A feeding device for making schist-like materials

A similar material and cutting technology, applied in the field of geotechnical engineering, can solve the problems of directional arrangement of flaky minerals without obvious layer thickness and inability to manufacture, and achieve the effect of great flexibility and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

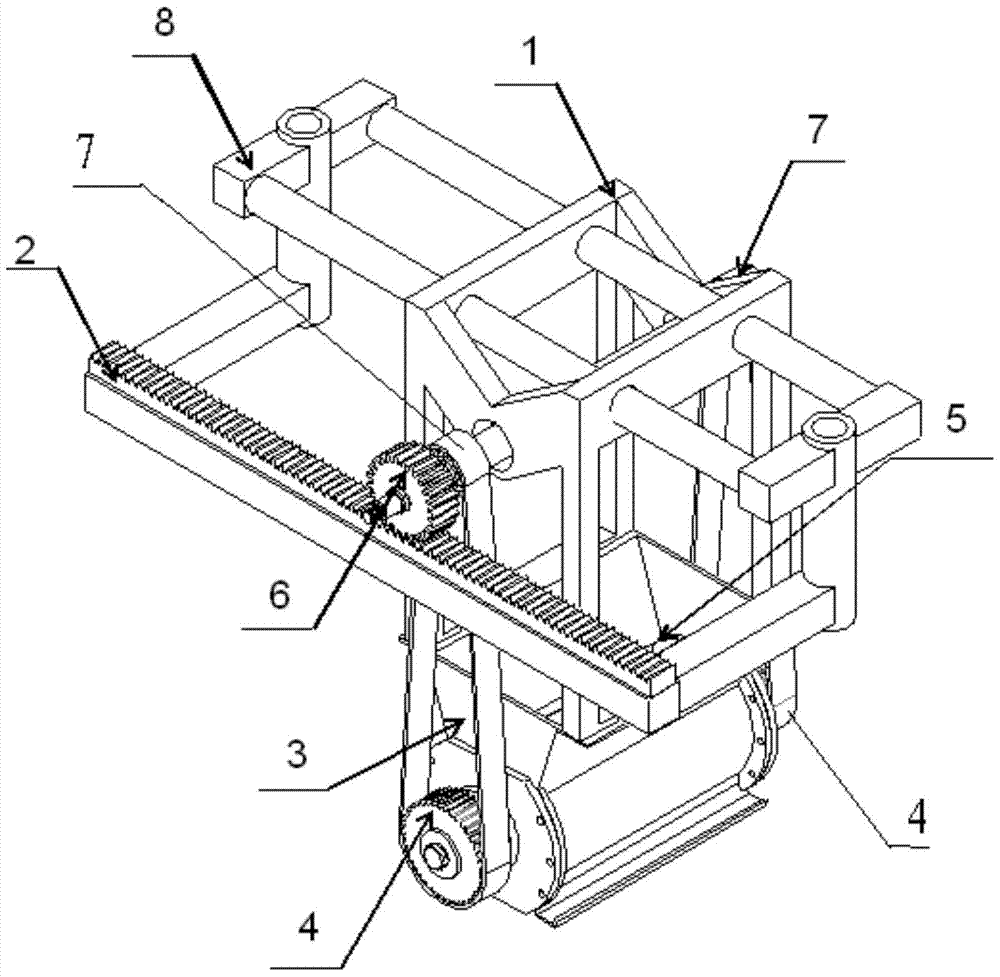

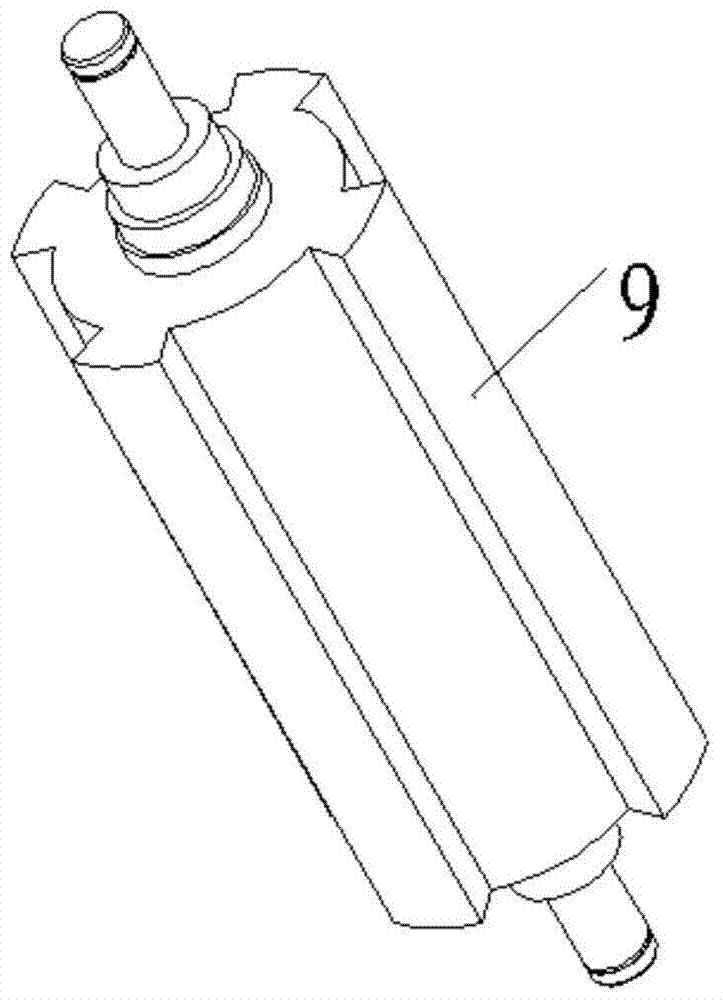

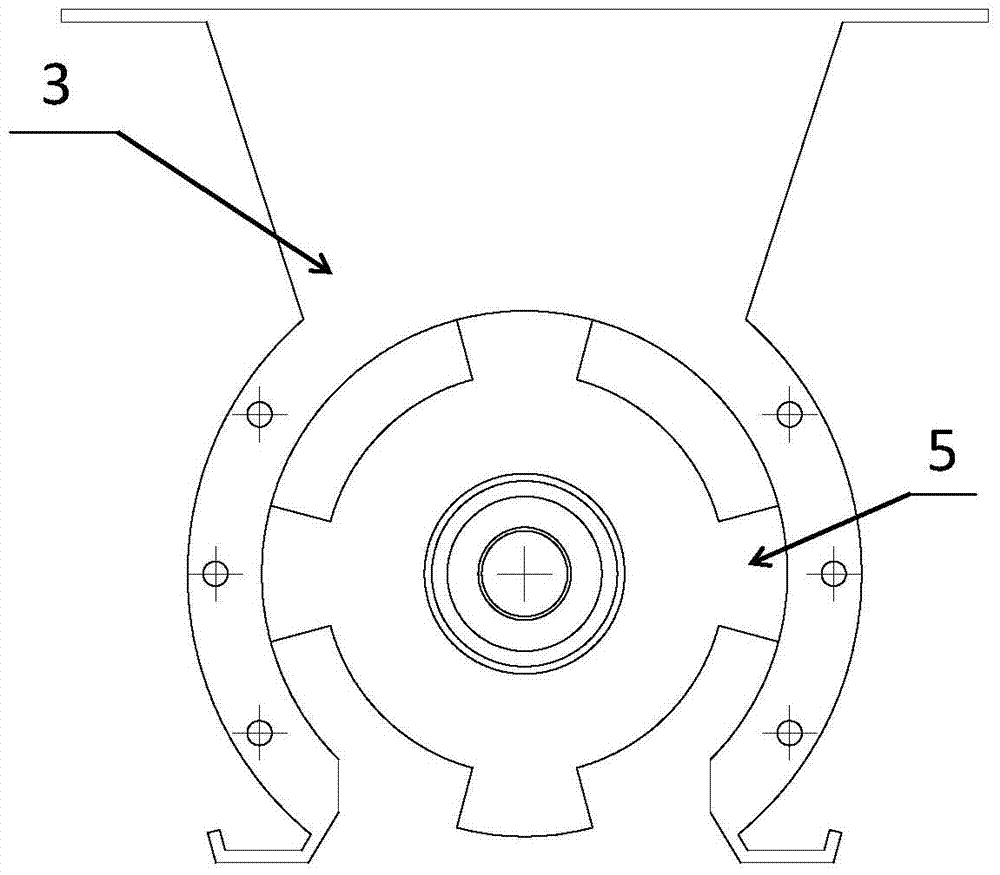

[0026] like figure 1 As shown, a blanking device for making schist-like materials of the present invention includes a gear bracket 1, a sliding bracket 8, a transmission system and a blanking system of the blanking device, and the transmission system is composed of a gear track 2 and a power synchronous wheel 4 at the discharge port. , power gear 6, support transmission synchronous wheel 7, and the blanking system is composed of hopper 3 and discharge port impeller 5. like figure 1 As shown, the power gear 6 and the support transmission synchronous wheel 7 are connected by the first rotating shaft, and the direction of rotation is consistent. It is connected with the support transmission synchronous wheel 7 by a synchronous belt to ensure that the direction of rotation is consistent, and the power synchronous wheel 4 of the discharge port and the impeller 5 of the discharge port transmit power through bearings. There are two power synchronous wheels 4 at the discharge port a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com