Armor plate, method for manufacturing armor plate and armored equipment

A kind of armor plate and armor technology, applied in the structure of armor plate, armored vehicles, transportation and packaging, etc., can solve the problems of armor plate deformation, weight increase, area weight, etc., and achieve the effect of improving the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

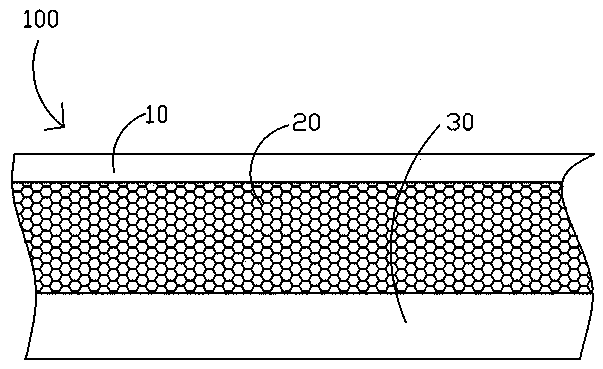

[0025] In order to realize the purpose of the above invention, please refer to figure 1 As shown, the present invention provides an armor plate 100 comprising a bulletproof steel plate 10 , a high molecular polyethylene plate 30 and a buffer layer 20 interposed between the bulletproof steel plate 10 and the high molecular polyethylene plate 30 . The armor plate 100 is used for helicopter armor, ship armor, military vehicles, bulletproof helmets and body armor, etc., and can effectively prevent damage caused by high-speed impacts such as bullets or explosives.

[0026] Generally speaking, the bulletproof steel plate 10 has the best protective performance among the three-layer materials, and is often used as the outer layer of the armor plate 100, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com