Twice method run flat tire one section forming and fitting drum

A technology for running flat tires and laminating drums, applied in tires, applications, household appliances, etc., can solve the problems of inner liner discounting, residual air bubbles, and improper carcass pressing, and improve product quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

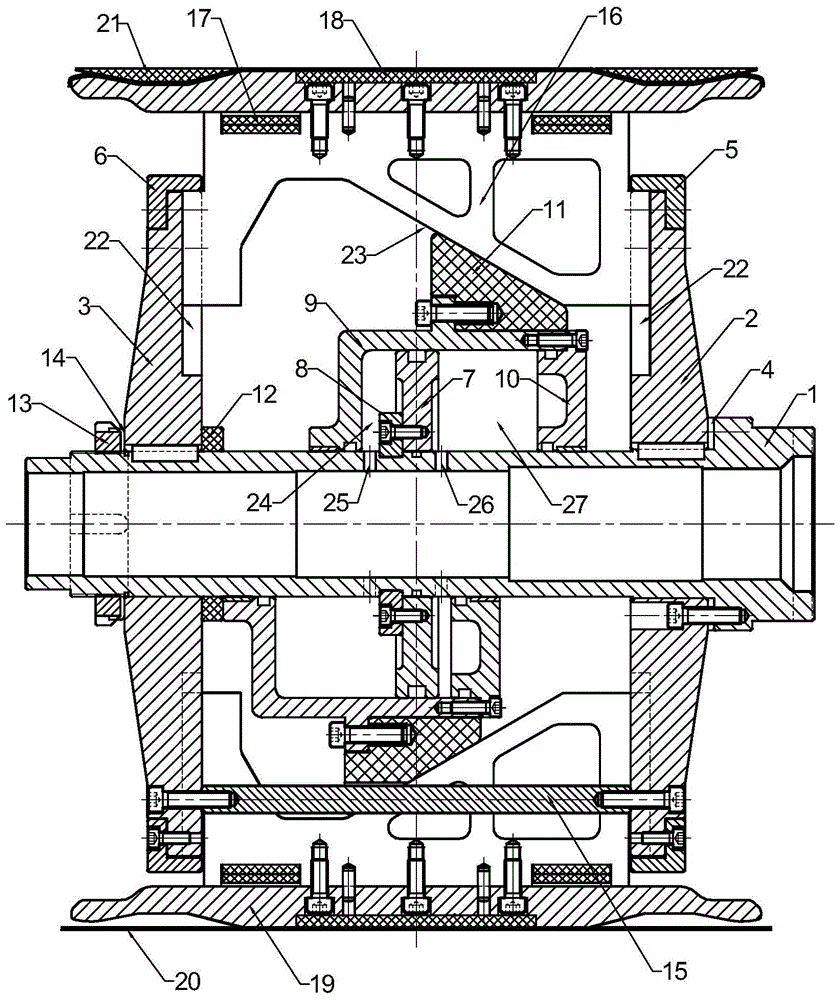

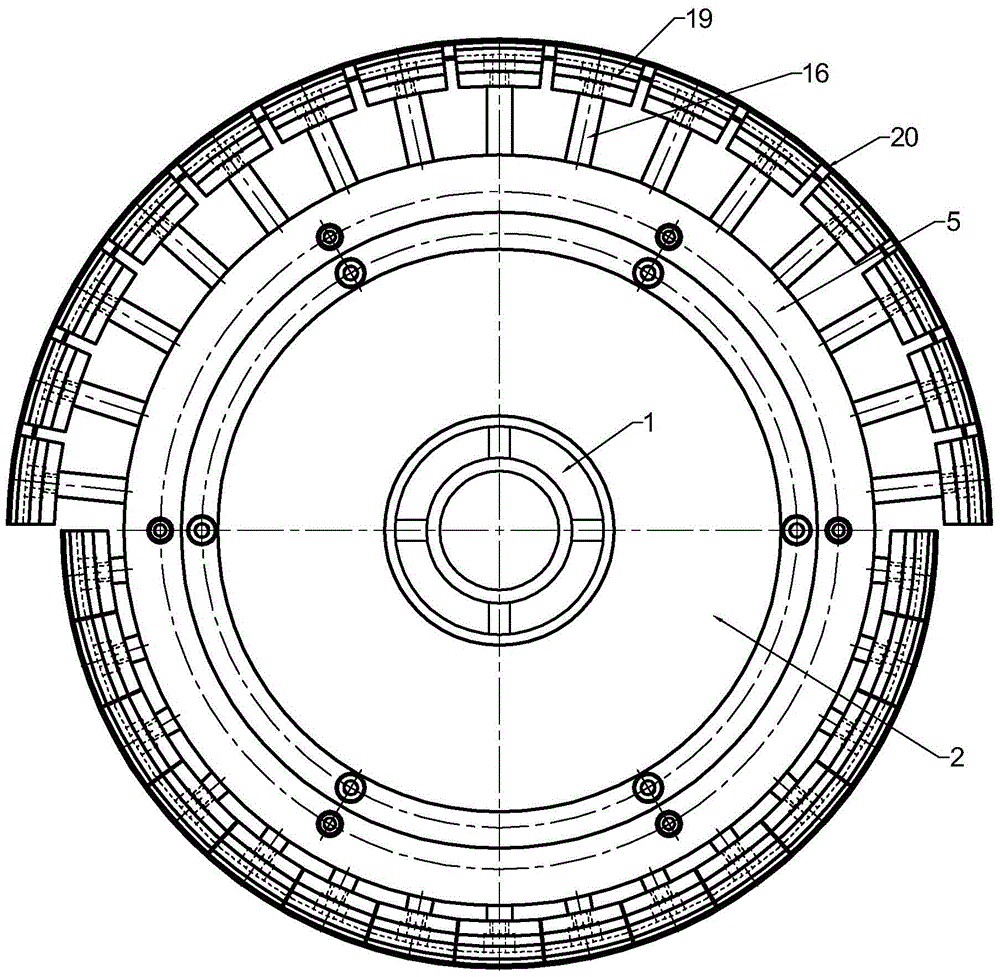

[0012] refer to Figure 1-Figure 2 , a one-stage forming and laminating drum for two-time run-flat tires, including a main shaft sleeve 1, a left guide disc 3 and a right guide disc 2 are arranged on both sides of the main shaft sleeve 1, and the right guide disc 2 passes through an adjustment gasket 4 It is fixedly connected to the main shaft sleeve 1 with screws, and the left guide disc 6 is fixedly connected to the main shaft sleeve 1 through a thrust washer 14 and a round nut 13. There are 6 connecting gears between the left guide disc 3 and the right guide disc 2 Rod 15 is respectively provided with left limit disc 6 and right limit disc 5 on left guide disc 3 and right guide disc 2, and left limit disc 6 and right limit disc 5 are connected with left guide disc 3 and right guide disc respectively. 2 fixedly connected, 30 symmetrically arranged radial guide grooves 22 (can be selected according to different products) on the left guide plate 3 and the right guide plate 2 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com