Plate chain slag remover bending angle limit protector

A technology of slag remover and protector, which is applied in the field of plate chain slag remover bending angle limit protector, can solve problems such as reducing the failure rate of slag remover, foreign matter jamming of plate chain slag remover, etc., and achieves improved slag removal Ability, height-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

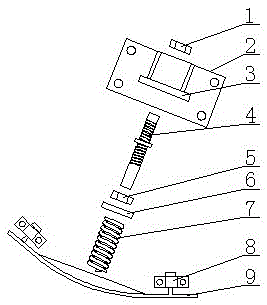

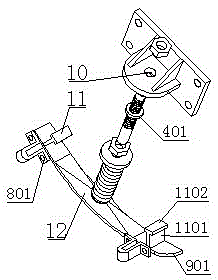

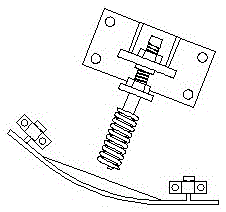

[0022] As shown in the figure, the angle limit protector of the plate chain slag remover includes an arc-shaped plate 9, and a positioning seat 2 for fixing to the side wall of the slag remover tank is arranged above the arc-shaped plate 9. The positioning seat 2 is provided with a positioning plate 3 with a bolt hole 10, the bottom of the positioning plate 3 is provided with a stud bolt rod 4 whose top passes through the bolt hole 10 and is connected and fixed with the positioning plate 3 by a lock nut 1, The middle part of the stud bolt rod 4 is provided with a positioning table 401 which is in close contact with the lower surface of the positioning plate 3, and the lower part of the stud bolt rod 4 is sequentially set with an adjusting nut 5, a catch 6 and a return spring 7, and the arc plate The upper surface of 9 is provided with a support seat 12 and a groove 13 is provided at the center of the support seat 12, the lower end of the return spring 7 is inserted into the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com