Electric power fitting aluminum pipe creasing machine

A metal fittings aluminum and tube pressing technology, which is applied in the field of electric power fittings aluminum tube creasing machine, can solve the problems of not meeting the needs of aluminum tube creasing, mismatching of aluminum tube creasing requirements, high production costs of enterprises, etc., and achieve structural design stability High, simple and ingenious structural design, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

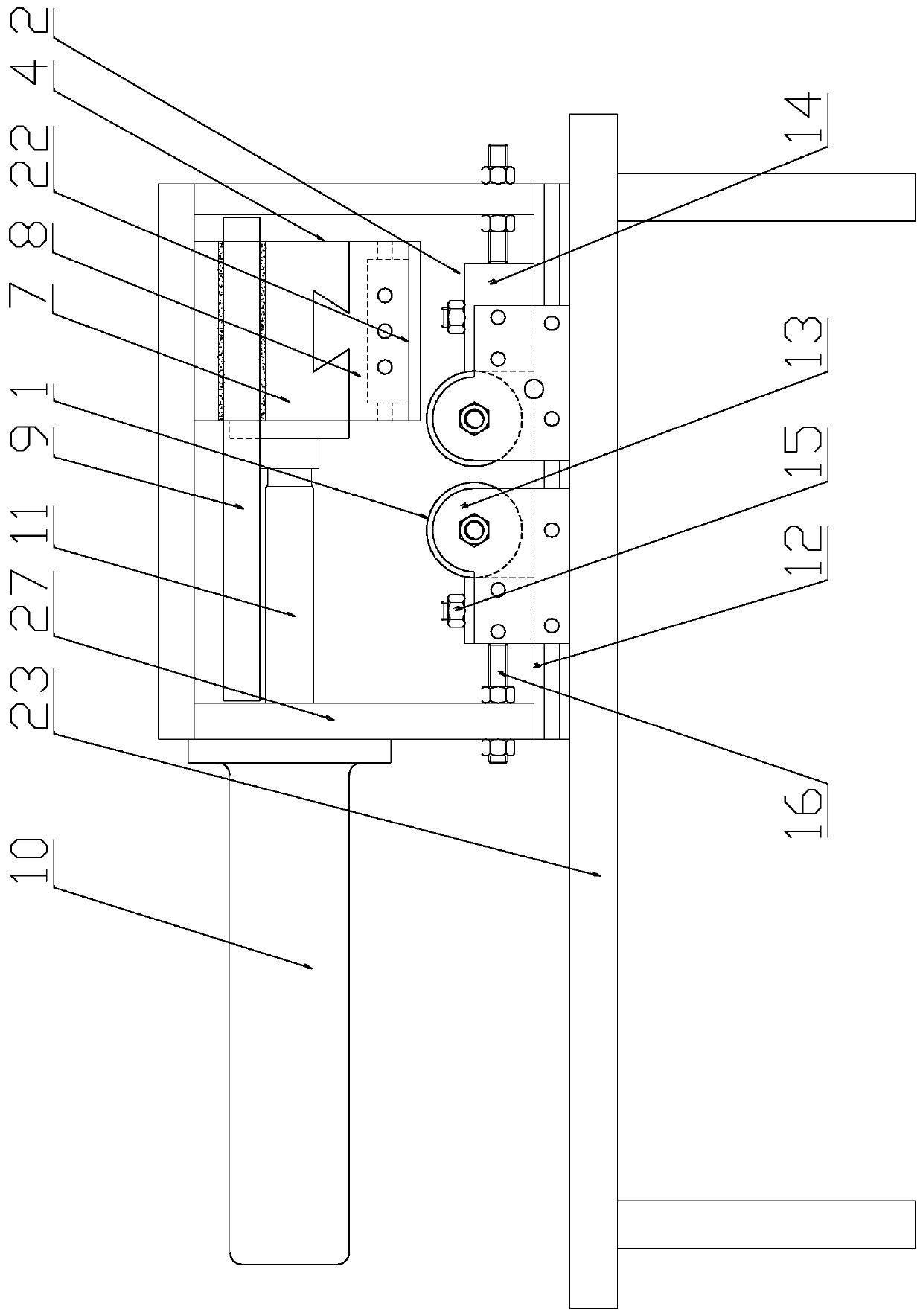

[0047] This embodiment includes an indentation mechanism, a power unit, and an electronic control unit for controlling the start and stop of the power unit; this embodiment needs to be placed on the workbench 23 during implementation.

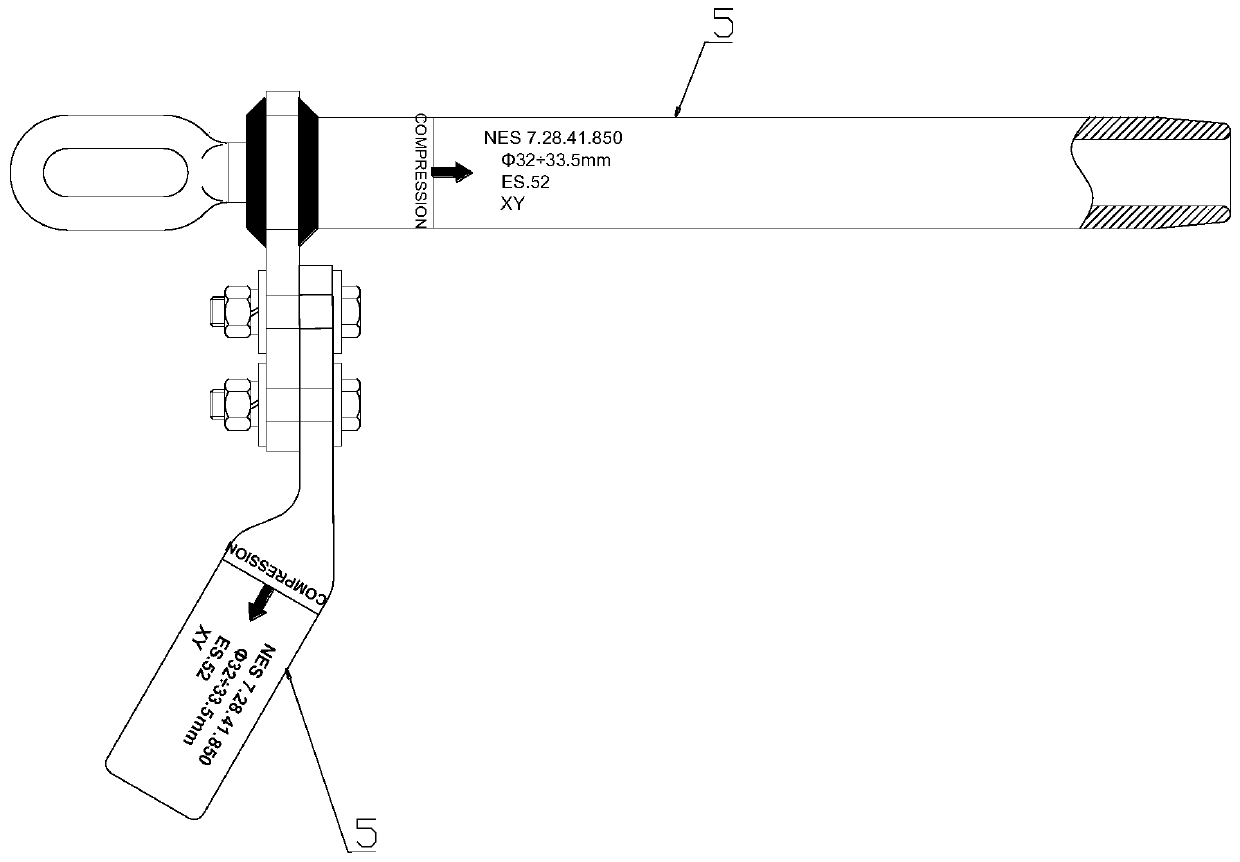

[0048] The indentation mechanism includes a pair of smooth rollers 1 whose relative distance can be adjusted. The rollers 1 are supported by the roller seat 2 and can rotate relative to the roller seat 2; Under the action of the power unit, it slides back and forth in the direction perpendicular to the axial direction of the roller 1; the workpiece aluminum tube 5 is placed in the space formed by the die 4 and the two rollers 1; the aluminum tube 5 is supported by the two rollers 1, and the aluminum tube 5 The surface is in contact with the die 4, and the axis of the aluminum tube 5 is parallel to the axes of the two rollers 1.

[0049] When using, as shown in the attached drawing of the manual Figure 3-Figure 4 As shown, the aluminum tube is...

Embodiment 2

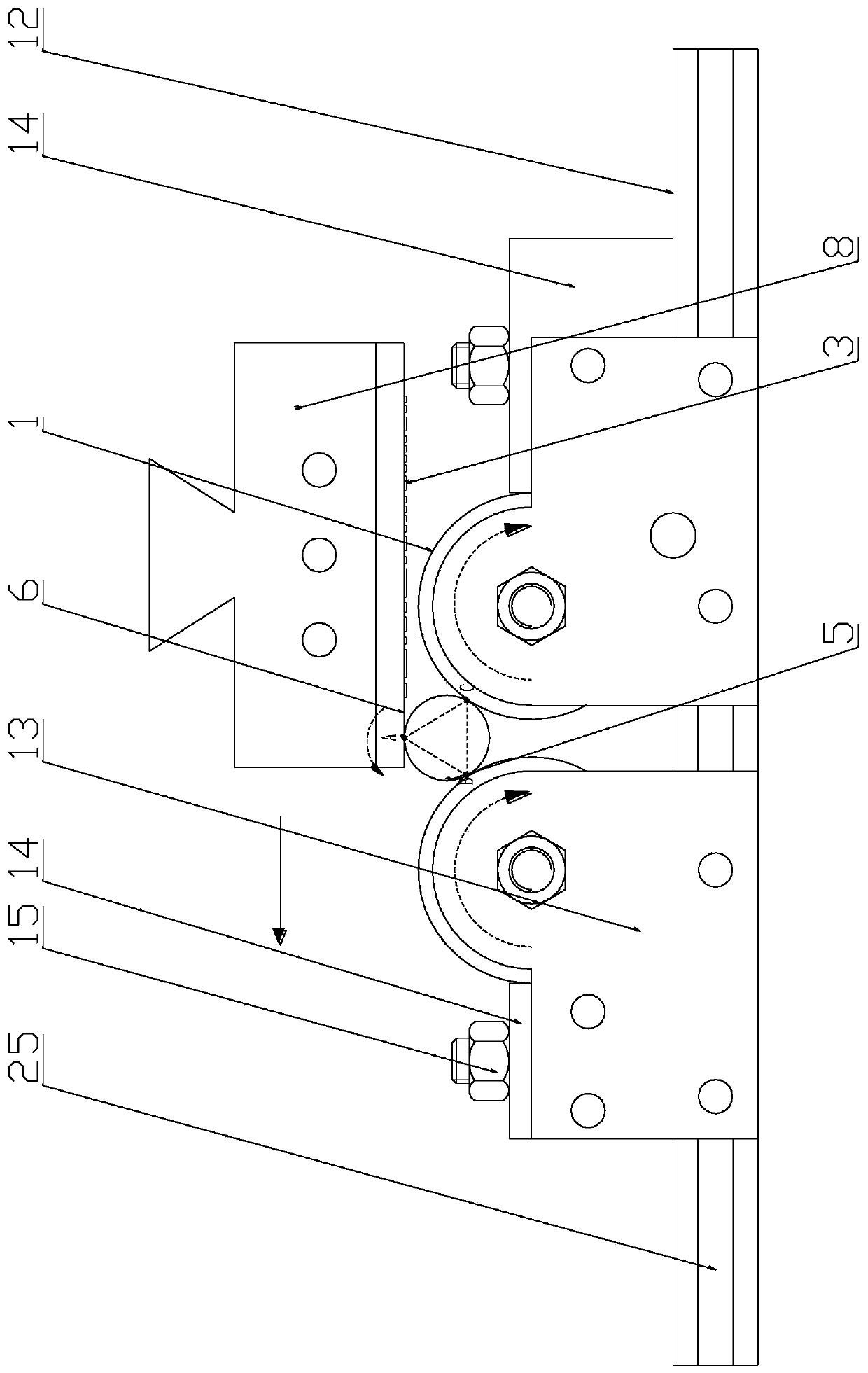

[0055] In this embodiment, the distance between the die and the rollers and the distance between the two rollers are precisely adjusted before use. The stress point where the flat bottom surface 6 of the die 4 contacts the upper surface of the aluminum tube 5 is point A, and the stress points where the aluminum tube 5 is supported on the two rollers 1 are respectively point B and point C; The connecting line between point B and force point C forms an equilateral triangle. The formation of an equilateral triangle makes the force on the aluminum tube more uniform during the rotation process, and the probability of deformation of the workpiece under pressure is almost zero, which further effectively ensures a high pass rate of the product, effectively controls the product quality, and brings considerable economic benefits to the enterprise;

Embodiment 3

[0057] This embodiment includes an indentation mechanism, a power unit, and an electronic control unit for controlling the start and stop of the power unit;

[0058] The indentation mechanism includes a pair of rollers 1 whose relative distance can be adjusted. The rollers 1 are supported by the roller seat 2 and can rotate relative to the roller seat 2; Under the action of the unit, it slides back and forth in the direction perpendicular to the axial direction of the roller 1; the workpiece aluminum tube 5 is placed in the space formed by the die 4 and the two rollers 1; the aluminum tube 5 is supported by the two rollers 1, and the upper surface of the aluminum tube 5 In contact with the die 4, the axis of the aluminum tube 5 is parallel to the axes of the two rollers 1.

[0059] The die 4 of the present embodiment specifically includes a letter template fixed base 7, a letter template movable base 8 and a letter template 22 provided with a word protrusion 3; The movable ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com