Special tool for thoracolumbar vertebral fracture repair surgery

A special tool and a technology for lumbar fractures, which are applied in the field of medical devices, can solve the problems of limited reduction of the height of the anterior column of the vertebral body and poor ability of expansion and reduction, and achieve the goals of shortening the operation time, increasing the healing rate, and improving the bone building ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

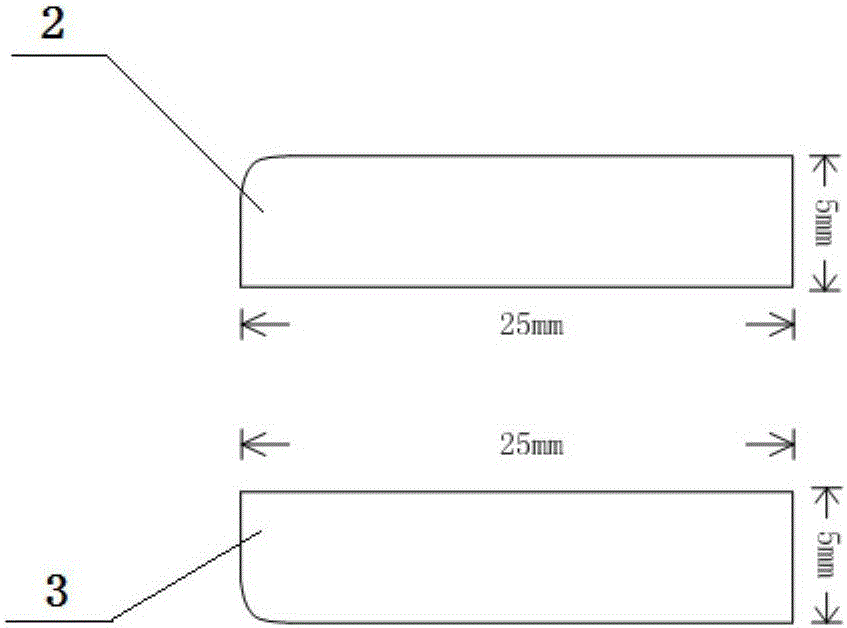

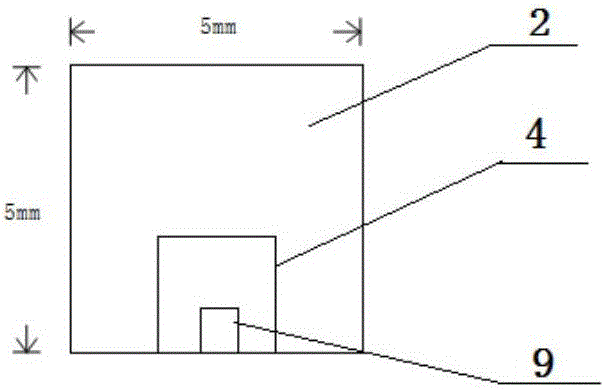

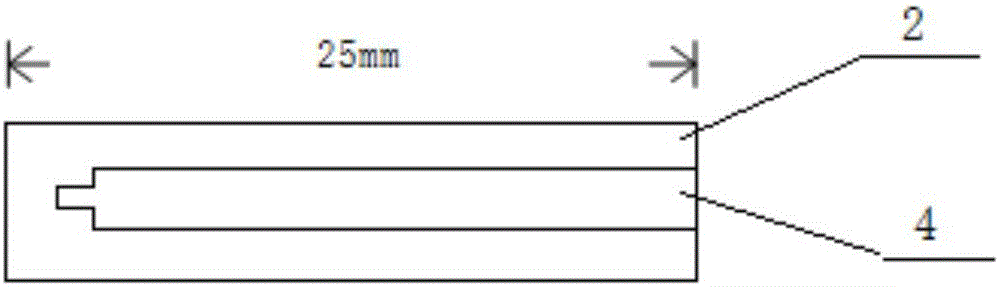

[0027] Embodiment 1: A special tool for thoracolumbar fracture repair surgery, including a repair contour fixation component and a shaped filler block 1, the repair contour fixation component is implanted into the fracture site to form a repair target contour, and the shaped filler block is inserted into the repair contour fixation component to form Stable repair filling; the repair contour fixing assembly includes at least one pair of upper fixing blocks 2 and lower fixing blocks 3, the bottom of the upper fixing block 2 is provided with a first keyway 4, the top of the lower fixing block 3 is provided with a second keyway, and the shape of the filling block 1 The top and the bottom are respectively provided with the first key body 6 matched with the key groove, and the first key body 6 on the upper and lower surfaces of the shaped filling block 1 is respectively inserted into the key groove of the upper fixed block 2 and the lower fixed block 3 to fix the upper and lower fixed...

Embodiment 2

[0035] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the upper and lower surfaces of the shaped filling block in this structure are respectively provided with an expansion spacer 10, and the expansion spacer has the upper and lower surfaces respectively. The second key body 11 matched with the first and second key grooves on the lower fixed block and the third key groove 12 matched with the first key body on the shaped filling block, wherein the length of the expansion spacer is consistent with the shaped filling block, and the thickness is 1.5mm; the second key body is matched with the first and second key grooves; the third key groove is matched with the first key body.

[0036] The specific operation process of performing the thoracolumbar fracture repair operation using the tool of this embodiment includes the following steps:

[0037] (1) Firstly, the dilator disclosed in the patent CN1748654A needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com