Novel water spraying screw rod air compressor

An air compressor and screw technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high cost, small market share, high price, etc., and achieve extended oil change cycle and oil aging. The effect of slowing down and improving gas production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

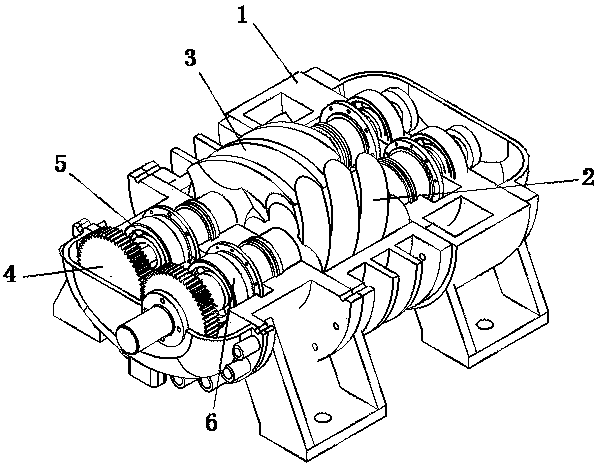

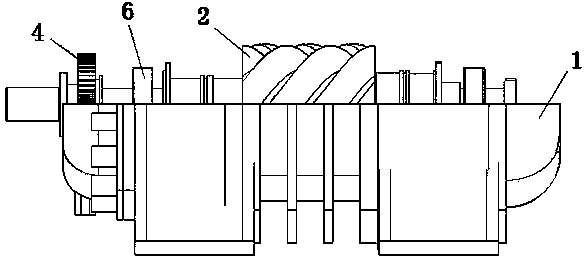

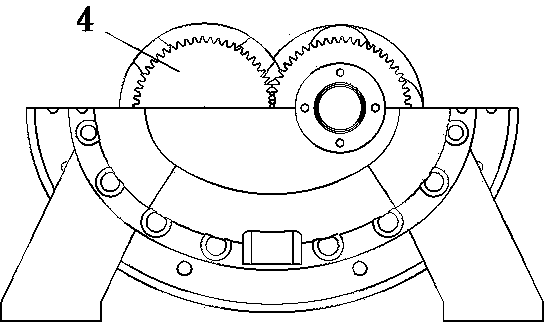

[0016] refer to Figure 1-Figure 4 As shown, a new type of water-sprayed screw air compressor includes a housing 1, a screw rotor, a synchronous gear 4, a bearing 5 and a shaft seal 6, and one side of the housing 1 is provided with an air inlet end and an air suction end, The left side is the intake end, and the right side is the suction end. The screw rotor includes a female rotor 3 and a male rotor 2. The female rotor 3 and the male rotor 2 are horizontally and parallelly arranged in the housing 1, and Supported on the bearing 5 at the intake end, the shaft seal 6 is located between the bearing 5 and the screw rotor. The shaft seal 6 prevents the lubricating oil of the bearing 5 from leaking into the housing 1 and the gas in the housing 1 from leaking outward. The synchronous gear 4 is located at the suction end of the housing 1 and is arranged on the screw rotor, between the female rotor 3 and the male rotor 2, between the outer circle of the screw rotor and the housing 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com