Embedding and rolling forming machine tool for radiator fins

A technology of roll forming and heat sink, which is applied in the direction of heat exchange equipment, etc., can solve the problems that cannot meet the meshing quality of heat sinks for large-scale power electronic components, cannot meet the fin mosaic process of extended heat sinks, and adjust asynchronously, etc. It achieves the effect of simple and reliable transmission structure, no deformation of cross section and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

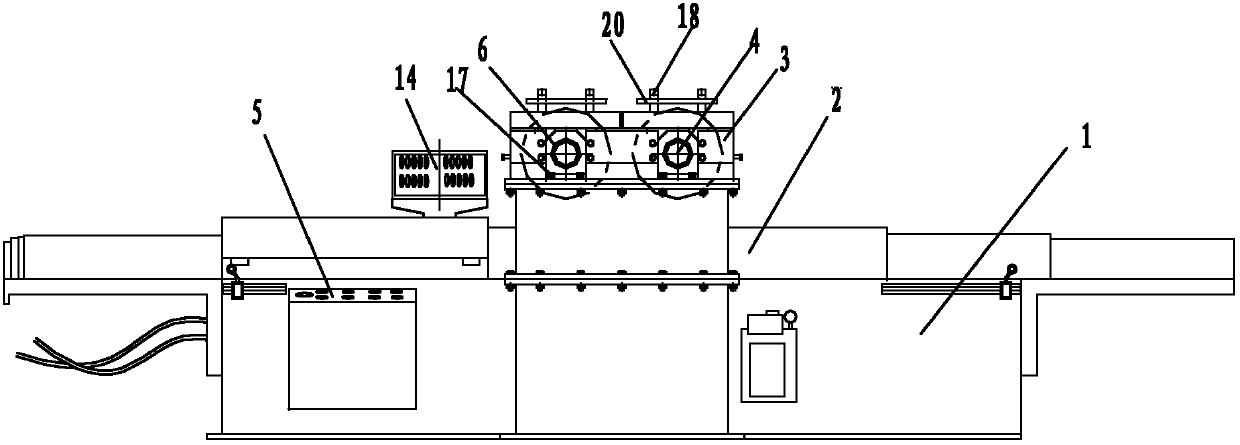

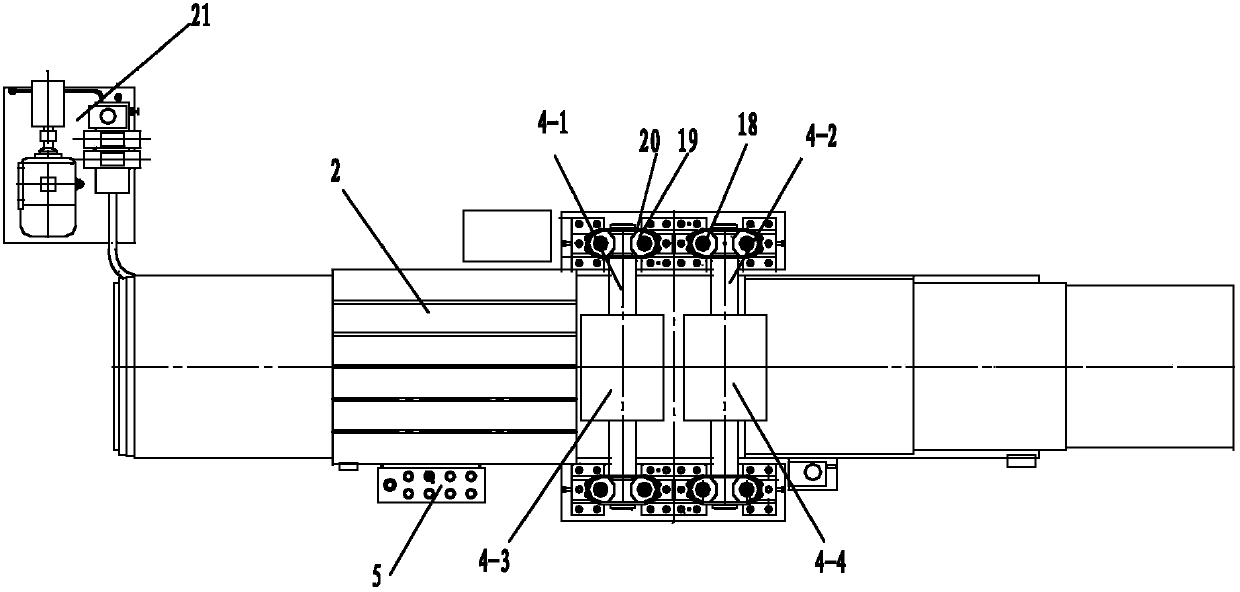

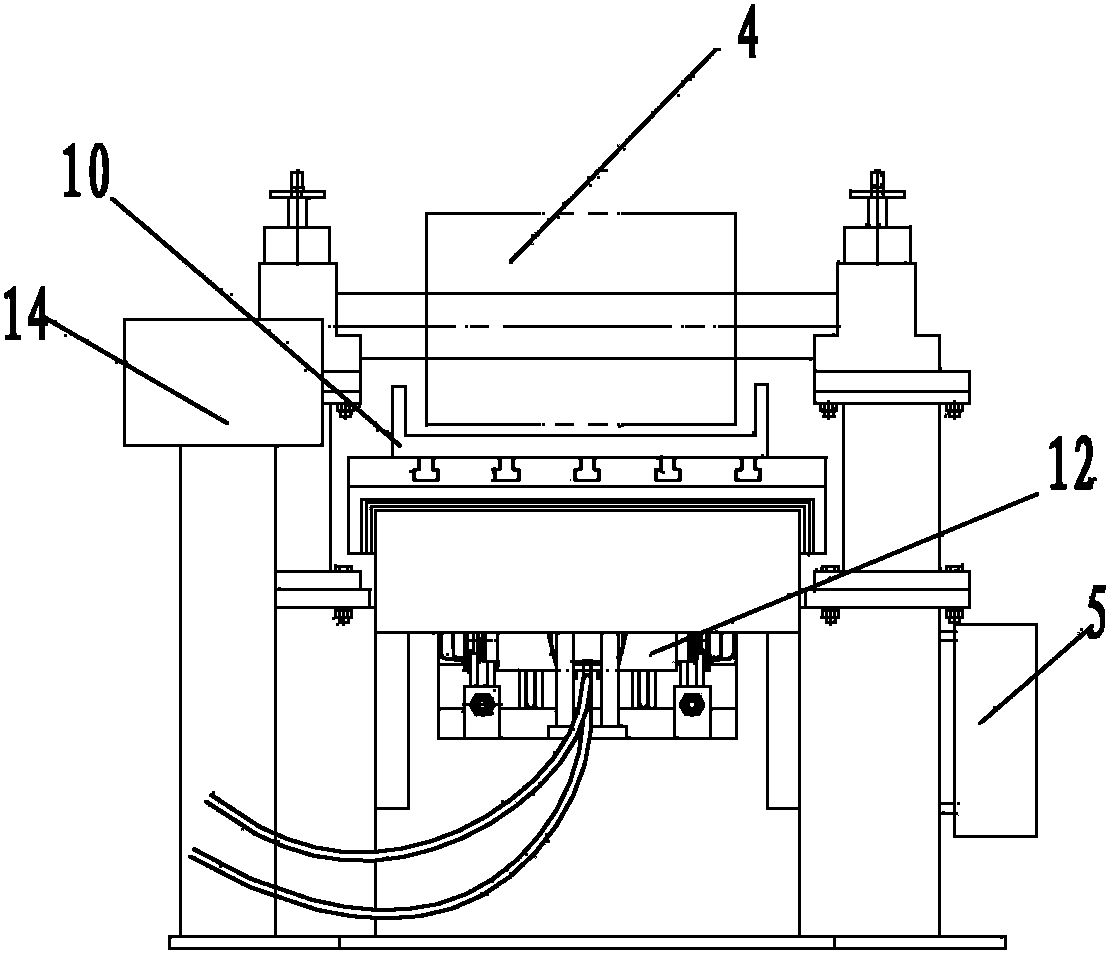

[0019] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a radiator fin inlaid roll forming machine tool, including a mobile workbench 2 placed on a bed 1, The pressure roller frame 3, the pressure roller shaft 4, the workbench drive system and the electrical operation table 5 are composed of a gantry type pressure roller frame fixed on the bed, and the pressure roller frame supports the pressure roller shaft through a sliding bearing 6, and the pressure roller The roller shaft is keyed with a press-fit disc group 7, spacers 8 are provided between the press-fit disc groups, and crimping teeth 9 are provided on the outer circumference of the press-fit disc; The positioning fixture 10 that restricts the longitudinal and axial movement of the workpiece, the workbench driving system includes a hydraulic cylinder 11, a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com