Connector Assemblies for Swing Training Equipment

A technology of connector components and training equipment, which is applied in the connection structure field of swing trainers, can solve the problems of inability to realize 360-degree swing, large spring swing range, and high spring cost, and achieve convenient and reliable assembly process, small swing range, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

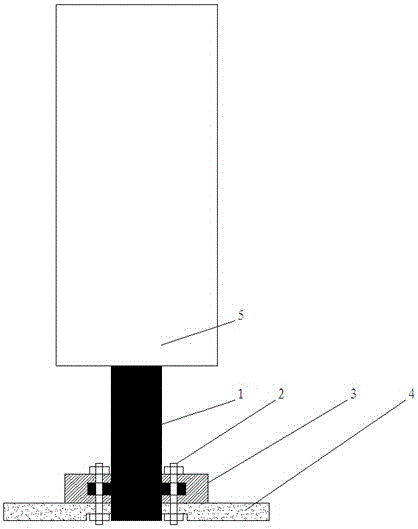

[0035] The present invention is illustrated by taking a sandbag trainer as an embodiment.

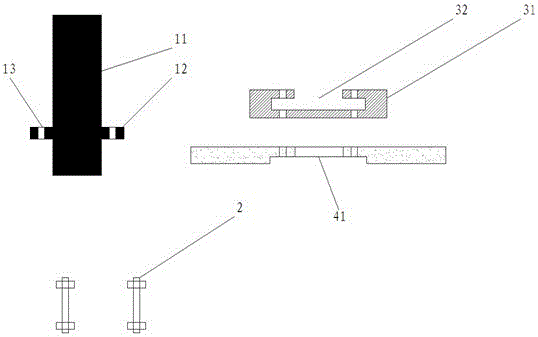

[0036] Such as figure 1 As shown, the connector assembly used for swing training equipment includes an iron pipe, and the iron pipe 1 includes a pipe body 11. A ring of bosses 12 extend horizontally from the surface of the pipe body 11, and a ring of bosses 12 are formed on the boss 12 There are bolt holes 13;

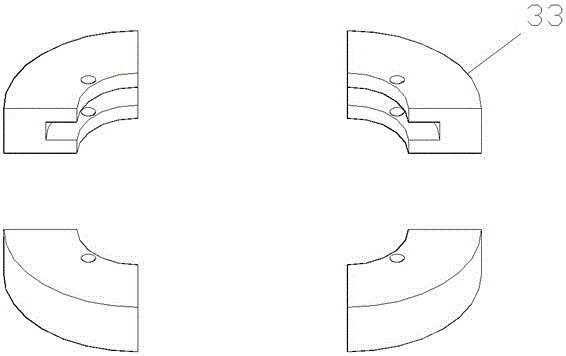

[0037] Also includes a connector 3, the connector 3 includes a synthetic body 31, the material composition of the synthetic body 31 includes plastics and / or rubber; the synthetic body 31 is provided with a through hole corresponding to the bolt hole 13 of the boss; the synthetic body The center of 31 is provided with an assembly hole 32 for limiting the iron pipe 1, and the assembly hole 32 includes a groove for accommodating the boss 12 of the iron pipe;

[0038] It also includes a base 4, and the base 4 is provided with an installation through hole corresponding to the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com