Dewatering method for carbon-powder-containing sludge of acid production wastewater generated after purification of flue gas of sintering machine

A flue gas purification and sludge dehydration technology, applied in water/sludge/sewage treatment, chemical instruments and methods, dehydration/drying/thickened sludge treatment, etc., can solve the problems of processing environment requirements and high cost of processing equipment, Achieve the effects of avoiding complex chemicals, achieving removal, and improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

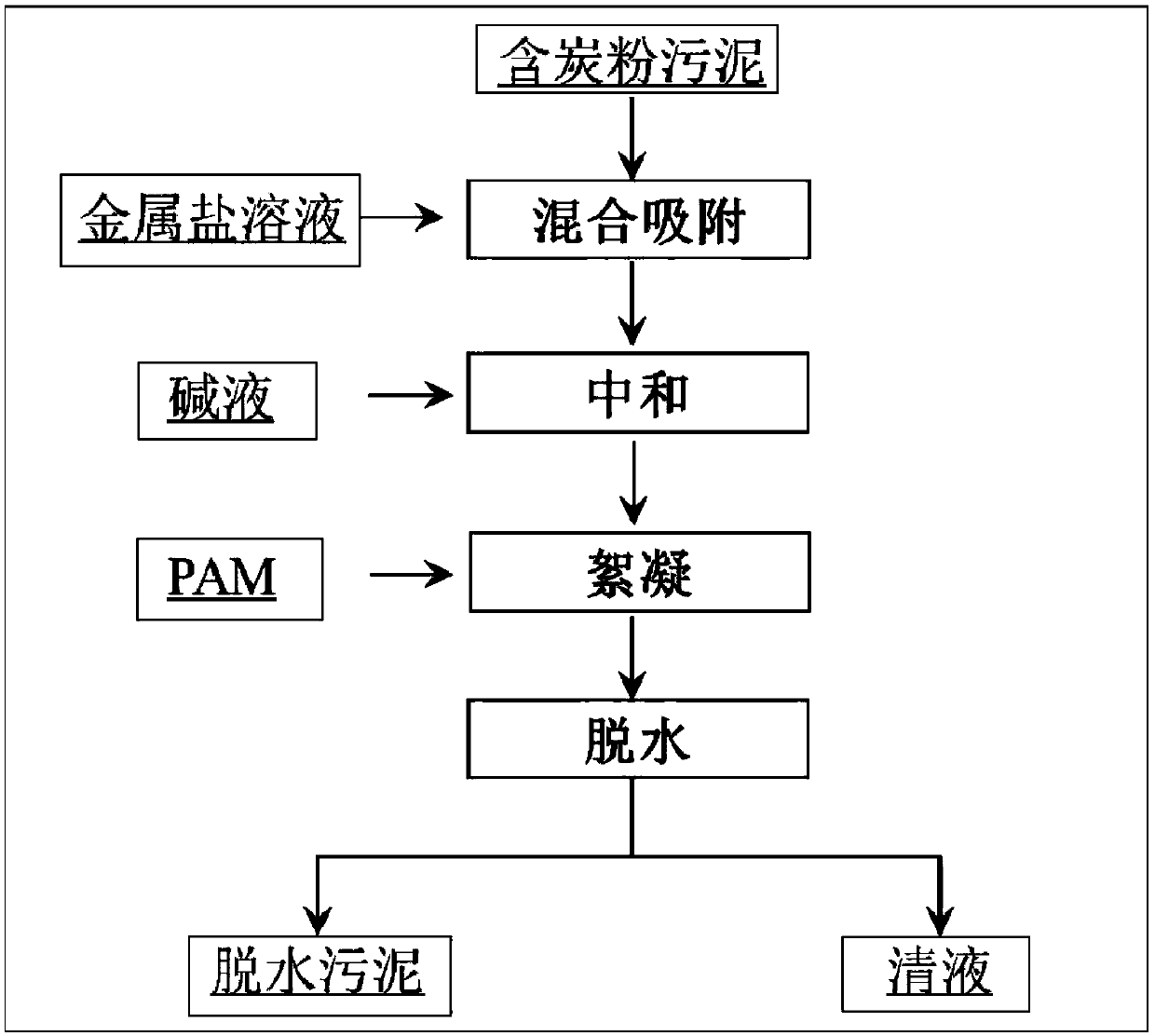

Method used

Image

Examples

Embodiment 1

[0034]Step 1: adding metal chlorides or metal oxides to the sludge containing carbon powder, adjusting the mass ratio of carbon powder to total metal ions to less than 1.5, preferably 1. The metal chloride or oxide is a metal chloride or oxide capable of forming insoluble precipitates under alkaline conditions. Here, the feature of rich surface functional groups and large specific surface area of activated carbon is utilized, and a certain amount of metal ions are added under acidic conditions at this time to modify the activated carbon so that the activated carbon forms a composite of activated carbon and metal ions; wherein, the carbon The particle size of the powder ranges from 1 to 100 μm, preferably 10 to 50 μm, and the metal chloride or oxide includes but is not limited to one or more of iron, copper, lead, calcium, zinc, cadmium, cobalt, nickel, and aluminum salts various;

[0035] Step 2: Add lye to the solution obtained after step 1 that has adjusted the ratio of c...

Embodiment 2

[0040] Other steps of the present invention remain unchanged, wherein in step 1, add metal chloride or metal oxide in this step to the sludge containing carbon powder, change the metal chloride or metal oxide into acid waste water containing metal ions, At this time, it is carried out according to the principle that other steps remain unchanged. After dehydration, the present invention can realize the synergistic removal of metal ions and carbon powder, which is very environmentally friendly and convenient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com