Snowfield tire

A technology for snow tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., which can solve problems such as not considering tire requirements, achieve strong driving force, increase traction capacity, and easily embedded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

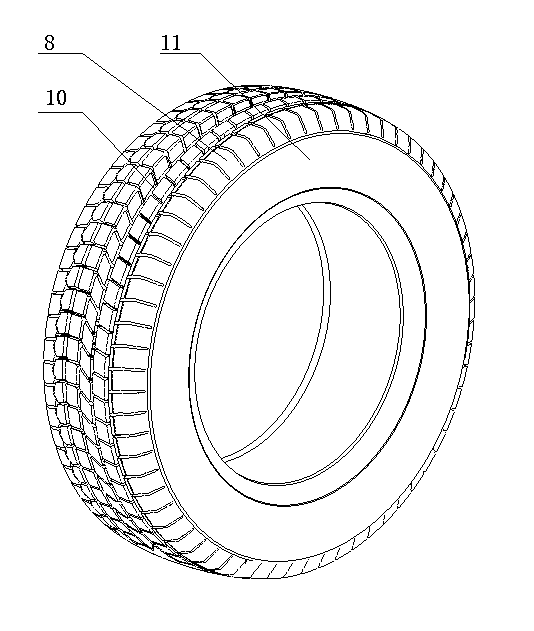

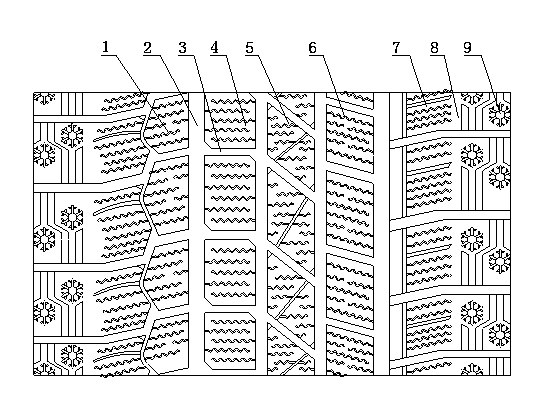

[0021] Such as Figure 1 to Figure 2 Shown, as a preferred embodiment, this embodiment provides a kind of snow tire, comprises tire body and tread, and tread comprises tread crown 10, tire shoulder 8 and sidewall 11, and tread crown 10 is arranged on tire body and is connected with In contact with the ground, the shoulder 8 connects the crown 10 and the sidewall 11. The crown 10 is composed of four longitudinal grooves 2 arranged in the circumferential direction of the tire body and several transverse grooves 3 arranged in the width direction of the tire body. Four rows are formed. A pattern block sequence, each pattern block of the pattern block sequence is provided with fine grooves.

[0022] The four-row pattern block sequence provided in this embodiment is pentagonal pattern block sequence 1, square pattern block sequence 4, rhombus pattern block sequence 5 and parallelogram pattern block sequence 6; among them, the square pattern block sequence 4 The length is 22 mm and ...

Embodiment 2

[0026] As the second preferred embodiment, the rest is the same as that of Embodiment 1, except that the sequence of four rows of pattern blocks provided in this embodiment is sequence 1 of hexagonal blocks, sequence 4 of rectangular blocks, sequence 5 of diamond blocks and Parallelogram block sequence 6; rectangular block sequence 4 has a rectangular block length of 20 mm and a width of 28 mm, diamond block sequence 5 has a rhombus block length of 30 mm and a width of 31 mm, parallelogram block sequence 6 has parallel The length of the quadrilateral pattern block is 20 mm, and the width is 28 mm. The arrangement and size of the sequence of four rows of pattern blocks can achieve the best effect.

[0027] The groove width of the longitudinal groove 2 provided in this embodiment is 10mm, and the groove depth is 10mm; the groove depth of the transverse groove 3 is greater than the groove depth of the longitudinal groove 2, and its groove depth is 11mm; Parallel to the horizontal...

Embodiment 3

[0029] As the third preferred embodiment, the rest is the same as Embodiment 1 or 2, the difference is that the sequence of four rows of pattern blocks provided in this embodiment is octagonal pattern block sequence 1, rectangular pattern block sequence 4, rhombus pattern block sequence 5 and parallelogram block sequence 6; rectangular block sequence 4 has a rectangular block length of 25 mm and a width of 26 mm, diamond block sequence 5 has a diamond block length of 28 mm and a width of 30 mm, and parallelogram block sequence 6 The length of the parallelogram pattern block is 25 mm, the width is 26 mm, and the arrangement and size of the sequence of four rows of pattern blocks can achieve the best effect.

[0030] The groove width of the longitudinal groove 2 provided in this embodiment is 8mm, and the groove depth is 9mm; the groove depth of the transverse groove 3 is greater than the groove depth of the longitudinal groove 2, and its groove depth is 10mm; Parallel to the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com