A Supporting Triangular Bracket for No. 0 Block of Cantilevered Bridge

A technology for triangular brackets and bridges, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of many influencing factors and potential safety hazards, and achieve the effect of clear force transmission, reduced labor intensity, and optimized configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

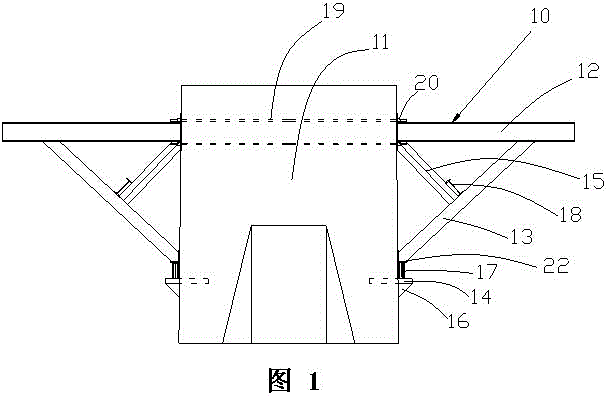

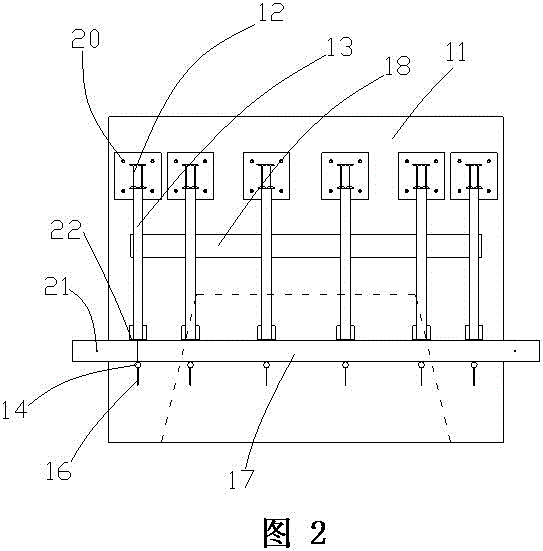

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0022] refer to figure 1 and figure 2 , a supporting triangular bracket for block 0 of a cantilevered bridge, comprising two sets of support frames 10 . The two sets of support frames 10 are arranged on the left and right sides of the pier body 11 . Each set of supporting frames 10 includes horizontal longitudinal beams 12 and diagonal brace beams 13 installed on pier body 11 . The upper part of the braced beam 13 is connected with the horizontal support beam 12, the lower part of the braced beam 13 is connected with a reinforced steel plate 22, the bottom surface of the reinforced steel plate 22 is connected with a crossbeam 17, and the bottom of the crossbeam 17 is connected with a bolt rod, and the bolt rod Insert into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com