Electronic cigarette atomizer

A technology of electronic cigarette atomizer and atomization components, which is applied in the direction of tobacco, smoker's supplies, applications, etc., which can solve the problems of easy burning support seat, full contact of airflow, and bad smoking experience, so as to avoid burnt smell and deformation Or collapse, improve the effect of smoking taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing:

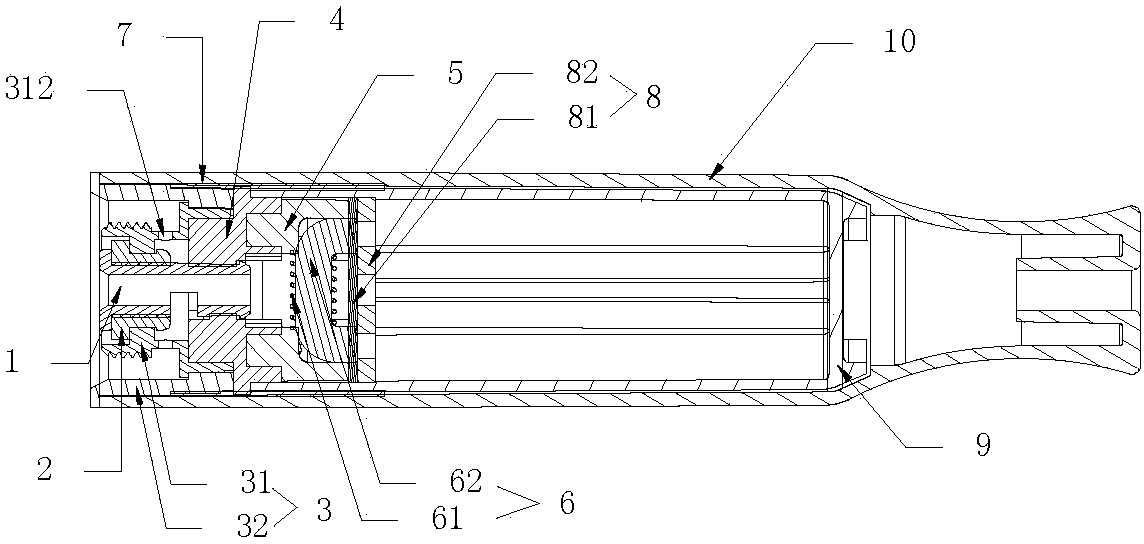

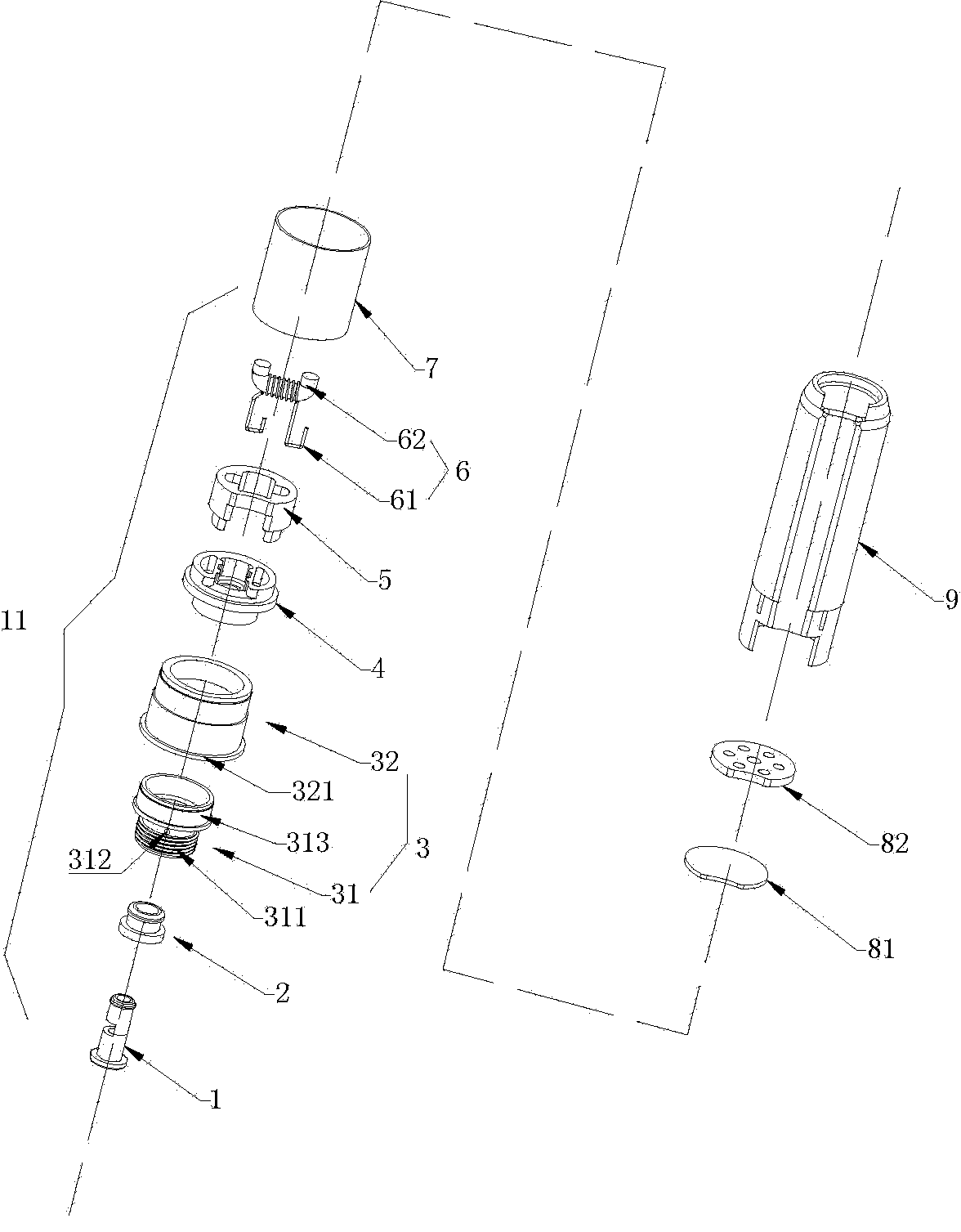

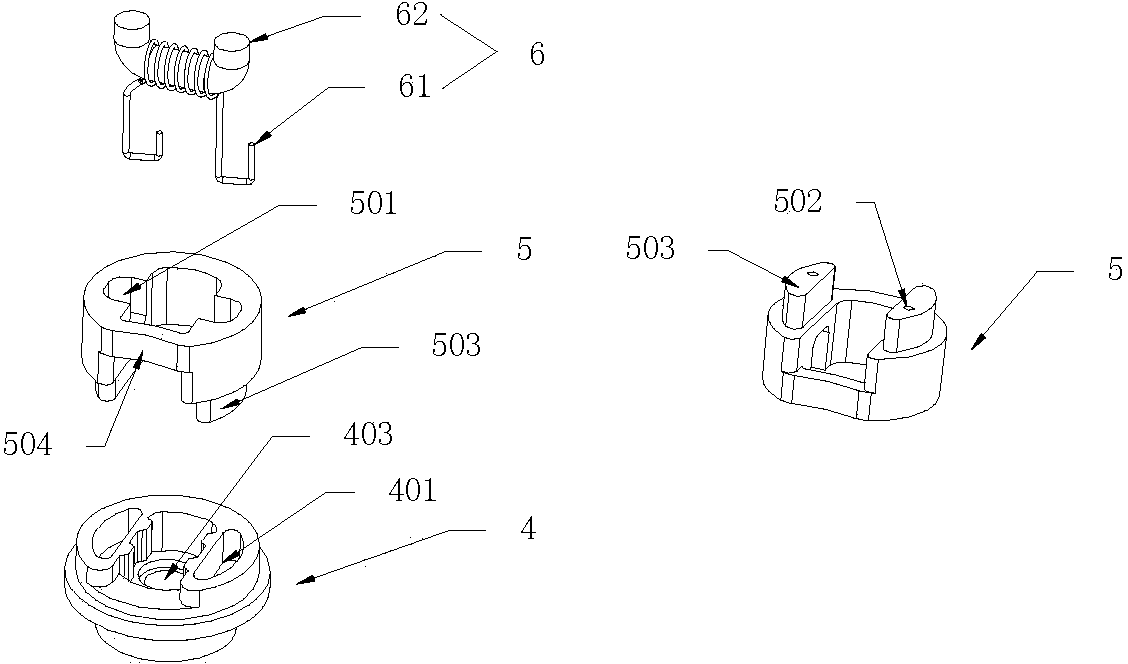

[0024] Figure 1 to Figure 5 A first embodiment of the invention is shown.

[0025] see figure 1 , 2 As shown, the electronic cigarette atomizer includes an outer casing 10, an atomization assembly 11 sequentially set in the outer casing 10, a filter sheet 81, a liquid seepage sheet 82, and a liquid storage cup 9. The atomization assembly 11 includes one end connected to the The battery rod is detachably connected to a conductive connection seat 3, a tubular electrode 1 arranged in the center of the connection seat 3, an insulating sleeve 2 arranged between the connection seat 3 and the tubular electrode 1, and a fixed seat 4 connected to the connection seat 3 , a support seat 5 connected to the fixed seat 4 and made of high-temperature-resistant hard insulating material, an atomizing unit that is overhead in the support seat 5 and consists of a liquid guide 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com