Centrifugal acceleration emission device based on motor driving

A centrifugal acceleration and launch device technology, applied in the field of mechanical acceleration devices, can solve problems such as material wear, affecting the normal use of devices, system reliability defects, etc., and achieve the effect of easy transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

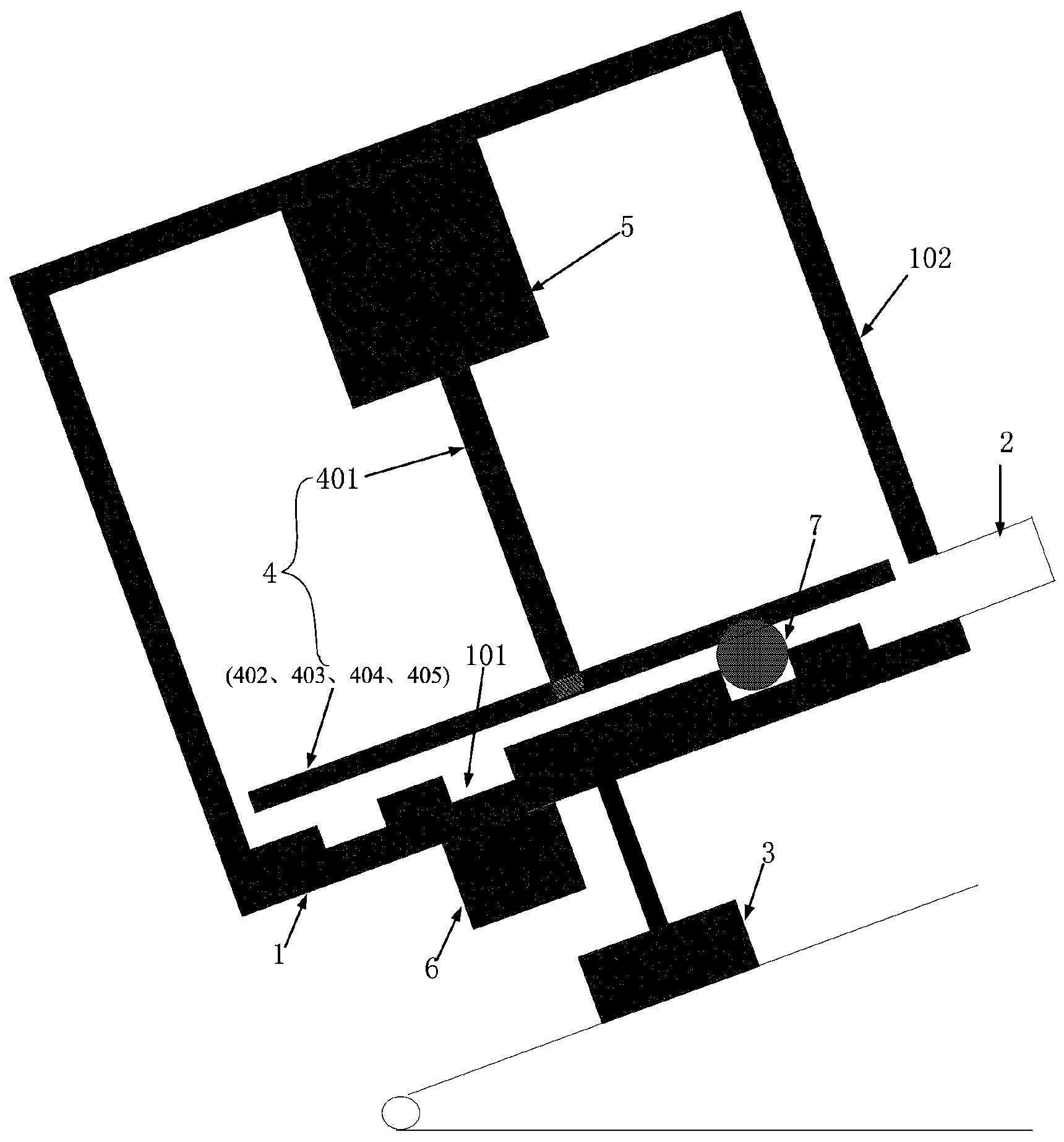

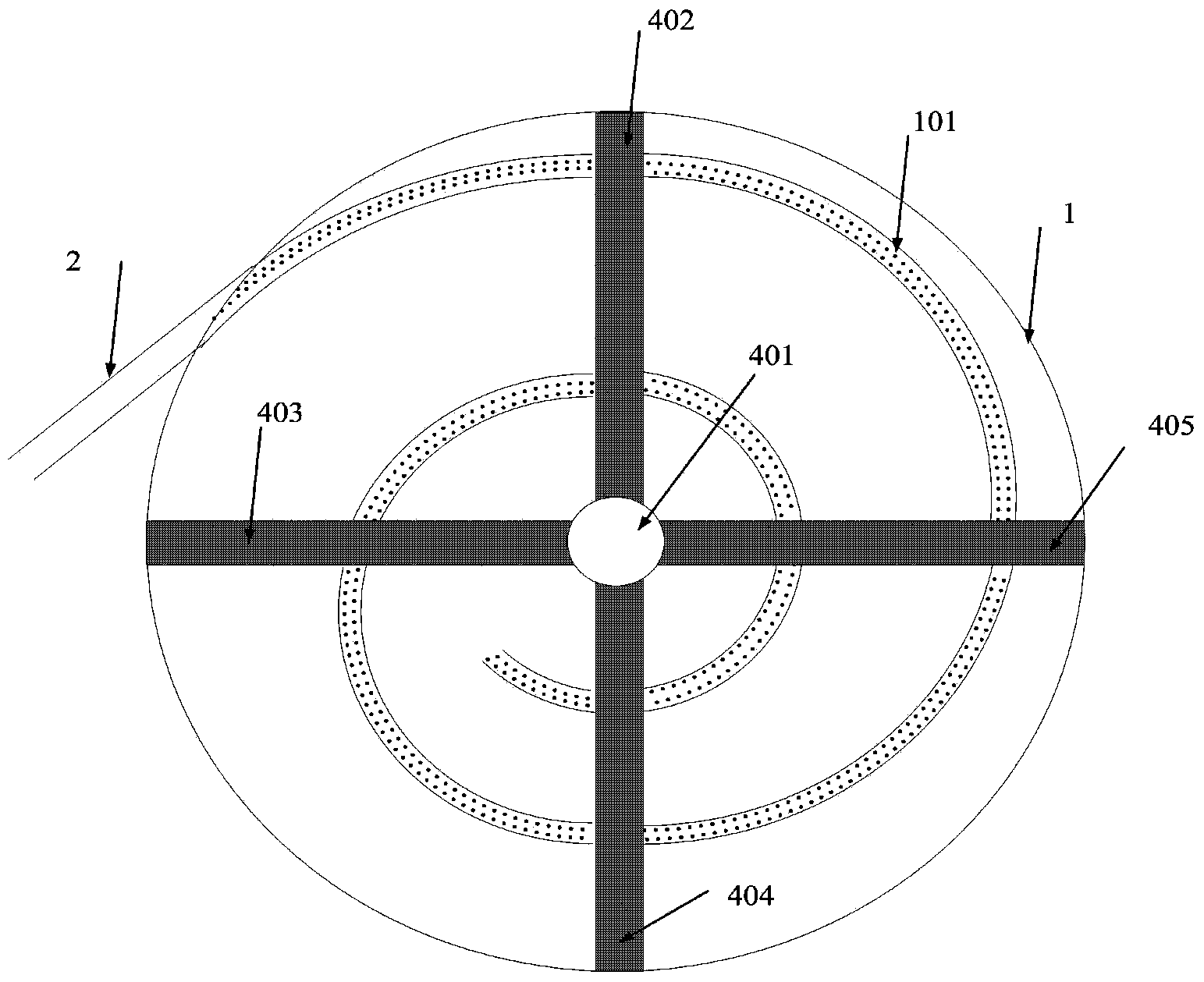

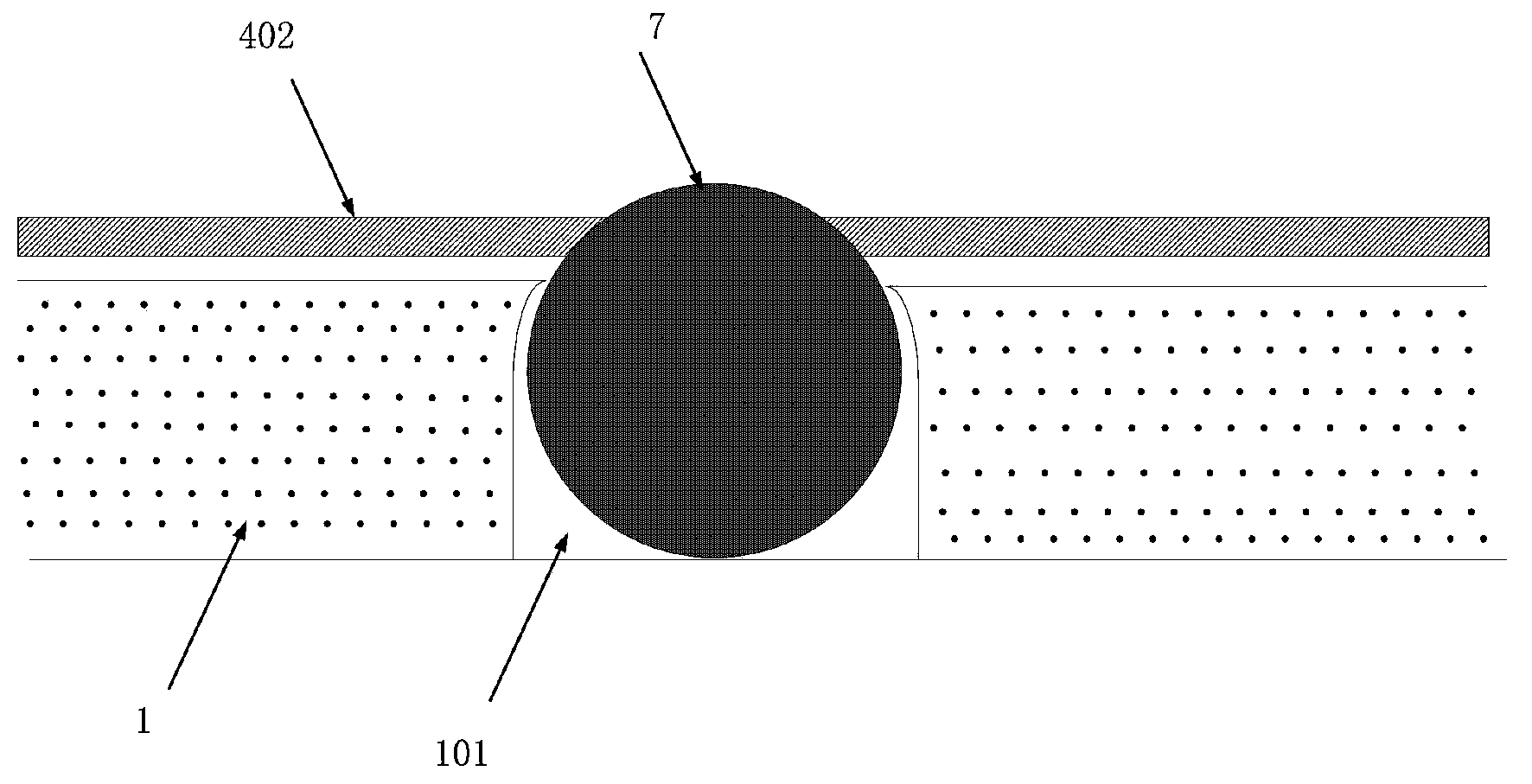

[0033] Such as figure 1 As shown, according to a preferred embodiment of the present invention, a centrifugal acceleration launching device driven by a motor includes: a circular wheel 1, an outer wall 102, a launch conduit 2, a launch angle adjustment base 3, a rotating drive part 4, The motor 5 and the filling device 6, the launch angle adjustment base 3 is wedged into the bottom of the fixed wheel 1 for adjusting the launch angle, wherein:

[0034] The circular wheel 1 and the outer wall 102 are combined to form an integral support, which is connected with the launch conduit 2, the rotating drive part 4, the motor 5, and the filling device 6 to form a whole launch, and the fixed wheel 1 is used as the bottom surface of the support. The wheel 1 includes an involute groove 101 and the starting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com