Heating plate mounting implement and using method

A trigger and machine technology, applied in the field of combined machines, can solve problems such as being difficult to implement, cannot be interchanged, and cannot be used universally, and achieve the effects of improving work efficiency, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

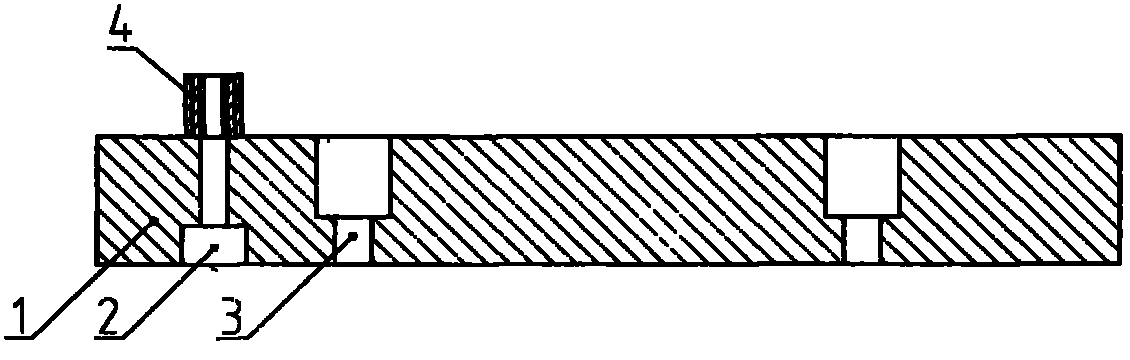

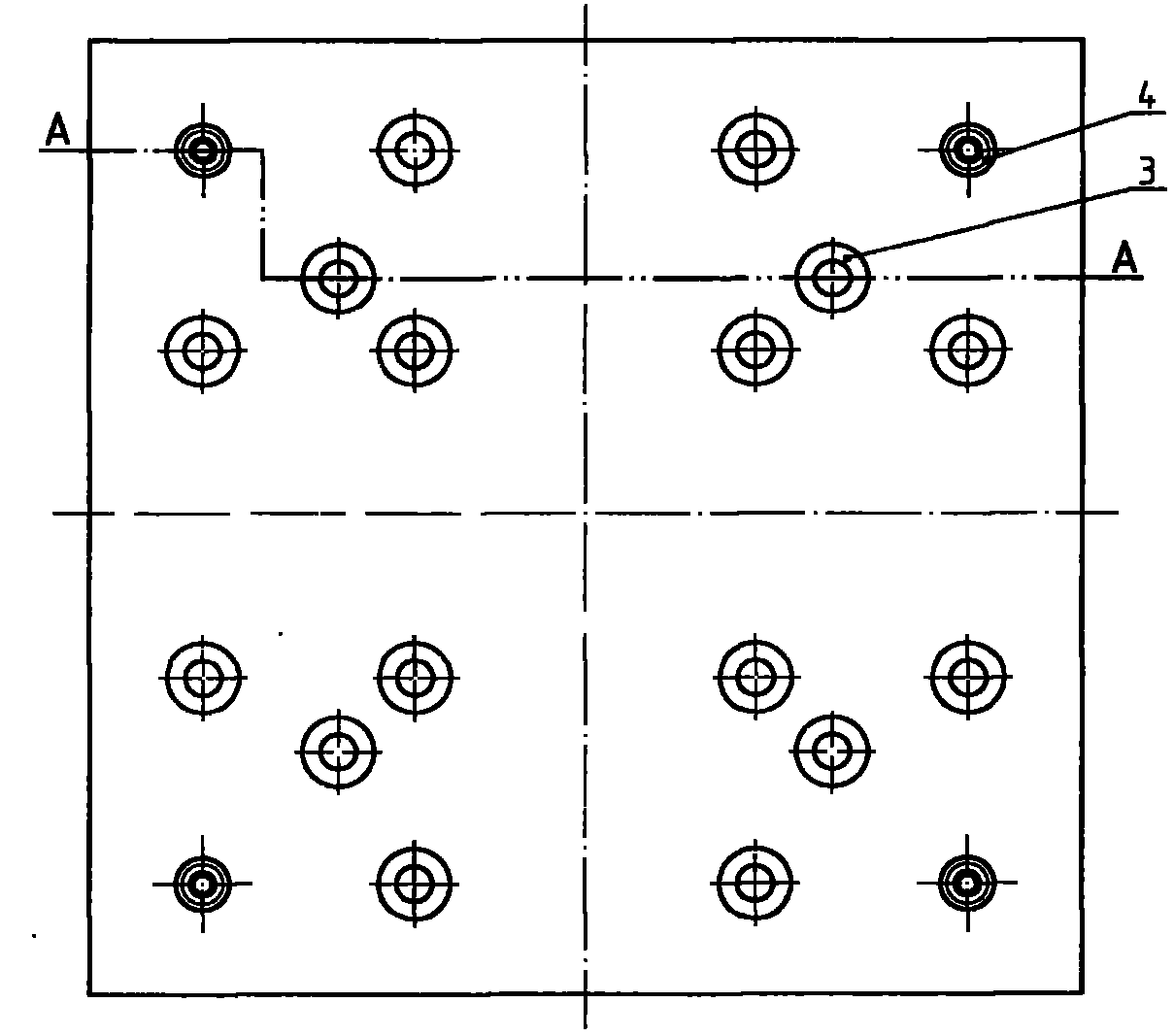

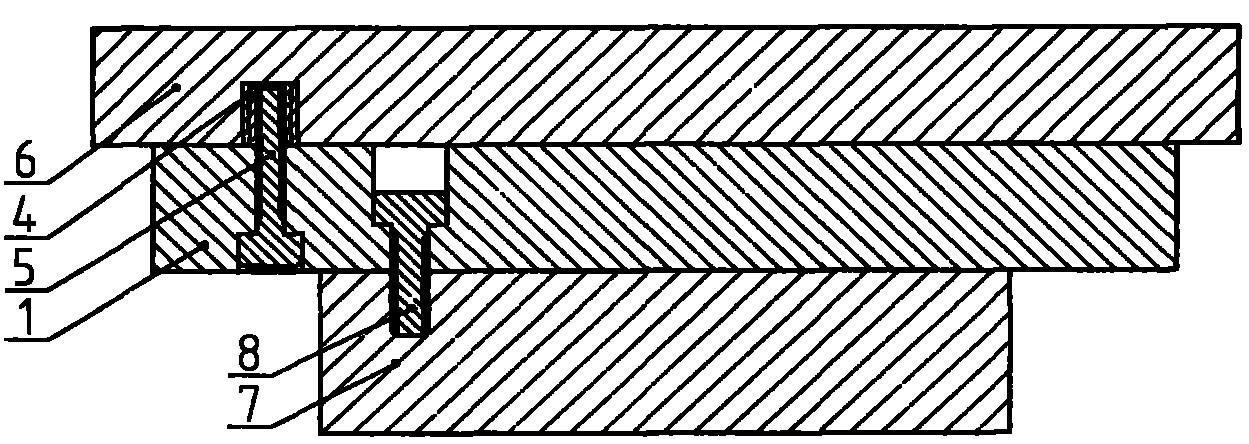

[0012] Embodiment 1 refers to Figure 1 to Figure 2 It can be seen that it includes a silk tube 4 and a connecting plate 1, wherein the silk tube 4 has an inner threaded button 4-3 and an outer threaded button 4-2, see Figure 4 and Figure 5 It can be seen that the silk tube 4 has a wrench groove 4-1 at one end for the convenience of installation. The four corners of the connecting plate 1 are provided with sinking slots 2, and the remaining planes of the connecting plate are provided with 16 sinking slots 3. When in use, the outer threads of the wire pipe 4-2 are connected with the 6 wire holes of the vulcanizing machine; Plate 1 sink hole 2 uses screw 5 to upwardly install connecting plate 1 on the vulcanizer 6 machine platform, and connecting plate 1 upper sink hole 3 uses screw 8 to downwardly install heating plate 7 on the connecting plate 1 .

[0013] refer to image 3 It can be seen that the use state is that the wire tube 4 is installed in the hole of the vulcanizi...

Embodiment 2

[0014] The structure of embodiment 2 is basically the same as that of embodiment 1, wherein four upper sink holes 3 are arranged on the remaining plane of the connecting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com