Building indoor rapid decoration method

A building and rapid technology, applied in building construction, construction, injection devices, etc., can solve the problems of high operation intensity, cracking of leveling mortar, low work efficiency, etc., to avoid residual air bubbles, reduce operation intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

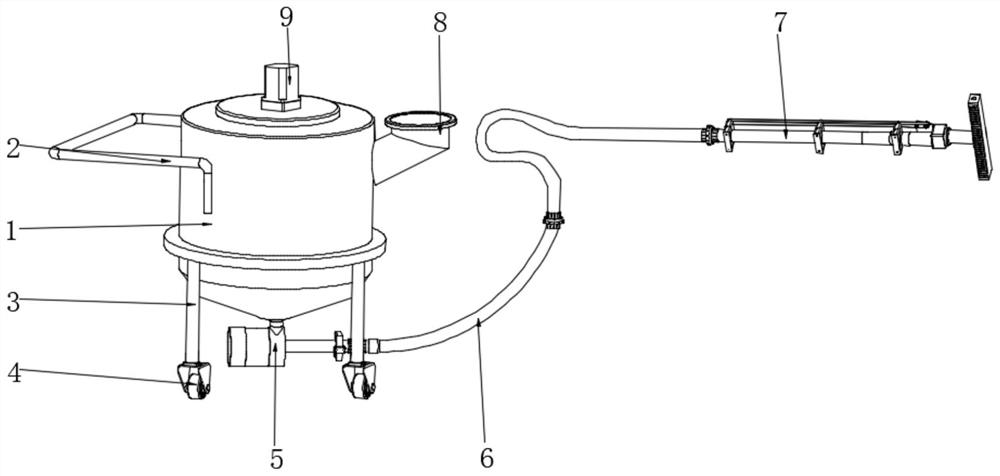

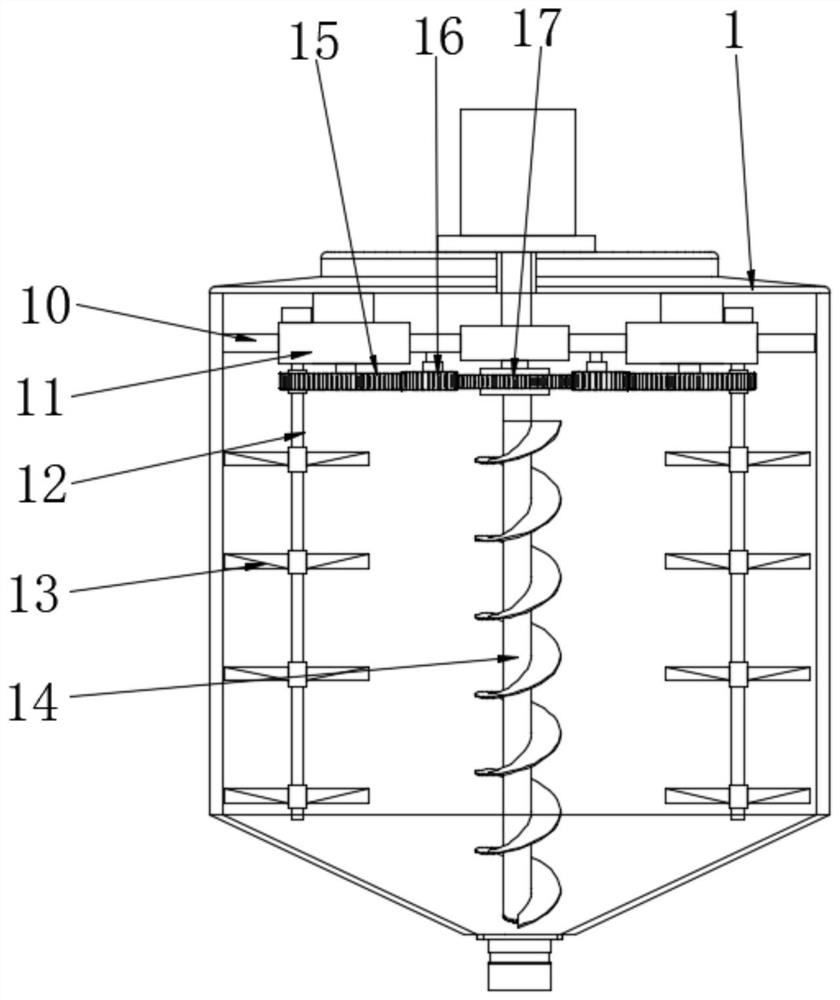

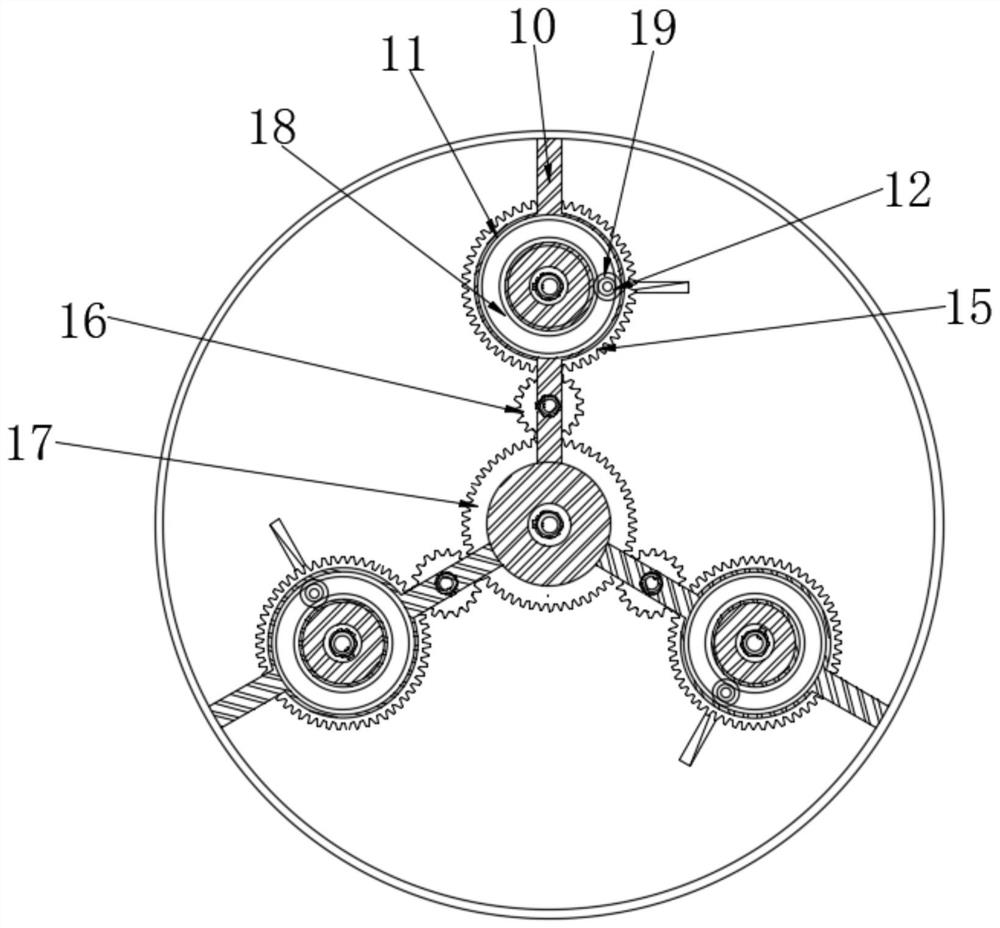

[0026] see Figure 1~4 , in an embodiment of the present invention, a method for fast interior decoration of a building, comprising the following steps:

[0027] S1. Move the spraying device and leveling mortar to the designated building room, and at the same time pre-clean the indoor ground of the building. After cleaning, sprinkle water on the indoor ground of the building to keep the ground moist;

[0028] S2. Preparation ratio of leveling mortar: 20 parts of cement, 60 parts of medium sand, 0.5 parts of defoamer, 1 part of stabilizer, 2.5 parts of water reducing agent, 2 parts of coupling agent, water addition: 1 / 2 of the volume of mortar slurry 20%~22%;

[0029] S3. Pour the leveling mortar and water into the spraying device according to the proportion and stir at a medium speed for ten minutes. After the stirring is completed, reduce the stirring to a low speed to maintain the viscosity of the slurry and avoid the phenomenon of sedimentation and stratification;

[0030...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com