Guiding connection mechanism and excavator

A technology of guide connection and guide parts, which is applied in the field of guide structure, can solve the problems of high processing precision and assembly precision, relatively high requirements for installation and debugging, complex structure and relative movement, etc., and achieve simple process manufacturing and simple transmission structure Reliable, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but it is only a preferred embodiment and is not used to limit the essential scope of the present invention.

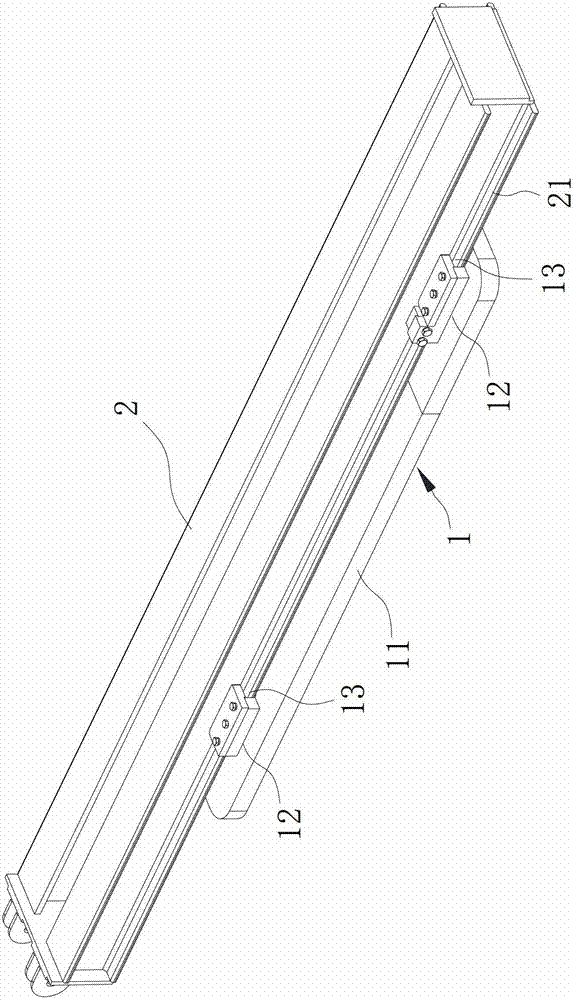

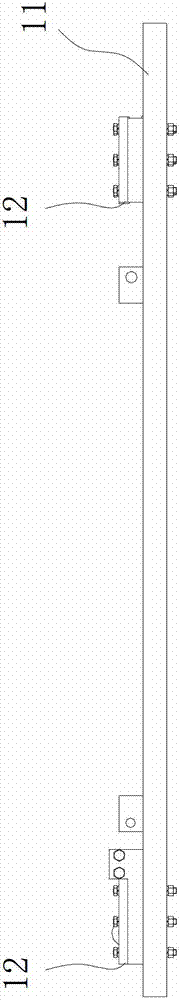

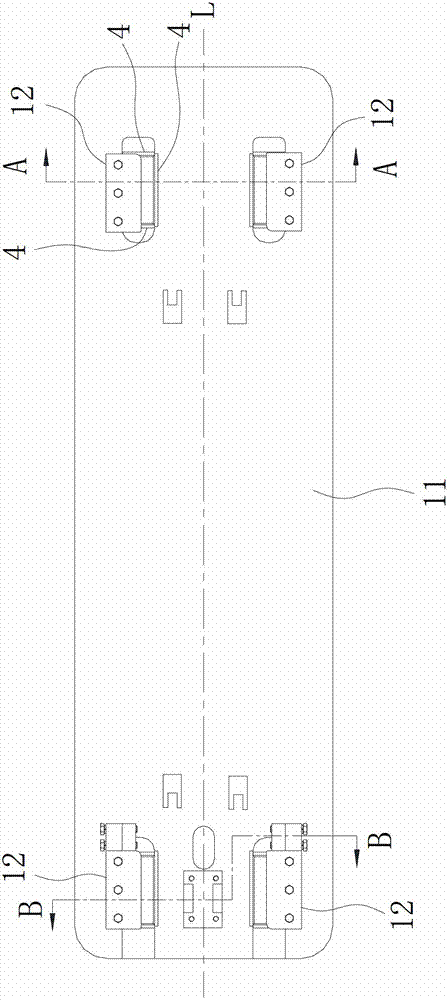

[0046] Please refer to Figure 1 to Figure 5 ,in figure 1 It is a three-dimensional schematic diagram of the guiding connection mechanism of the present invention, figure 2 It is a schematic diagram of the front view of the guide groove device of the guide connection mechanism of the present invention, image 3 It is a top view schematic diagram of the guide groove device of the guide connection mechanism of the present invention, Figure 4 for image 3 A-A sectional view of, Figure 5 for image 3 B-B sectional view, the guide connection mechanism of the present invention is mainly used to connect the body of the roadheader...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com