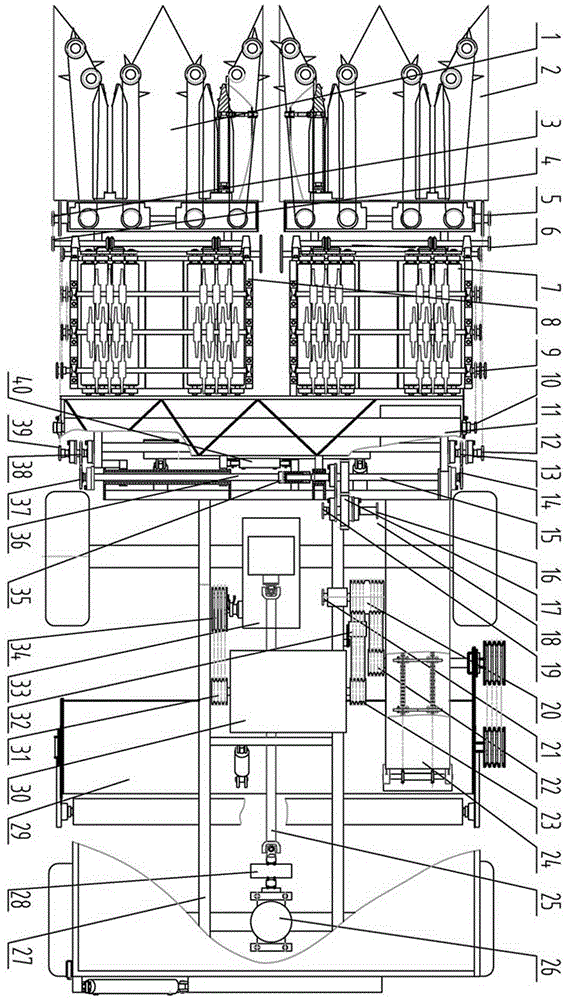

A four-row corn harvester transmission mechanism with adjustable row spacing

A corn harvester and transmission mechanism technology, applied in the field of machinery, can solve the problems of easy falling into the ground, no four-wheel drive function, poor climbing ability, etc., to improve the reliability and adaptability of use, optimize the design of the transmission mechanism, drive Simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation of a four-row corn harvester transmission mechanism with adjustable row spacing of the present invention will be further described below in conjunction with the accompanying drawings: start the engine (30), and the power of the engine (30) is installed on the left pulley (31) of the engine. The V-belt is transmitted to the gearbox clutch (34) all the way to provide power for the whole machine to travel. At the same time, the rear output shaft of the travel gearbox (33) transmits power to the rear drive axle (26) through the universal joint drive shaft (25). Thereby realized the four-wheel drive; the power of the engine (30) is transmitted to the transmission pulley (20) through the V-belt installed on the right pulley (23) of the engine, and is assembled on the right pulley of the engine by controlling the harvesting clutch wheel (32). (23) and the tension degree of the V-belt on the transmission pulley (20), thereby controlling the separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com