Elastic compressing mechanism

A technology of elastic pressing and cohesion, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of poor universality of elastic pressing mechanism, no buffer function, complex structure, etc., and achieves small shape, low production cost, and processing. Create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

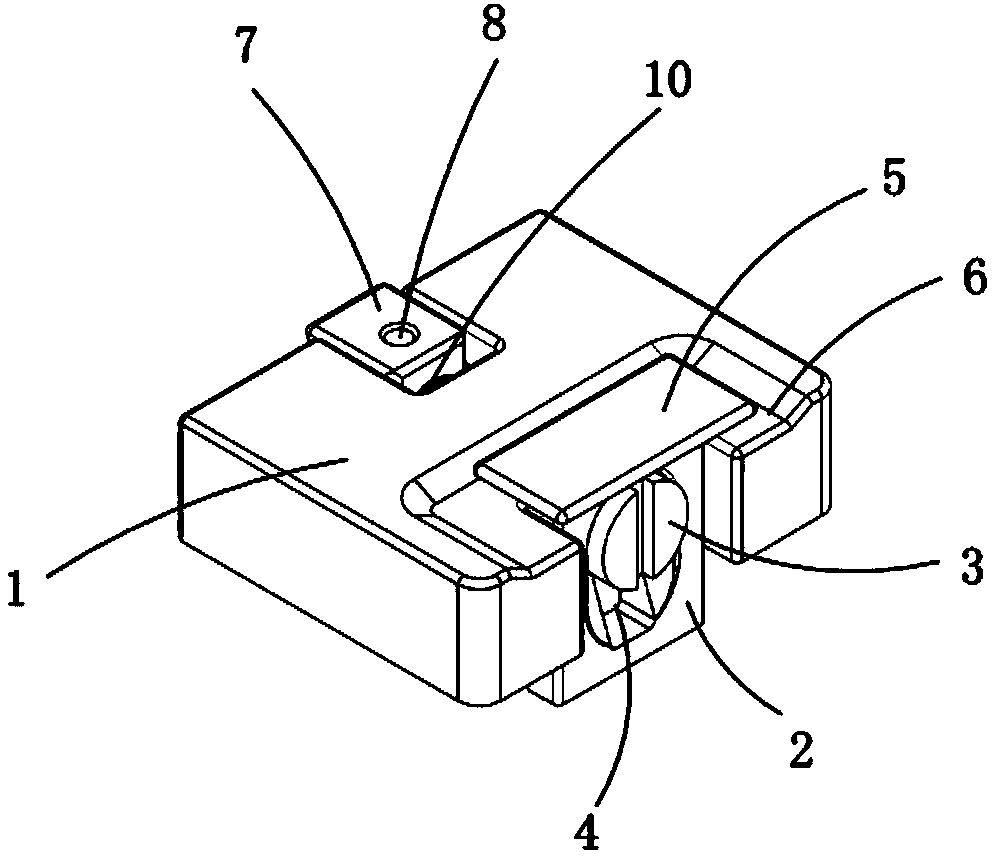

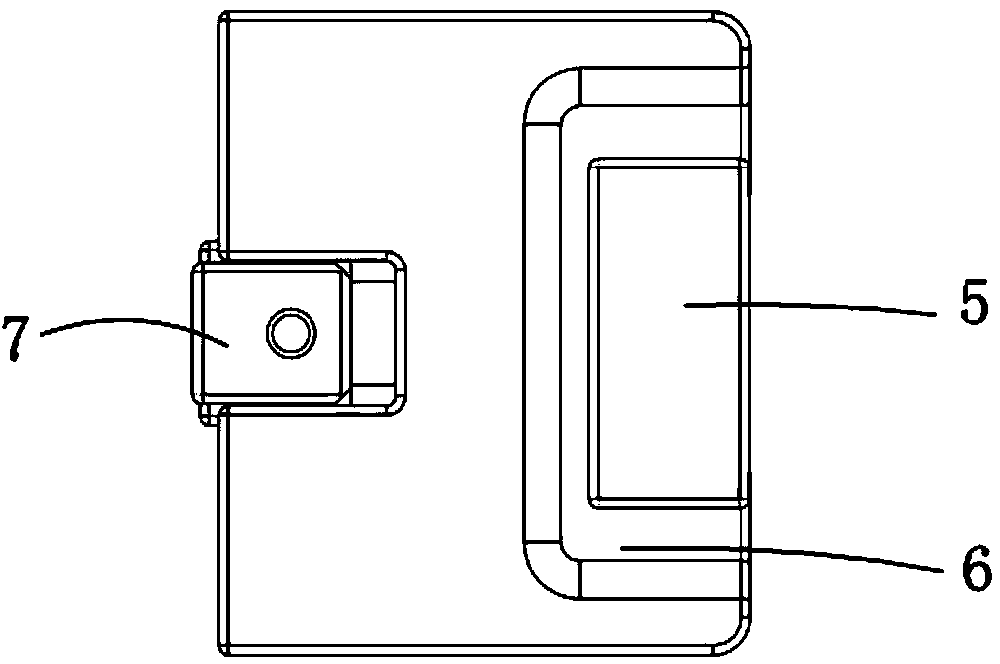

[0021] Examples, see attached Figure 1~6 , an elastic pressing mechanism, including a fixed seat 1, and also includes a handle 2 and a push rod 3, a racetrack-shaped through hole 4 is provided on the handle, and internal helical teeth are arranged in the race-track-shaped through hole, and the push rod is There are external helical teeth, and the pull handle and the ejector rod are movably connected together through the mutual meshing of the internal helical teeth and the external helical teeth.

[0022] The fixing seat is fixed on the jig or the equipment panel by means of screw connection, which facilitates the fixing of the whole mechanism.

[0023] The upper end of the pull handle is connected to a carrier board 5, and a groove 6 is provided on the fixing seat at the carrier board to facilitate manual operation of the carrier board.

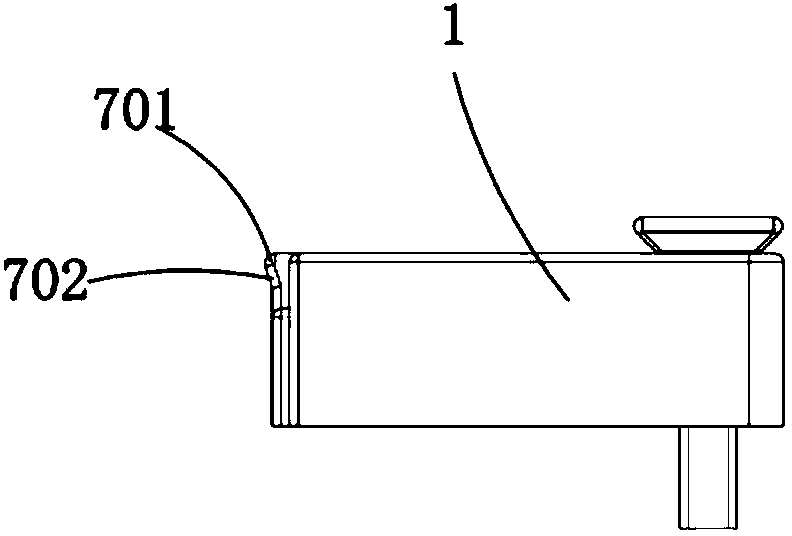

[0024] The ejector rod passes through the fixed seat, and the left end of the ejector rod is connected with a jacking block 7, the ejector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com