Industry and electricity integrated electric switch device with central locking polar integrated control unit

An electric and locking lever technology, which is applied to point switches, electrical equipment for manipulating turnouts or line breakers, and railway car body parts, etc. It can solve the problems of difficult electrical maintenance, low safety and reliability, and weak power, etc. problem, to achieve the effect of strong ability to adapt to ice and snow climate, simple and reliable transmission structure, and convenient polarity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] specific implementation plan

[0045] 1. Central lock electric switch machine

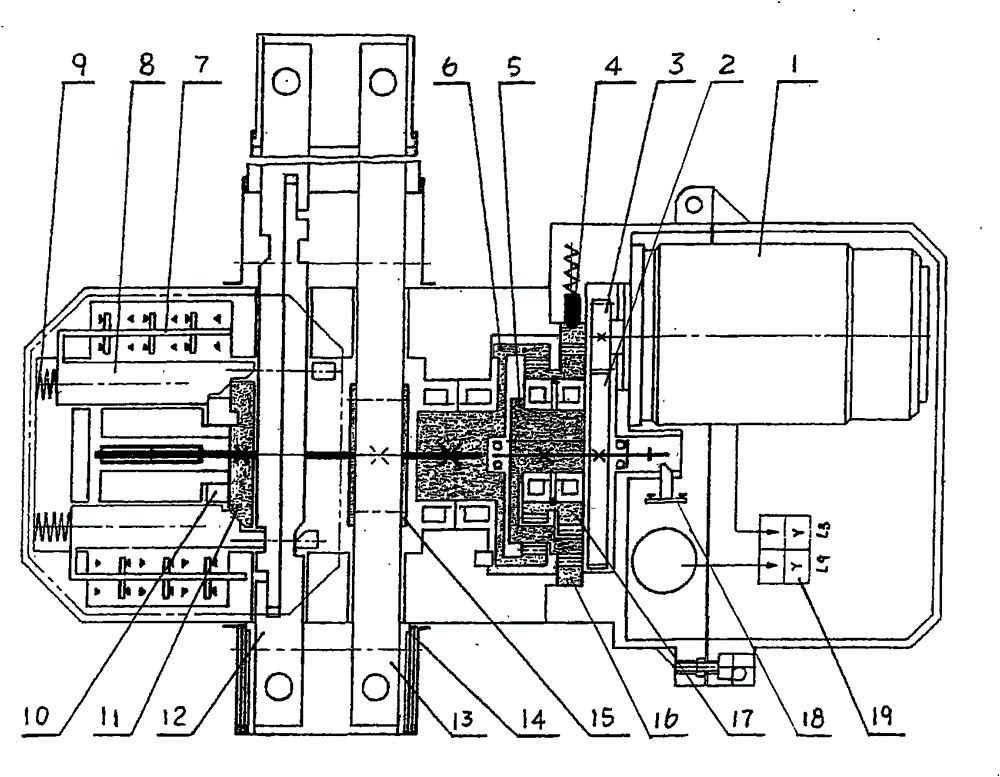

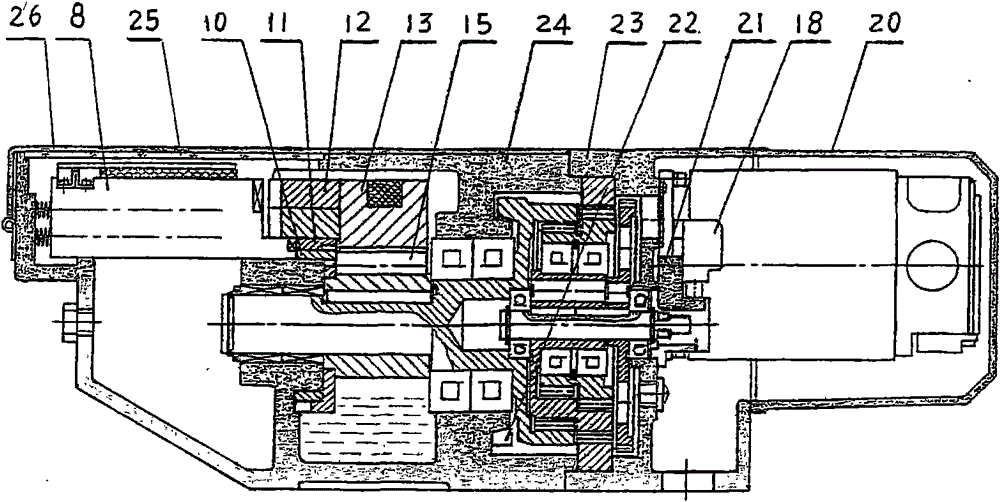

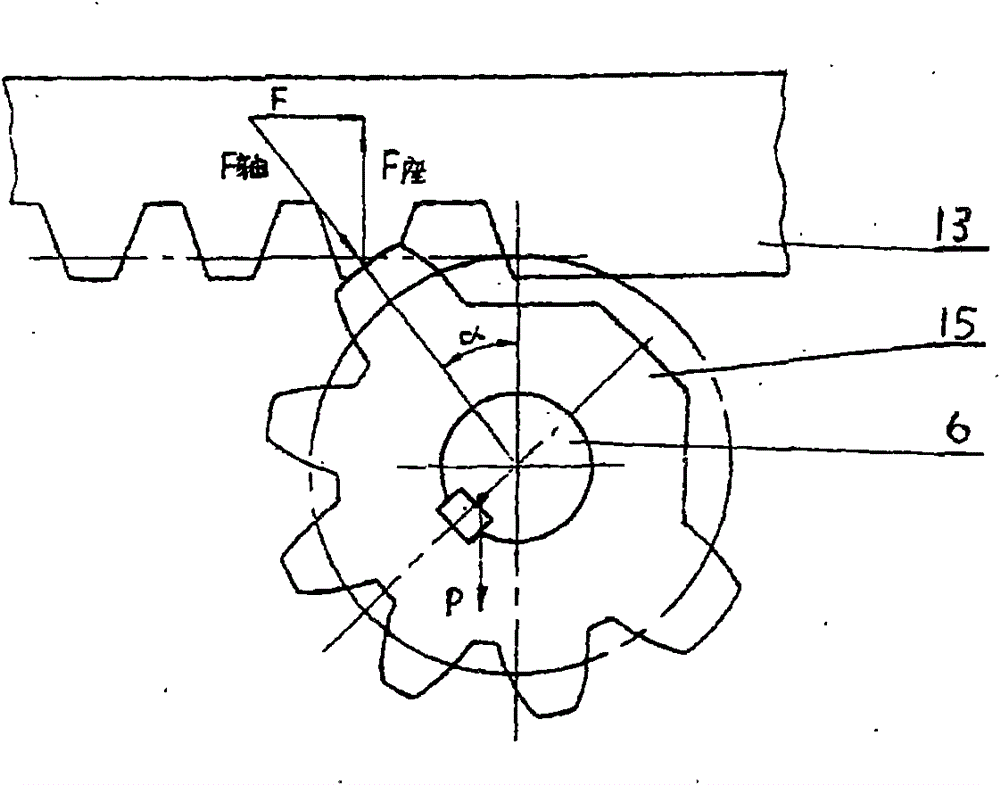

[0046] The working principle and structural axial section of the central lock electric switch machine 32, such as figure 1 , 2 As shown, it consists of power, deceleration, motion detection, and display four chambers connected in series. DC motor 1, through Z1 pinion 3 / band Z2 large gear input shaft 2 / 2K-H / band stopper Z6 output wheel shaft 6 / moving lock wheel 15 / moving lock bar 13, complete the left position moving lock (as image 3 shown). Simultaneously, start plate 11 pushes out left inspection lock block 8, and right inspection lock bar 12 unlocks, and the left indication switch 7 of linkage with left inspection lock block 8 disconnects right position indication, and right inspection lock block 8 is in two internal inspection lock springs 9 Under the promotion of the switch, insert the locking straight mouth of the left check lock lever 12 linked with the switch rail, the check obli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com