Tea bag outer bag film sealing and precutting production device

A production device and tea bag technology, which are applied in the directions of packaging, external support, transportation and packaging, etc., can solve the problems affecting the appearance of the outer bag of the tea bag, the displacement of the edge sealing position of the outer bag, the deviation of the pre-tear opening, etc. Novel structure, small wound surface and small position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

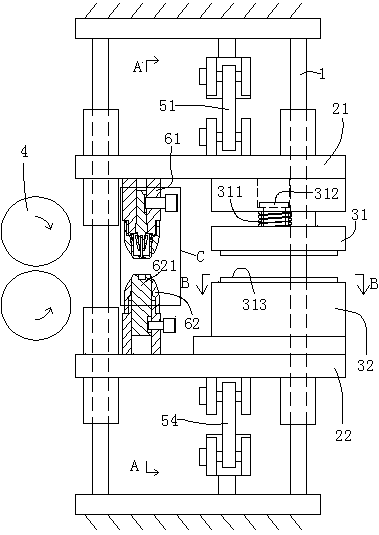

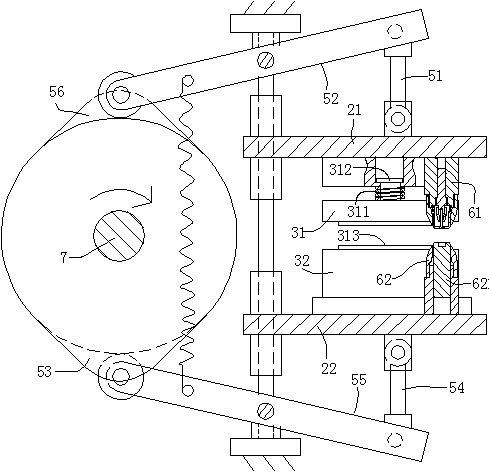

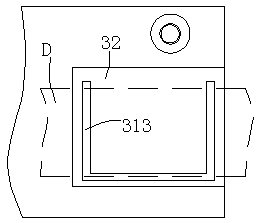

[0016] refer to Figure 1 to Figure 5 , a tea bag outer bag film edge sealing and pre-cut production device, including a longitudinal guide rod 1 connected to a fixed frame, and a pair of upper sliders that can intermittently run opposite to each other are arranged on the longitudinal guide rod 21. The lower slider 22, a pair of hot-melt briquetting blocks for clamping the outer bag film to seal the edge is arranged between the upper and lower sliders. In order to realize the production of the pre-tear opening of the teabag outer bag, The upper slider and the lower slider are located between the discharge ends and are provided with a group of elastic knife head assemblies that cooperate with each other for the pre-cutting of the outer bag film. A pair of horizontal pulling rollers 4 that rotate intermittently and are used to pull the outer bag film forward are provided.

[0017] In this embodiment, one side of the upper slider is sleeved on the longitudinal guide rod, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com