Creasing-free stamping die for manufacturing U-shaped stainless steel plates

A stamping die and stainless steel technology, applied in the field of sheet metal dies, can solve problems such as unsatisfactory product appearance quality, and achieve the effect of improving appearance quality and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

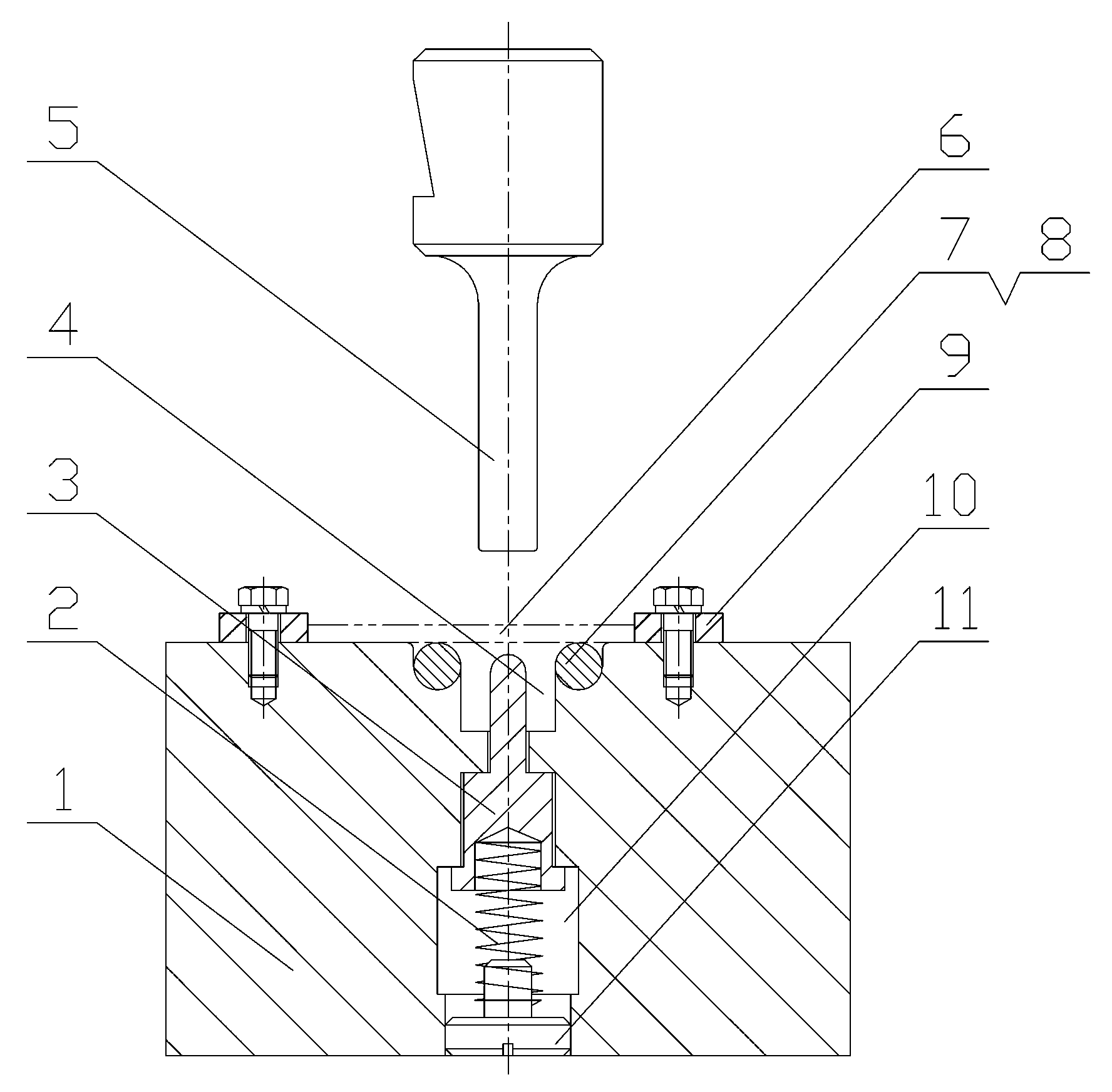

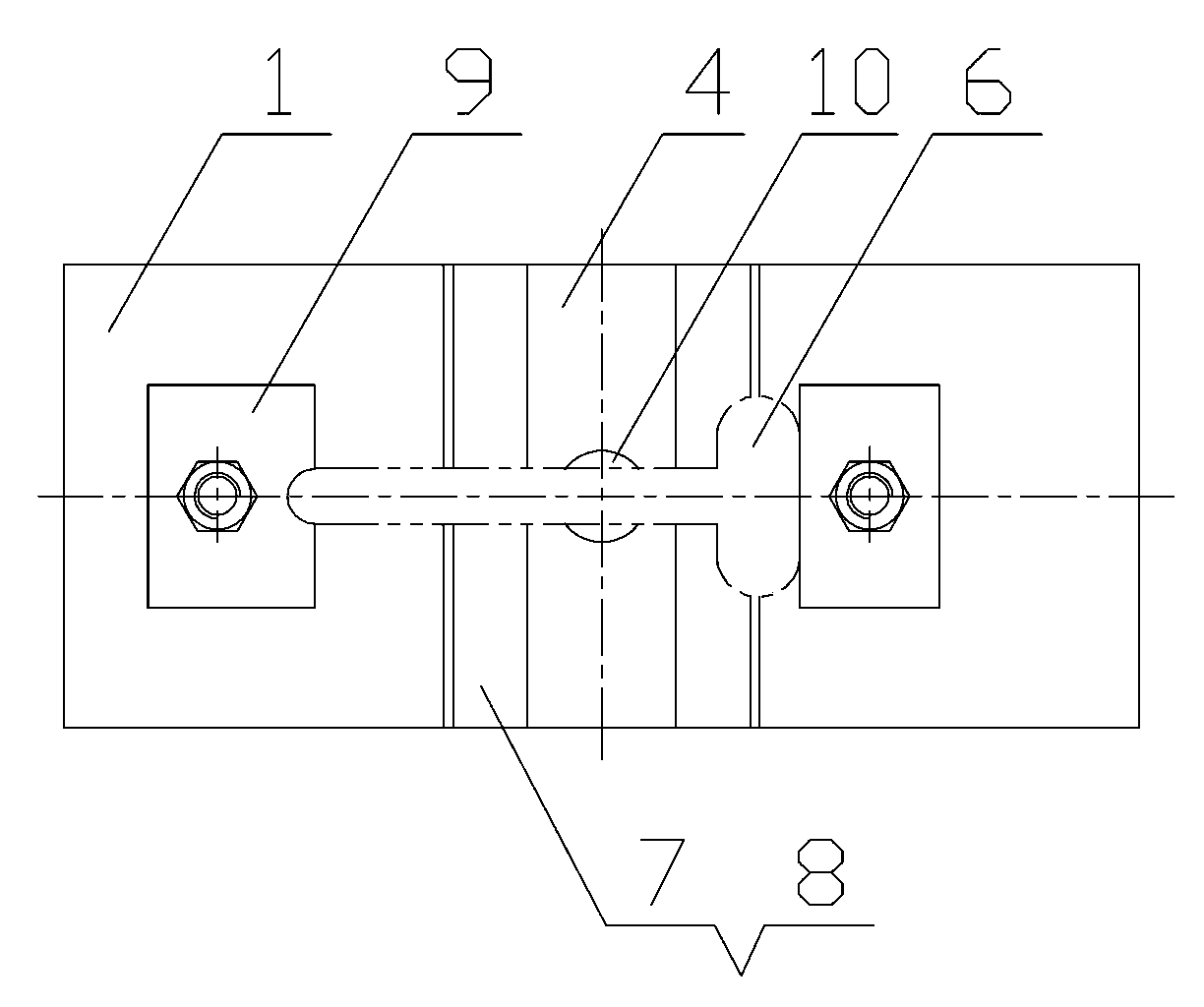

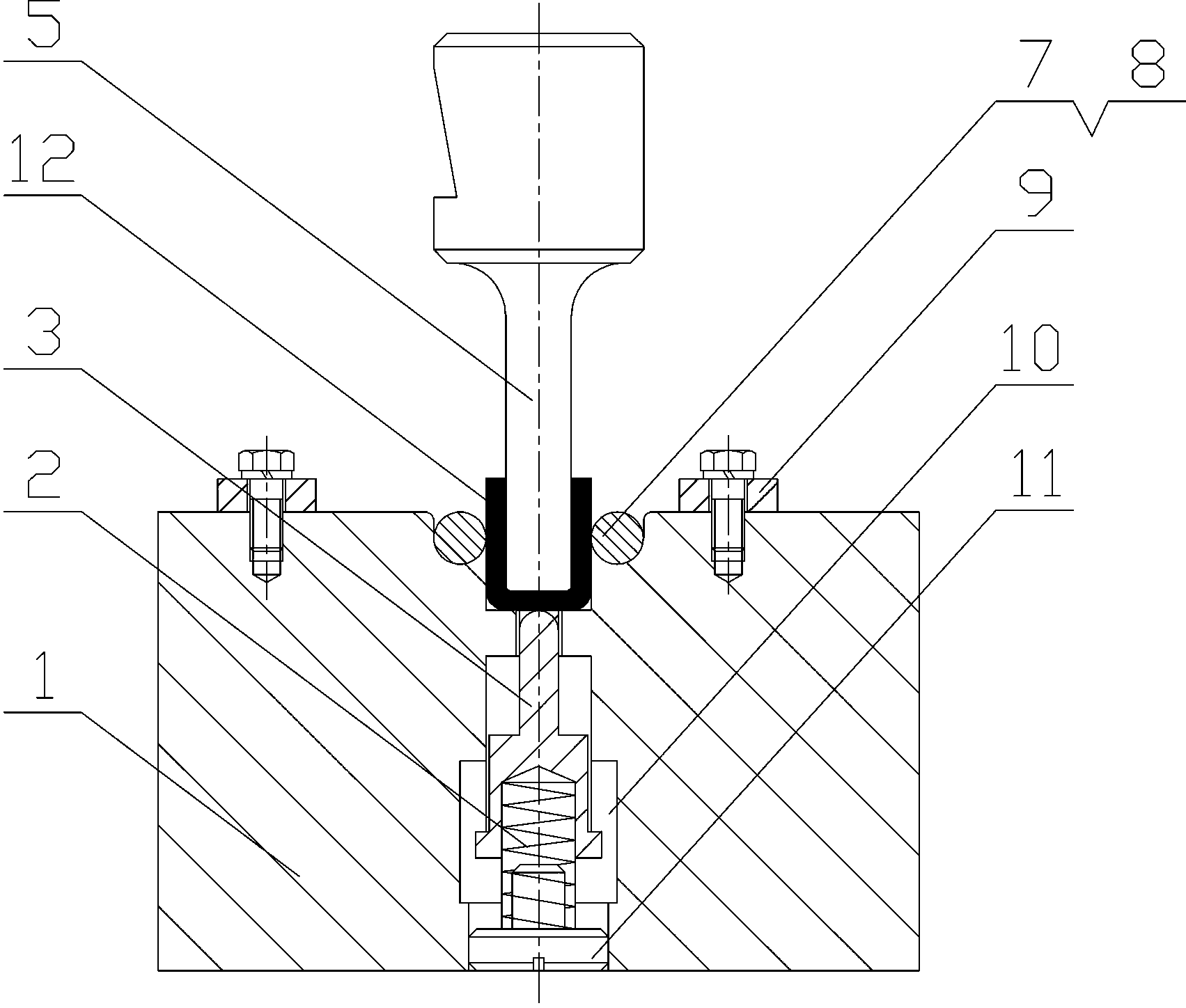

[0011] see figure 1 , figure 2 with image 3 , the present invention has upper mold 5 and lower mold 1 arranged oppositely, and mold cavity 4 is arranged in lower mold 1, and the bottom of mold cavity 4 is located in lower mold 1 and is provided with installation hole 10, and the installation hole 10 is equipped with and stretches into mold cavity 4 The top piece device, the left and right sides of the top of the lower mold 1 are equipped with adjustable positioning plates 9. The present invention all has semicircular groove 7 at the top of the left and right side walls of cavity 4, and rolling bar 8 is equipped with rolling in semicircular groove 7, and the inner surface of two rolling bars 8 is flush with the left and right side walls of cavity 4.

[0012] The ejector in this embodiment includes an adjusting screw 11 threadedly connected with the mounting hole 10 of the lower mold 1 and a top sleeve 3 whose head extends into the cavity 4, and a compression screw is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com