Perpendicular positioning installation device of pitot sensor

A technology for vertical positioning and installation of devices, used in measuring devices, instruments, liquid/fluid solid measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

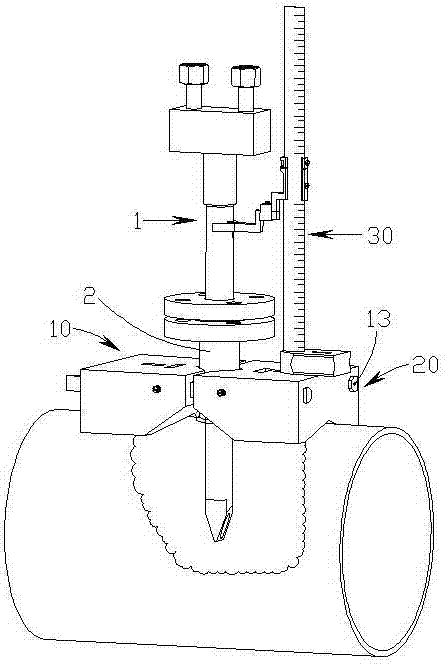

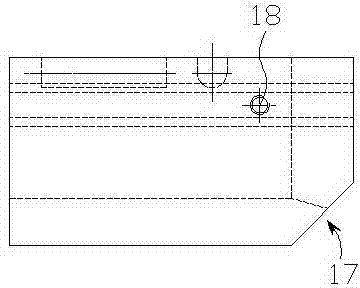

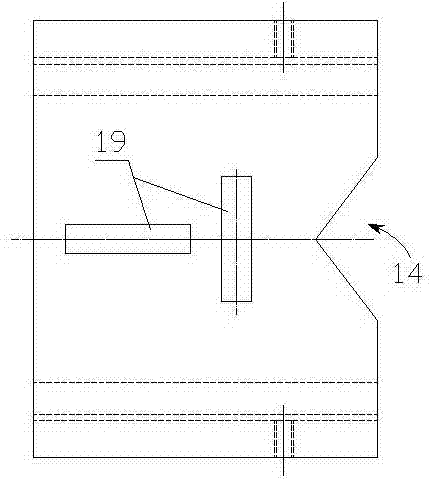

[0013] see figure 1 - Figure 6 ,in figure 1 It is a schematic diagram of the structure when the vertical positioning installation device of a bitobar sensor of the present invention is used to install the bitobar sensor 1 on the pipeline through the vertical positioning of the cylindrical pipe seat 2, a vertical positioning installation device of the bitobar sensor of the present invention, Comprising two rectangular parallelepiped compression blocks 10, 20 and a height gauge 30 equal in length, width and height, each rectangular parallelepiped compression block 10 is provided with front and rear two trapezoidal trapezoids along the length direction. Groove 11,12, the trapezoidal groove 11,12 that described two pieces of pressing block 10,20 is provided with its upper part is positioned and connected by matching trapezoidal pin 13, and the opposite end face of described two pressing blocks 10,20 is formed by V-shaped grooves 14 on the end surfaces are respectively cut from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com