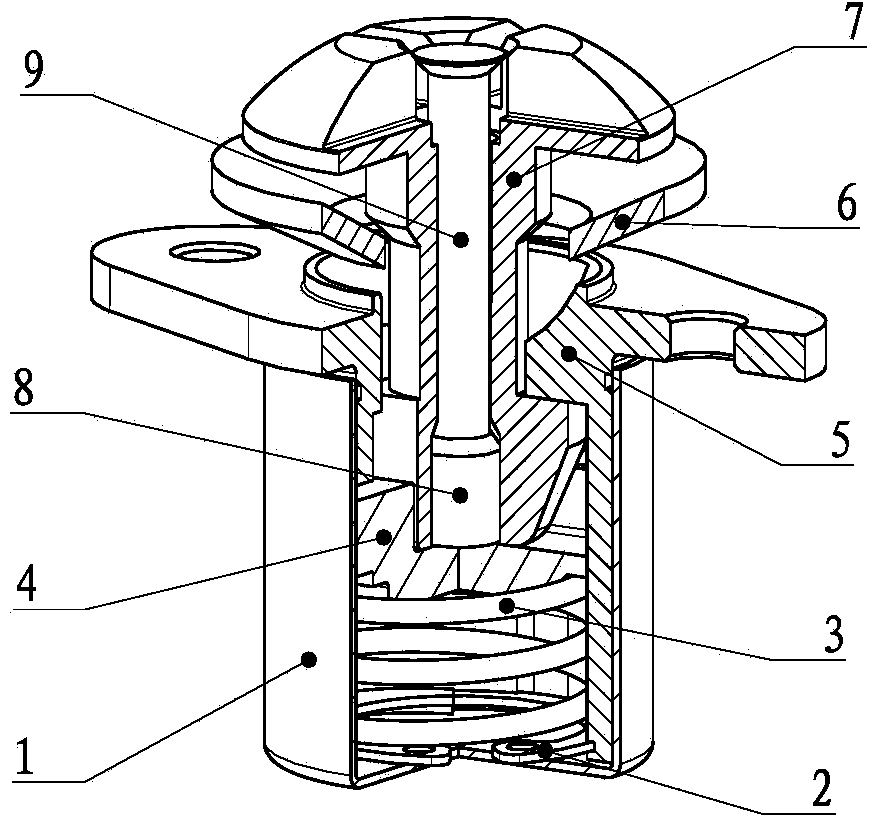

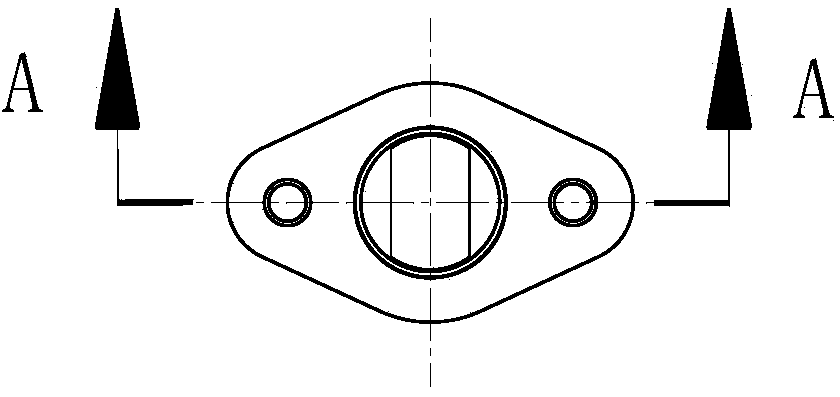

The invention discloses a bearing quick-release lock and belongs to the fields of quick release connection of a fairing and an access panel which are frequently released in an aviation helicopter structure. The bearing quick-release lock is characterized by comprising a lock seat assembly and a lock pin assembly, wherein the lock seat assembly comprises a sealing cap, a snap spring, a compression spring, a sliding block and a lock seat; the lock pin assembly consists of a washer, a lock pin, a bush and an ejection rod. The bearing quick-release lock disclosed by the invention has the advantages of light structural weight, attractive appearance, high reliability, sealing property and certain bearing capacity, and can be suitable for quick release connection of a fairing at a position where the vibration environment is particularly severe. According to the quick-release lock disclosed by the invention, after locking, the lock pin is clamped by a clamping groove of the sliding block, so that the lock pin cannot extend by rotating; the lock pin can be unlocked by rotating after the ejector rod is pushed by a tool and is enabled to push the sliding block to move until the lock pin cannot be clamped by the sliding block; after locking, the ejector rod ejects to be in flush with the head of the lock pin, so whether the virtual locking exists or not can be effectively judged.

Description

technical field [0001] The invention belongs to the field of quick-release connection of fairings and mouth covers that are often disassembled in the structure of aviation helicopters, and relates to a quick-release lock structure. Background technique [0002] Helicopters have many moving parts and high vibration levels, and the vibration environment is particularly harsh at engine fairings, tail reducer fairings and other parts. Due to the frequent maintenance of the engine and tail reducer, the fairing needs to be disassembled frequently. Since the helicopter fairing is often complex in shape, considering the need for frequent disassembly and maintenance of the fairing and the structural size and weight of the connecting parts, the relationship between the fairing and the structure The spaces are often connected with small quick-release nails. Several kinds of quick-release nails used by several military and civilian helicopters currently in service have frequently encou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B64D29/06F16B21/08

Inventor 刘纪福吴硕曹元宝项文科王记桓

Owner CHINA HELICOPTER RES & DEV INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com