Centrifugal pump for conveying viscous medium

A centrifugal pump and medium technology, which is used in the components of pumping devices for elastic fluids, pumps and pumps for special fluids, etc., which can solve the problem of difficult to guarantee sealing effect and life, poor end-face tracking and fit, and medium liquid film lubrication. It can improve the effect and service life of the mechanical seal, the influence of pressure deformation under working conditions is small, and the anti-torque ability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

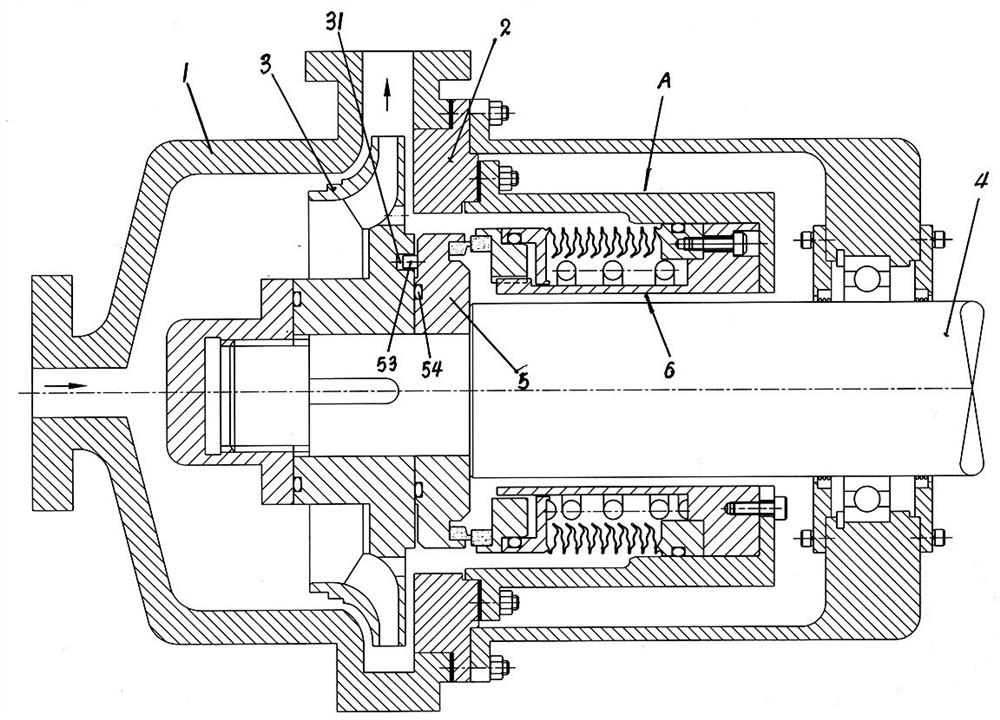

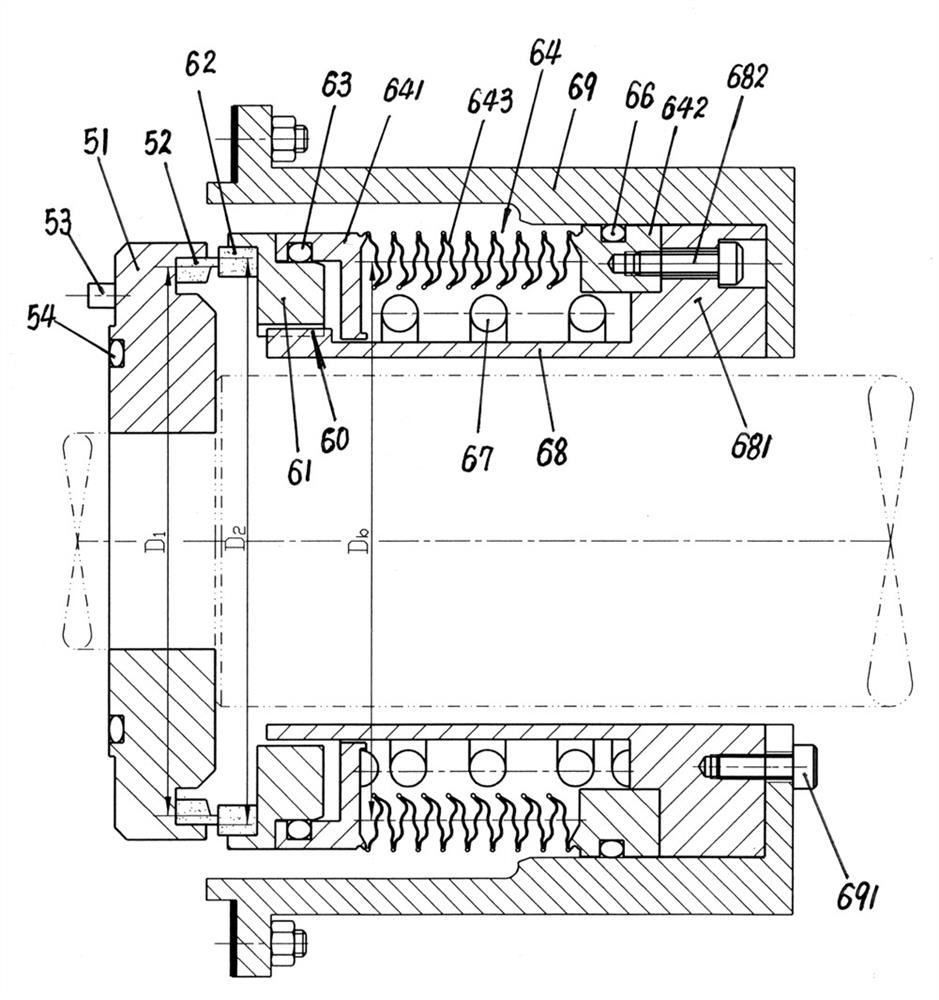

[0033] The present invention is used to convey the centrifugal pump of viscous medium, comprises pump body 1, pump cover 2, impeller 3, pump shaft 4, mechanical sealing device A, mechanical sealing device A is composed of moving ring assembly 5, static ring assembly 6.

[0034] The moving ring assembly 5 is composed of a moving ring seat 51 , a moving ring 52 , an anti-rotation pin 53 and a sealing ring 54 .

[0035] On the right end surface of the moving ring seat 51, there is an inner stop groove, and the moving ring 52 is embedded and fixedly installed in the inner stop groove provided on the moving ring seat 51, and the moving ring seat 51 is installed on the shaft of the pump shaft 4 through the central shaft hole. At the shoulder, the moving ring seat 51 is axially squeezed and fixed by the impeller 3, and a positioning pin hole 31 is opened on the right end face of the impeller 3, and the anti-rotation pin 53 fixedly installed on the left end face of the moving ring seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com