Material packaging production line

A packaging production line and material technology, applied in packaging, packaging machines, transportation packaging, etc., can solve the problems of high labor costs and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

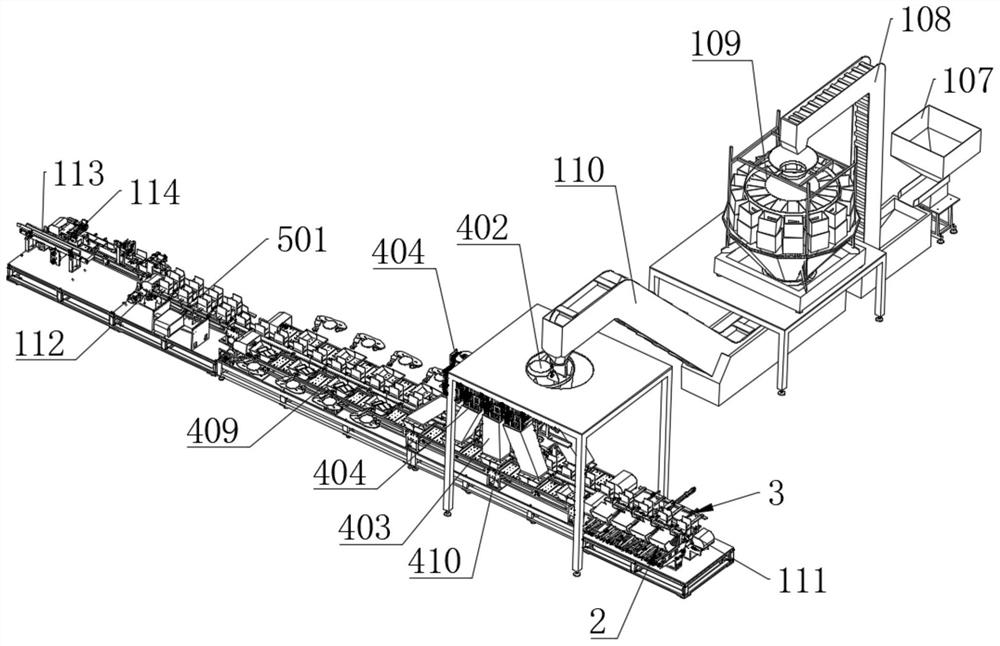

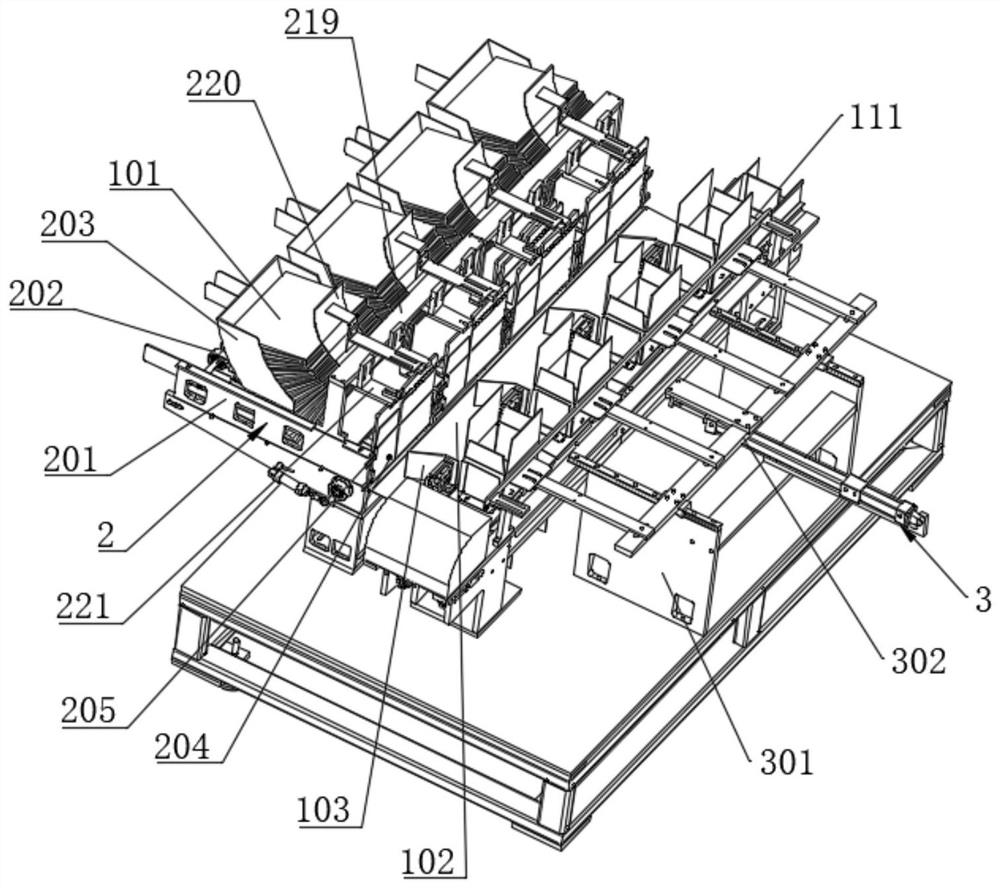

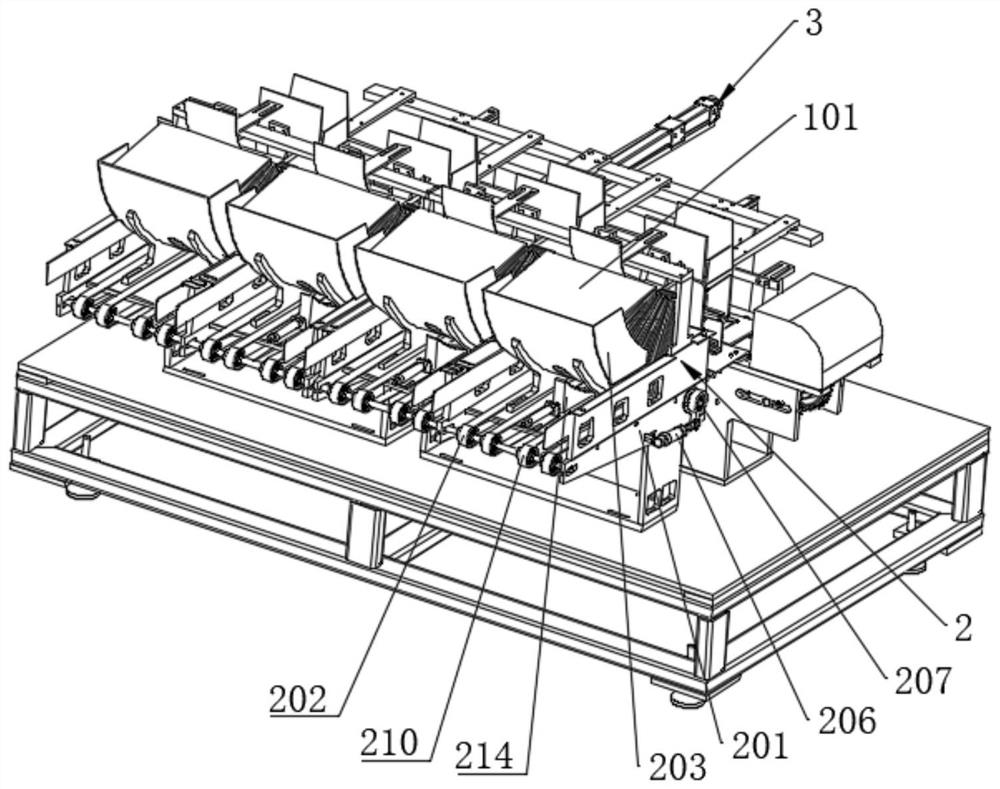

[0061] Example: as attached Figure 1-20 A material packaging production line shown includes a packaging box 101, a box opening device for the packaging box 101, a distributing device for weighing the material and loading it into the corresponding packaging box 101, and a packaging box for the material The box sealing device that box 101 closes;

[0062] as attached Figure 14 As shown, the packaging box 101 includes a box body 1011 and a left small tongue 1012, a right small tongue 1013, an outer big tongue 1014 and an inner big tongue 1015 arranged on the upper edge of the box body 1011;

[0063] as attached Figure 2-7 As shown, the box opening device includes a box feeding mechanism 2, a box suction mechanism 3, and a first belt transmission mechanism 111 arranged between the box feeding mechanism 2 and the box suction mechanism 3; the box sending mechanism 2 includes a box feeding bracket 201, the box sending bracket 201 is provided with a box sending assembly 202 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com