Patents

Literature

32results about How to "The transmission structure is simple and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

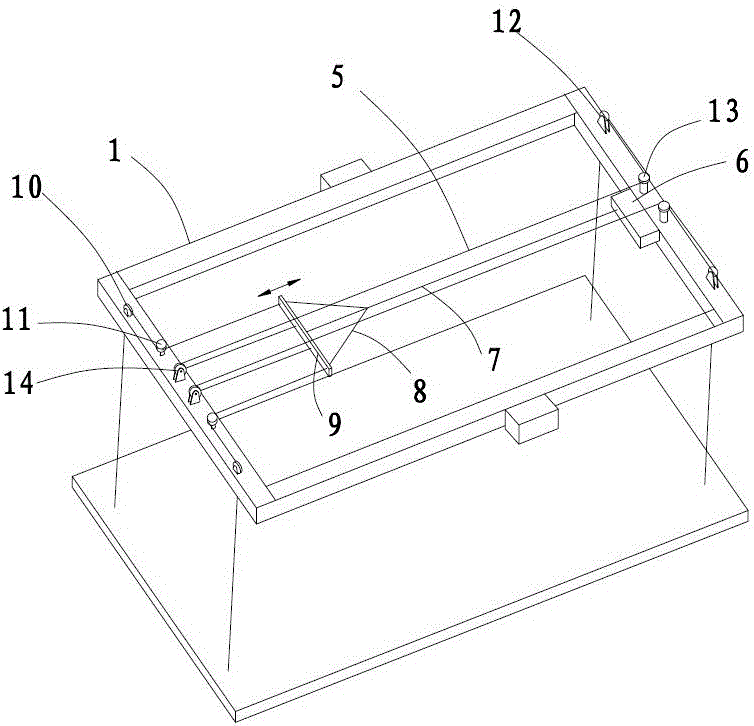

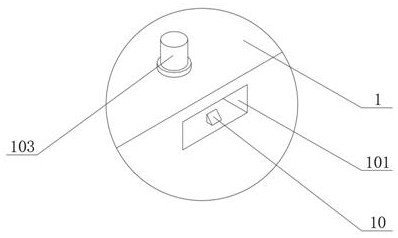

Ceiling type lifting bed for monitoring sleep state

InactiveCN105877273AMonitor Sleep HabitsAvoid damageStuffed mattressesSpring mattressesSleep stateEngineering

The invention relates to a ceiling type lifting bed for monitoring the sleep state and solves the problems that a sensor structure arranged in a bed body is easily damaged when pressed. The lifting bed comprises a top frame, wherein a bed body is suspended below the top frame. The lifting bed is characterized in that a horizontal pressure induction layer is embedded between an upper surface and a lower surface of the bed body and comprises air bags uniformly arranged on the bed body, wherein each air bag adopts a double-layer bag body and is divided into upper bag body and lower bag body which are mutually independent by a horizontal elastic interlayer, the upper bag body is filled with a powdery spray material with an indicating color, and a pressure sensor is arranged in the lower bag body; a pressure-buffering communicating pipe is arranged between upper bag bodies of the adjacent air bags, and the lower bag bodies are independently arranged. The pressure induction layer formed by the air bags is arranged on the bed body, the sleeping habit of a human body can be monitored, each air bag is divided into an upper bag body and a lower bag body, the upper bag bodies are interconnected through pressure-buffering communicating pipes for a deferred reaction, and the condition that the air bags are damaged due to excessive local pressing is avoided.

Owner:ZHEJIANG UNIV

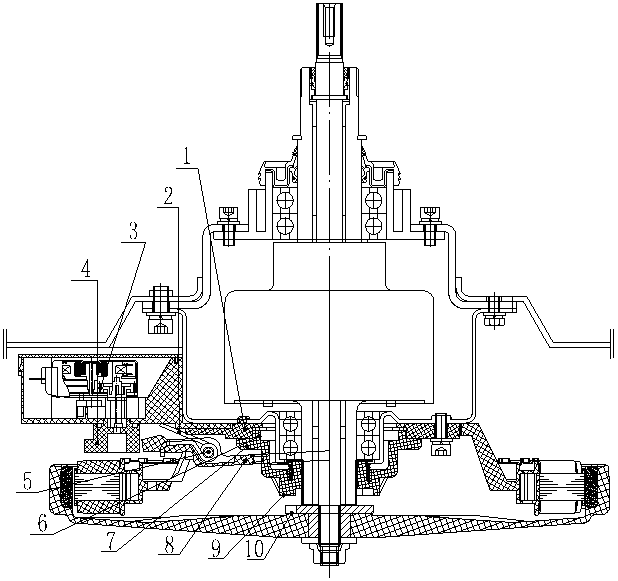

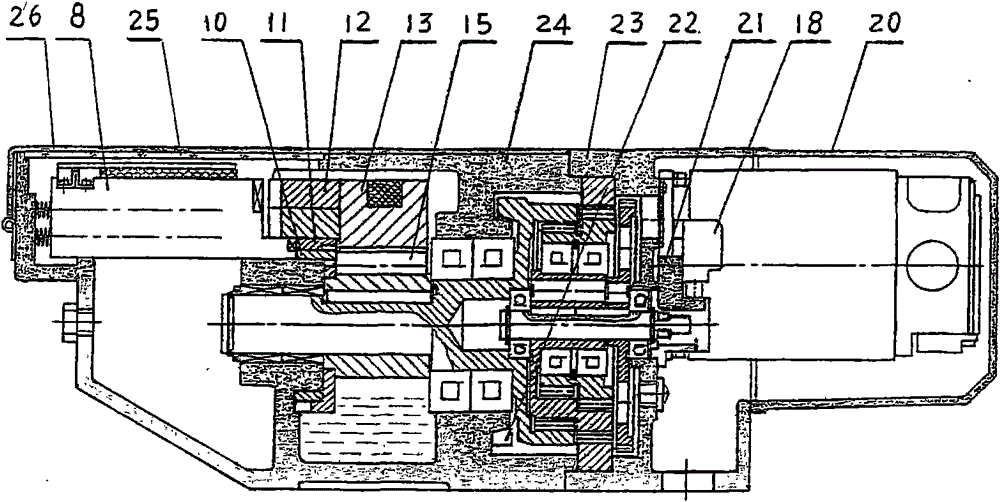

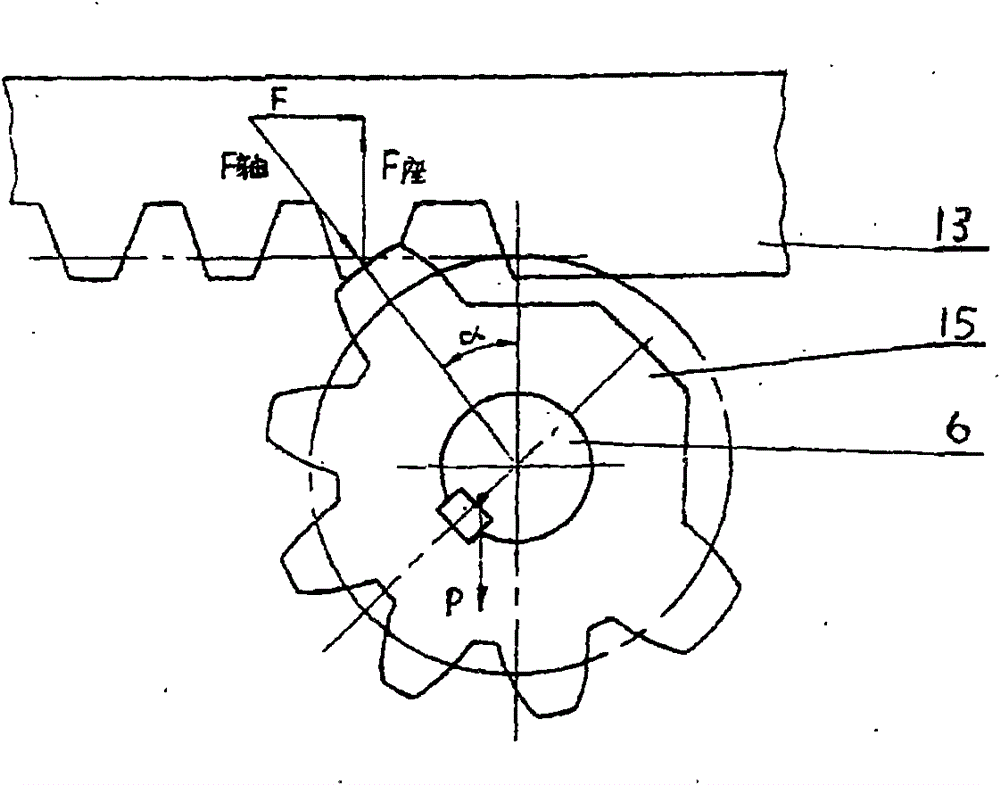

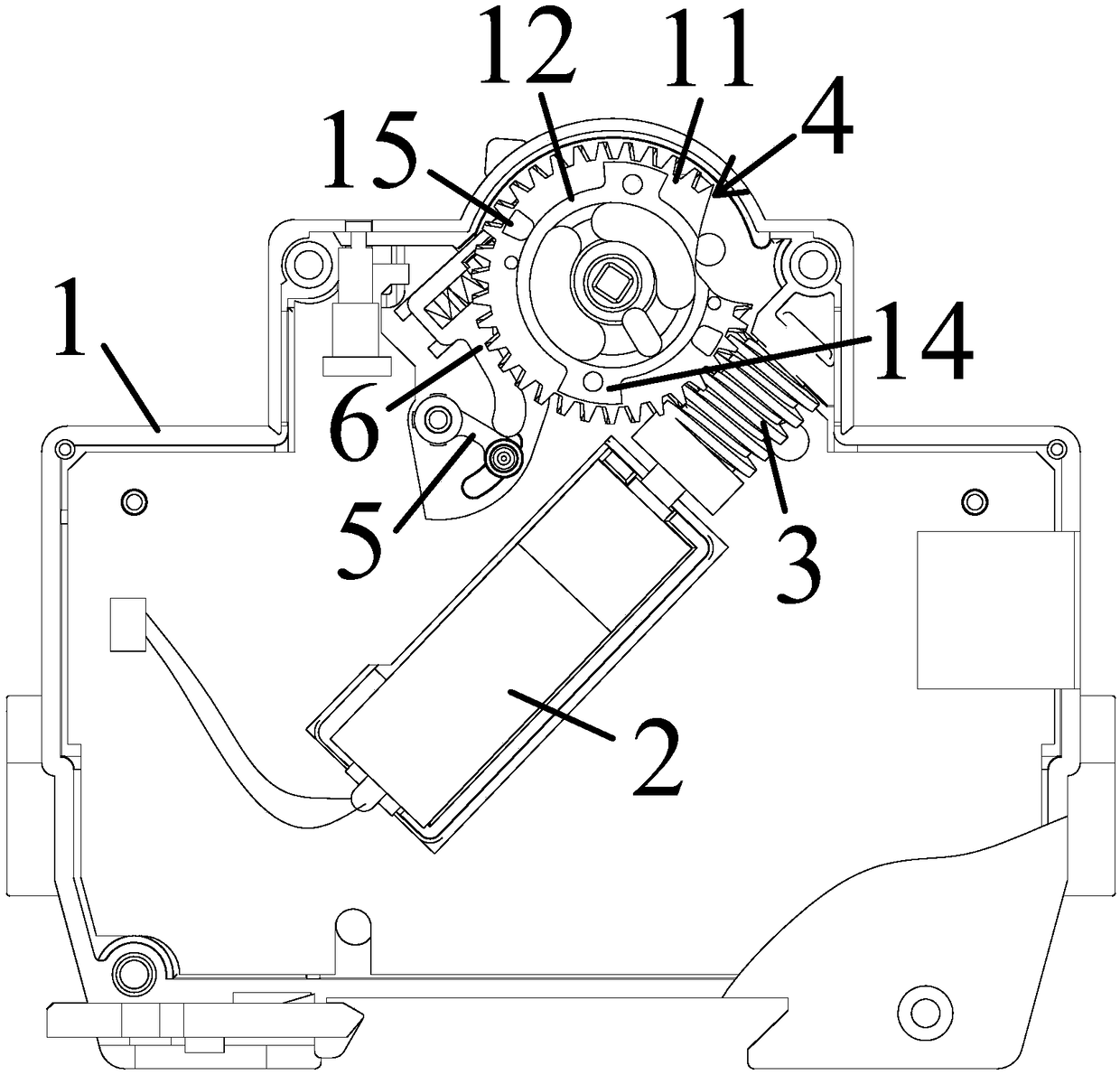

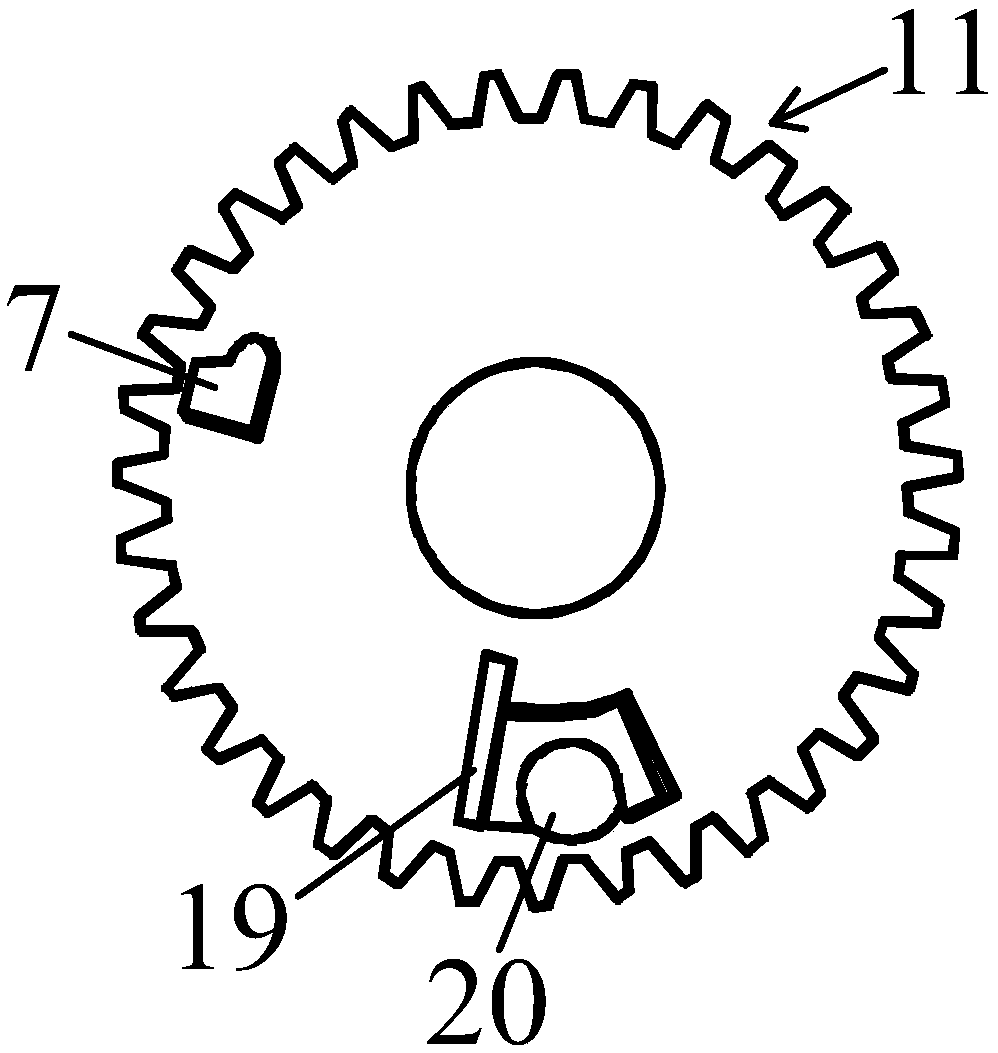

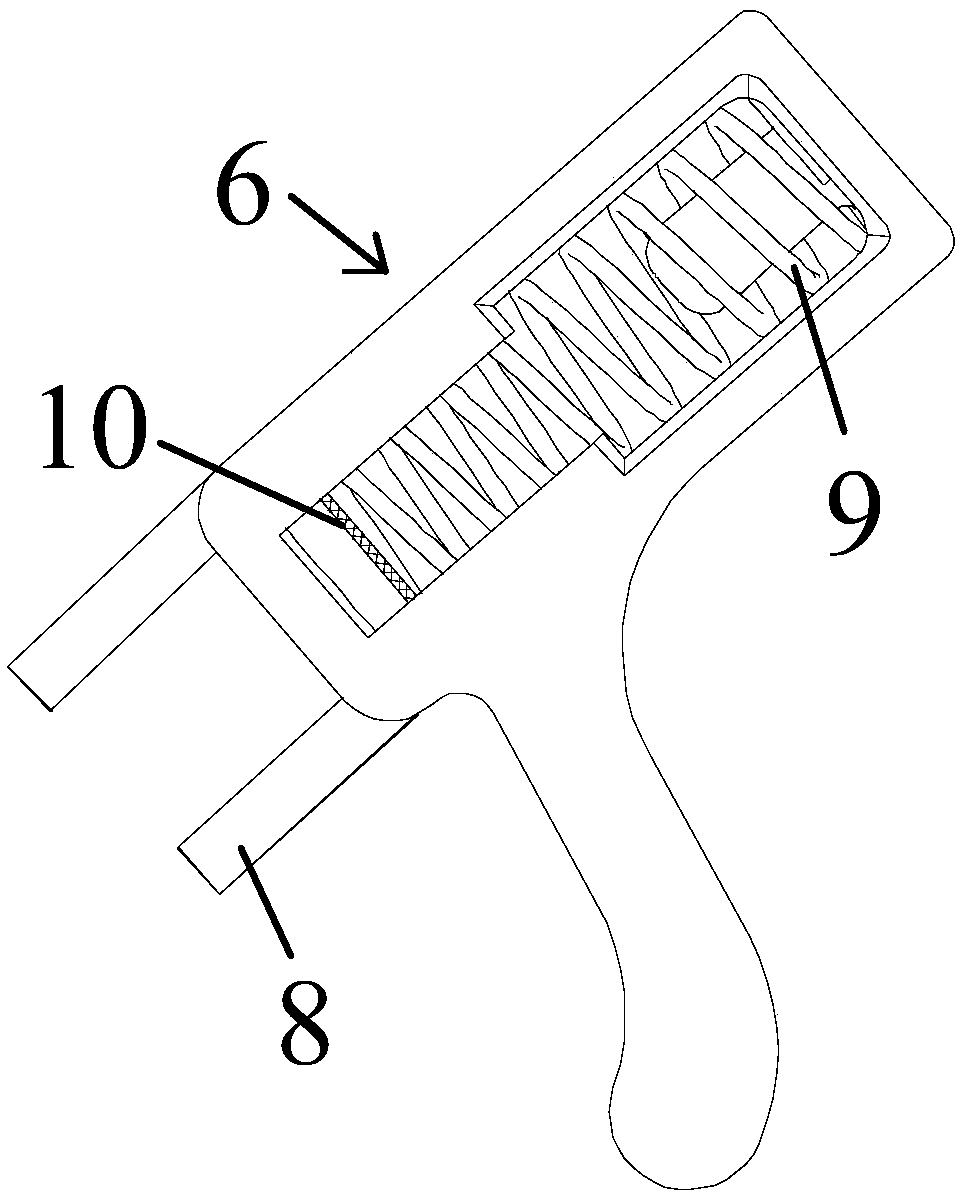

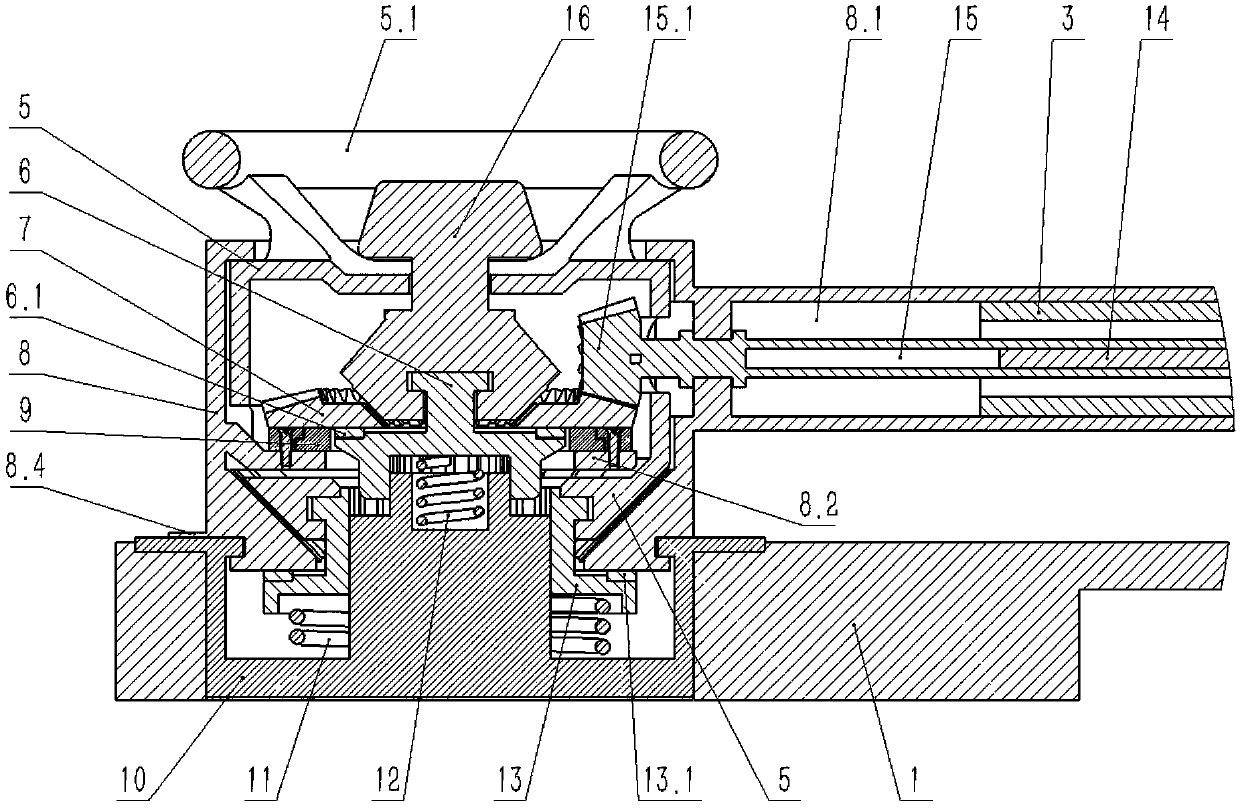

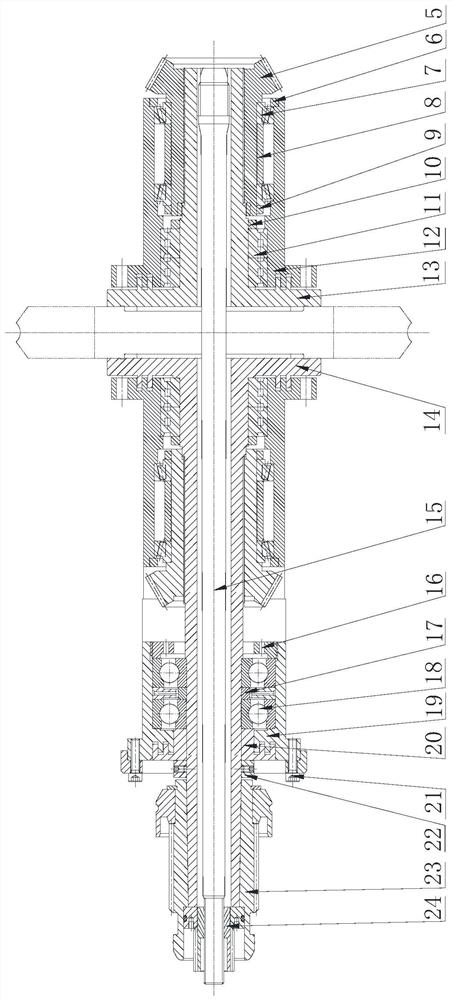

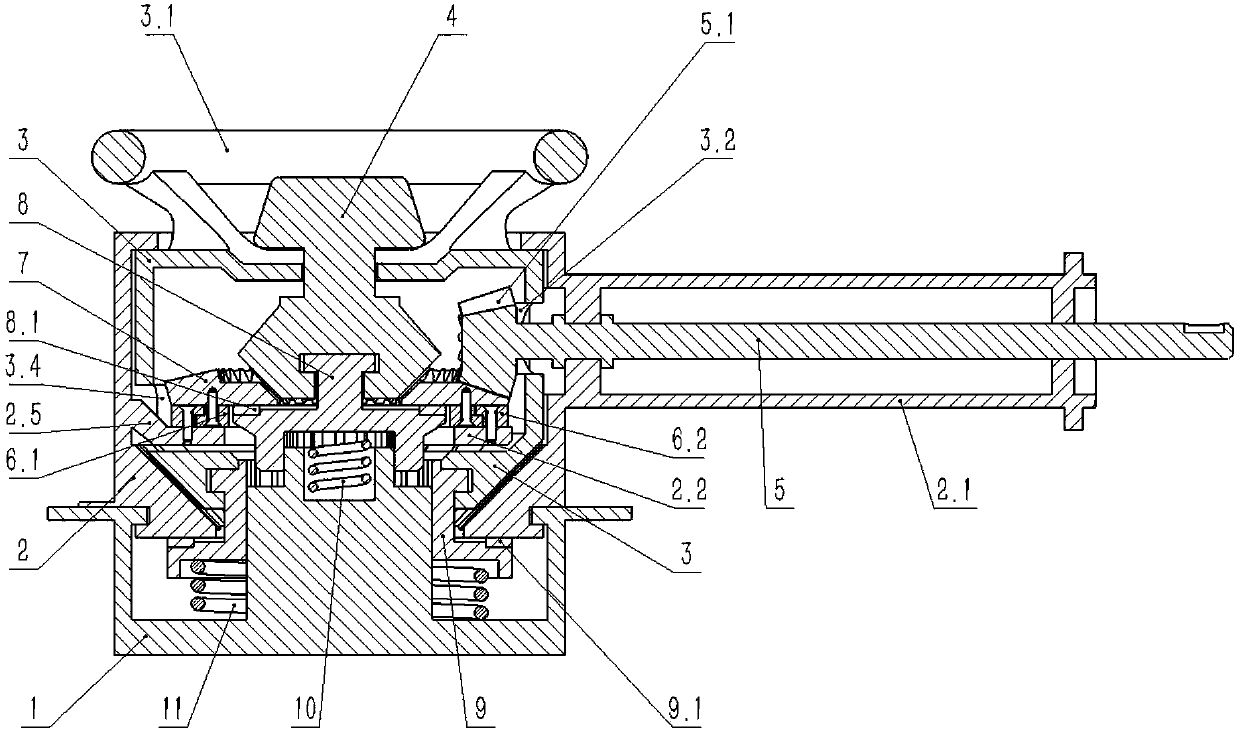

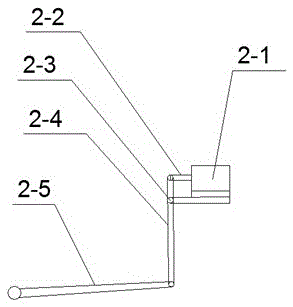

Mechanical clutch device for deceleration clutch of washing machine

InactiveCN104878564BThe transmission structure is simple and reliableReduce impact soundOther washing machinesTextiles and paperSynchronous motorElectric machinery

The invention discloses a mechanical clutch device for a deceleration clutch of a washing machine, relates to the technical field of washing machines, and overcomes the defects that the conventional washing machine clutch adopting the meshing clutch method is more complex in transmission structure, and is not energy-saving, and is high in impacting noise. The device comprises a sliding block, and is characterized in that the sliding block is mounted on the lower shaft sleeve of the deceleration clutch in an up-and-down sliding manner through a spline; the sliding block is movably connected with one end of a shifting lever and is controlled by the shifting lever to slide vertically; the shifting lever is rotationally mounted on a shifting lever supporting rotating shaft in a sliding manner coaxially through a lifting lever restoration torsional spring; the other end of the shifting lever is movably connected with a crank; the crank and a synchronous motor are coaxially and fixedly connected to be mounted on the casing of the deceleration clutch; the upper end of the sliding block is clutched with a washing clutch plate while the lower end of the block is clutched with the a dewatering clutch gear; a slanting surface for driving the lifting lever to slide is arranged on the protruded side of the crank. According to the invention, the mechanical clutch device is simple and reliable in transmission structure, and low in meshing speed and is energy-saving, and the impacting noise during the gear meshing process can be effectively reduced.

Owner:NINGGUO JULONG IND

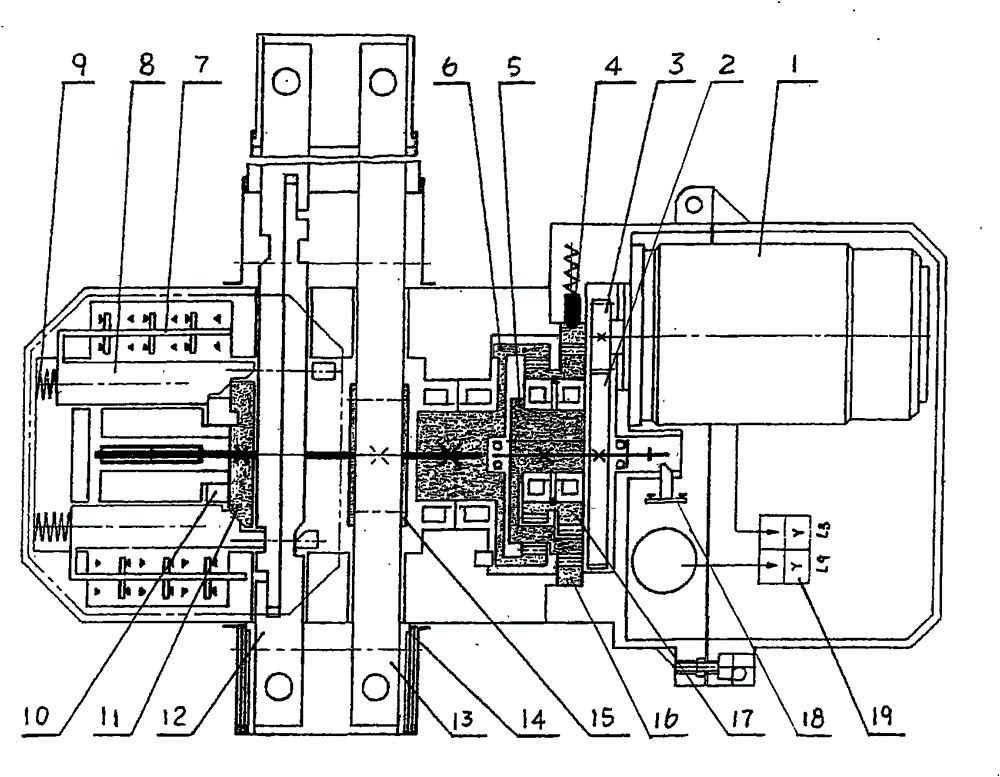

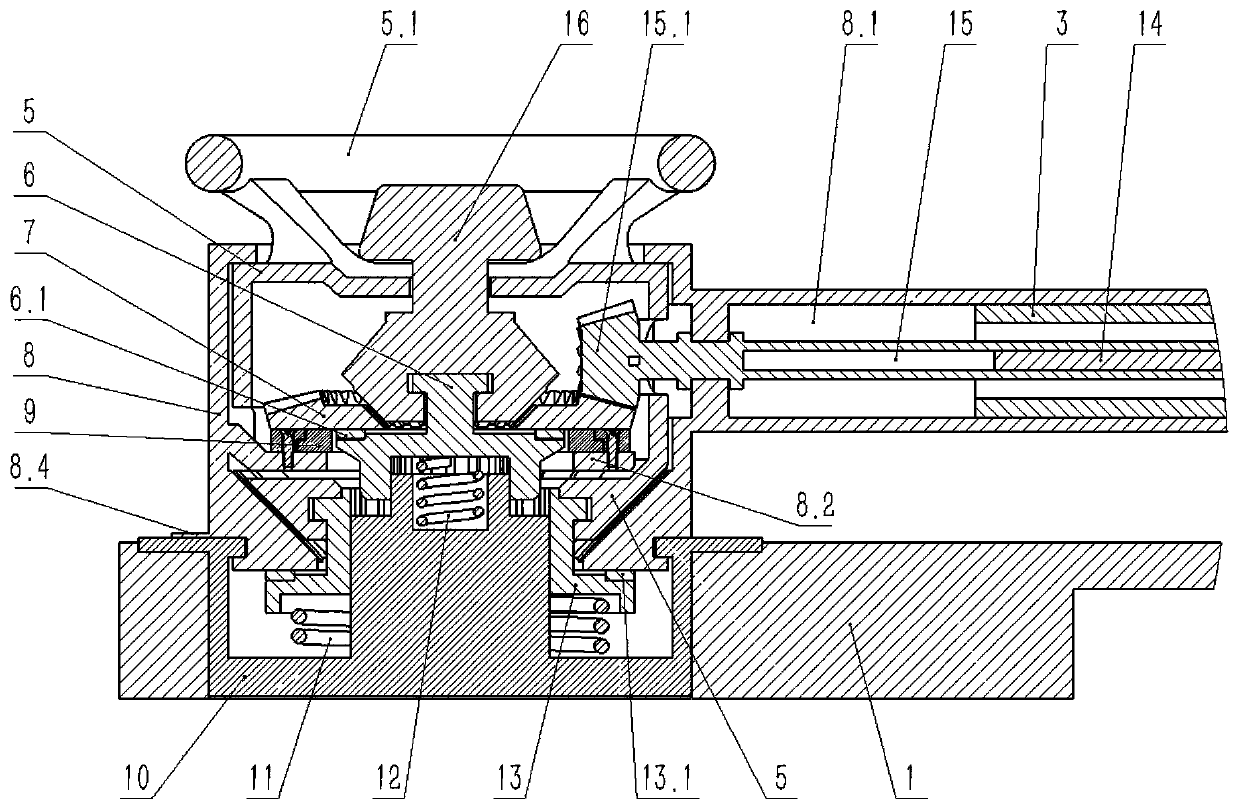

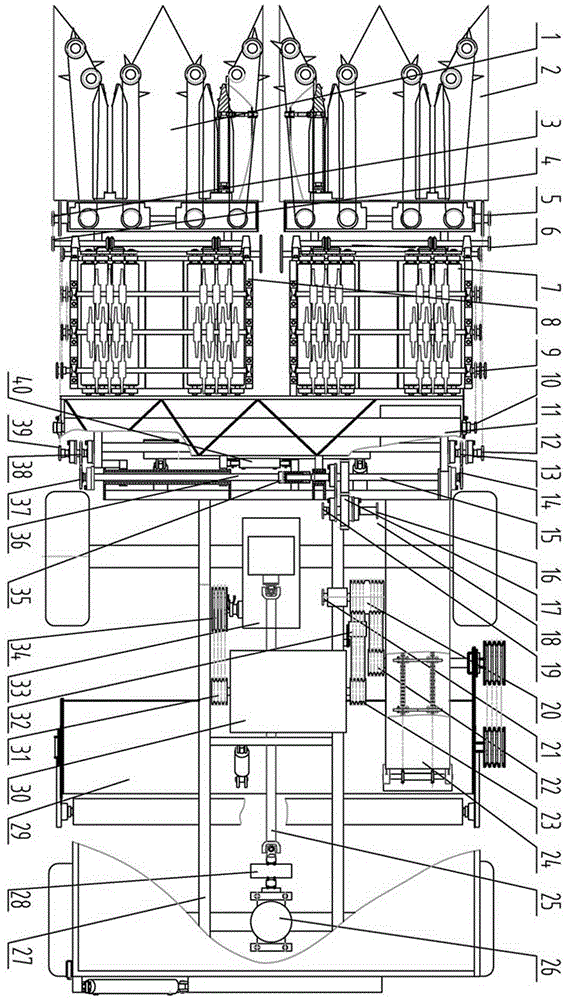

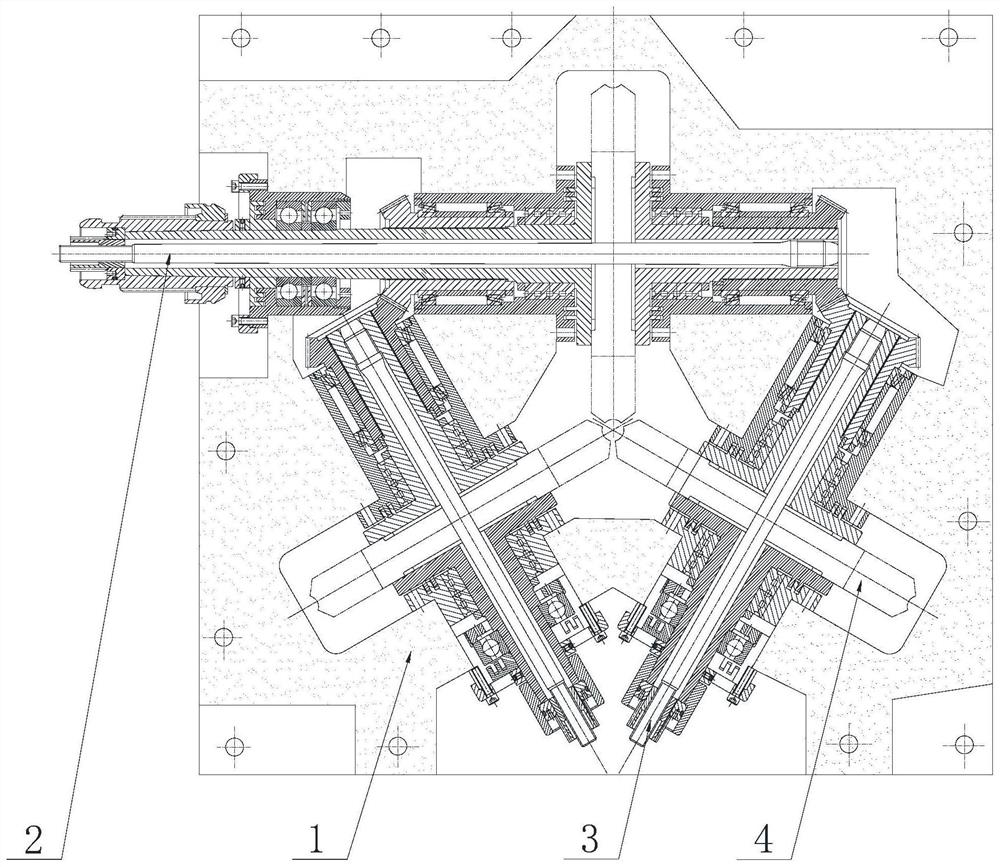

Industry and electricity integrated electric switch device with central locking polar integrated control unit

InactiveCN102745210AGreat locking strengthHigh strengthRail switchesElectric devices for scotch-blocksLow speedDifferential transmission

The invention relates to a railway industry and electricity integrated electric switch device with a central locking polar integrated control unit. A high-strength anti-retreating moving lock mechanism, an integrated visible lock checking expression mechanism, a closed oil immersion overload unloading double speed transmission mechanism, a double speed, rapid stopping and high-efficiency permanent magnet direct-current motor and the like are integrated to form a compact non-squeezable central locking electric switch machine, wherein the high-strength anti-retreating moving lock mechanism is composed of a ball iron box seat / a heavy-duty bearing / an upper rack moving lock rod / a short and thick tooth crest lock; a lock checking rod / a direct-acting contact expression switch / a four-head lock checking block / a spiral starting disk / an axial quick-acting ring which are flatly placed and connected by body separation form the integrated visible lock checking expression mechanism; the closed oil immersion overload unloading double speed transmission mechanism integrates a 2K-H displacement and variable level differential transmission shaft with multiple tooth differences and short teeth, a stopping output wheel shaft with an eccentric bushing hammer; the compact central locking electric switch machine which can not be squeezed, a lengthened rail brace slide plate ( base rail / switch tie) central multi-lug insulation hinge, a crank and straight linked arm and a linked switch rail and point rail form an industry and electricity integrated squeezable and non-squeezable unit by means of a zero-clearance sleeved elasticity group pin and a double-port microgap hinge, low speed turnout unitization of single opening and single action, double slip separated action, hump double action and the like is achieved, a intermediate speed and high speed turnout switch rail and a point rail are synchronous in sections and combined with combination unitization to form the safe, reliable, advanced, adjustment-free, protection-free and industry and electricity assembled power-driven turnout of the whole transmission and whole spreading central locking electrode control device.

Owner:孙志伟

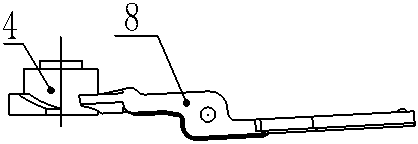

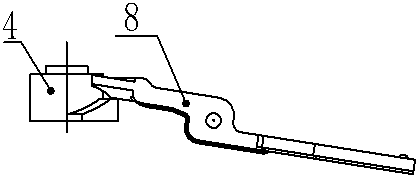

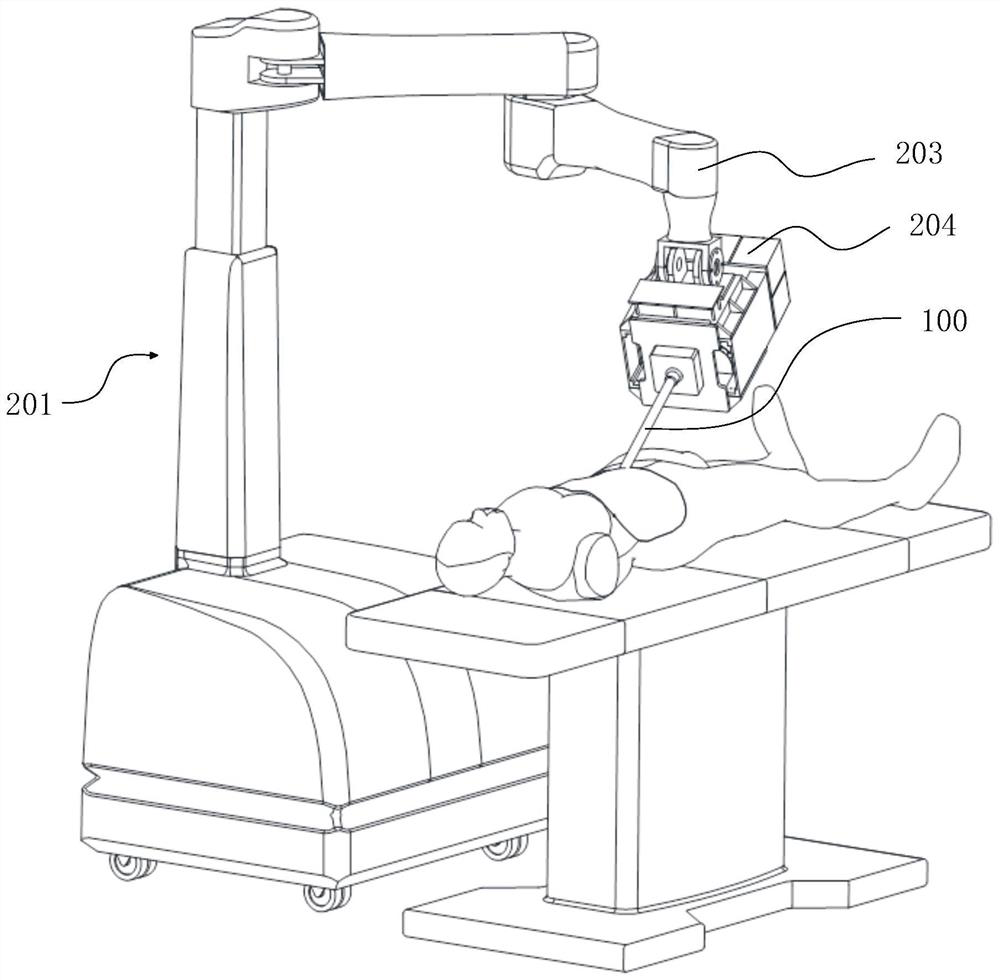

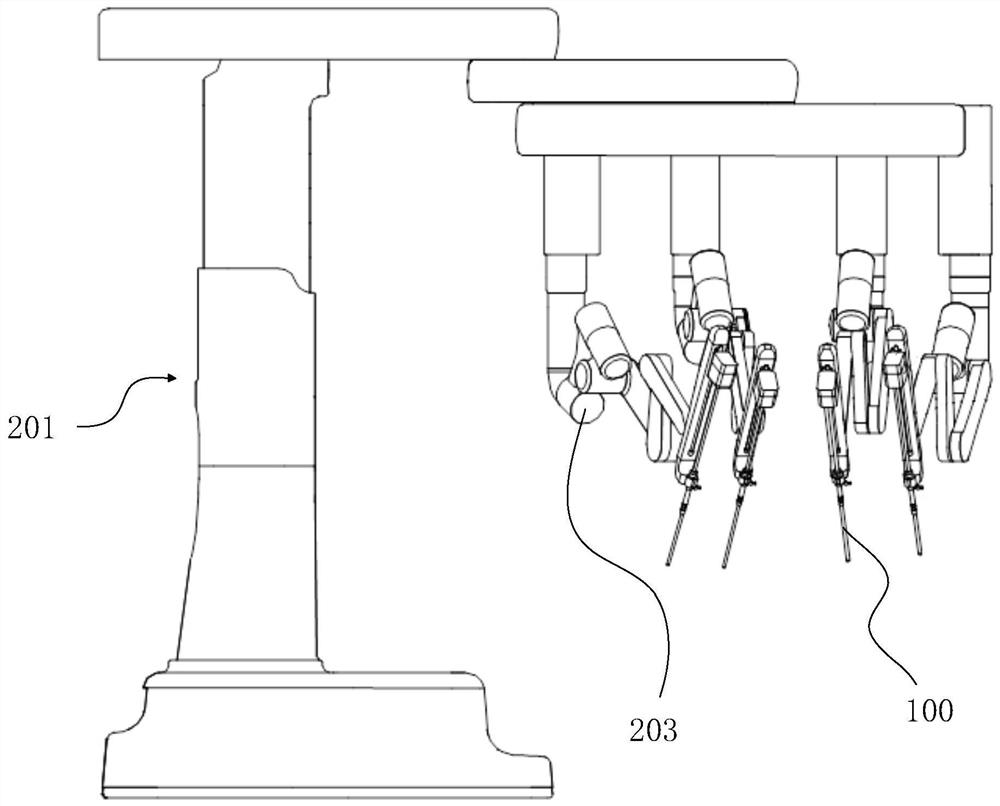

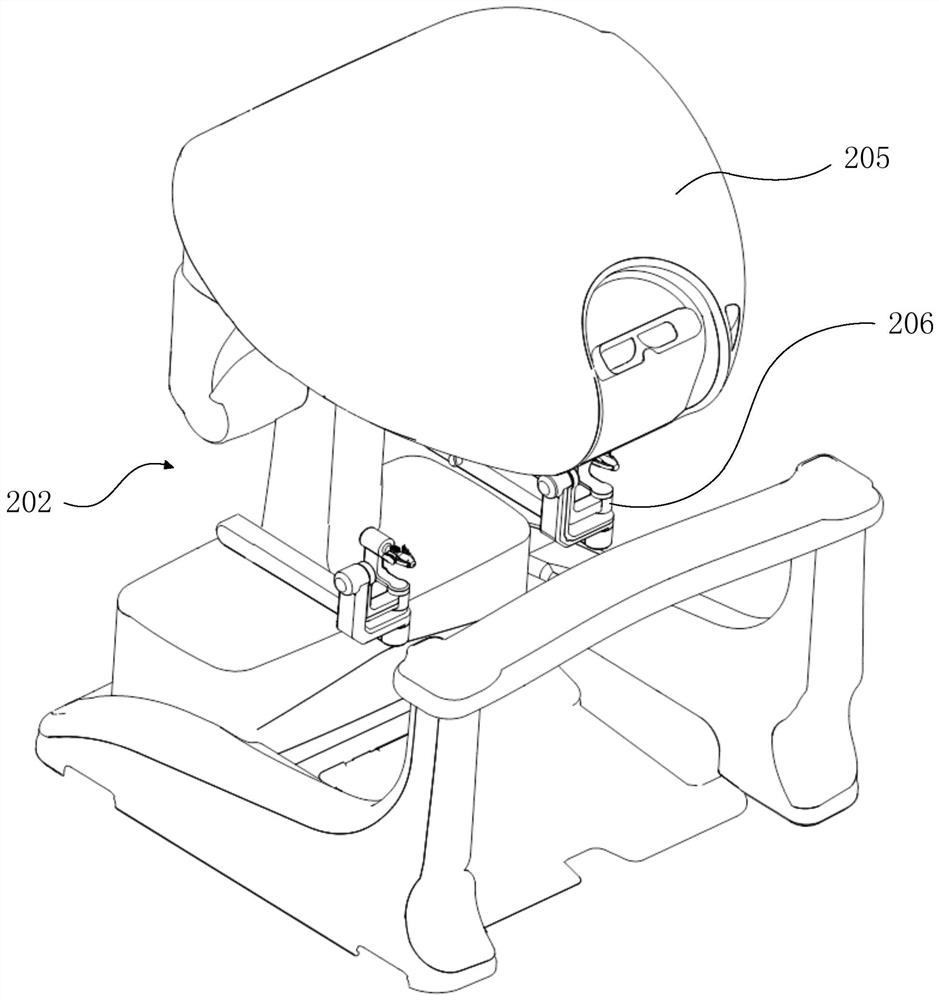

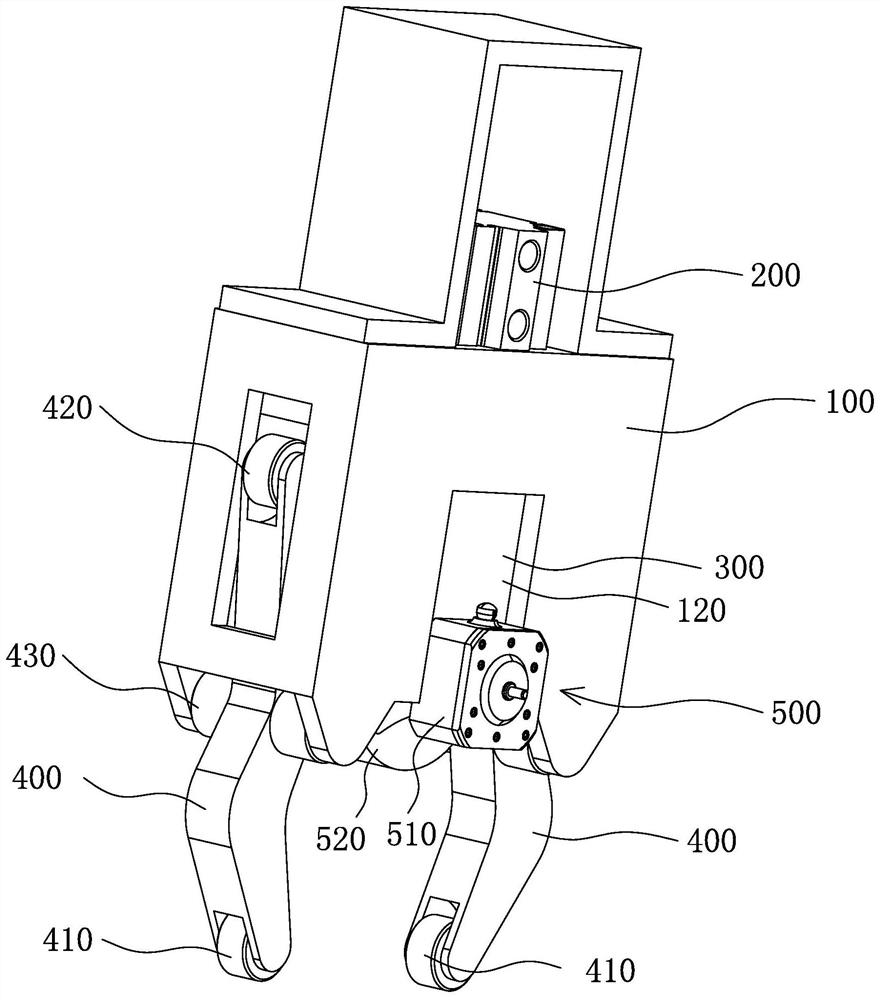

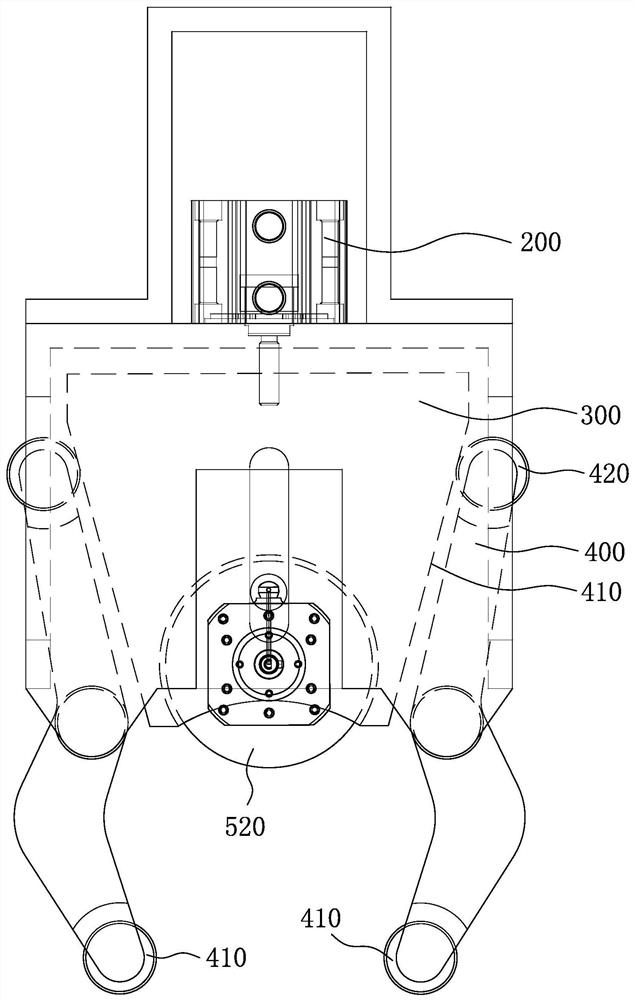

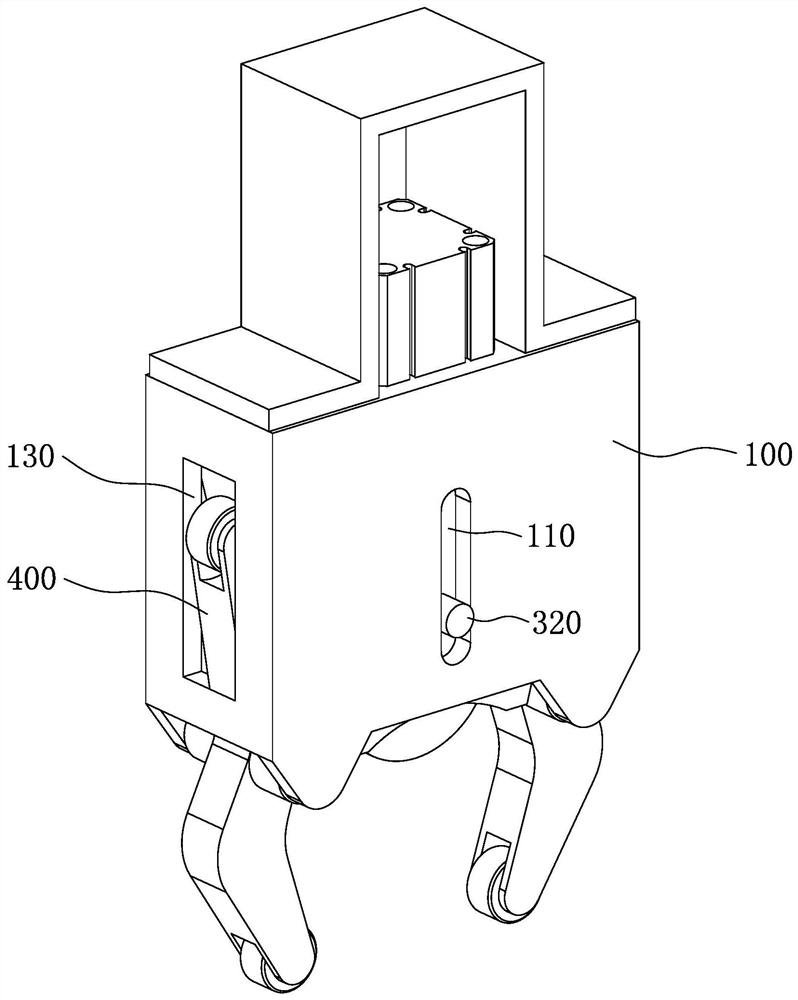

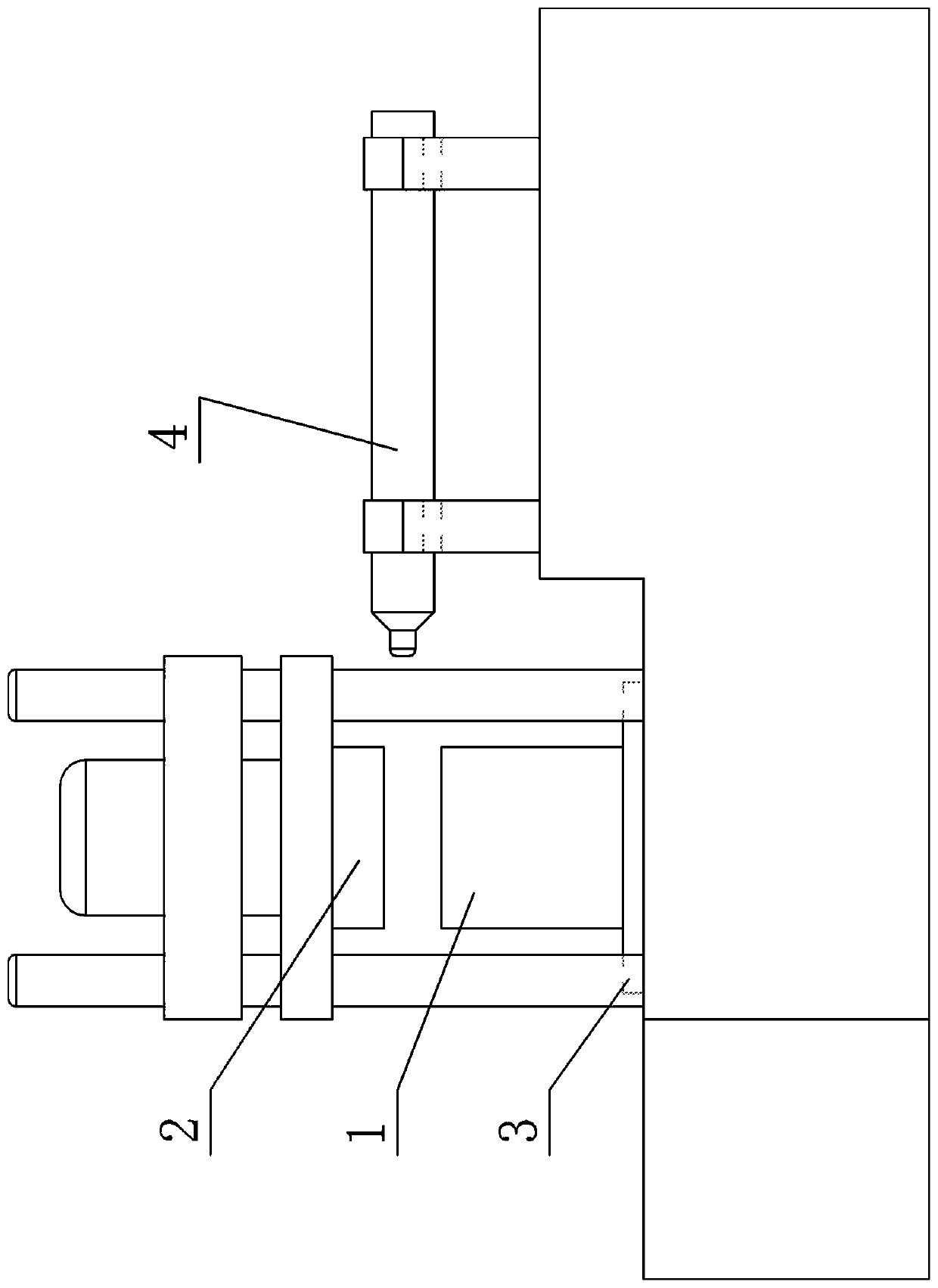

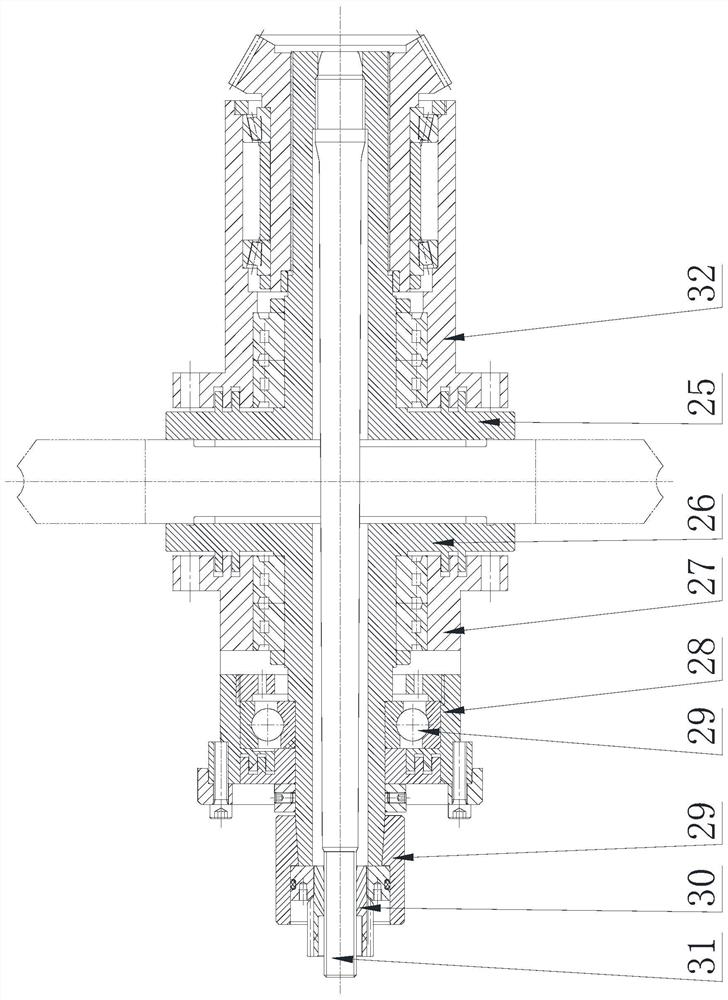

Surgical operating instrument and surgical robot

PendingCN113813050ASimple transmission structureCompact structureSurgical robotsSurgical instrumentInvasive surgery

The invention provides a surgical operating instrument and a surgical robot, wherein the surgical operating instrument comprises a mounting assembly, an execution assembly and a first driving mechanism; the execution assembly comprises an end executor arranged at the far end of the execution assembly; the near end of the execution assembly can be rotatably connected to the mounting assembly; the first driving mechanism comprises a first driving assembly and a flexible transmission part; the first driving assembly is arranged on the mounting assembly; the flexible transmission part is in transmission connection with the first driving assembly; the near end of the execution assembly is in transmission connection with the flexible transmission part; and the first driving assembly can rotate and drive the execution assembly to rotate around the longitudinal axis of the first driving assembly. According to the surgical operating instrument provided by the invention, the flexible transmission part is adopted; the transmission structure is simplified; transmission is simple and reliable; the structure of the mounting assembly is more compact; the size of the transmission structure and the mounting assembly is reduced; the weight is reduced; the requirements of minimally invasive surgery for the freedom degree, flexibility and accuracy of the surgical operating instrument are met; and the operation quality is guaranteed.

Owner:SHENZHEN JINGFENG MEDICAL TECH CO LTD

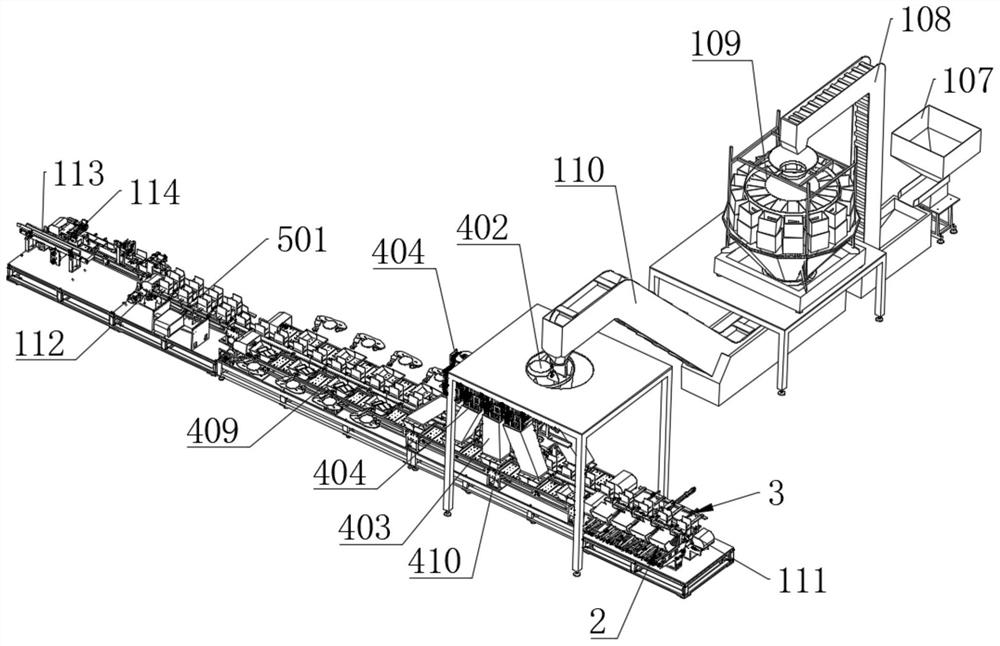

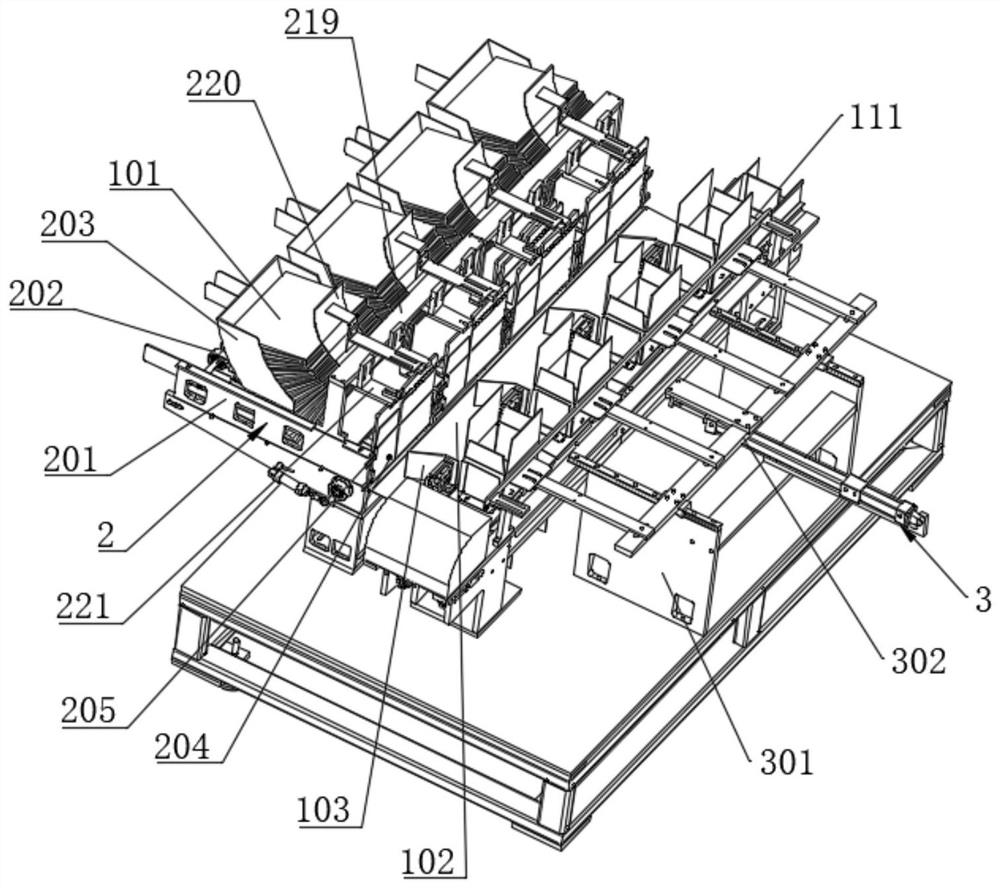

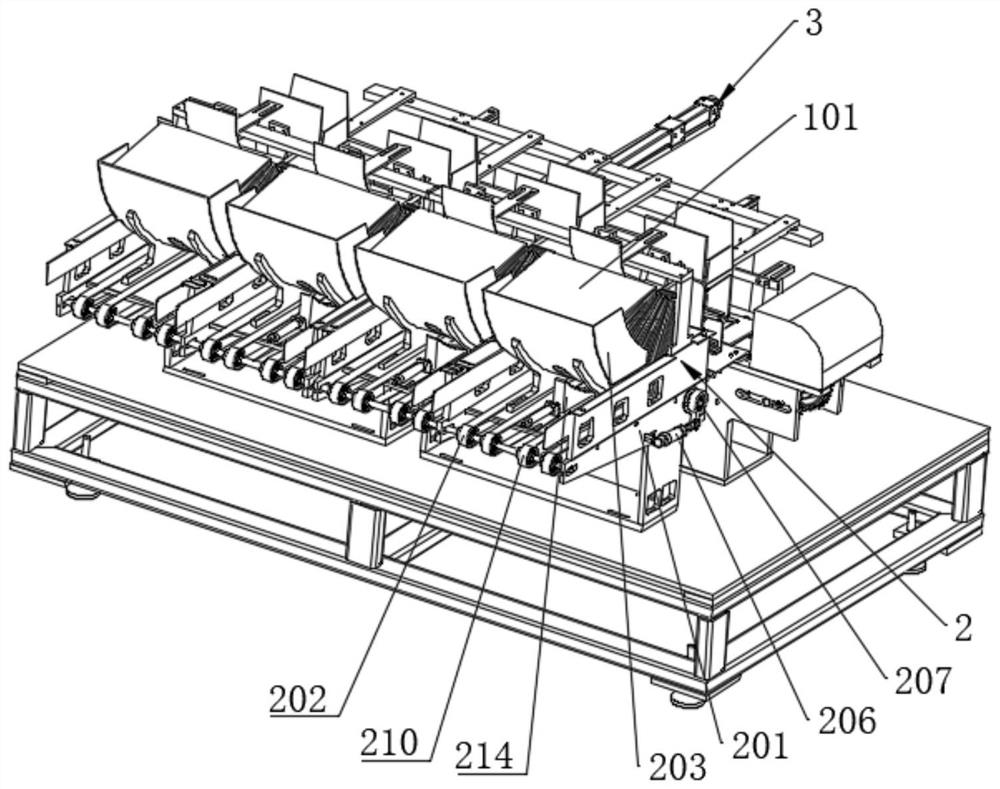

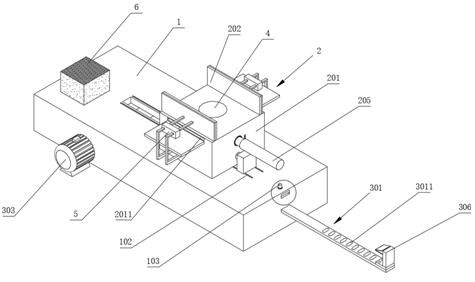

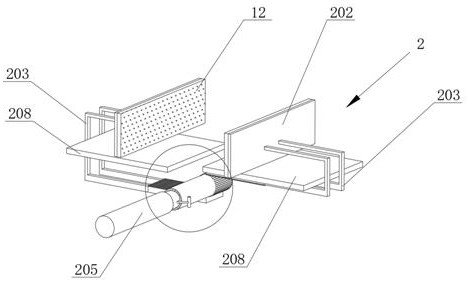

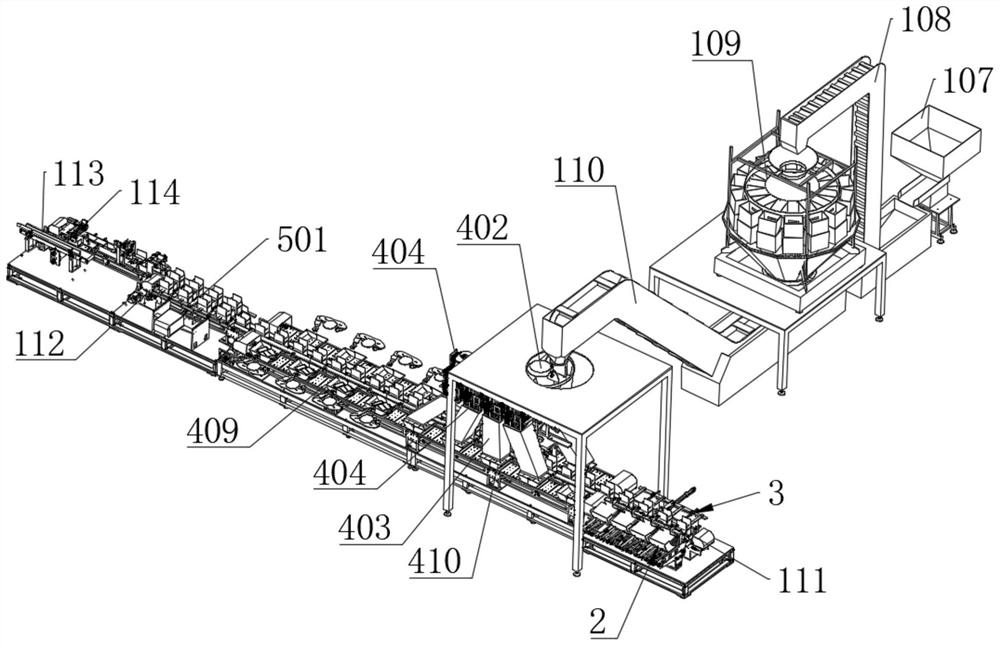

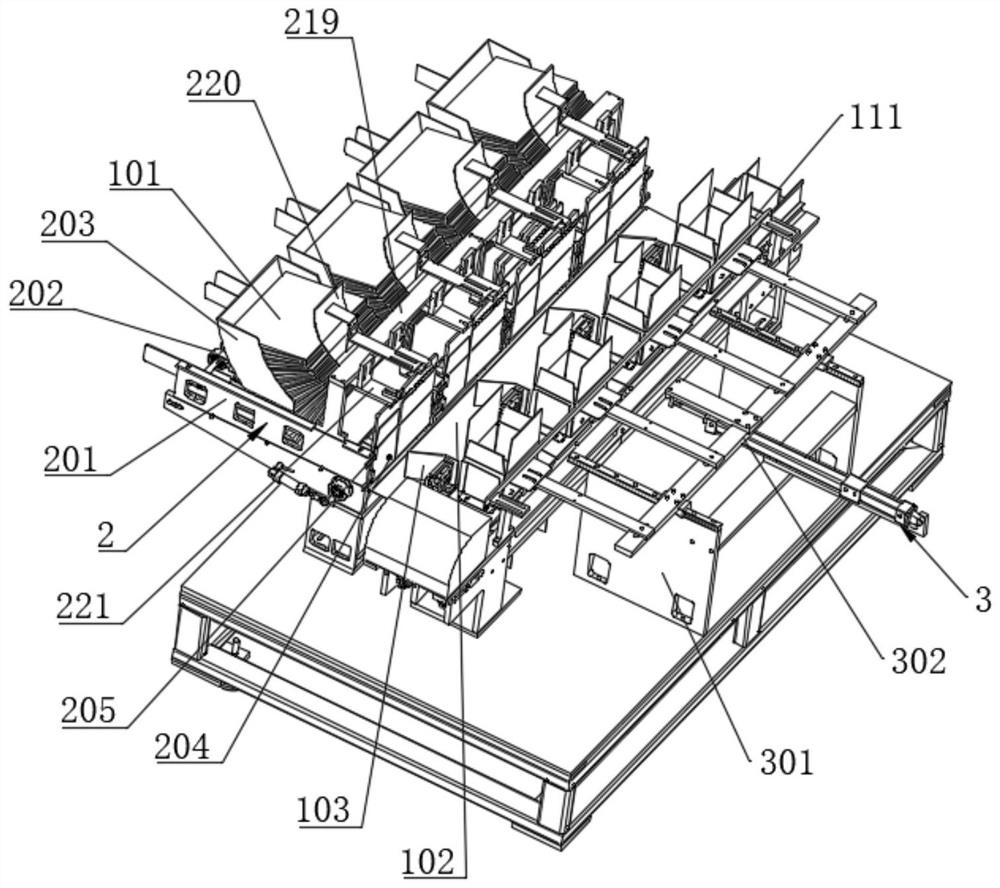

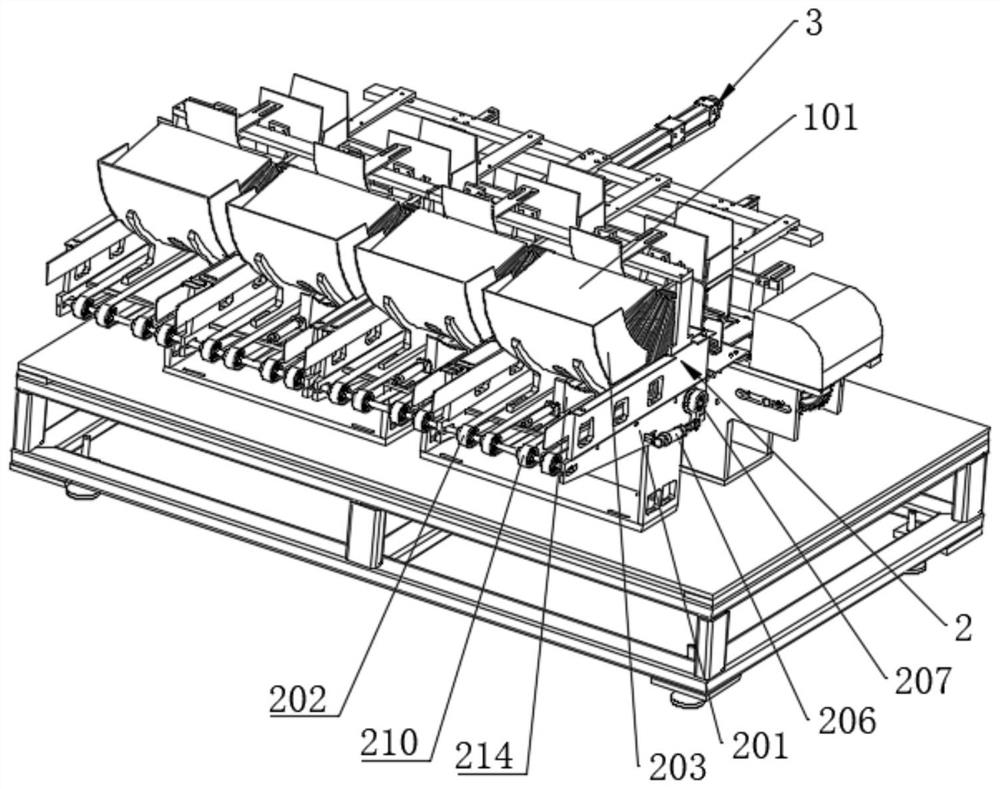

Material packaging production line

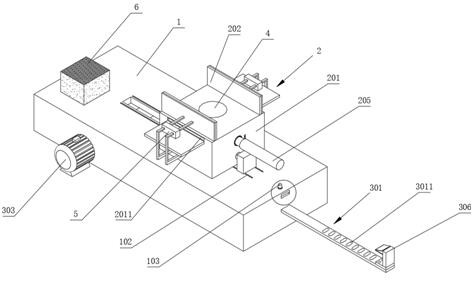

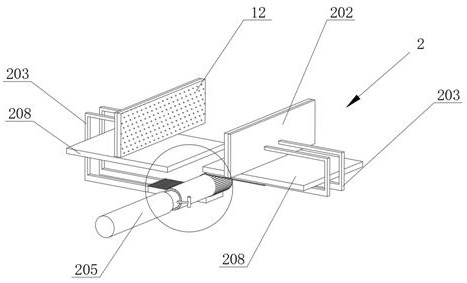

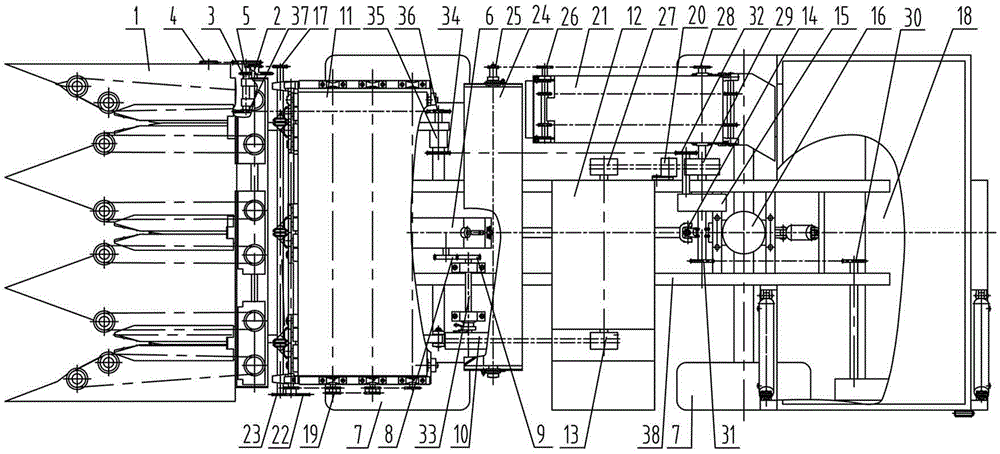

ActiveCN113353344ASmooth transmissionThe transmission structure is simple and reliableWrapper twisting/gatheringSolid materialMicrocomputerProduction line

The invention discloses a material packaging production line. The material packaging production line comprises a packaging box, a box opening device, a material distributing device and a box sealing device. The box opening device comprises a box feeding mechanism, a box sucking mechanism and a first belt conveying mechanism arranged between the box feeding mechanism and the box sucking mechanism. The material distributing device comprises a vibration direct conveying device, a feeding elevator, a microcomputer combination scale, a discharging elevator and a material distributing support. An upper material receiving hopper is arranged above the material distributing support. A plurality of lower material receiving hoppers are arranged on the two sides of the material distributing support. A closed-loop transmission assembly is arranged on the top of the material distributing support and provided with a plurality of material distributing bins. The box sealing device comprises a box sealing conveying assembly, a first box pushing assembly, a left-right pressing plate assembly, a rear pressing plate assembly, a glue spraying assembly and a front pressing plate assembly, wherein the left-right pressing plate assembly, the rear pressing plate assembly, the glue spraying assembly and the front pressing plate assembly are sequentially arranged in the conveying direction of the box sealing conveying assembly. The material packaging production line is suitable for the box packaging requirement of any weighable material, the production efficiency can be obviously improved, the labor cost can be greatly reduced, and accordingly the economic benefits of enterprises are improved.

Owner:温州凯祥包装机械有限公司

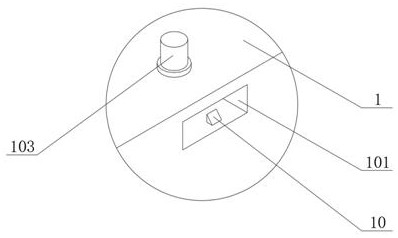

Fixing device for industrial adhesive product production

ActiveCN112894650AAvoid damageThe transmission structure is simple and reliableMaterial gluingWork holdersElectrical connectionManufacturing engineering

The invention relates to a fixing device for industrial adhesive product production. The fixing device comprises a base, a fixing mechanism for clamping an industrial adhesive product at the top end of the base, and a transmission mechanism for driving the fixing mechanism to directionally move in the base, wherein the fixing mechanism is in sliding connection with the upper surface of the base, and the transmission mechanism is fixedly connected to the lower end of the fixing mechanism; and the fixing mechanism comprises a fixing table for containing the industrial adhesive product, vertical clamping plates which are arranged at the two sides of the upper end of the fixing table and are parallel to each other, and a transmission rod for driving the clamping plates to move horizontally, an electronic scale is arranged at the upper end of the fixing table, a pressure sensor is arranged in the middle of the transmission rod, and the pressure sensor and the electronic scale are electrically connected to a controller respectively. According to the fixing device for industrial adhesive product production, materials in various shapes can be fixed through the fixing mechanism, the electronic scale and the pressure sensor on the fixing mechanism can measure the weight of the fixed materials and monitor the clamping force, and damage to a clamped object can be avoided while the fixing effect is guaranteed.

Owner:厦门奈克斯新材料有限公司

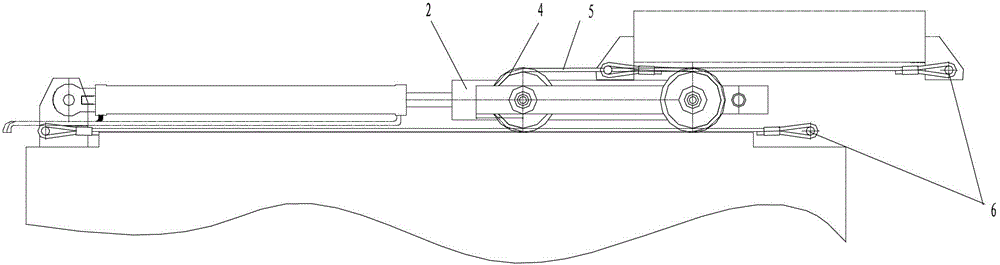

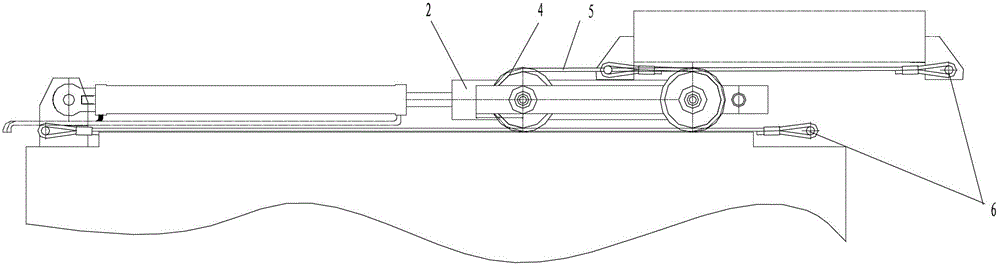

Creeling transmission mechanism for coiler of carding machine

ActiveCN103541051AThe transmission structure is simple and reliableLess chance of chain breakageCarding machinesSprocketEngineering

A creeling transmission mechanism for a coiler of a carding machine comprises a driving air cylinder, moving chain wheels, a linkage frame, a chain, fixed chain wheels and a trolley driving connecting block; the chain winds on the two moving chain wheels and the two fixed chain wheels; two ends of the chain are fixed on a machine base plate; the trolley driving connecting block is fixedly connected with the chain; the driving air cylinder simultaneously drives the two moving chain wheels to perform linear reciprocating motion and accordingly the chain is driven to perform linear reciprocating motion; the trolley driving connecting block which is hinged to the chain drives a trolley to perform reciprocating motion. According to the chain and chain wheel transmission mechanism, the chain is not easy to fall off from the chain wheel, the chain can be tensioned due to adjustment of one fixed chain wheel when the chain is extended slightly after long time operation, the chain fracture probability is small due to the fact that the transmission mechanism is stable and reliable in structure, and meanwhile corresponding connecting pieces can be conveniently replaced to perform rapid and economic maintenance when the chain is accidentally fractured due to the fact that the chain is a standard part, low in cost and good in universality.

Owner:SAURER CHANGZHOU TEXTILE MACHINERY CO LTD

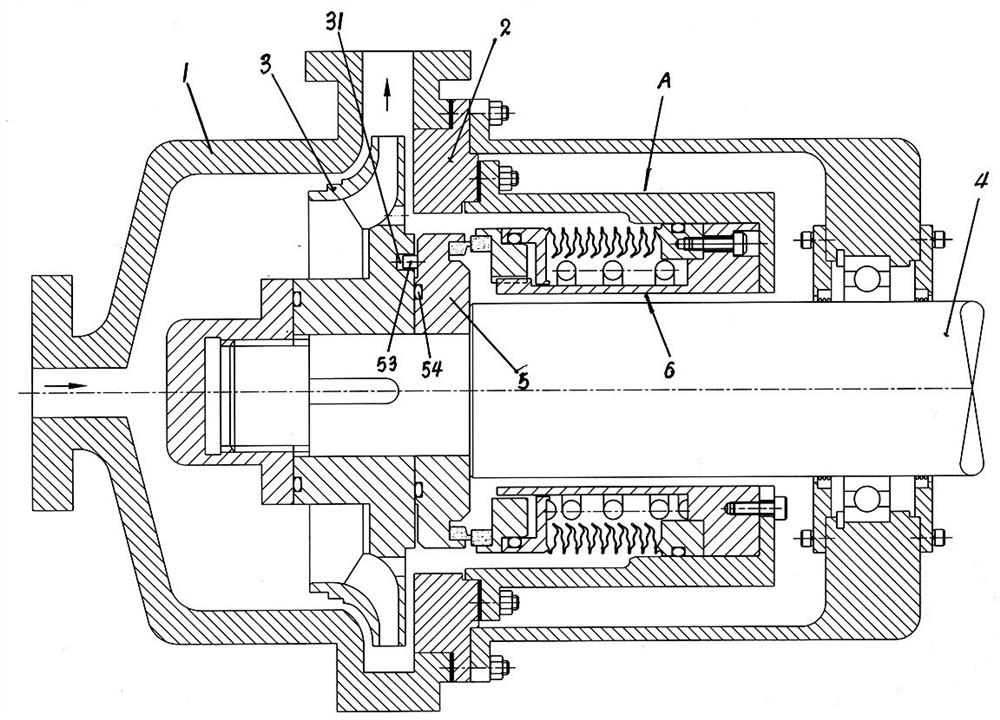

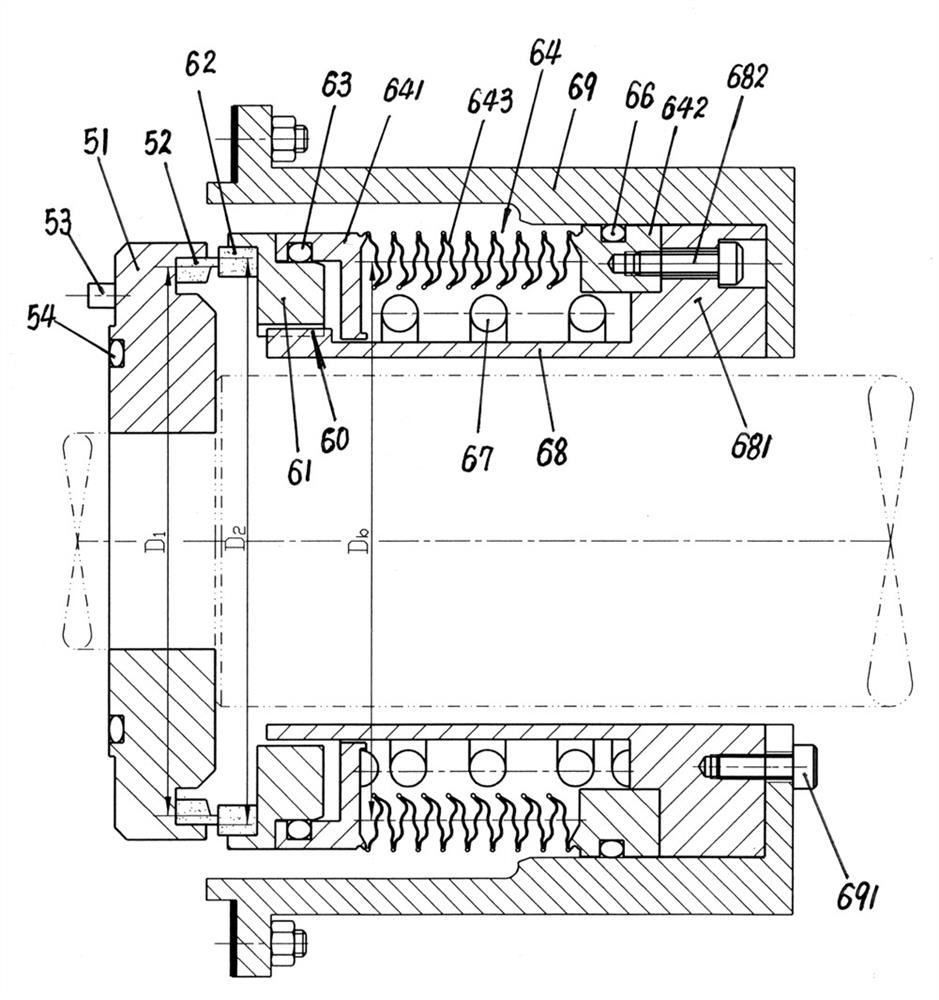

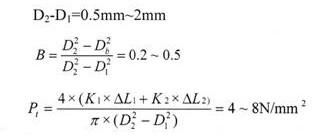

Centrifugal pump for conveying viscous medium

PendingCN112833023AThe transmission structure is simple and reliableStrong anti-torque abilitySpecific fluid pumpsPump componentsCentrifugal pumpEngineering

The invention discloses a centrifugal pump for conveying a viscous medium. The centrifugal pump is mainly characterized in that a static ring assembly for mechanical sealing of the centrifugal pump is composed of a static ring base, a static ring, a static ring base sealing ring, a corrugated pipe assembly, a corrugated pipe front end ring sealing ring, a corrugated pipe rear end ring sealing ring, a compensation spring, a static ring sleeve and a gland; and the columnar compensation spring is installed on the outer circle of the static ring sleeve. The left end pressure of the columnar spring acts on a corrugated pipe front end ring, the corrugated pipe is a large-spacing corrugated pipe, mechanical sealing parameters are set, and the columnar compensation spring is sealed and protected. The corrugated pipe and the columnar spring are combined to provide compensation force, and the phenomenon that the medium forms condensation products in wave plate grooves to affect the telescopic change of the corrugated plate grooves is not likely to occur. The moving end face following fitting performance of the compensation static ring is not affected, the working condition using requirements that the medium viscosity is larger than 10000 CPS, the temperature reaches 275 DEG C and the pressure reaches 2 Mpa can be fully met, the mechanical sealing effect of the centrifugal pump is improved, and the service life of the centrifugal pump is prolonged.

Owner:丹东克隆先锋泵业有限公司

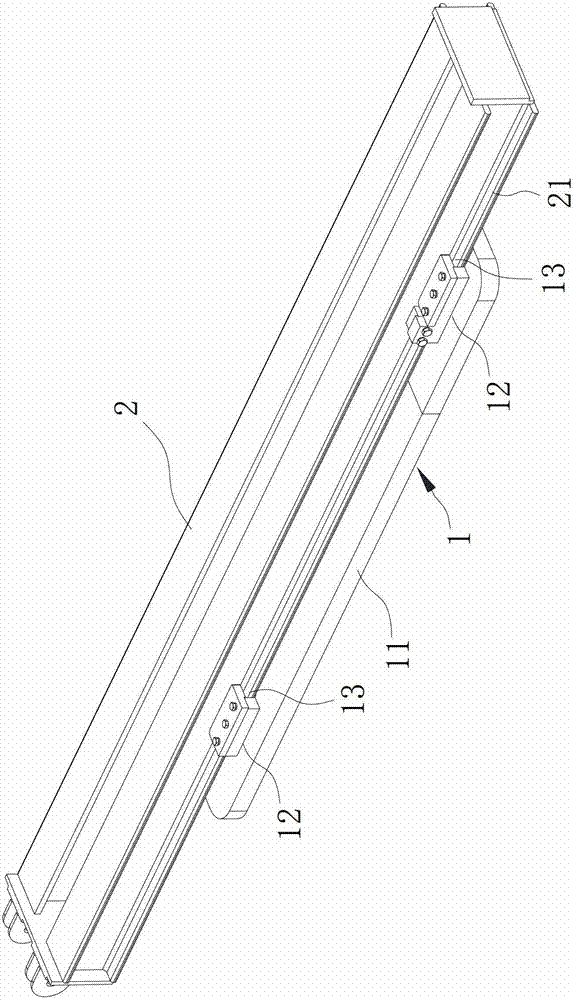

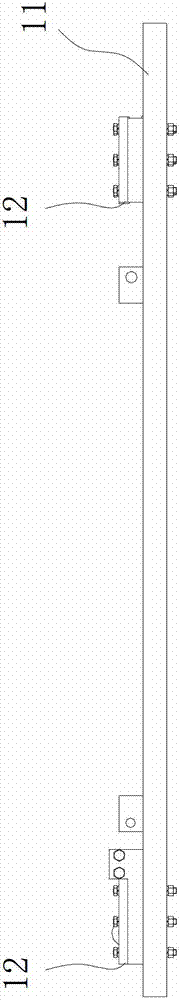

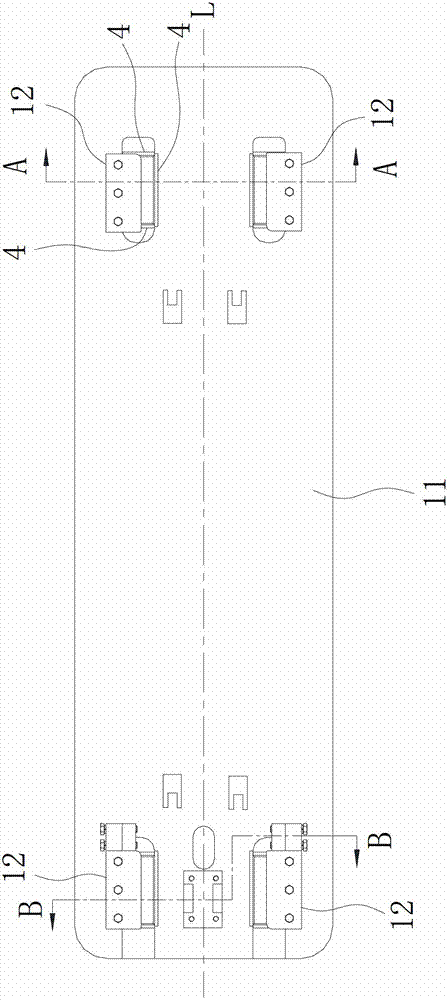

Guiding connection mechanism and tunneling device

The invention discloses a guiding connection mechanism and an excavator. The guiding connection mechanism is used for connecting the body of the excavator and a bolting machine, and guiding the bolting machine to slide on the body of the excavator. The guiding connection mechanism comprises a guide groove device which is arranged on the body of the excavator, and a sliding part which is arranged on the guide groove device, can slide on the guide groove device and is used for arranging the bolting machine. The guiding connection mechanism and the excavator of the invention are in favor of the accurate positioning of the bolting machine, and have the high working efficiencies, and simple and reliable structures.

Owner:益阳市科技成果转化服务中心 +1

Embedding and rolling forming machine tool for radiator fins

InactiveCN102716992AEasy meshIncrease travel distanceHeat exchange apparatusHydraulic cylinderEngineering

The invention belongs to an electronic radiator and particularly relates to an embedding and rolling forming machine tool for radiator fins. The embedding and rolling forming machine tool is characterized in that a workbench driving system comprises a hydraulic cylinder, a driving trolley, four support shafts, round wheels and steel wire ropes, wherein the piston of the hydraulic cylinder is fixedly connected the driving trolley; the four support shafts are fixedly connected to the left and the right sides of the driving trolley respectively; one round wheel is mounted on each support shaft; one end of each steel wire rope is fixed on a machine tool body; the other end of the steel wire rope is fixed on a movable workbench; and round grooves in the circumferences of the four round wheels on the four support shafts are in contact connection with the four steel wire ropes respectively, so as to form a pair of left driving hair springs and a pair of right driving hair springs. The embedding and rolling forming machine tool has the benefits that in the process that the hydraulic cylinder drives the driving trolley to move, the workbench mounted on the driving trolley moves not only along with the driving trolley but also relative to the driving trolley under the action of the two pairs of hair springs, so that the moving distance of the workbench is increased, and short distance input and long distance output are realized; and the embedding and rolling forming machine tool ensures that the pressing-in quality is reliable, insert plates are not distorted and cross sections are free of deformation.

Owner:中色(天津)特种材料有限公司

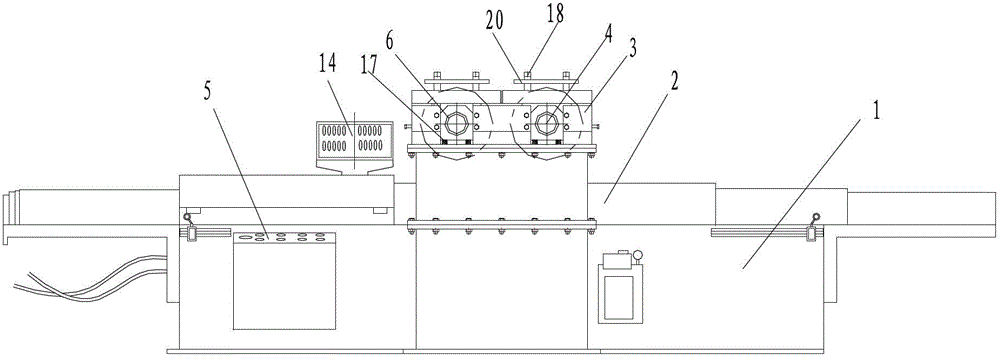

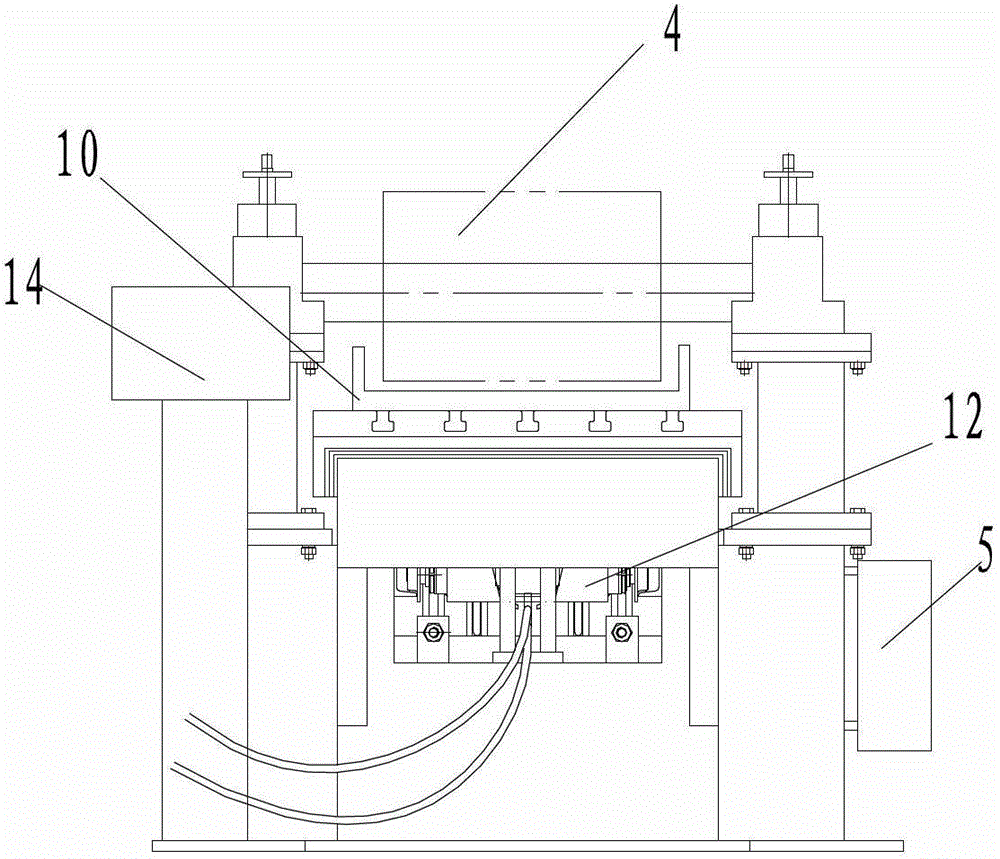

Frame body adjusting mechanism and pipe expansion machine with same

PendingCN107983855AReduce labor intensityThe transmission structure is simple and reliableHeat exchange apparatusEngineeringHeat exchanger

The invention provides a frame body adjusting mechanism and a pipe expansion machine with the same. The frame body adjusting mechanism comprises a frame main body for mounting an expansion rod suspension mechanism with an expansion rod, and an expansion rod transmission module mounted on the frame main body and connected with the expansion rod suspension mechanism for driving the expansion rod suspension mechanism to lift, wherein the expansion rod transmission module comprises an expansion rod transmission lead screw, and an expansion rod transmission nut sleeving the expansion rod transmission lead screw; and the expansion rod transmission nut is connected with the expansion rod suspension mechanism, so that the expansion rod suspension mechanism is lifted under the effects of the expansion rod transmission lead screw and the expansion rod transmission nut. The frame body adjusting mechanism solves the problem of lower efficiency during machining of metal pipes of heat exchangers inthe prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

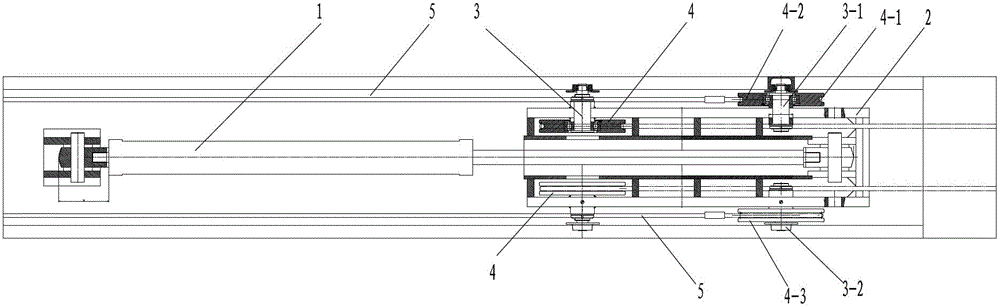

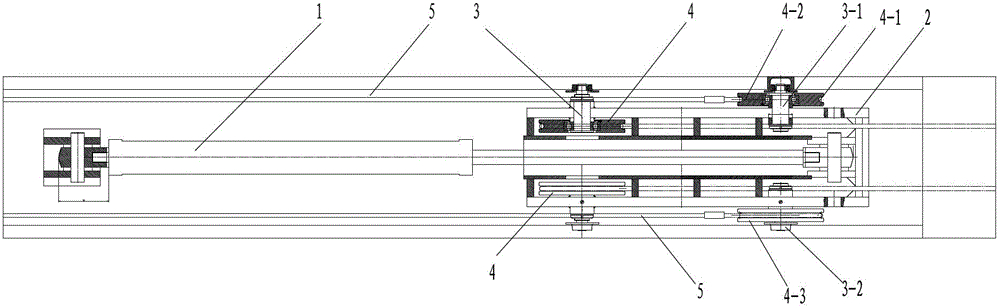

Linearly reciprocating hydraulic drive mechanism

InactiveCN102745476BIncrease travel distanceReduce volumeFluid-pressure actuatorsMechanical conveyorsHydraulic cylinderReciprocating motion

The invention belongs to the field of hydraulic drive, and particularly relates to a linearly reciprocating hydraulic drive mechanism. The linearly reciprocating hydraulic drive mechanism is characterized in that: the linearly reciprocating hydraulic drive mechanism comprises a hydraulic cylinder, a drive trolley, four support shafts, round pulleys and wire ropes, the four support shafts are respectively fixedly connected with the left and the right sides of a carriage, a round pulley is mounted on each support shaft, the circumferences of the round pulleys are provided with round grooves, one end of each wire rope is fixed on a machining tool body, the other ends of the wire ropes are fixed on a movable working table, the round grooves on the circumferences of the four round pulleys of the four support shafts are respectively in contact with the four wire ropes, the fixed points of the two wire ropes moving to the left are on the left, and round the round pulleys on the right support shafts, the fixed points of the two wire ropes moving to the right are on the right, and round the round pulleys on the left support shafts, and thereby a left pair of drive hair wires and a right pair of drive hair wires are formed. The linearly reciprocating hydraulic drive mechanism has the advantage that: the drive trolley is driven by the hydraulic cylinder, and by means of the two pairs of hair wires, the drive trolley ensures that the movable working table not only can move along with the drive trolley but also can move relative to the drive trolley. The linearly reciprocating hydraulic drive mechanism achieves the purpose of increasing the moving distance of the working table.

Owner:中色(天津)特种材料有限公司

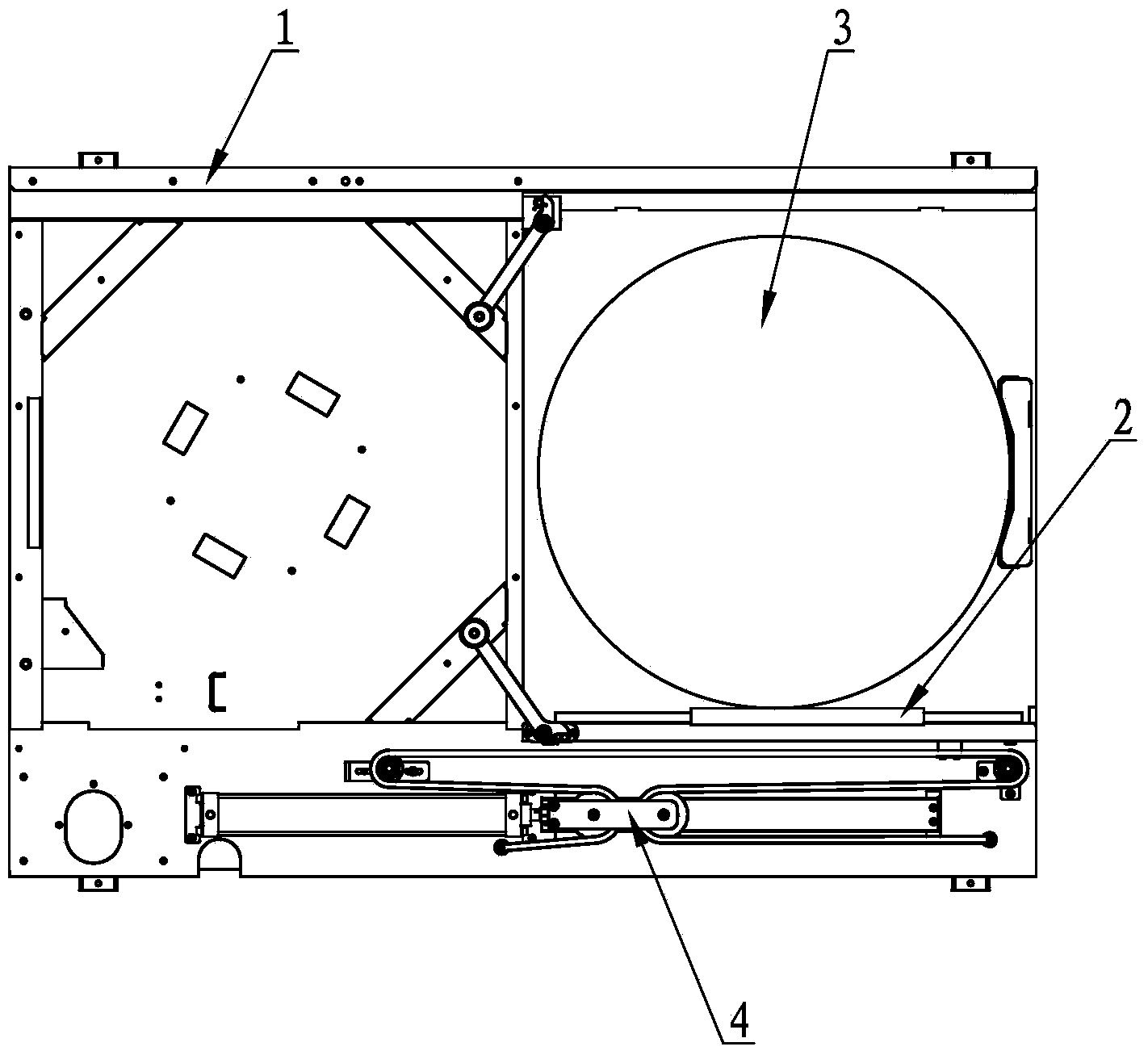

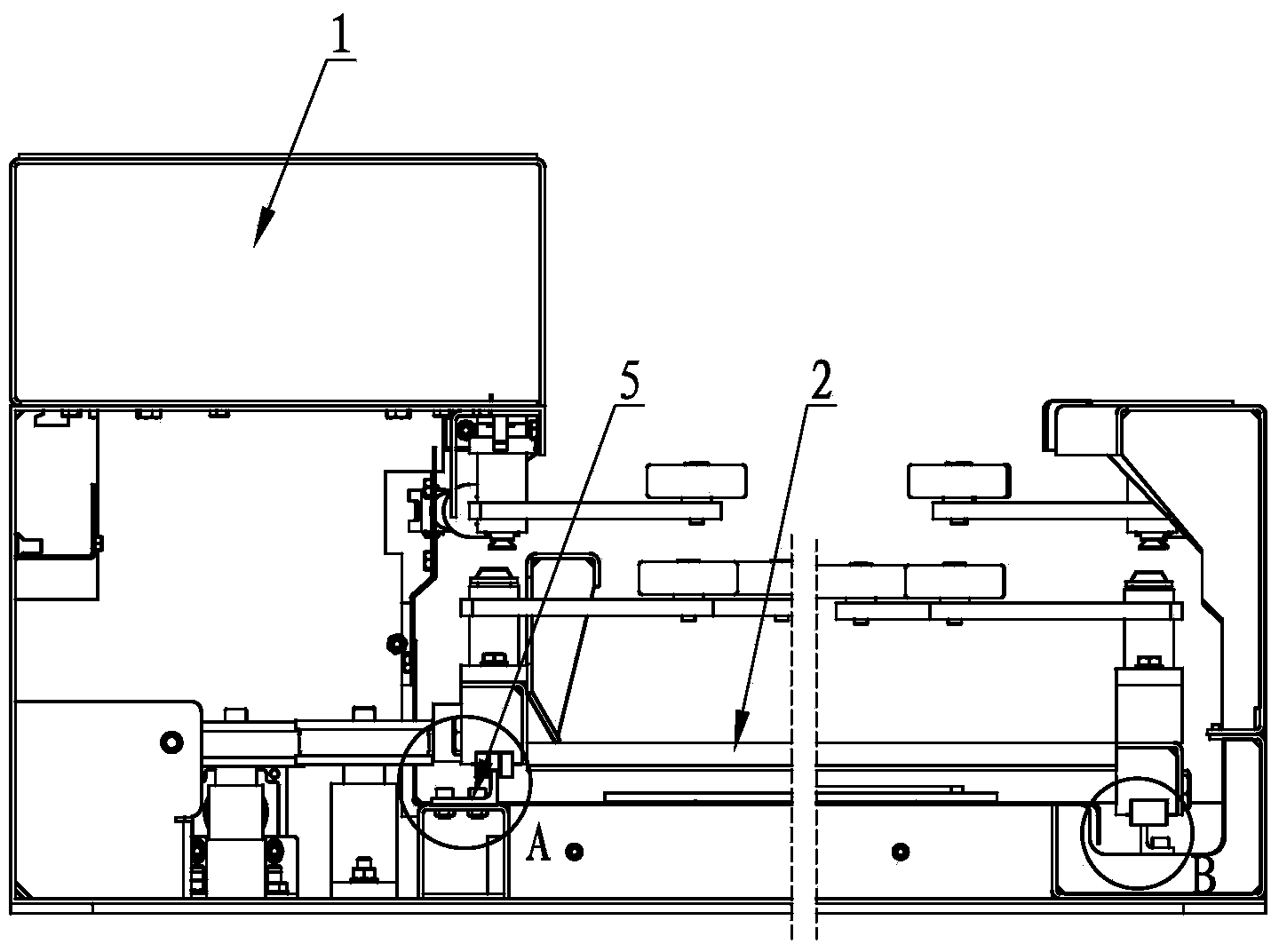

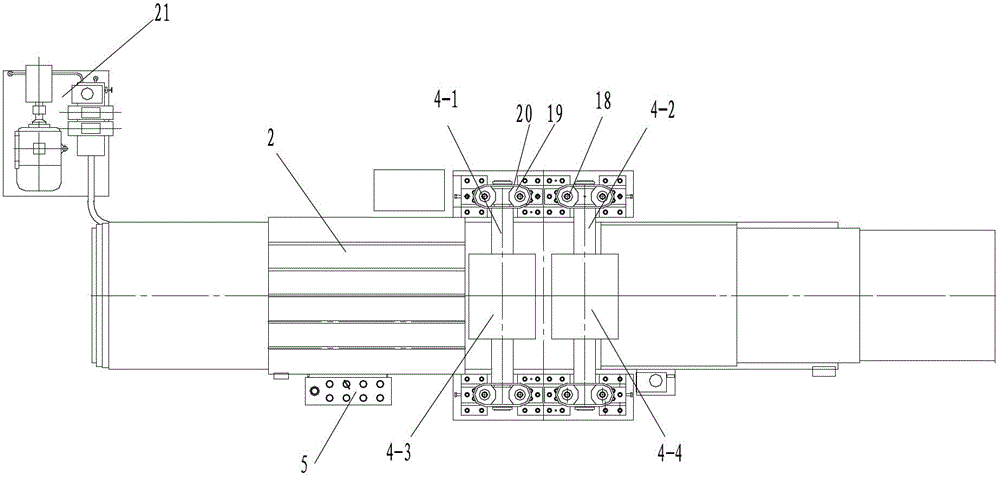

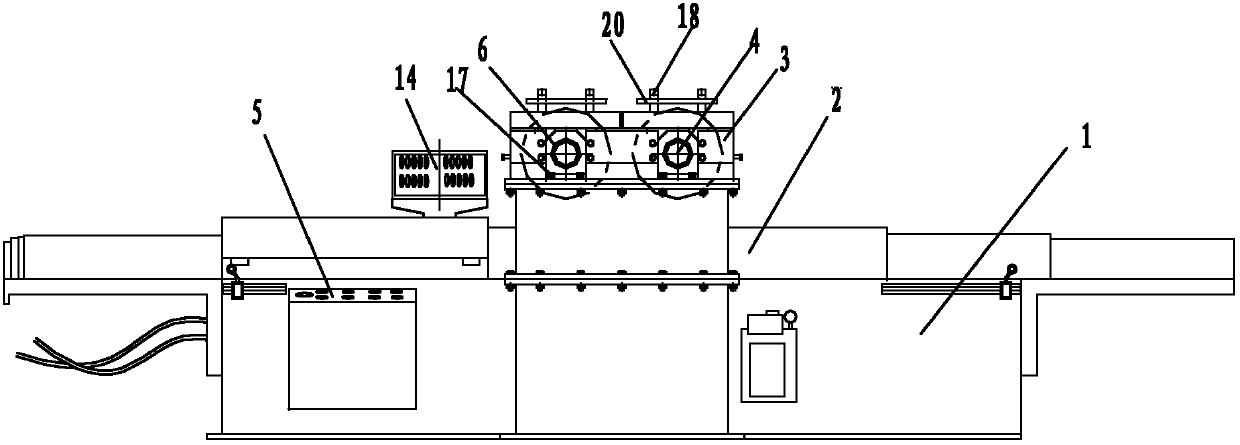

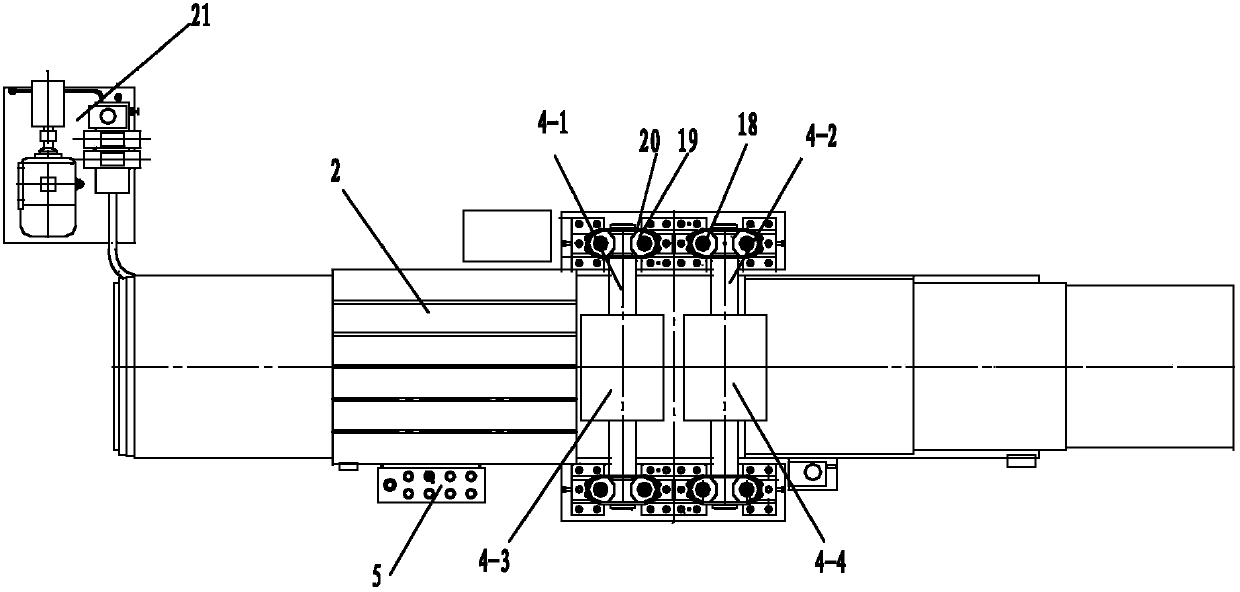

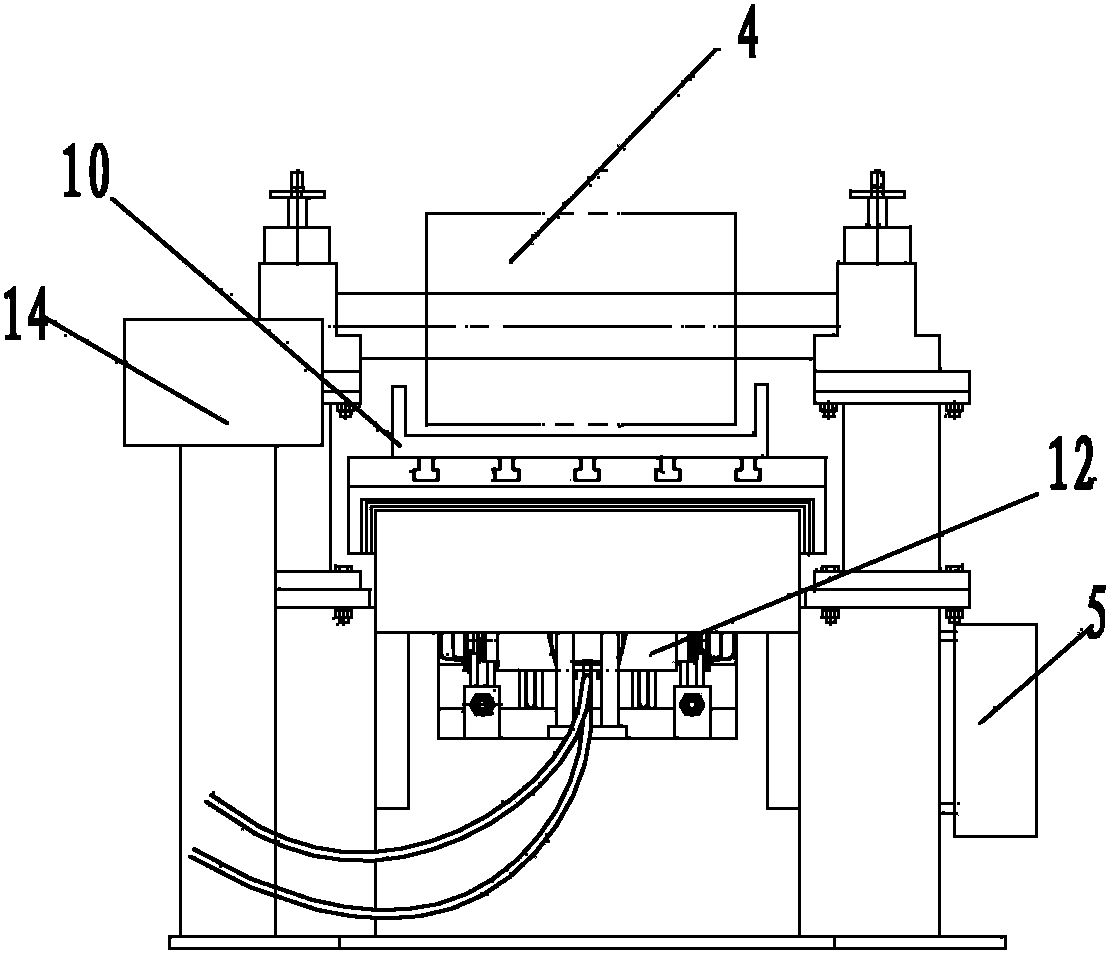

An automatic grasping and pre-twisting machine for mold adjusting thread nuts

Owner:HAITIAN PLASTICS MACHINERY GRP

A circuit breaker and its opening and closing device

ActiveCN106373834BAvoid dead center stuck situationsGuaranteed reliabilityContact driving mechanismsProtective switch operating/release mechanismsEngineeringCircuit breaker

A switching-on / off device comprises a shell, a motor arranged inside the shell, a worm driven by the motor, and a worm gear component matching the worm. The switching-on / off device further comprises a linkage rod which is arranged at one side of the worm gear component and pivoted to the inner wall of the shell and is used for driving the circuit breaker to be switched off, and a push rod which is arranged on the inner wall of the shell between the worm gear component and the linkage rod in a linear movement way. The worm gear component is provided with a first worm gear boss corresponding to the push rod. For switching-off operation, the first worm gear boss rotates reversely with the worm gear component, slides along the rod body of the push rod and pushes the push rod to move linearly to the linkage rod, so as to push the linkage rod to rotate and switch off the circuit breaker.

Owner:浙江合兴电工有限公司

Vibration bidirectional energy feedback transmission device for new energy vehicle

PendingCN111806225AImprove cruising mileageThe transmission structure is simple and reliableAuxillary drivesMachines/enginesPower batteryNew energy

The invention discloses a vibration bidirectional energy feedback transmission device for a new energy vehicle. The device comprises a shell, a first transmission mechanism, a second transmission mechanism, a main transmission mechanism and a generator, according to the device, useless energy of vibration in the running process of the vehicle can be converted into electric energy to charge the power battery, so that real-time recovery and utilization of the vibration energy are realized, and the cruising mileage of the new energy vehicle is further increased; the device is simple and reliablein gear transmission structure, small in size, small in occupied space on a vehicle, capable of being easily installed between a vehicle body and an axle and convenient to arrange.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

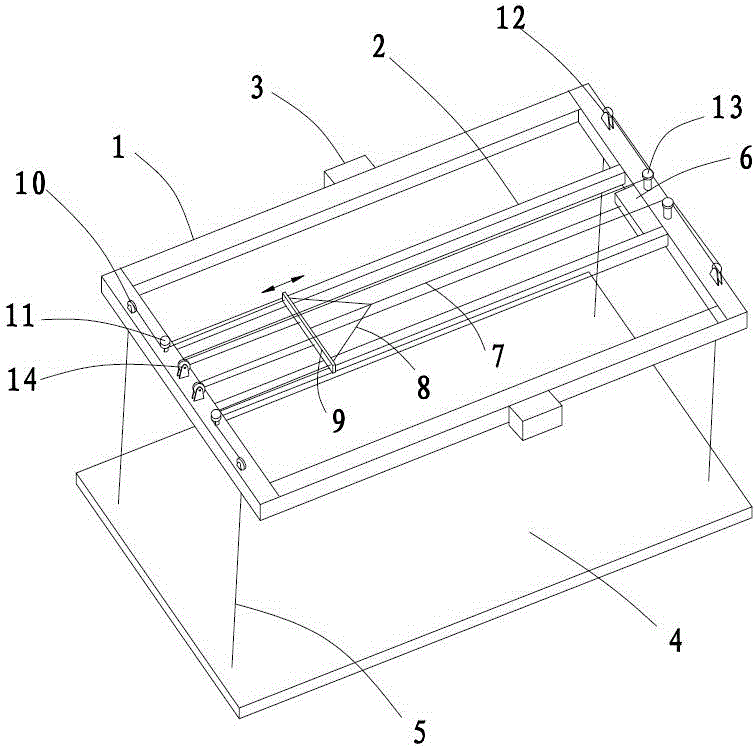

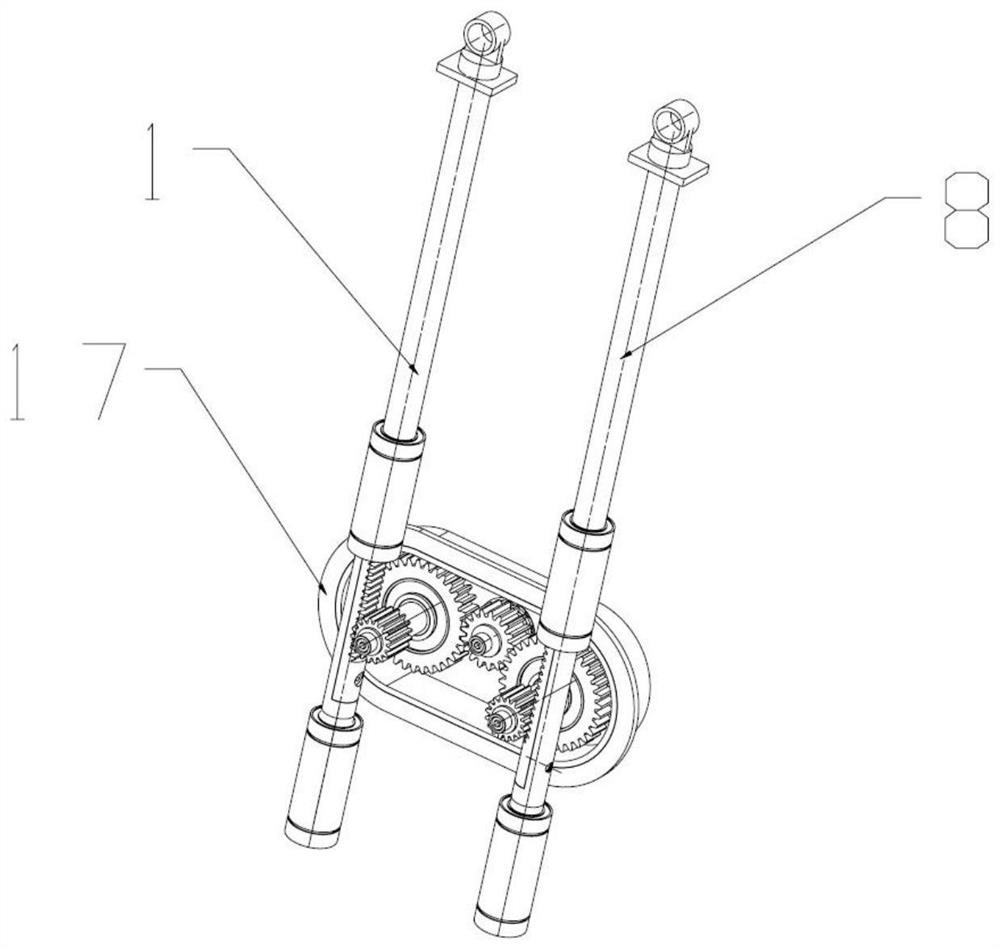

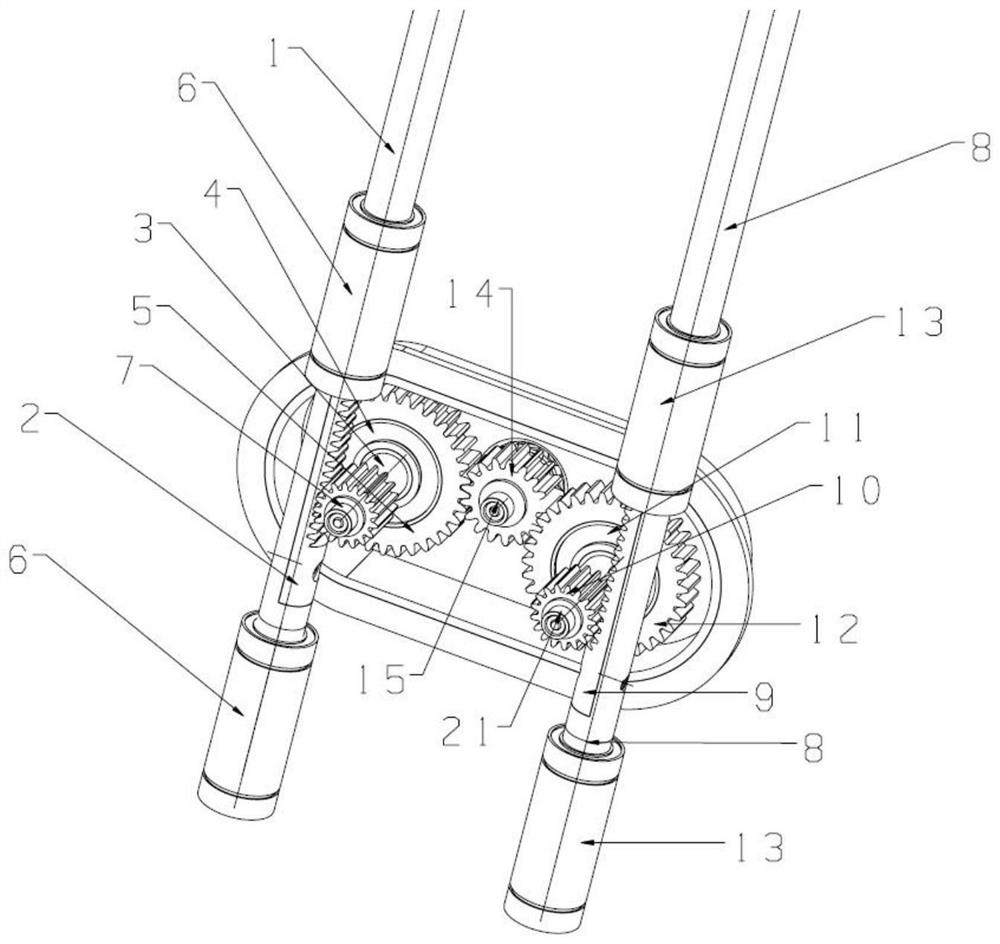

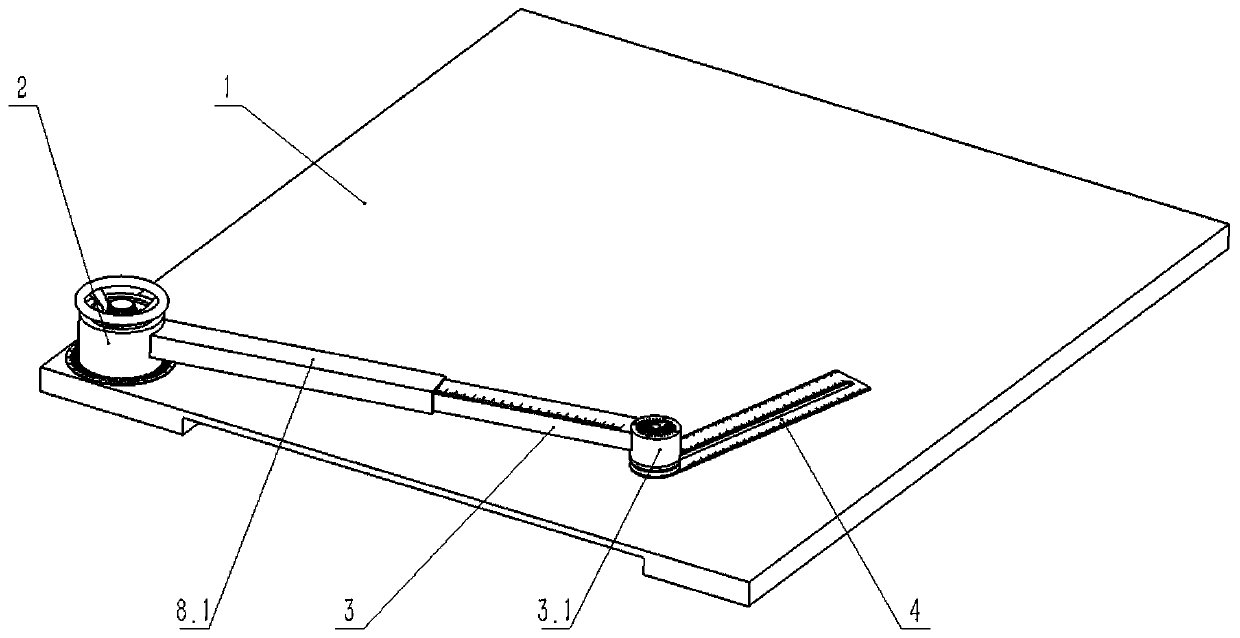

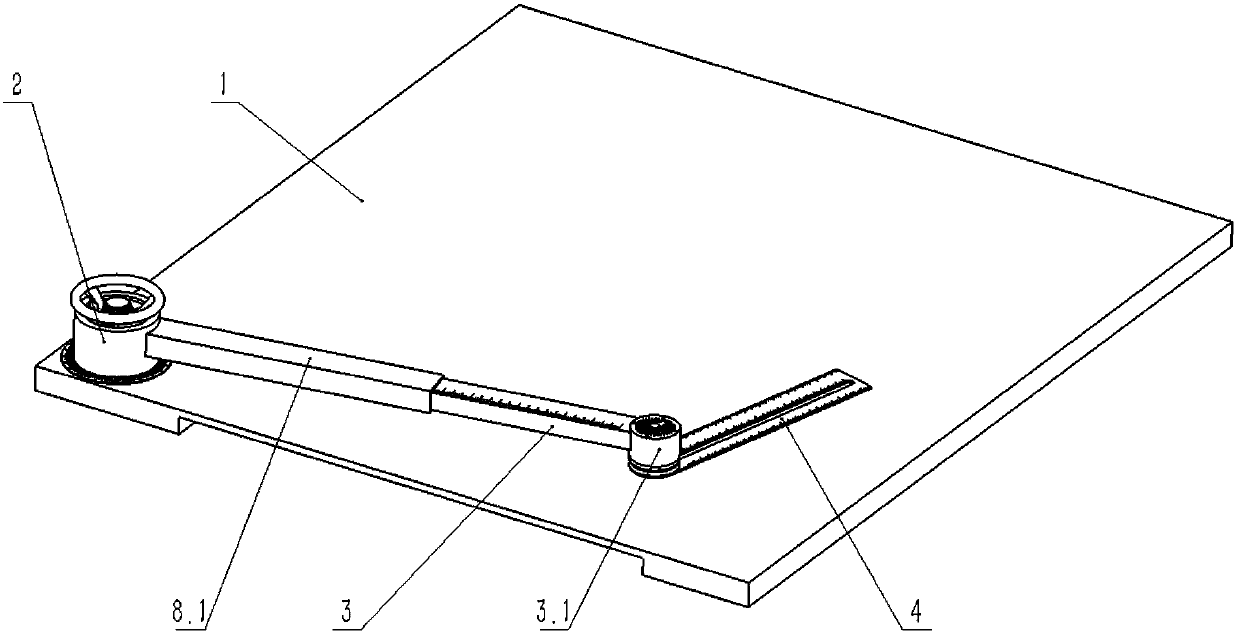

A robotic arm type auxiliary drawing device

ActiveCN107757201BThe transmission structure is simple and reliableEasy to operateWriting aidsEngineeringTooth number

The invention discloses a mechanical arm type auxiliary drawing device. The auxiliary drawing device comprises a drawing board, a coaxial input device, an inner telescopic arm, a ruler, LED lamp beads, an inner square shaft and an outer square shaft; the coaxial input device is arranged at the right lower corner of the drawing board; the inner square shaft and the inner telescopic arm form a revolute pair; the inner square shaft and the outer square shaft form a movable pair; a second small bevel gear is arranged at the front end of the inner square shaft; a graduated scale is arranged on theupper side of the inner telescopic arm; the inner telescopic arm and an outer telescopic arm form a movable pair; a ruler mounting base is arranged at the front end of the inner telescopic arm; the ruler and the ruler mounting base form a revolute pair; an observation hole channel is formed in the center of a ruler rotating disc; the tooth number ratio of a first small bevel gear to a first largebevel gear is equal to the tooth number ratio of the second small bevel gear to a second large bevel gear; the center of the lower end of the ruler rotating disc is of a cavity structure, and the three LED lamp beads are uniformly distributed on the side wall of a cavity of the ruler rotating disc; and a sight bead is arranged at the center position of the lower end of the observation hole channel, a ruler middle position scale line is arranged at one edge of a long straight hole, and a straight line where the edge is located passes through the center of the sight head.

Owner:江苏海港成套设备安装有限公司

A fixture for the production of industrial adhesive products

ActiveCN112894650BAvoid damageGuaranteed fixed effectMaterial gluingWork holdersElectrical connectionProcess engineering

The invention relates to a fixing device for the production of industrial adhesive products. The upper surface of the base is slidably connected, and the transmission mechanism is fixedly connected with the lower end of the fixing mechanism; the fixing mechanism includes a fixing table for holding industrial adhesive products, vertical splints arranged on both sides of the upper end of the fixing table and parallel to each other, a driving The transmission rod for the horizontal movement of the splint, the upper end of the fixed platform is provided with an electronic scale, the middle section of the transmission rod is provided with a pressure sensor, and the pressure sensor and the electronic scale are respectively electrically connected with a controller; the fixing device for the production of industrial adhesive products passes through The fixing mechanism can fix materials of various shapes. The electronic scale and pressure sensor on the fixing mechanism can measure the weight of the fixed material and monitor the clamping force, which can ensure the fixing effect and avoid the damage of the clamped object.

Owner:厦门奈克斯新材料有限公司

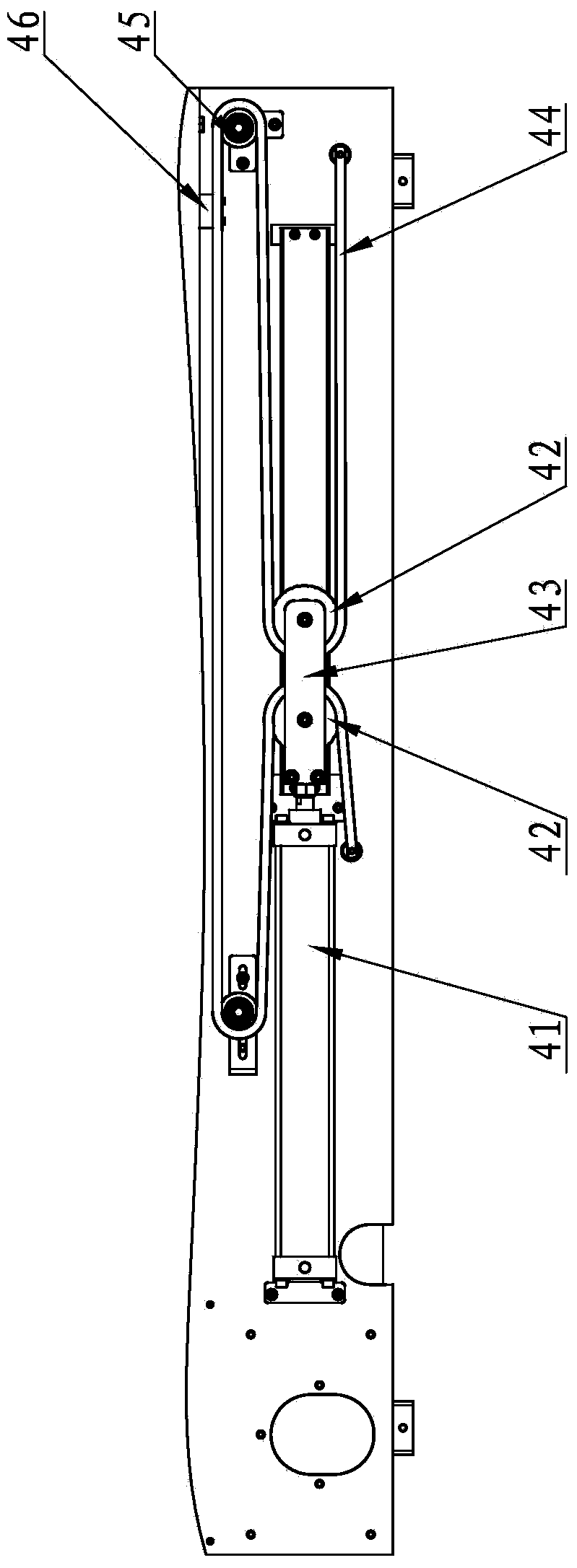

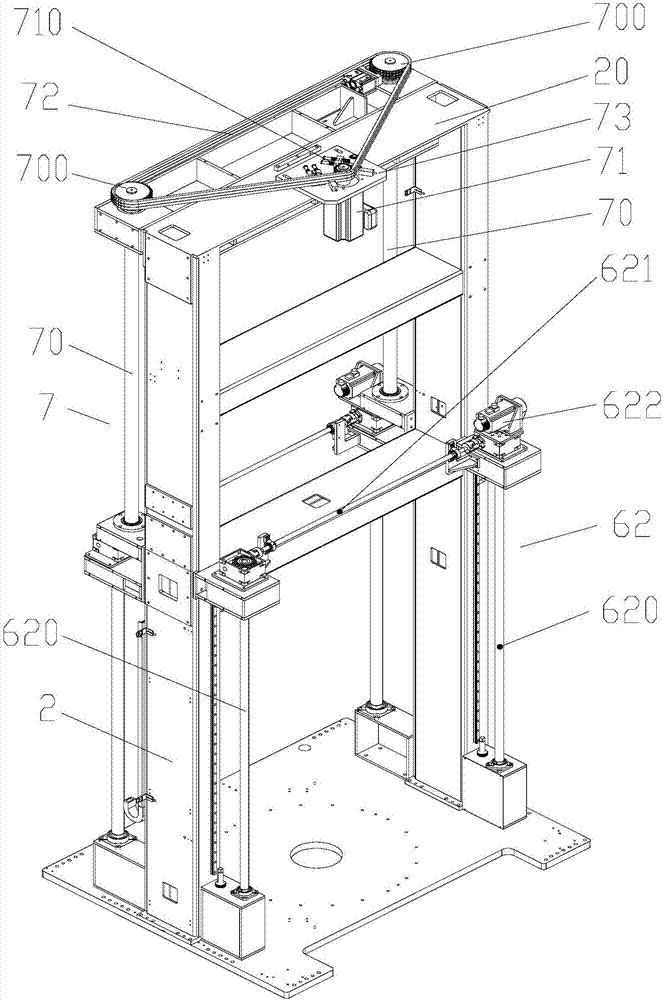

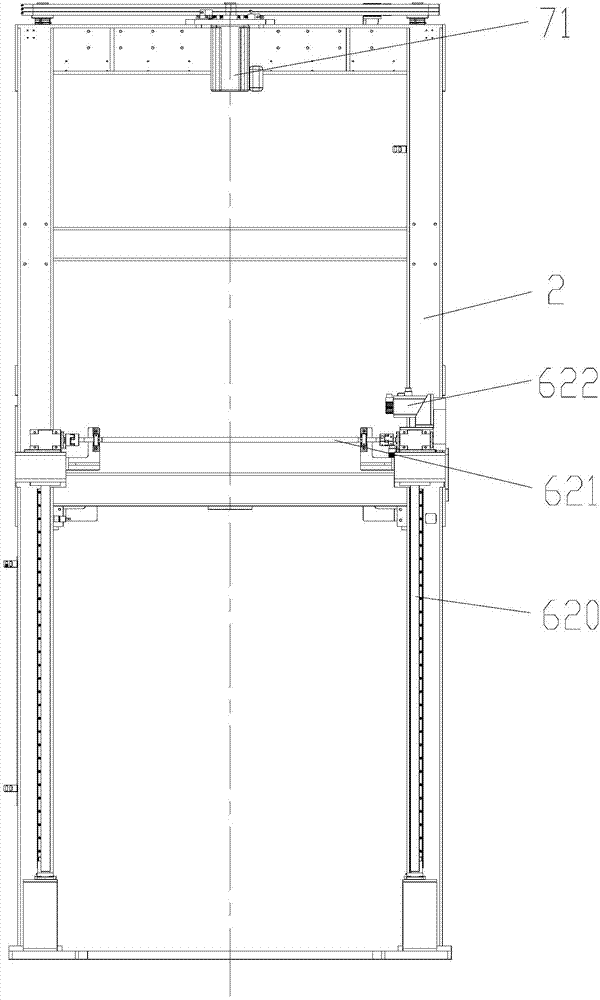

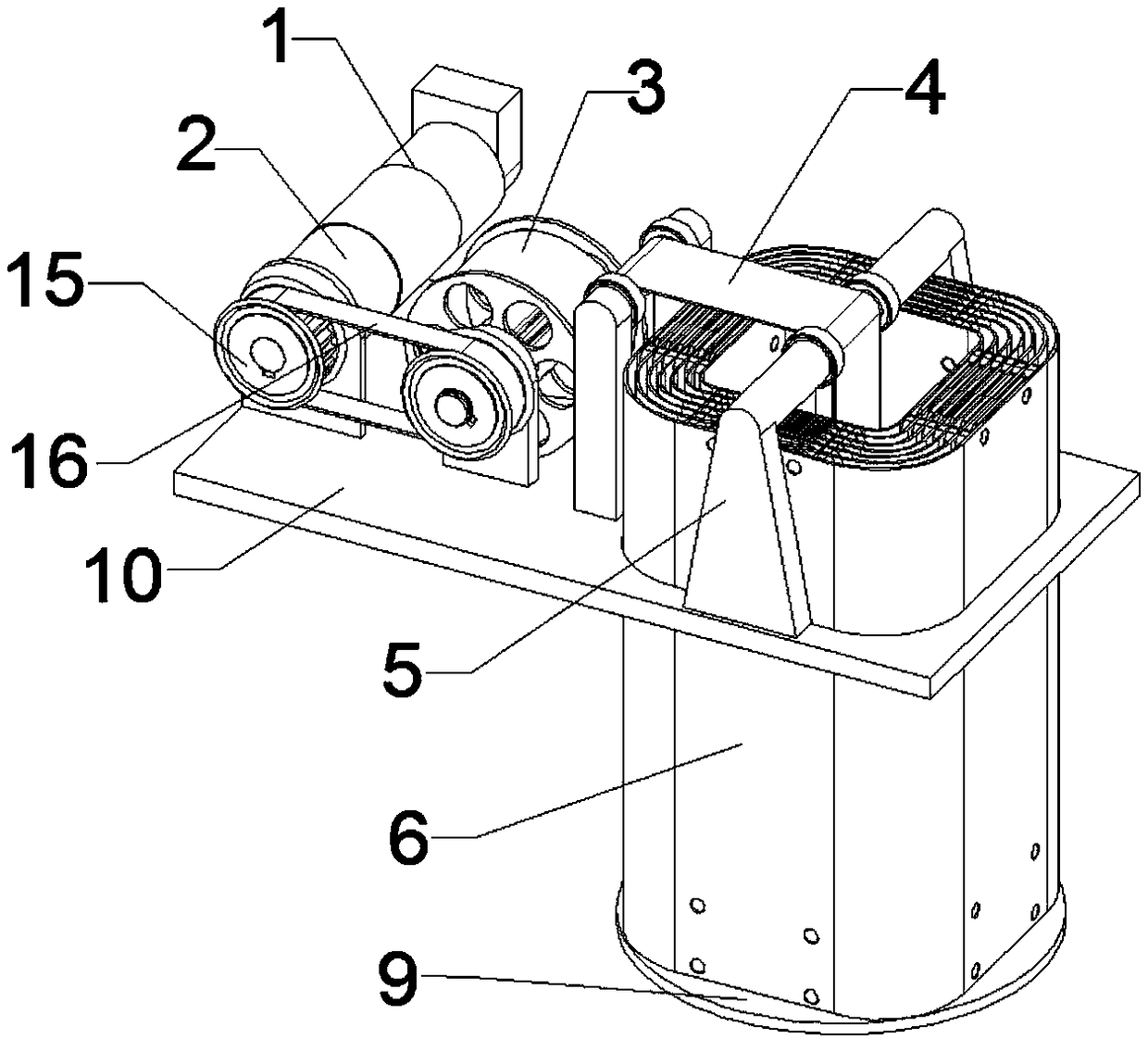

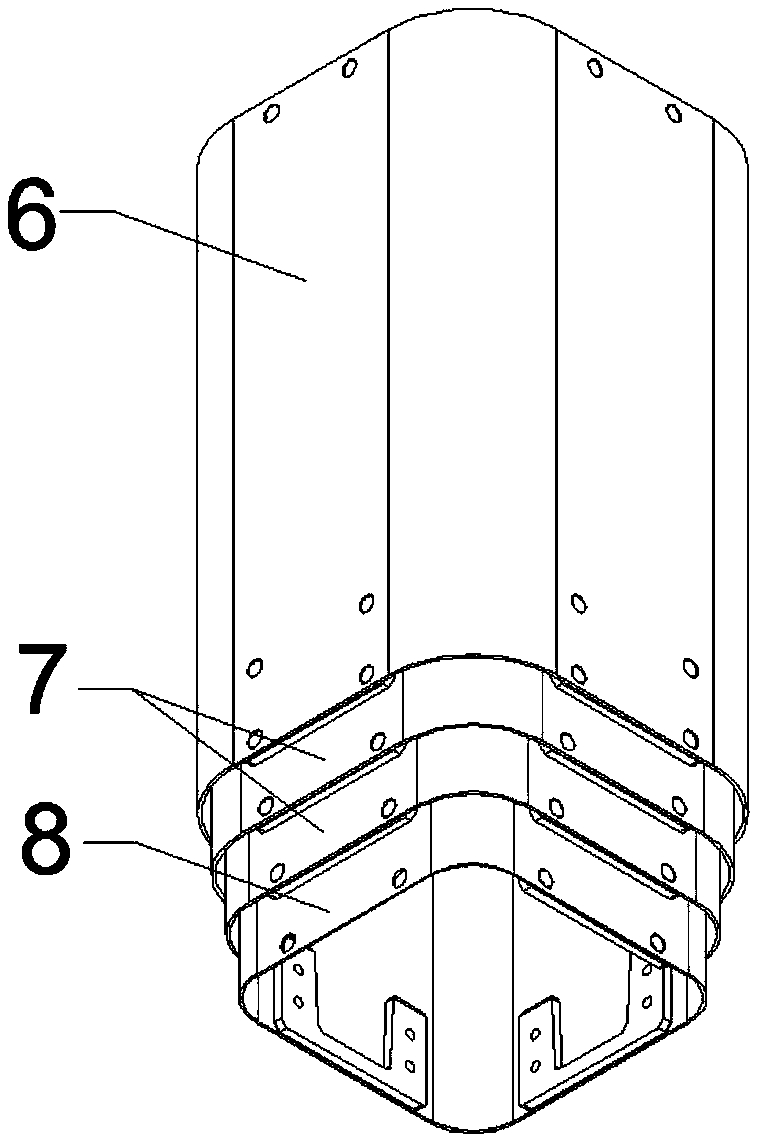

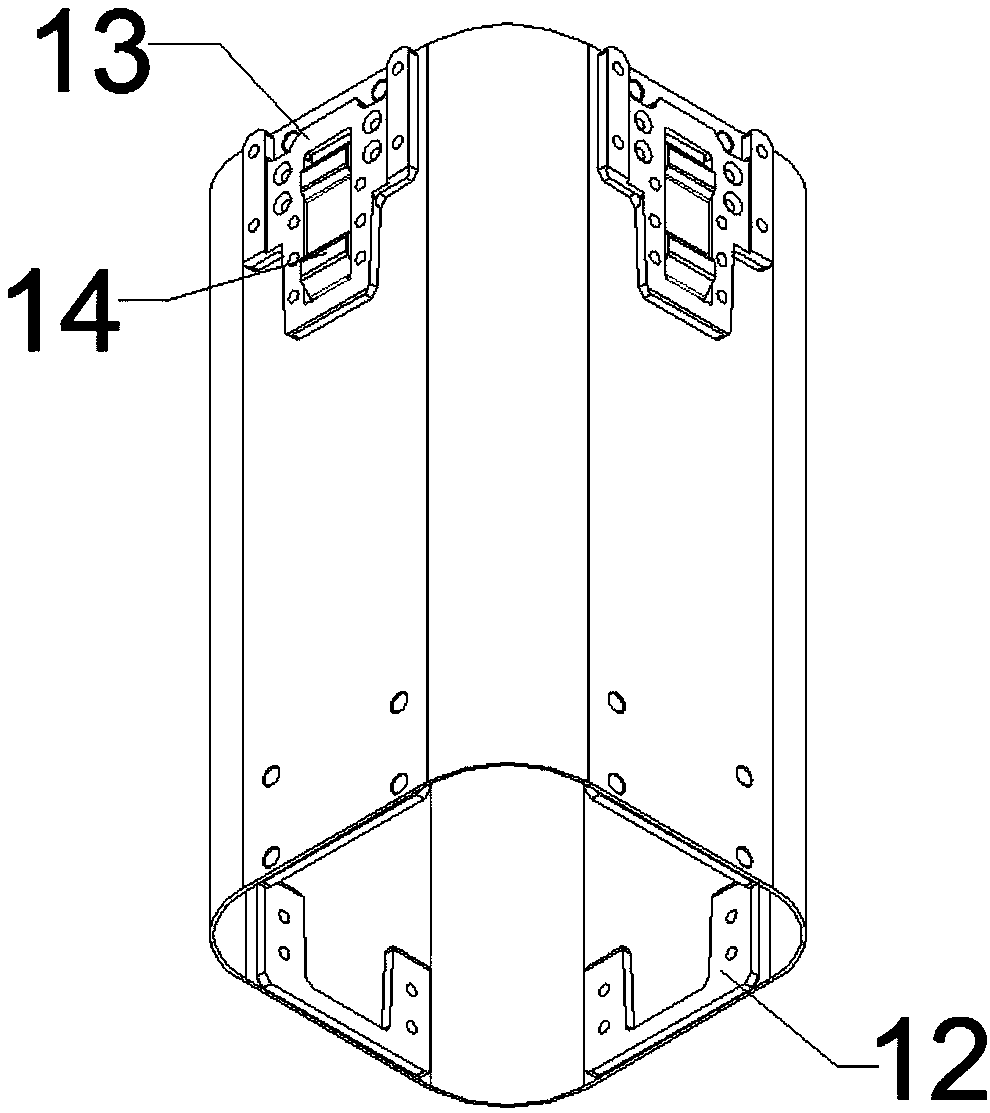

Multi-stage sleeve type lifting mechanism for robot

The invention discloses a multi-stage sleeve type lifting mechanism for a robot. The mechanism includes a driving assembly, a reel, a flat belt bogie and a multi-stage sleeve, wherein the multi-stagesleeve is a rectangular parallelepiped sleeve, the multi-stage sleeve comprises an outermost sleeve, multiple intermediate sleeves and an innermost sleeve, the bottom of the innermost sleeve is fixedly provided with a bottom plate, the driving assembly and a drum are driven by a synchronous belt, the drum is connected with the bottom plate through a flat belt, a top stop plate, a bottom stop plateand a guide plate are arranged between two adjacent-stage sleeves, an expansion plate spring is arranged in the middle of the guide plate, when the flat belt winds to drive the multi-stage sleeve toexpand and contract, that the sleeves are stably clamped to each other without twisting or falling off can be guaranteed by the structure. Compared with the prior art, the structure has good rigidity,high stability, can prevent twisting and has high positioning precision.

Owner:SHENZHEN LAUNCH DIGITAL TECH

Embedding and rolling forming machine tool for radiator fins

InactiveCN102716992BEasy meshIncrease travel distanceHeat exchange apparatusHydraulic cylinderShortest distance

The invention belongs to an electronic radiator and particularly relates to an embedding and rolling forming machine tool for radiator fins. The embedding and rolling forming machine tool is characterized in that a workbench driving system comprises a hydraulic cylinder, a driving trolley, four support shafts, round wheels and steel wire ropes, wherein the piston of the hydraulic cylinder is fixedly connected the driving trolley; the four support shafts are fixedly connected to the left and the right sides of the driving trolley respectively; one round wheel is mounted on each support shaft; one end of each steel wire rope is fixed on a machine tool body; the other end of the steel wire rope is fixed on a movable workbench; and round grooves in the circumferences of the four round wheels on the four support shafts are in contact connection with the four steel wire ropes respectively, so as to form a pair of left driving hair springs and a pair of right driving hair springs. The embedding and rolling forming machine tool has the benefits that in the process that the hydraulic cylinder drives the driving trolley to move, the workbench mounted on the driving trolley moves not only along with the driving trolley but also relative to the driving trolley under the action of the two pairs of hair springs, so that the moving distance of the workbench is increased, and short distance input and long distance output are realized; and the embedding and rolling forming machine tool ensures that the pressing-in quality is reliable, insert plates are not distorted and cross sections are free of deformation.

Owner:中色(天津)特种材料有限公司

A front-mounted, four-wheel-drive corn harvester transmission mechanism

A front-arranged four-wheel-drive maize harvesting machine transmission mechanism of a peeling machine is structurally characterized in that a diesel engine is installed in the middle of the whole machine. A left belt wheel of the diesel engine is connected with a walking clutch through a triangular belt, and a transmission gear installed at the right end of a clutch shaft is meshed with a gearbox power input gear. A right belt wheel of the diesel engine is connected with a combination grouping belt wheel installed at the input end of a middle transmission box through a combination grouping triangular belt, and a harvesting clutch wheel is installed on a frame in front of the combination grouping belt wheel. A steering driving axle is connected with a rear output shaft of a walking gearbox through a transmission shaft. A power input chain wheel of a returning-to-field machine is connected with a left driving chain wheel installed at the left output end of the middle transmission box through a chain. An auger power input chain wheel and an elevator power input chain wheel are connected with a right driving chain wheel installed at the right output end of the middle transmission box through a chain. A header power input chain wheel is connected with a right transmission chain wheel through a series of transmission chain wheels and chains, and a left transmission chain wheel is connected with a power output chain wheel installed at the right output end of the middle transmission box through a chain. By means of the structure, the whole machine transmission system is simple and reliable, low in cost and complete in function.

Owner:SHANDONG CHANGLIN AGRI SCI EQUIP

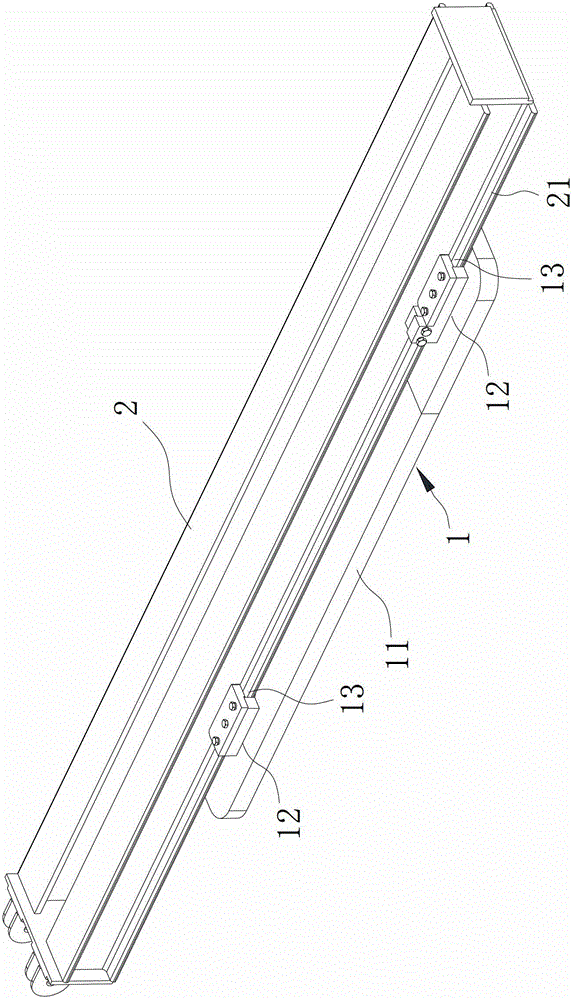

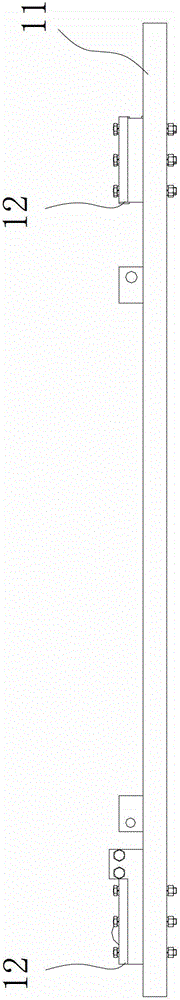

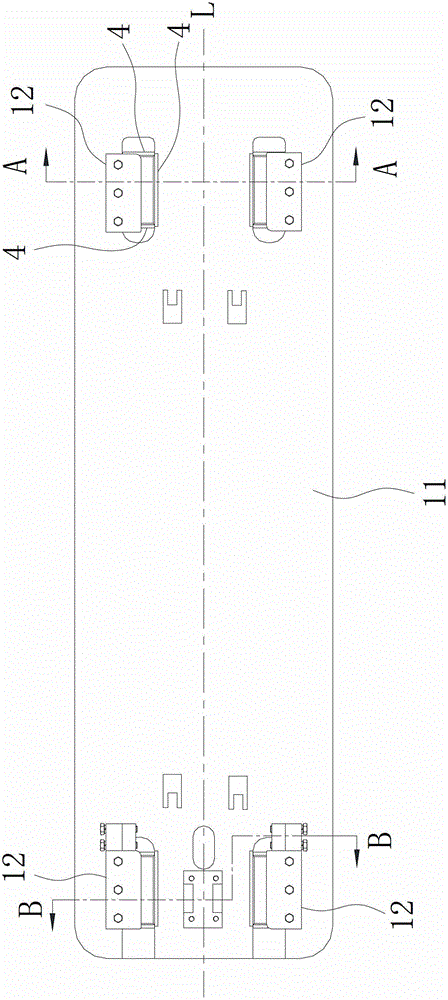

Guiding connection mechanism and excavator

ActiveCN102733806AImprove work efficiencyThe transmission structure is simple and reliableSlitting machinesEngineeringExcavator

The invention discloses a guiding connection mechanism and an excavator. The guiding connection mechanism is used for connecting the body of the excavator and a bolting machine, and guiding the bolting machine to slide on the body of the excavator. The guiding connection mechanism comprises a guide groove device which is arranged on the body of the excavator, and a sliding part which is arranged on the guide groove device, can slide on the guide groove device and is used for arranging the bolting machine. The guiding connection mechanism and the excavator of the invention are in favor of the accurate positioning of the bolting machine, and have the high working efficiencies, and simple and reliable structures.

Owner:益阳市科技成果转化服务中心 +1

A four-row corn harvester transmission mechanism with adjustable row spacing

The invention discloses a transmission mechanism of a four-row corn harvesting machine with adjustable row spacing. An engine is mounted in the middle of the whole machine; a left belt wheel of the engine is connected with a gearbox clutch; a traction gearbox is connected with a rear driving axle; a right belt wheel of the engine is connected with a transmission belt wheel; the transmission belt wheel is connected with a belt wheel of a returning machine; a transmission chain wheel is connected with a left transmission chain wheel; a right transmission chain wheel is connected with a chain wheel of a lift conveyer; a transmission gear is connected with a gear on a fixed middle shaft; the fixed middle shaft is connected with a movable middle shaft in a sliding manner; a driving chain wheel of the fixed middle shaft is connected with a transmission chain wheel of a fixed corncob picking device through a series of chains and chain wheels and connected with an input chain wheel of a first stripping machine through chains; an output chain wheel of the first stripping machine is connected with an input chain wheel of an auger; a driving chain wheel of the movable middle shaft is connected with a transmission chain wheel of a movable corncob picking device through a series of chains and chain wheels and connected with an input chain wheel of a second stripping machine through chains. With the adoption of the structure, a transmission system of the whole machine is simple, reliable and complete in function.

Owner:SHANDONG CHANGLIN AGRI SCI EQUIP

Mechanical arm type auxiliary drawing device

ActiveCN107757201AThe transmission structure is simple and reliableEasy to operateWriting aidsEngineeringTooth number

The invention discloses a mechanical arm type auxiliary drawing device. The auxiliary drawing device comprises a drawing board, a coaxial input device, an inner telescopic arm, a ruler, LED lamp beads, an inner square shaft and an outer square shaft; the coaxial input device is arranged at the right lower corner of the drawing board; the inner square shaft and the inner telescopic arm form a revolute pair; the inner square shaft and the outer square shaft form a movable pair; a second small bevel gear is arranged at the front end of the inner square shaft; a graduated scale is arranged on theupper side of the inner telescopic arm; the inner telescopic arm and an outer telescopic arm form a movable pair; a ruler mounting base is arranged at the front end of the inner telescopic arm; the ruler and the ruler mounting base form a revolute pair; an observation hole channel is formed in the center of a ruler rotating disc; the tooth number ratio of a first small bevel gear to a first largebevel gear is equal to the tooth number ratio of the second small bevel gear to a second large bevel gear; the center of the lower end of the ruler rotating disc is of a cavity structure, and the three LED lamp beads are uniformly distributed on the side wall of a cavity of the ruler rotating disc; and a sight bead is arranged at the center position of the lower end of the observation hole channel, a ruler middle position scale line is arranged at one edge of a long straight hole, and a straight line where the edge is located passes through the center of the sight head.

Owner:江苏海港成套设备安装有限公司

Linearly reciprocating hydraulic drive mechanism

InactiveCN102745476AIncrease travel distanceReduce volumeFluid-pressure actuatorsMechanical conveyorsHydraulic cylinderReciprocating motion

The invention belongs to the field of hydraulic drive, and particularly relates to a linearly reciprocating hydraulic drive mechanism. The linearly reciprocating hydraulic drive mechanism is characterized in that: the linearly reciprocating hydraulic drive mechanism comprises a hydraulic cylinder, a drive trolley, four support shafts, round pulleys and wire ropes, the four support shafts are respectively fixedly connected with the left and the right sides of a carriage, a round pulley is mounted on each support shaft, the circumferences of the round pulleys are provided with round grooves, one end of each wire rope is fixed on a machining tool body, the other ends of the wire ropes are fixed on a movable working table, the round grooves on the circumferences of the four round pulleys of the four support shafts are respectively in contact with the four wire ropes, the fixed points of the two wire ropes moving to the left are on the left, and round the round pulleys on the right support shafts, the fixed points of the two wire ropes moving to the right are on the right, and round the round pulleys on the left support shafts, and thereby a left pair of drive hair wires and a right pair of drive hair wires are formed. The linearly reciprocating hydraulic drive mechanism has the advantage that: the drive trolley is driven by the hydraulic cylinder, and by means of the two pairs of hair wires, the drive trolley ensures that the movable working table not only can move along with the drive trolley but also can move relative to the drive trolley. The linearly reciprocating hydraulic drive mechanism achieves the purpose of increasing the moving distance of the working table.

Owner:中色(天津)特种材料有限公司

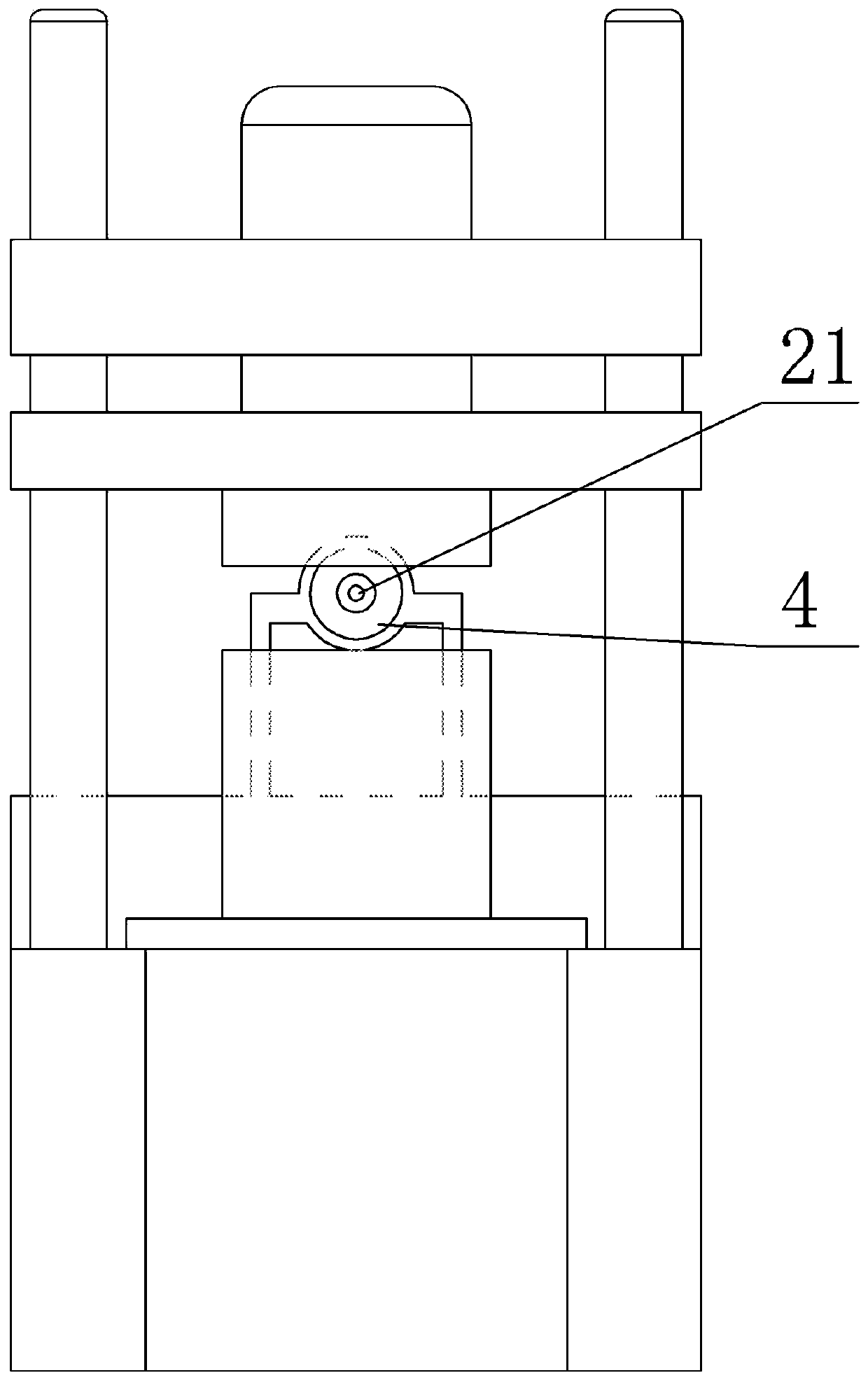

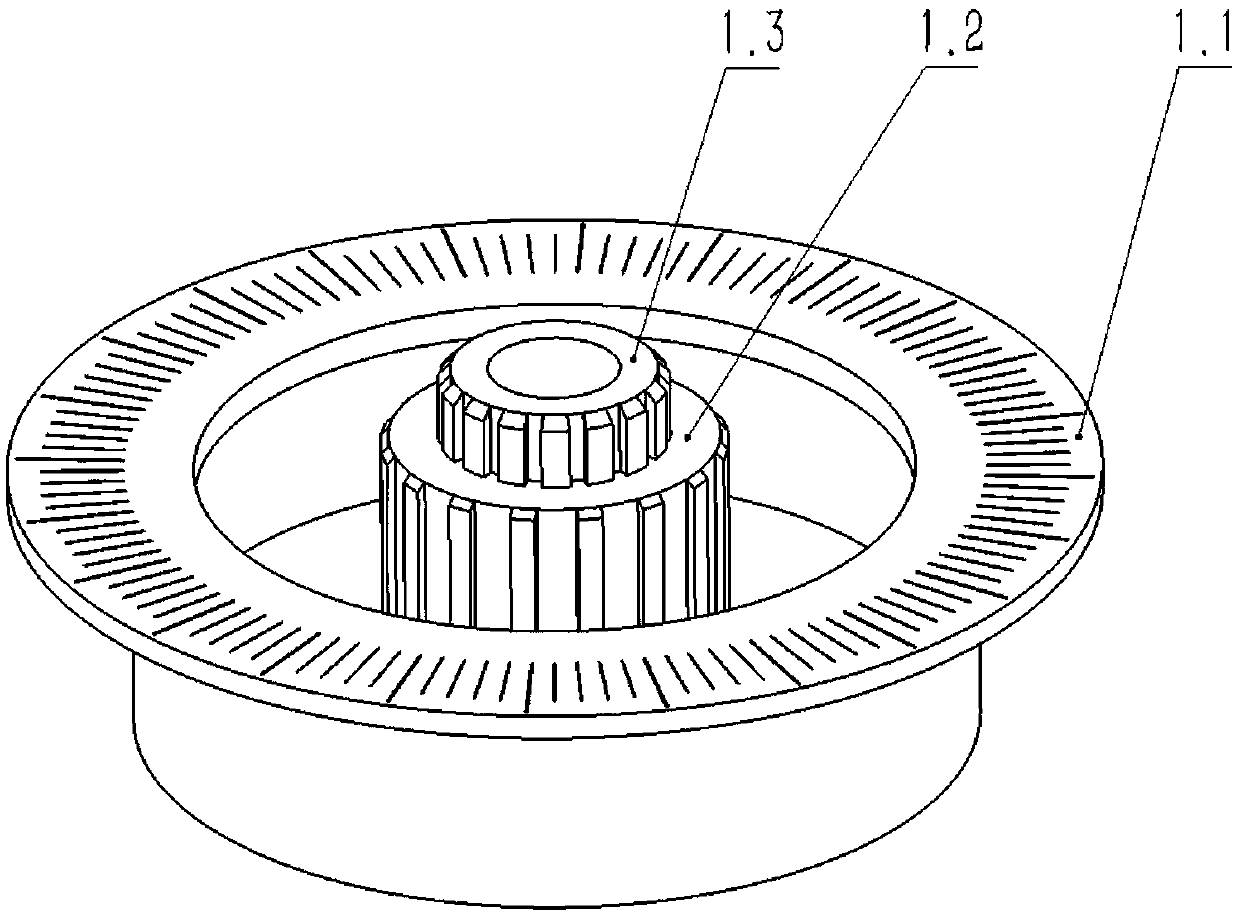

Grouping injection molding method

InactiveCN110978376AThe transmission structure is simple and reliableLarge amount of materialDomestic articlesEngineeringRing mode

The invention provides a grouping injection molding method. The grouping injection molding method is used for carrying out grouping of injection molding holes distributed in the periphery of a rotor in a ring mode for injection molding, so that the position of magnetic steel in the large-stack thick rotor is stable and reliable, the method improves the production efficiency, and the injection molding cost is reduced, The M injection molding holes are uniformly distributed on the top of the to-be-injection-molded rotor in the ring mode, the to-be-injection-molded rotor is placed in a cavity ofa lower mold, injection molding discharging ports of an upper mold align with the L injection molding holes arranged continuously, wherein M = N * L, the bottom of the lower mold is arranged on a servo turntable, a servo motor is driven to drive the servo turntable to rotate, the injection molding of the L injection molding holes per single time is completed, preset rotating angles correspond circularly by the servo motor, the injection molding of the next set of L injection molding holes is carried out until the operation that mold is opened and the rotor is taken out after the injection molding is conducted of all the injection molding holes at the top of the rotor is completed.

Owner:SUZHOU LVKON NEW ENERGY TECH CO LTD

Single-shaft transmission roller detachable three-high mill

PendingCN111744957AImprove efficiencyReduce maintenance costsMetal rolling stand detailsRollsStructural engineeringManufacturing engineering

The invention relates to the technical field of bar mills, and provides a single-shaft transmission roller detachable three-high mill. The mill comprises a rack and three shaft assemblies arranged onthe rack, wherein every two shaft assemblies form an angle of 60 degrees, the rack is of a split structure, the three shaft assemblies comprise an input long shaft assembly and two transmission shortshaft assemblies, and the transmission short shaft assemblies are connected with the input long shaft assemblies for transmission. According to the mill, by adopting the split rack, the three-high mill which is simple and reliable in transmission structure is formed by cooperation of the long shaft assembly and the short shaft assemblies, and the investment cost is greatly reduced through the simpler structure; during equipment maintenance, rollers can be quickly disassembled in a quick disassembly manner, the roller dismounting and mounting accuracy are maintained, and remounting and reuse are not affected.

Owner:四川易尚天交实业有限公司

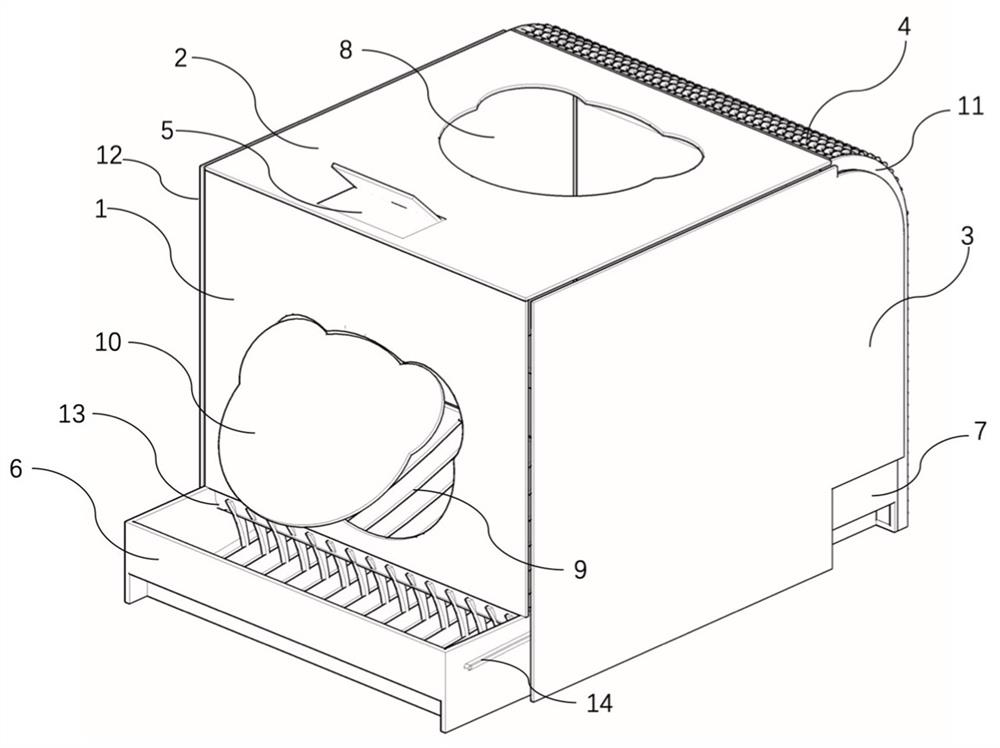

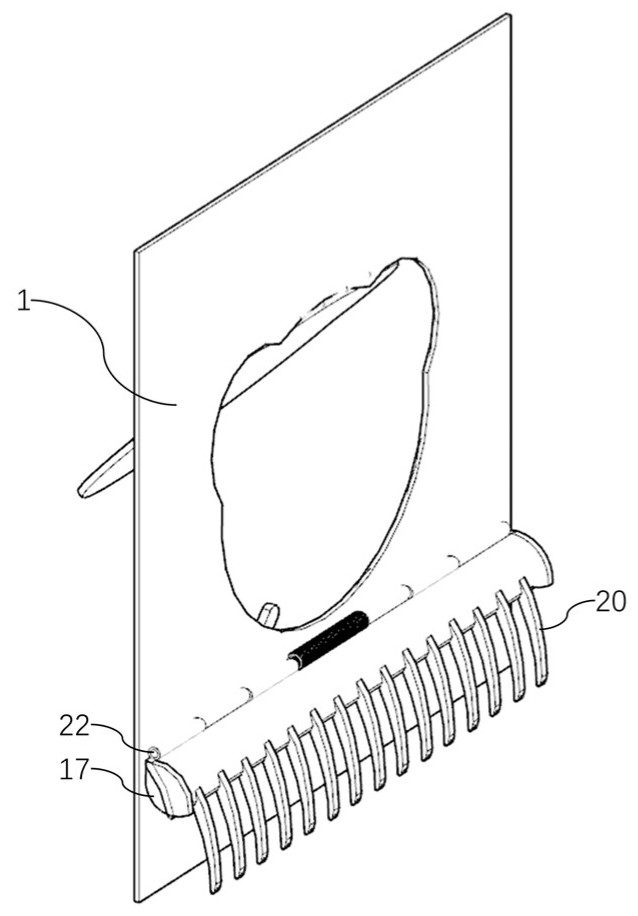

Novel cat litter box without manually shoveling excrement

The invention discloses a novel cat litter box without manually shoveling excrement, and relates to the technical field of pet appliances. The novel cat litter box comprises: a cat litter drawer box, an excrement box, a spring hinge comb shovel mechanism, and a box body component, wherein the spring hinge comb shovel mechanism is fixedly installed on the inner side of a front plate, guide blocks are arranged on the two sides of a hinge, a mechanical transmission group can be formed with guide rails on the outer sides of the drawer box, and with a pulling action of the cat litter drawer box, condensed cat litter can be shoveled into the excrement box, so that cat litter can be cleaned without manual shoveling.

Owner:廖宇超

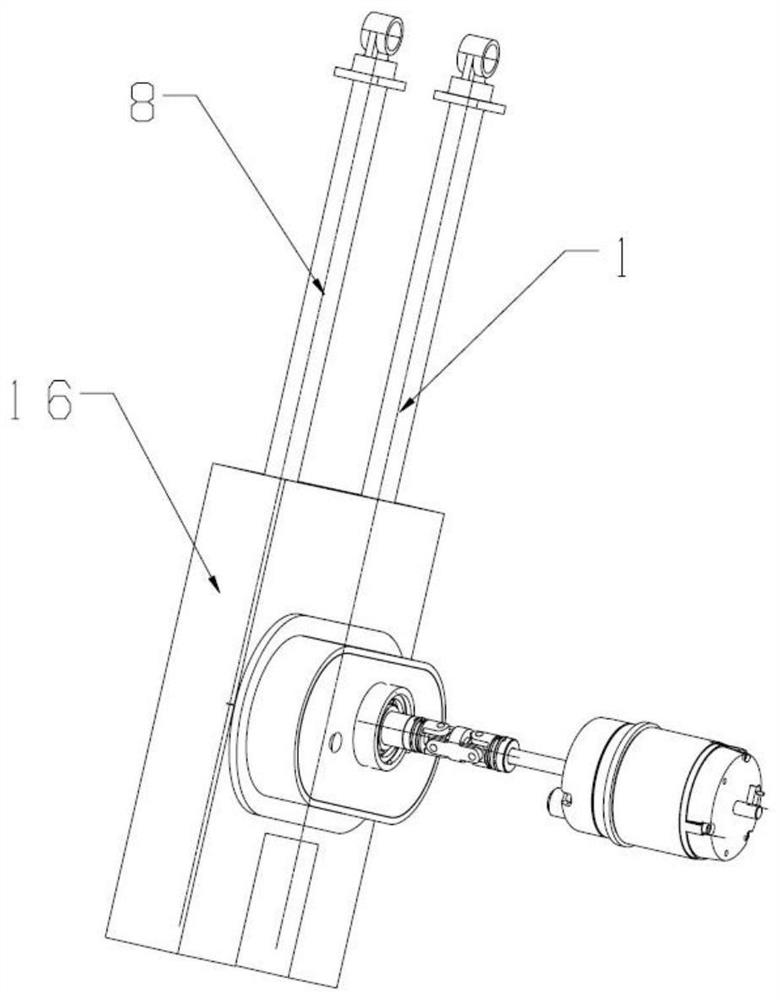

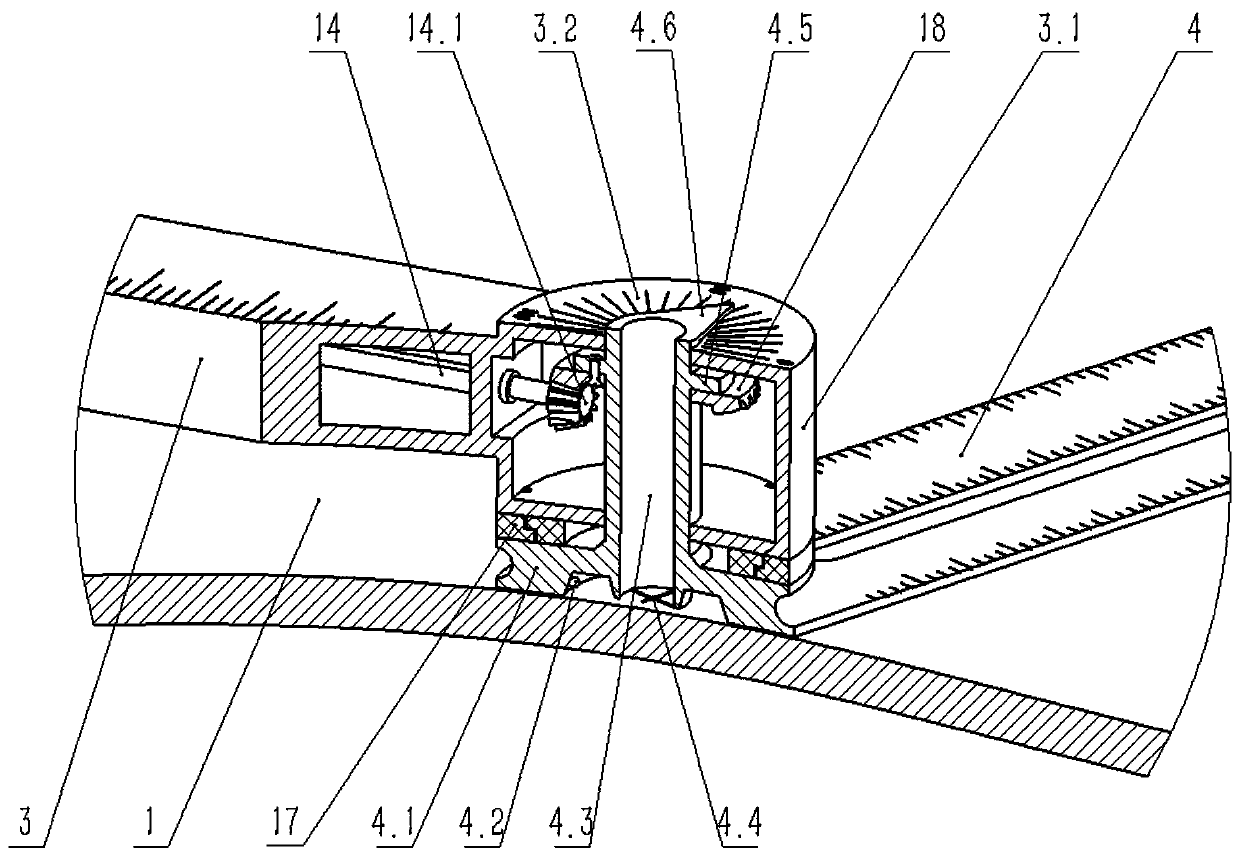

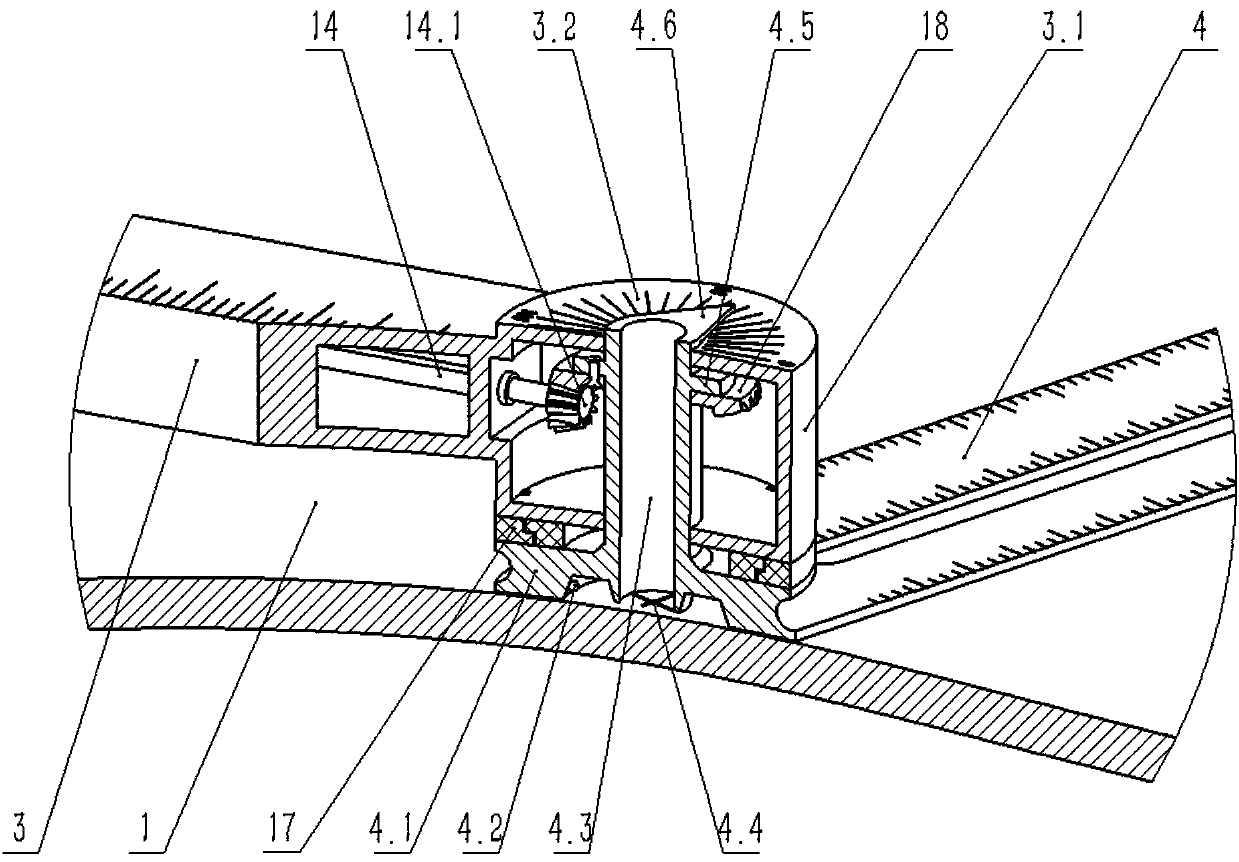

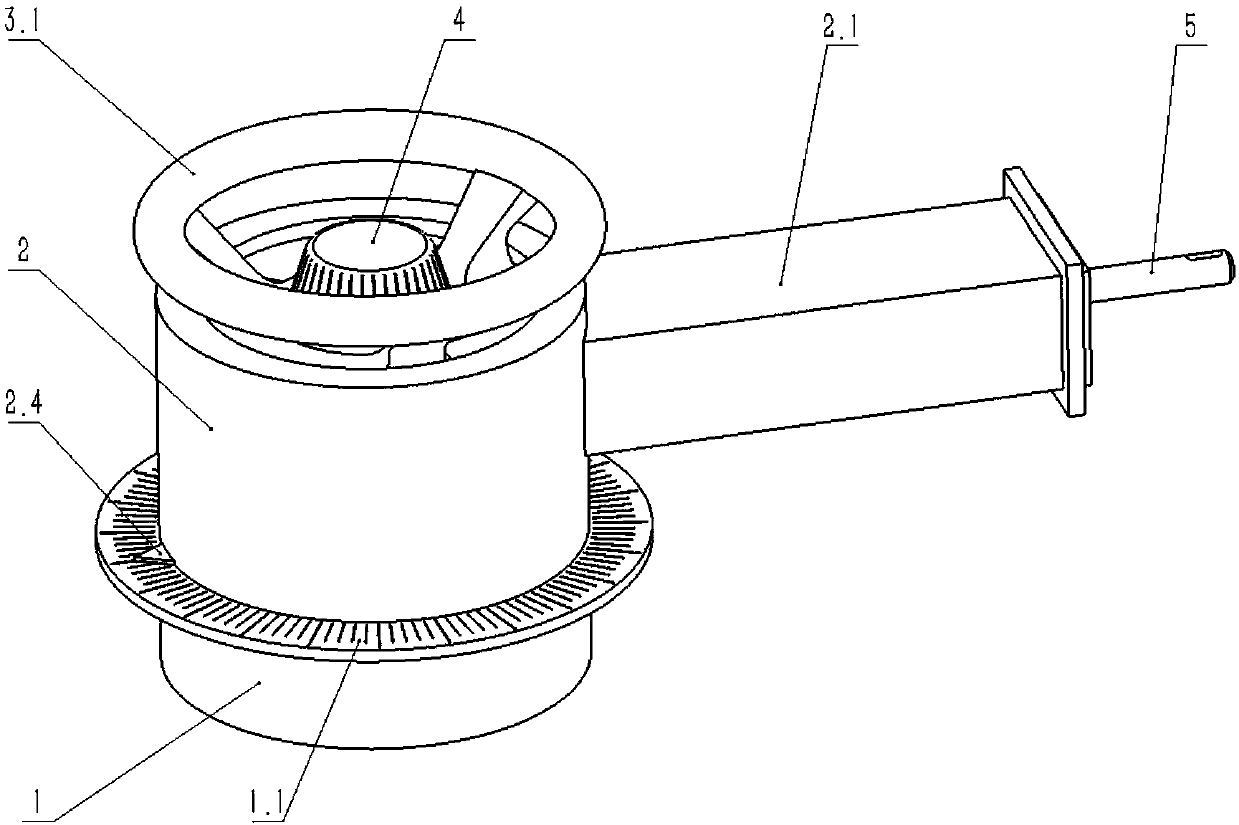

Coaxial input transmission device

ActiveCN107606065AThe transmission structure is simple and reliableEasy to operateToothed gearingsEngineeringMechanical engineering

The invention discloses a coaxial input transmission device. The coaxial input transmission device comprises a base, an outer cylinder, an inner cylinder, a rotary knob, an output shaft, a rotary table bearing, a bevel gear wheel, an upper locking sleeve, an upper locking sheet, a lower locking sleeve, a lower locking sheet, an upper spring and a lower spring; the upper locking sleeve, the lower locking sleeve and the base form a moving pair, and one spring is arranged between the upper locking sleeve and the base as well as the lower locking sleeve and the base; the rotary knob and the upperlocking sleeve form a revolute pair; the inner cylinder and the lower locking sleeve form a revolute pair; anti-skid teeth I which can mesh with each other are arranged at the center of the bevel gearwheel and the lower end of the rotary knob separately; anti-skid teeth II which can mesh with each other are arranged at the lower end of the inner cylinder and the lower end of the inner side of theouter cylinder separately; the upper locking sleeve can lock the rotation of the output shaft; the lower locking sleeve can lock the rotation of an output arm; a hand wheel can control the output armto rotate; when the hand wheel does not rotate, the output arm is locked, and the rotary knob can control the output shaft to rotate; and when the rotary knob does not rotate, the output shaft is locked.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

A material packaging production line

ActiveCN113353344BSmooth transmissionThe transmission structure is simple and reliableWrapper twisting/gatheringSolid materialMicrocomputerProduction line

The invention discloses a material packaging production line, which comprises a packaging box, a box opening device, a material distributing device and a box sealing device; The first belt transmission mechanism; the material distribution device includes a vibrating straight feeder, a feed hoist, a microcomputer combination scale, a material discharge hoist, and a material distribution bracket. A lower receiving hopper, a closed-loop transmission assembly is arranged on the top of the material distribution bracket, and multiple distribution bins are installed on the closed-loop transmission assembly; the sealing device includes a sealing transmission assembly, a first pushing assembly and a transmission direction along the sealing transmission assembly. Set left and right platen assemblies, rear platen assemblies, glue spraying assemblies and front platen assemblies. The present invention is applicable to the boxing requirements of any weighable material, not only can significantly improve production efficiency, but also can greatly reduce labor costs, thereby improving the economic benefits of the enterprise.

Owner:温州凯祥包装机械有限公司

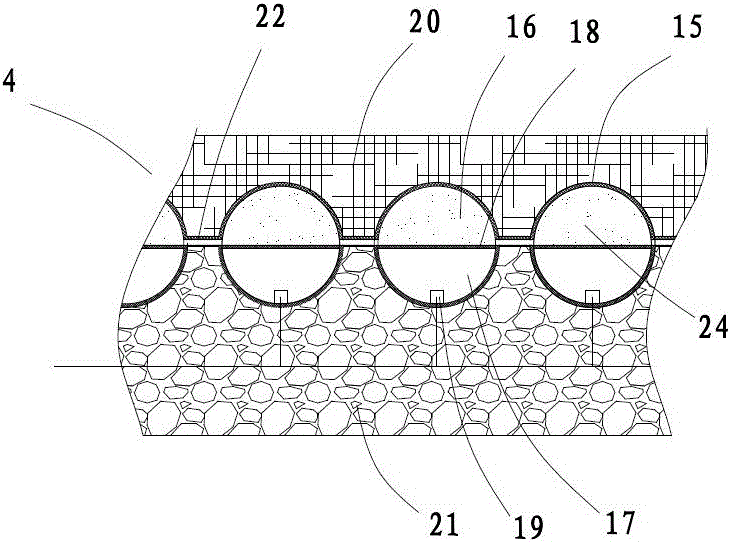

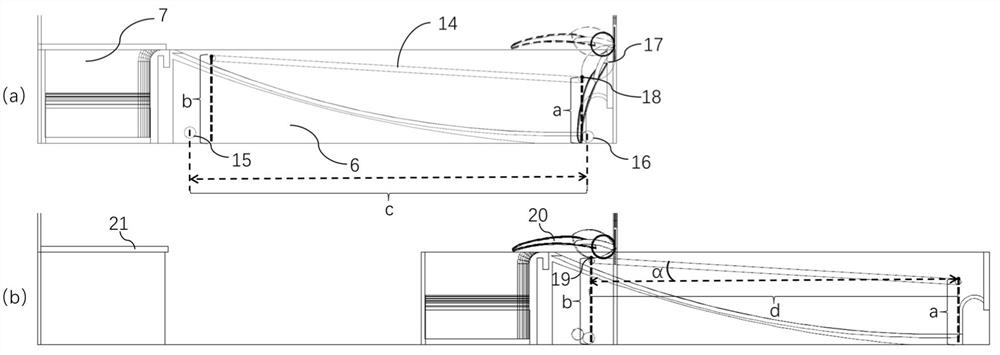

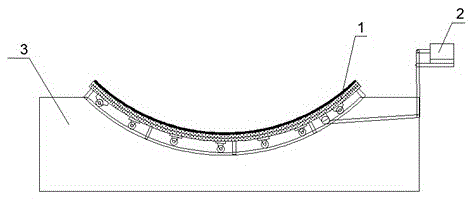

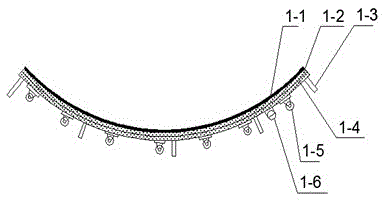

Cement-poured trough type solar condenser and tracking device

InactiveCN105546840ALow costSuitable for large-scale commercial developmentSolar heating energySolar heat collector controllersEngineeringAluminum foil

The invention discloses a cement-poured trough type solar condenser and tracking device. The cement-poured trough type solar condenser and tracking device comprises a combined condenser, a hydraulic transmission unit and a concrete support body, wherein the combined condenser is mainly characterized in that a paraboloid structure is made of cement concrete in a grinding tool, reflective aluminum foil is adhered to the inner surface of the paraboloid, and positioning pins, rollers and a transmission unit mounting port are mounted on the back surface of the paraboloid. The combined condenser is placed in the concrete support body and can track the trajectory of the sun. Under the assistance of the hydraulic transmission unit, the sun is tracked automatically. The paraboloid is made of cement, the sun tracking mechanism is simple and low in cost, and large-scale commercialization of trough type solar systems is facilitated.

Owner:李俊娇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com