Ultra-thin centrifugal ventilator

A centrifugal fan, ultra-thin technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of large installation space of centrifugal fan, high working noise and high manufacturing cost of centrifugal fan, and meet the requirements of Design concept, low working noise and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

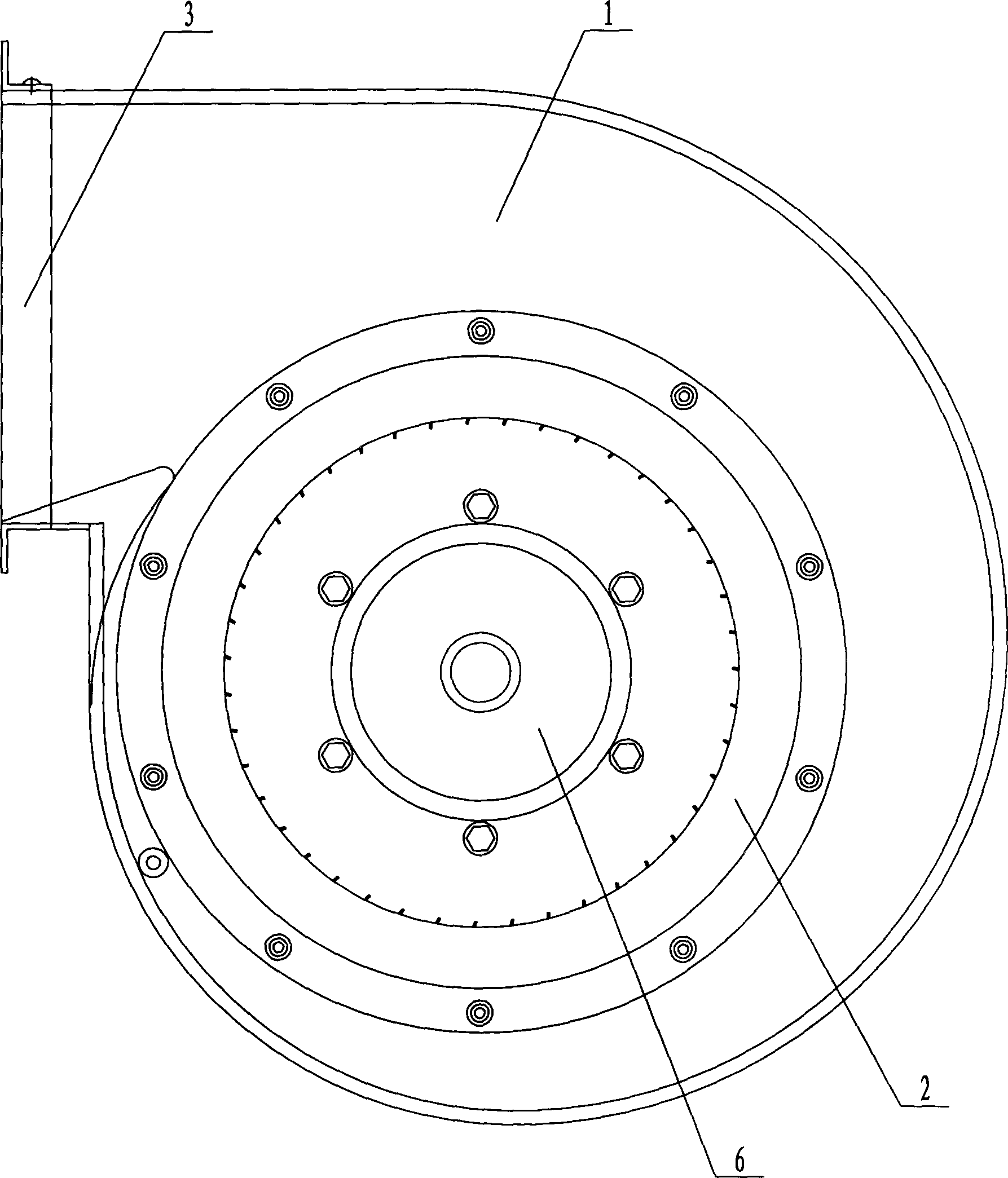

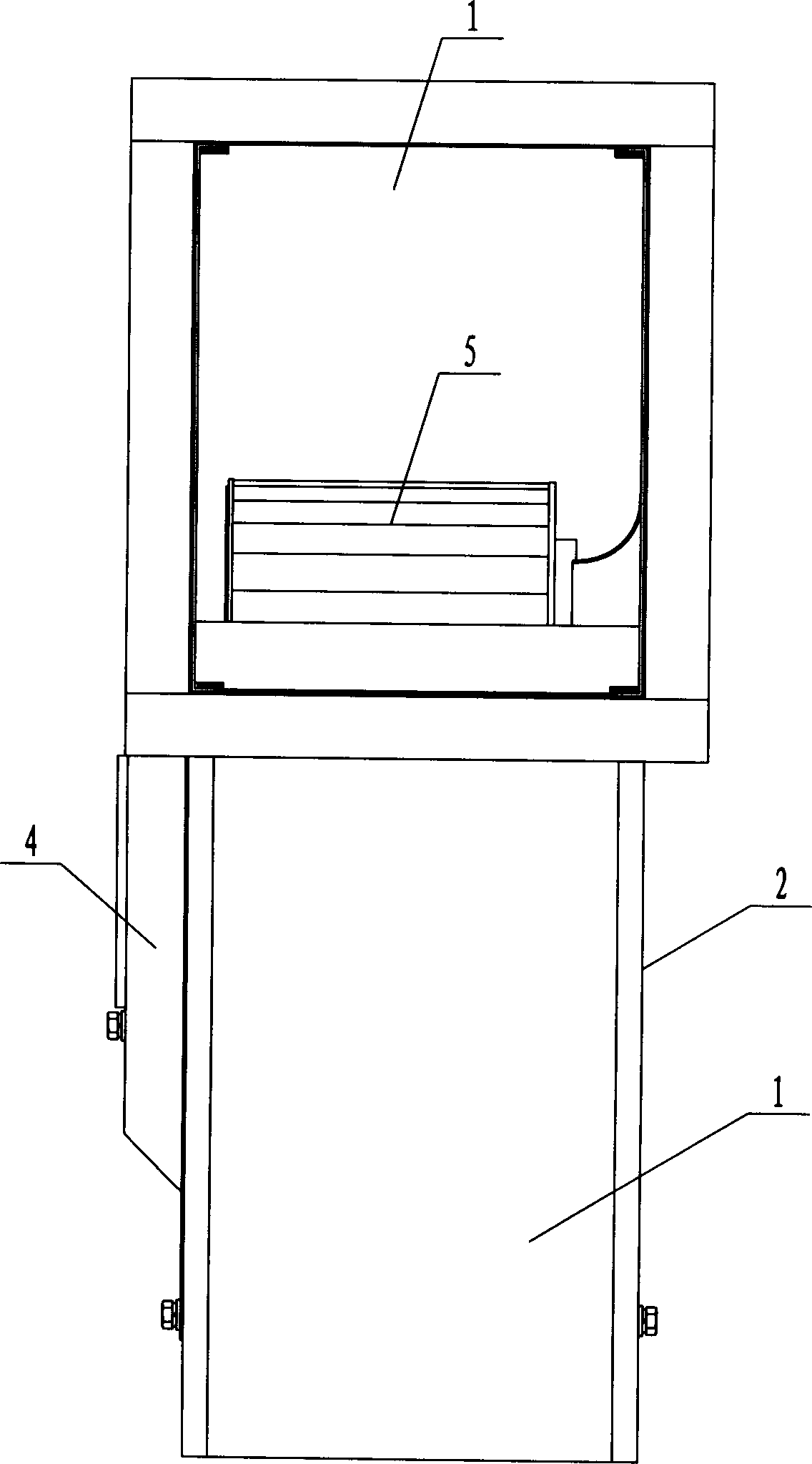

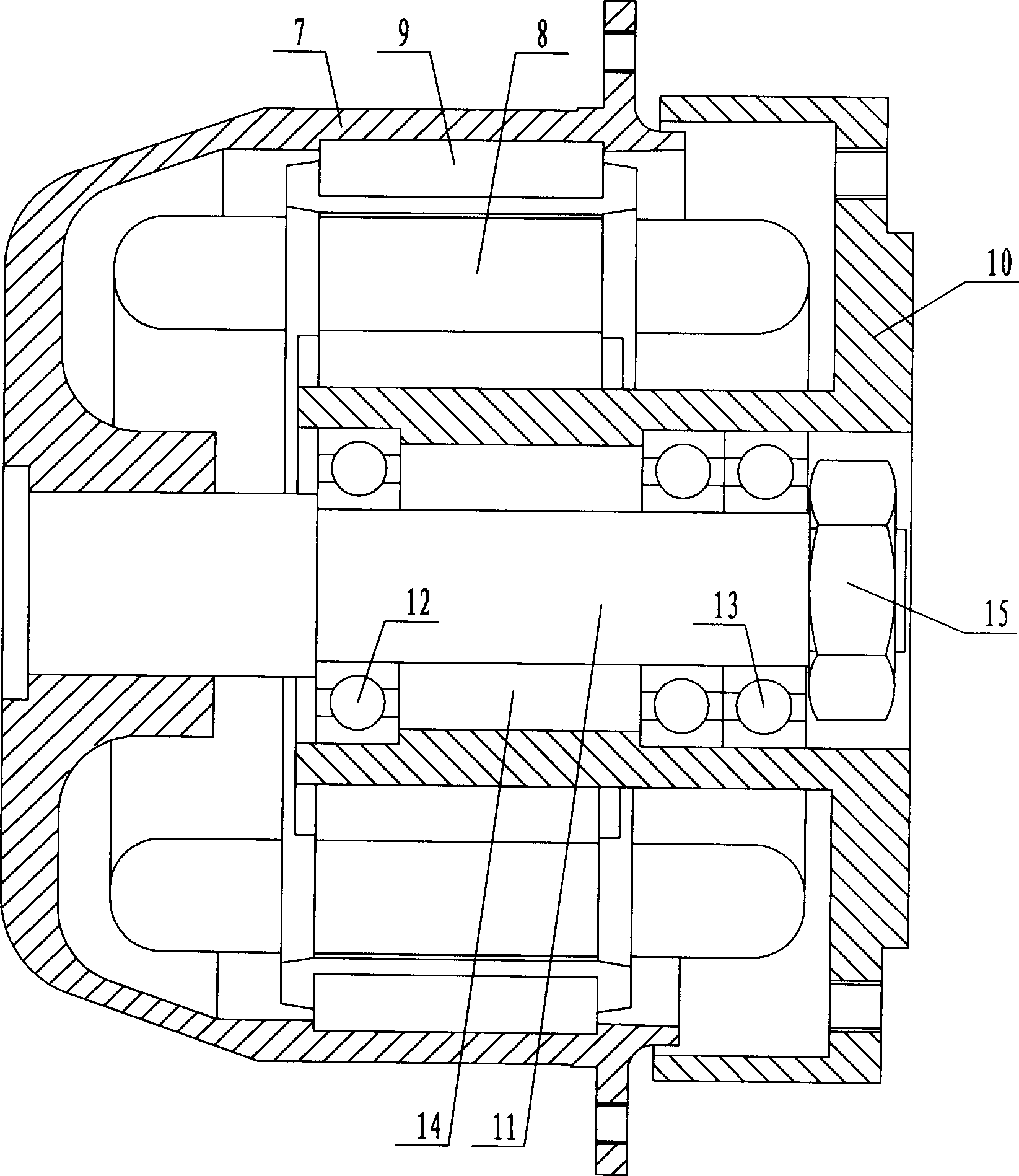

[0011] like figure 1 , figure 2 , image 3 As shown, the ultra-thin centrifugal fan is characterized in that it includes: an ultra-thin volute 1, an air inlet 2 arranged on the side of the ultra-thin volute 1, an air outlet 3 arranged on the end face of the ultra-thin volute 1, A fan mounting bracket 4 is provided on the same side of the ultra-thin volute 1 as the air inlet 2, and an impeller 5 is arranged inside the ultra-thin volute 1, and a single-shaft extension is arranged inside the impeller 5. The rotor three-phase asynchronous motor 6, the structure of the three-phase asynchronous motor 6 with a single shaft extending outer rotor includes: an outer rotor 7 and an inner stator 8, the inner stator 8 is coaxially arranged in the outer rotor 7, and the inner stator 8 An induction coil 9 is wound on the outer ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com