Double buffer photoresist spraying system

A double-buffering and double-buffering technology, applied in liquid ejection devices, ejection devices, separation methods, etc., can solve the problems of generating air bubbles, increasing the cost of photoresist liquid use, and time-consuming, so as to ensure non-stop supply and save light. Liquid resistance and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] During the photoresist coating process, there will be phenomena such as poor coverage and poor flatness. One of the reasons for these phenomena is that air bubbles remain inside the photoresist during the filter pre-wetting process, making the photoresist not Continuous coating on chip (wafer) surface. However, to avoid the above-mentioned reasons, photoresist fluid is usually wasted, and photoresist fluid is an expensive material.

[0023] Therefore, the present invention provides a double-buffer photoresist liquid spraying system to solve the above-mentioned shortcomings. For a clearer representation, the present invention will be described in detail below in conjunction with the accompanying drawings.

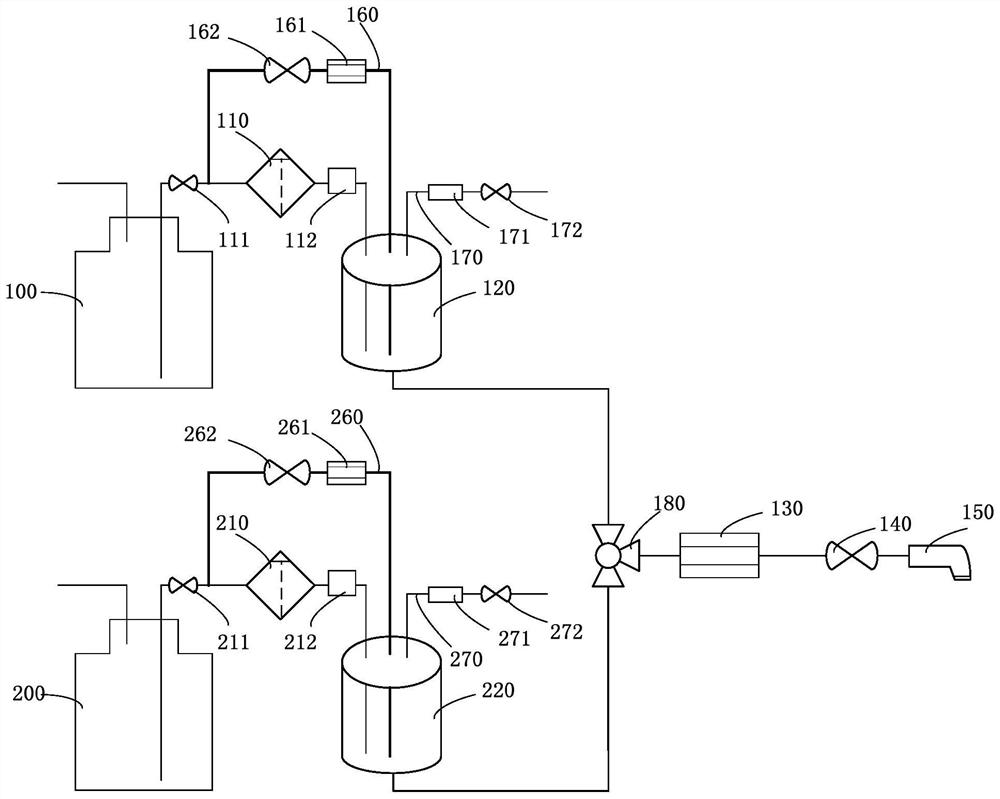

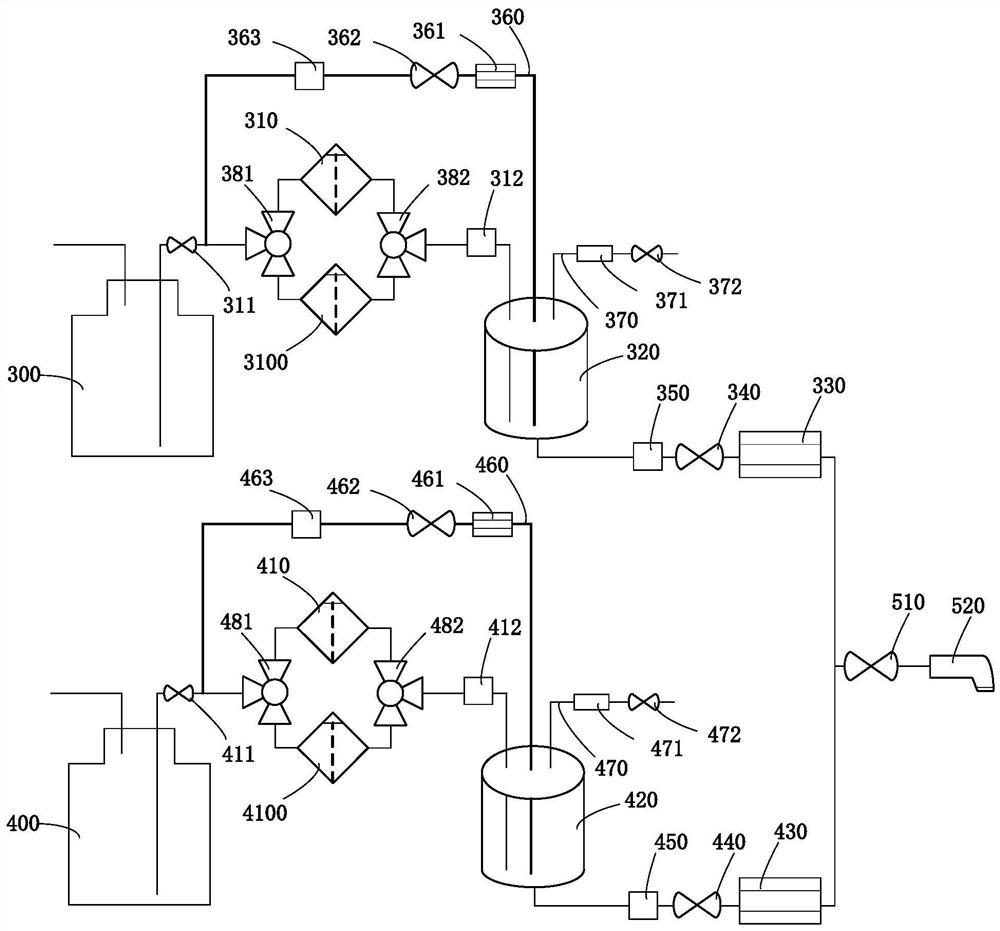

[0024] The embodiment of the present invention provides a double-buffer photoresist spraying system, please refer to figure 1 , the system includes:

[0025] The first liquid storage tank 100 is used to store and supply photoresist liquid (photoresist liquid figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com